Casting long and thin hole forming sand core structure

A technology of slender holes and sand cores, which is applied in the field of casting sand core structures with slender holes, can solve the problems of easy occurrence of sand sticking and pores, high cost of castings, and difficulty in reducing the manufacturing cost of castings, so as to facilitate recycling and reuse, The straightness of the hole shape is high, and the effect of ensuring the shape quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

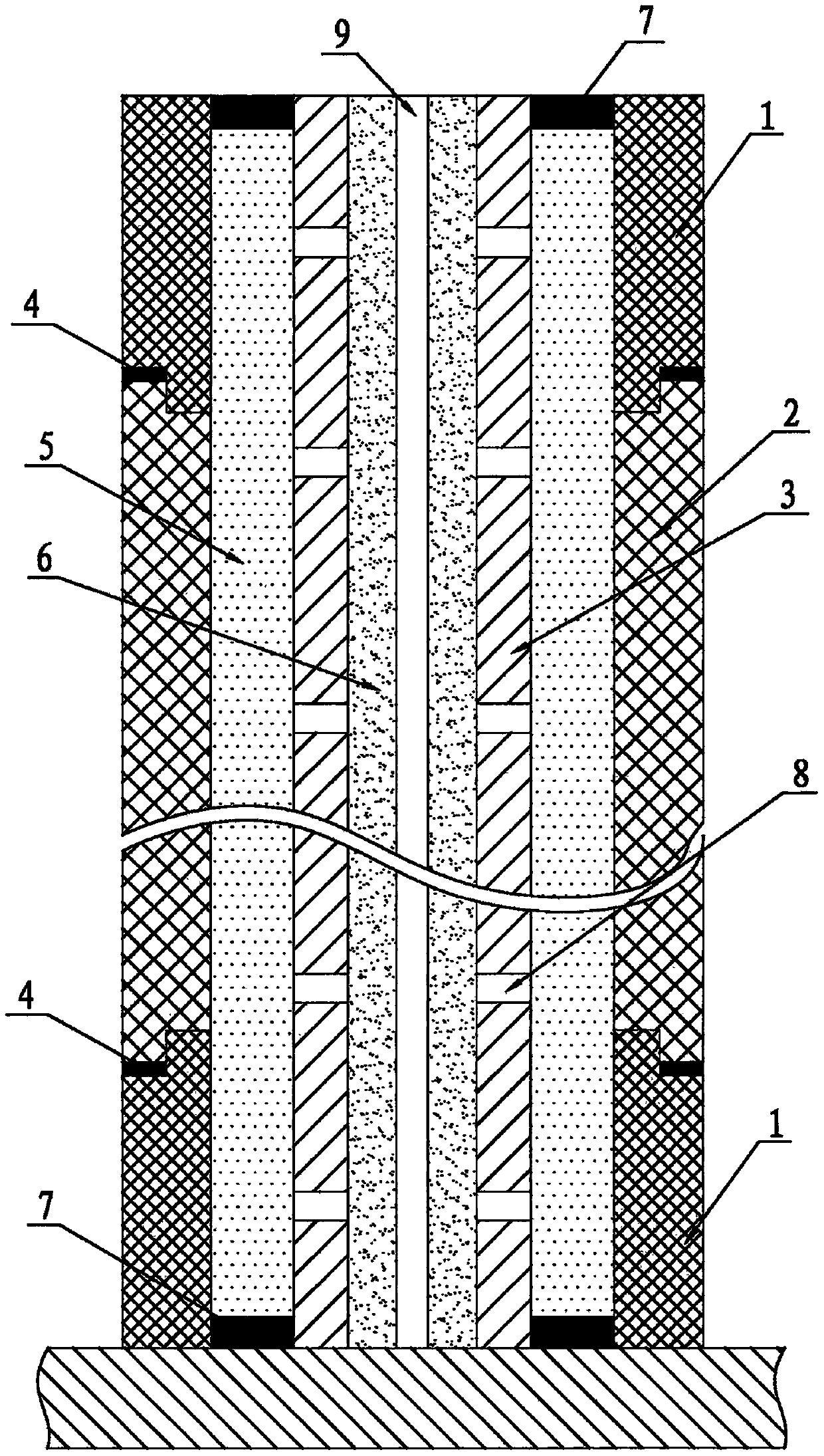

Embodiment 1

[0023] Example 1: A sand core molding structure with elongated holes in castings, including end refractory casing 1, transitional refractory casing 2, process steel pipe 3, casing bonding resin layer 4, outer sand core layer 5, inner sand The core layer 6 and the end sealing layer 7, the transitional refractory sleeve 2 is set between the end refractory sleeves 1, the