Numerical control wire-electrode cutting impulsing power source with controllable current waveform

A technology of pulse power supply and current waveform, applied in circuits, electric processing equipment, metal processing equipment, etc., can solve the problems of slow rise of high-voltage electric pulse waveform, inability of pulse power supply to control current waveform, and inability to shut down in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

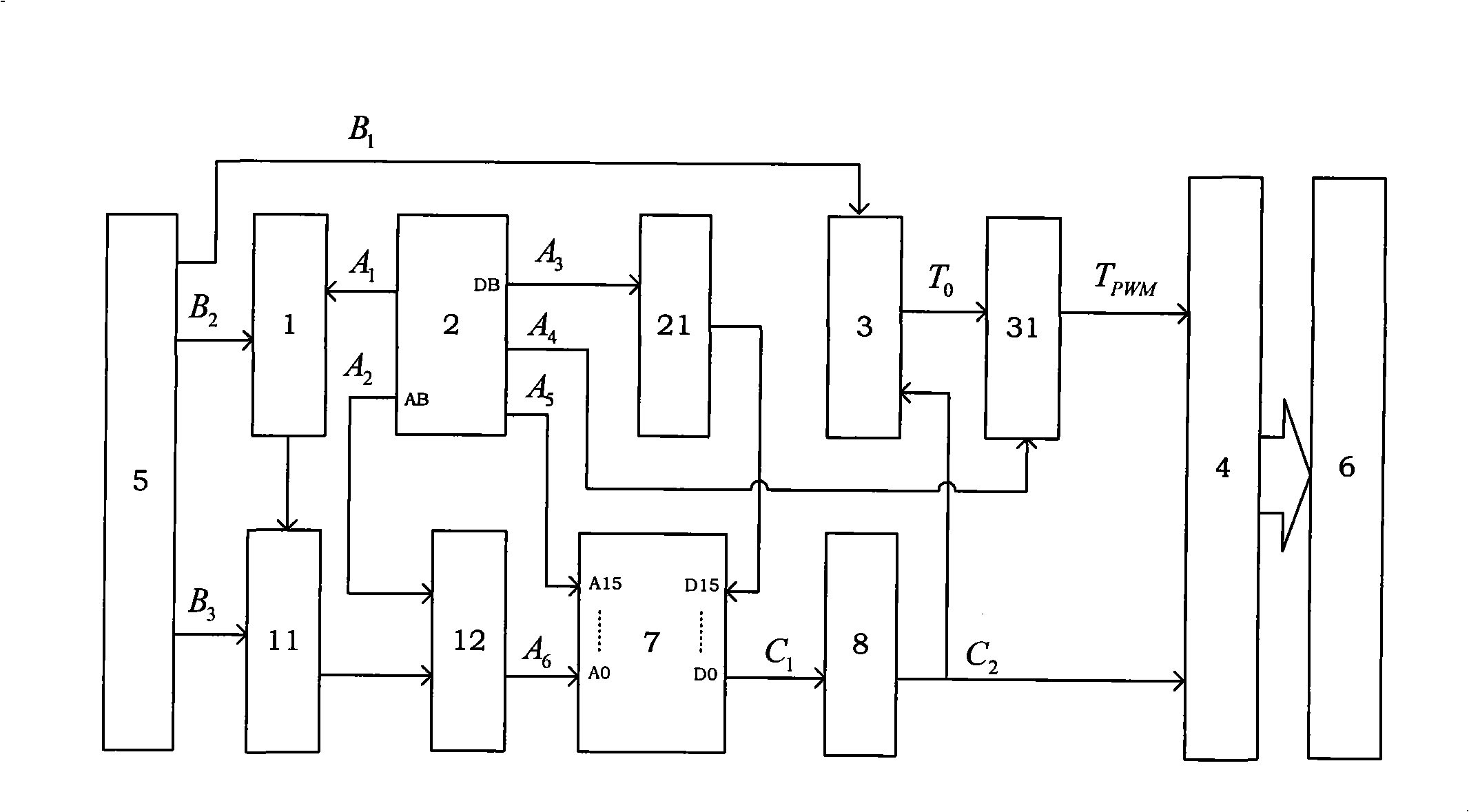

