Tea leaf flattening device

A tea, pressing roller technology, applied in tea processing before extraction, spring/shock absorber, vibration suppression adjustment, etc., can solve the problem of lack of automatic means for green tea flattening and shaping, to improve the shaping efficiency and avoid pushing and discharging , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

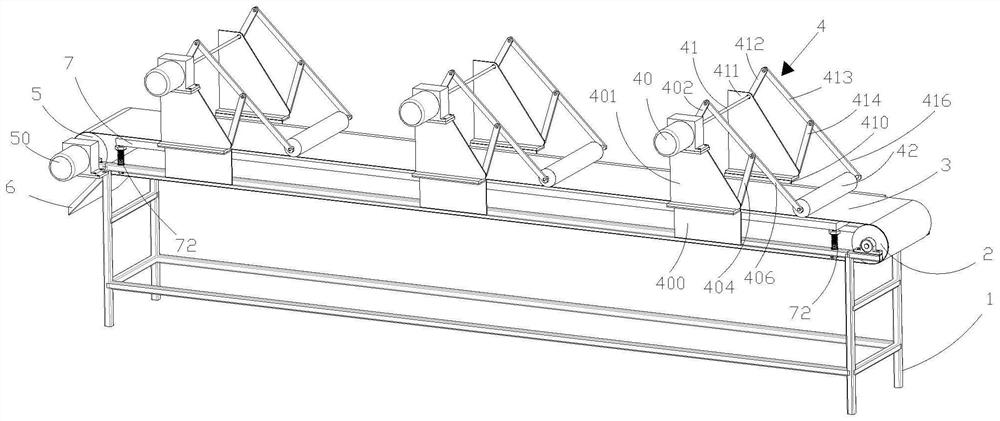

[0049] A tea flattening device

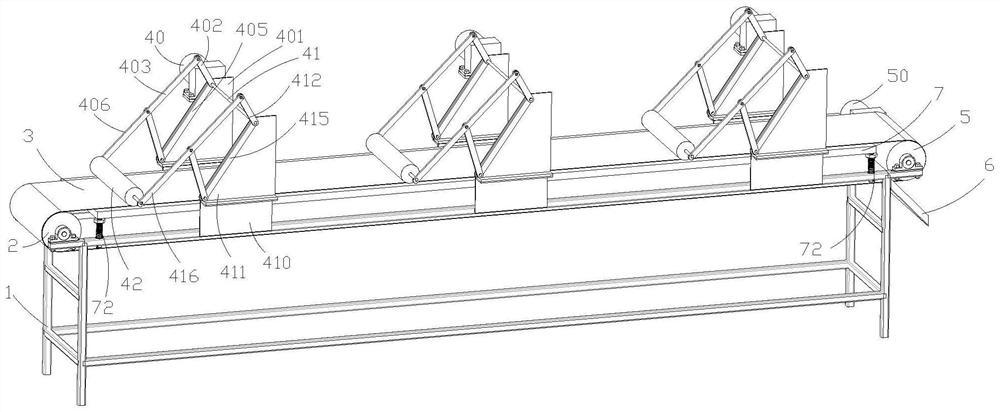

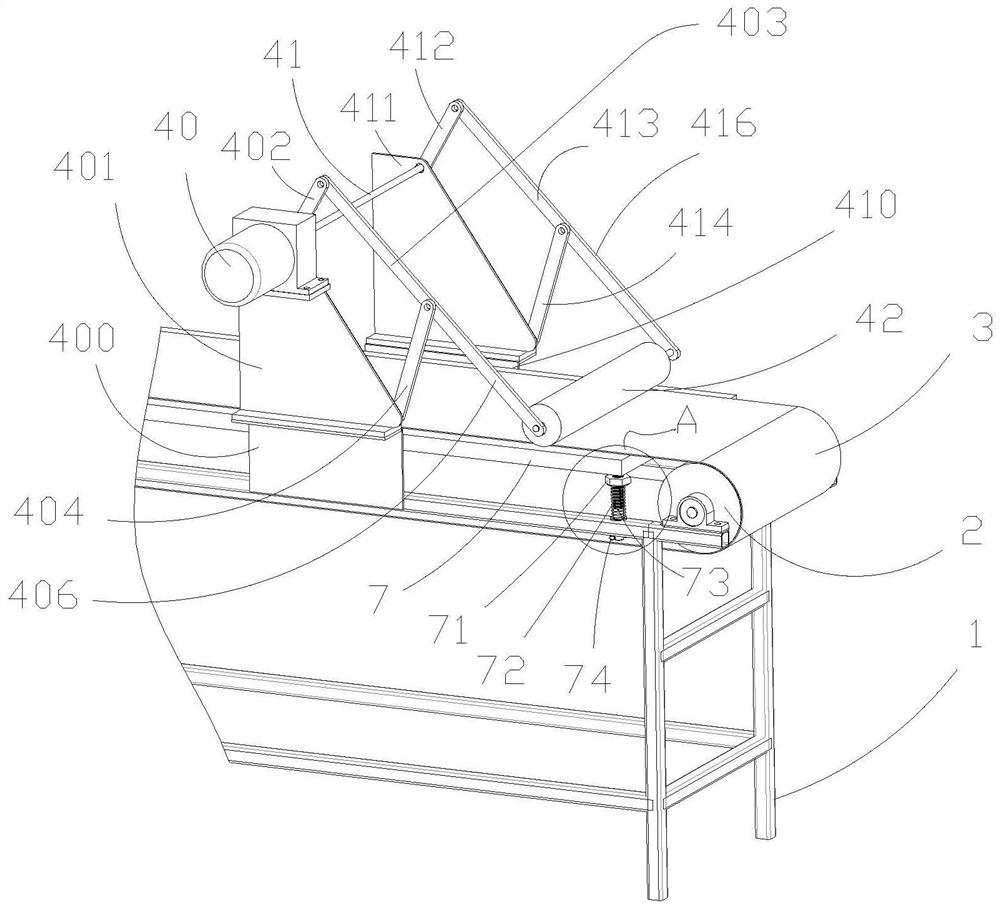

[0050] refer to figure 1 , figure 2 , Figure 9 , A tea flattening device proposed in this embodiment includes: a frame 1 , a conveyor belt 3 , a pressure unit 4 and a pressure adjustment unit 7 .

[0051] The conveyor belt 3 is horizontally installed on the frame 1, and the conveyor belt 3 is used for transporting materials, namely tea leaves. Specifically, in this embodiment, the frame 1 is provided with a driving roller 5 and a driven roller 2, the conveyor belt 3 is arranged on the driving roller 5 and the driven roller 2, and the driving roller 5 is connected with a conveyor belt drive motor 50, and the conveyor belt The belt driving motor 50 drives the driving roller 5 to rotate to drive the driven roller 2 and the conveyor belt 3 to rotate. In this embodiment, both the driving roller 5 and the driven roller 2 are arranged on the frame 1 through strip-shaped holes, so as to adjust the distance between the driving roller 5 and the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com