three are connected through the sleeve bonding resin layer 4 to form a hollow refractory sleeve, and the process steel pipe 3 is set in the refractory sleeve In the inner hole of the pipe, the two are coaxially arranged, and the pipe body of the process steel pipe 3 is evenly provided with vent holes 8, the diameter of the vent holes 8 is 1 to 3 mm, and the outer sand core layer 5 is arranged on the Between the process steel pipe 3 and the inner hole of the refractory casing, the radial thickness of the outer sand core layer 5 is 5 to 10 mm. The two ends of 5 are provided with end surface sealing layer 7, and the...

Embodiment 2

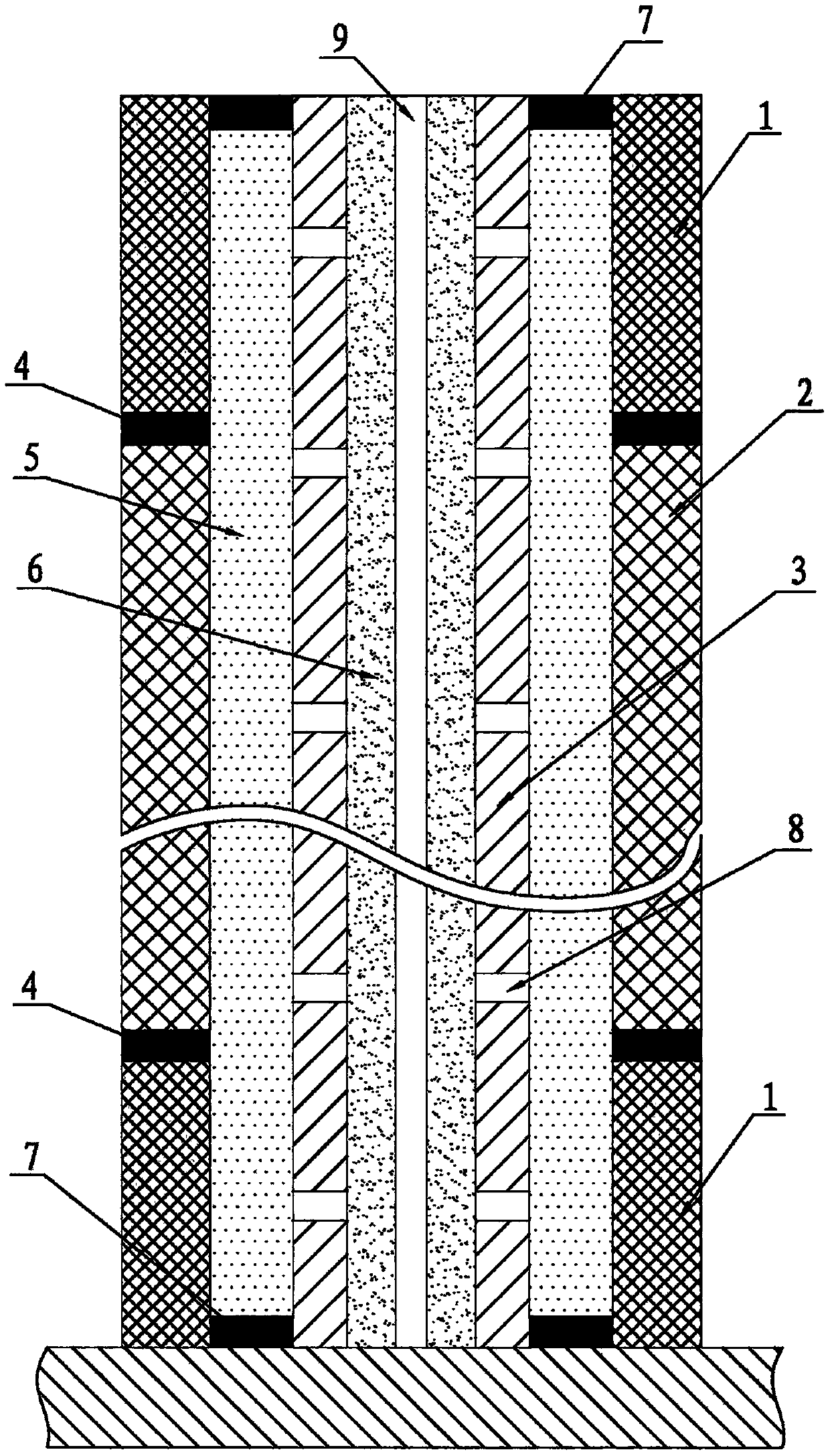

[0024] Embodiment 2: The difference from Embodiment 1 lies in the docking structure between the end refractory sleeve 1 and the transitional refractory sleeve 2. In this example, the two pass through a stepped hole-axis matching structure to realize coaxial docking.