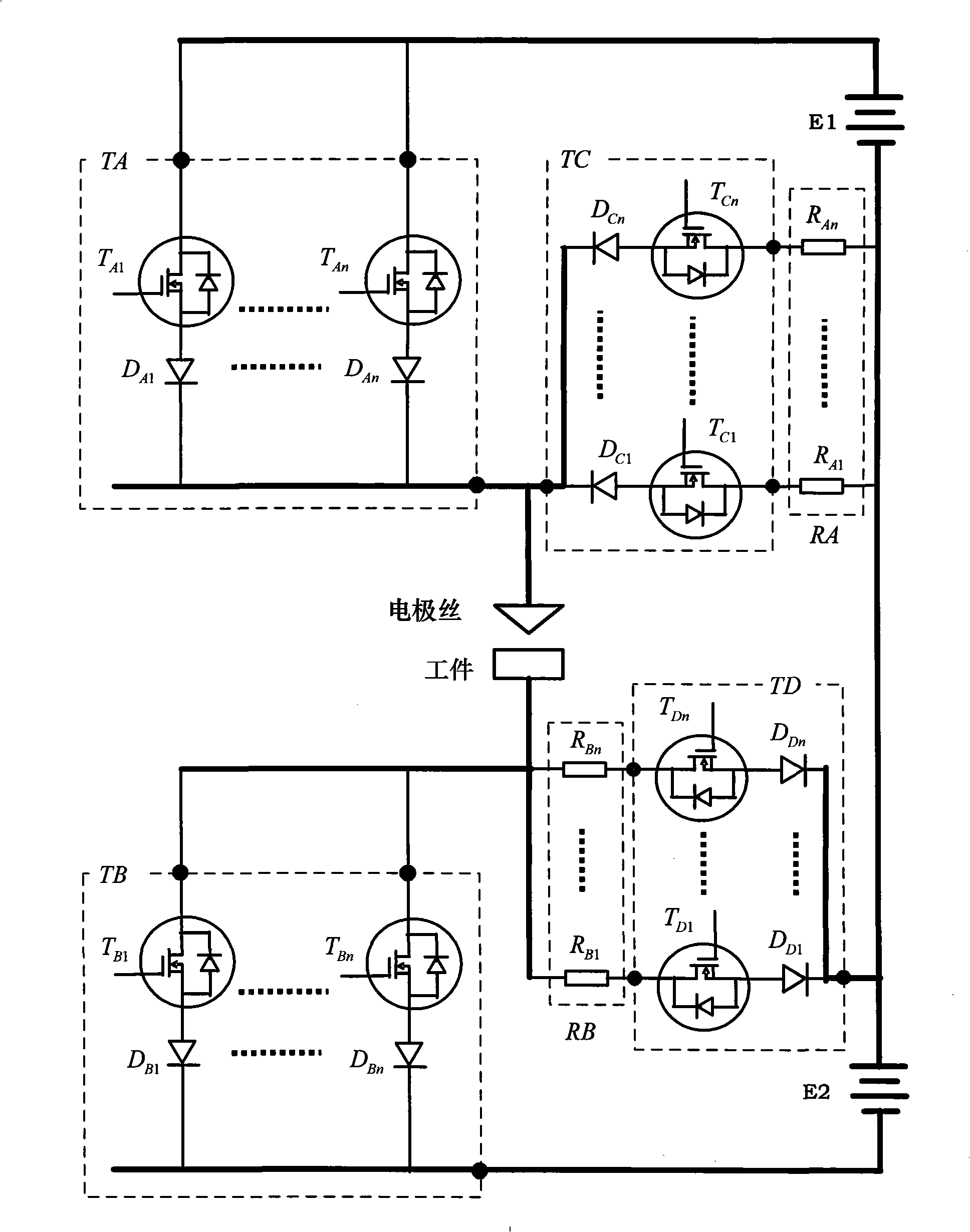

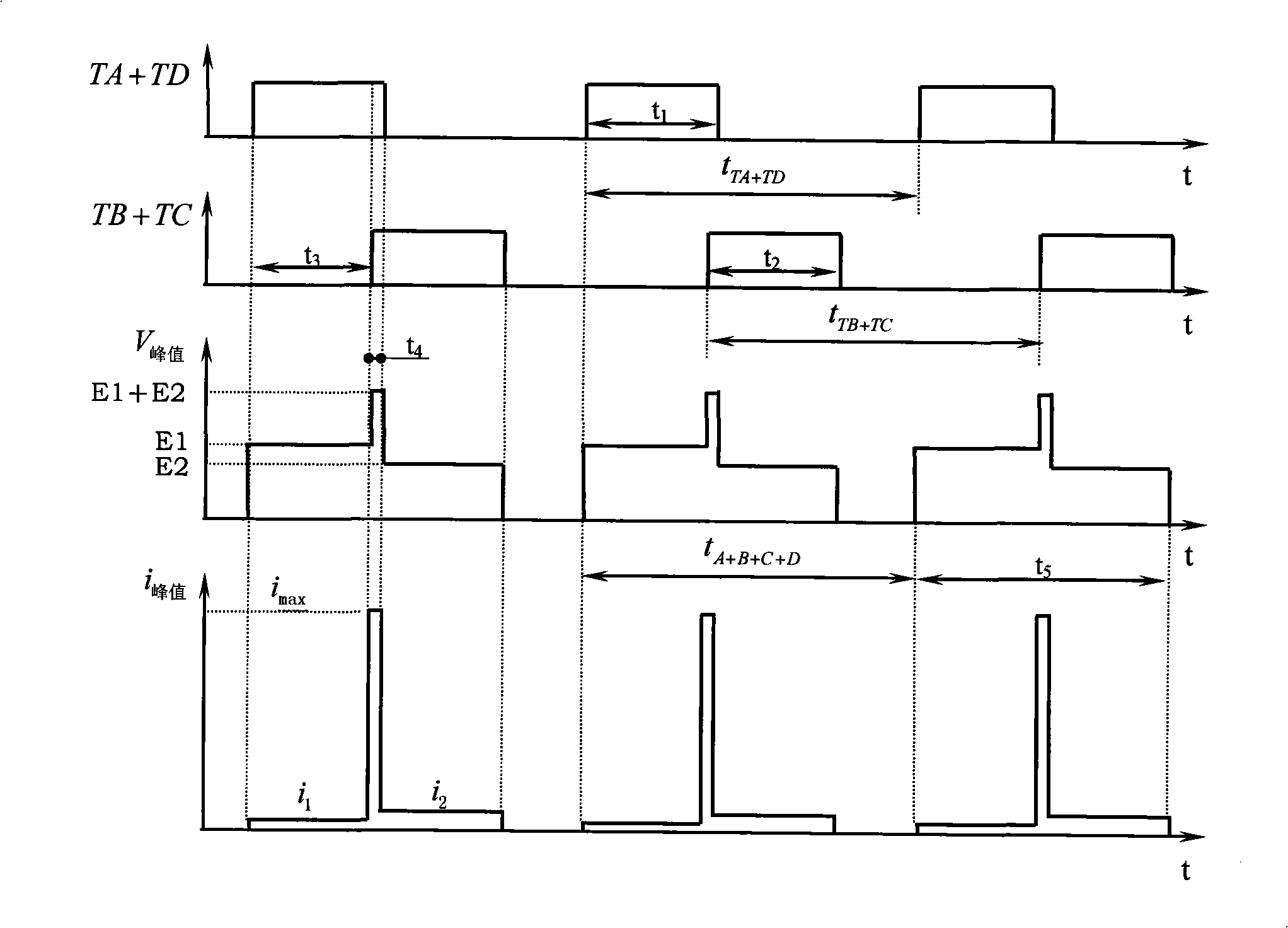

[0030] The present invention is a digitally controlled wire-cutting pulse power supply with controllable current waveforms. The "waveform data" required for different processing is stored in the read-only memory 7, and the waveform data is written in batches by the central processor 2 using software programming technology. In the read memory 7; this waveform data also can change the stored waveform data in the read-only memory 7 online by the central processing unit 2, and arbitrarily change the pulse drive signal T PWM waveform. The upper address A generated in CPU 2 5 , the low address A generated by the address selector 12 6 1. Under the action of the time period output by the clock circuit 5 and the period controller 1, the "selected waveform data" is output cyclically. Online real-time change and control of the high address A through the central proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com