Embodiment 3

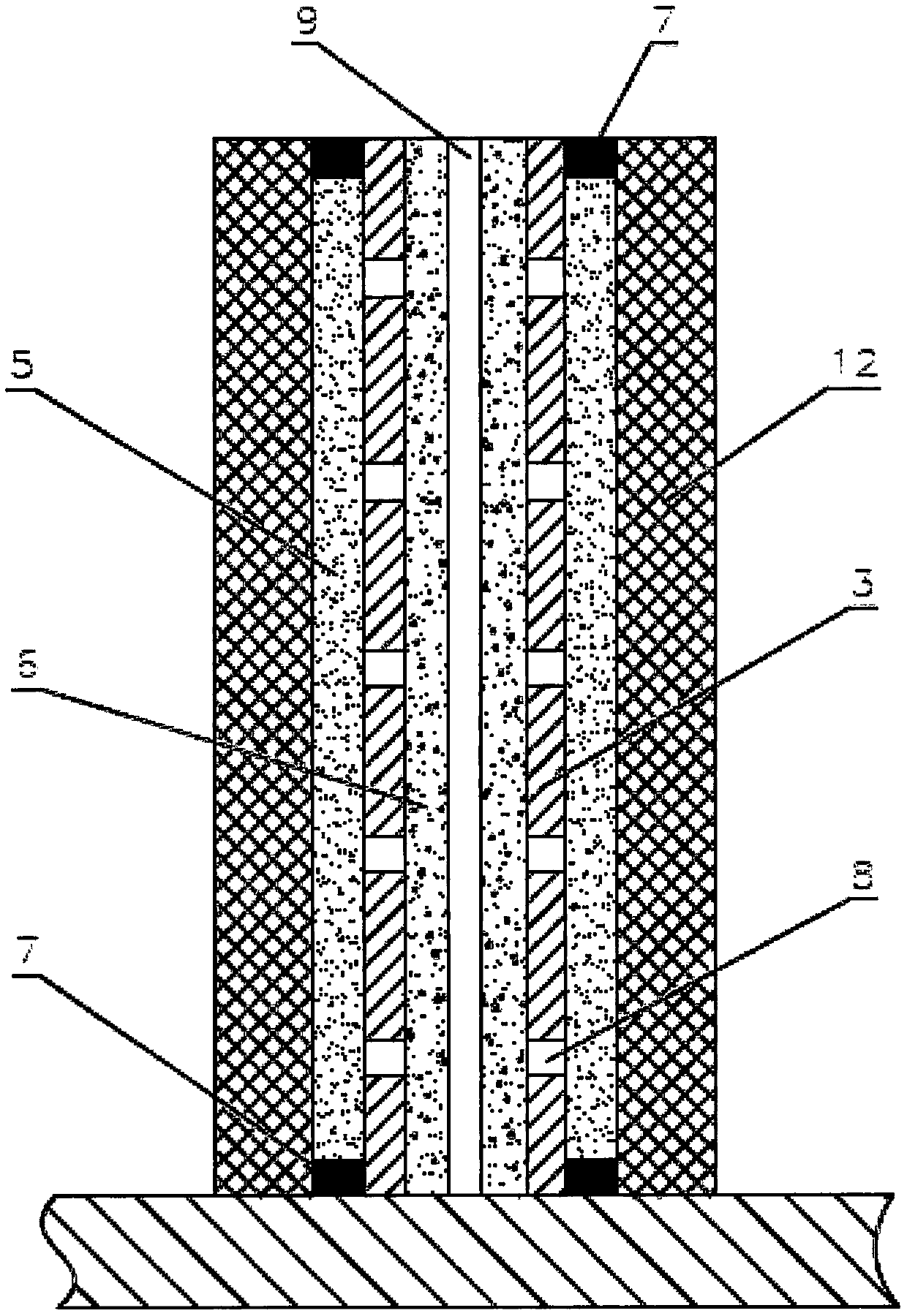

[0025] Embodiment 3: The difference from Embodiments 1 and 2 is that an integral ceramic tube 12 is used, and the end refractory sleeve 1 and the transitional refractory sleeve 2 and the butt joint structure between them are not required.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com