Axial displacement variable convexity roll shape design method and device

A design method and variable crown technology, applied in design optimization/simulation, complex mathematical operations, geometric CAD, etc., can solve problems such as the inability to take into account the shape and quality of the roll life, so as to achieve both roll life and reduce radial grinding The effect of quantity and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

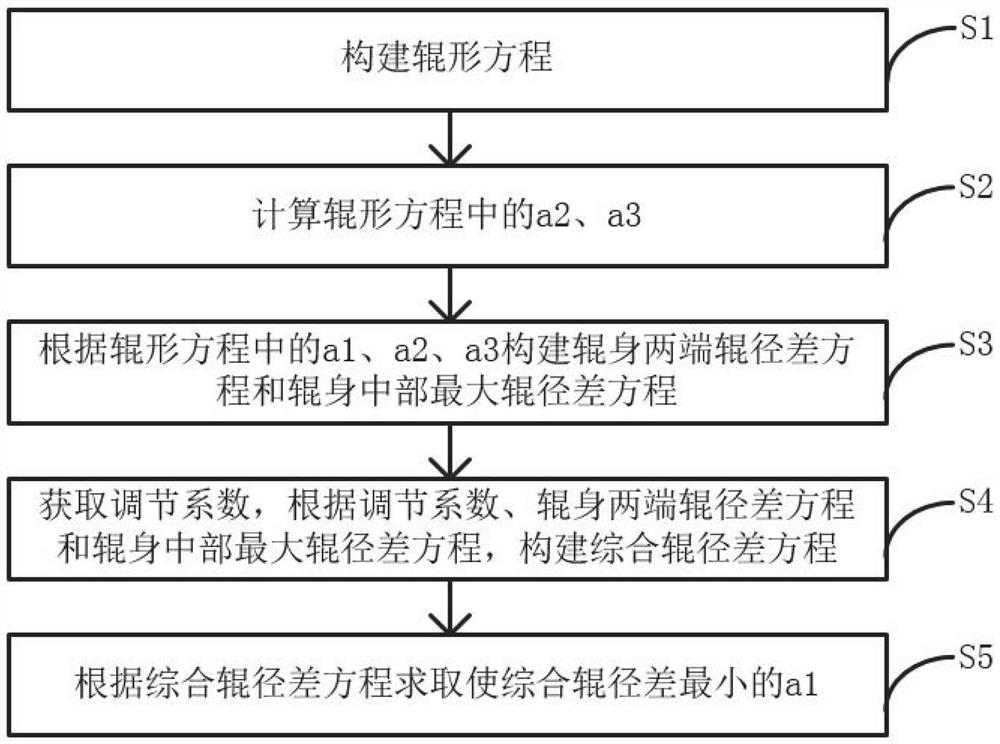

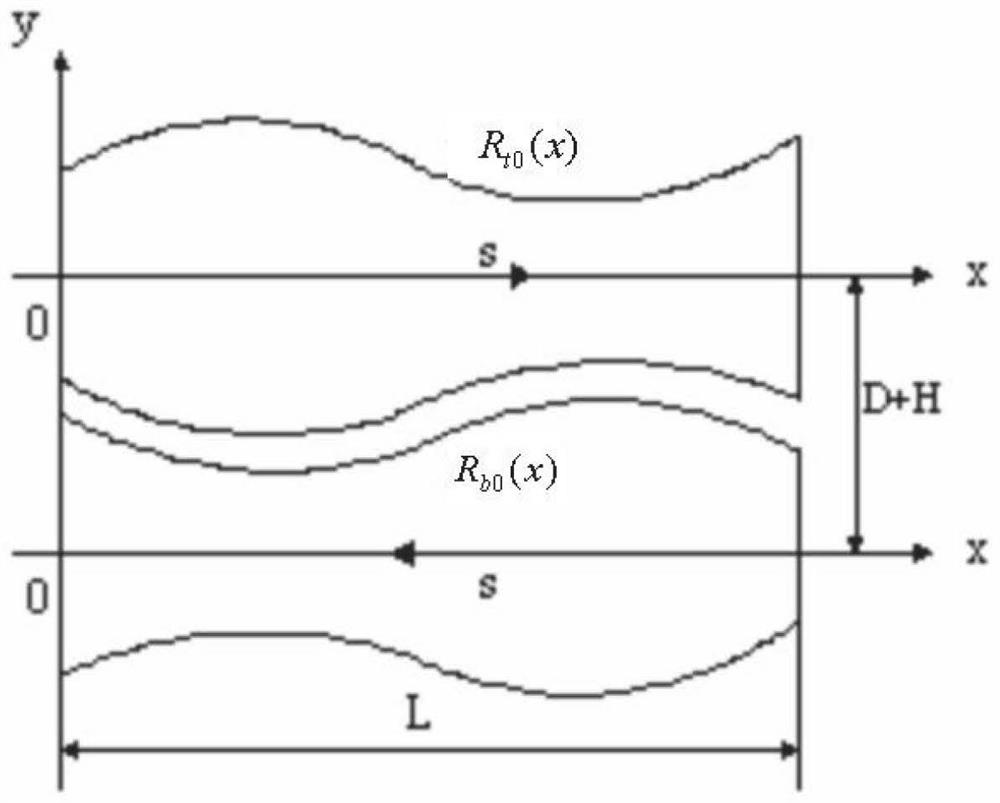

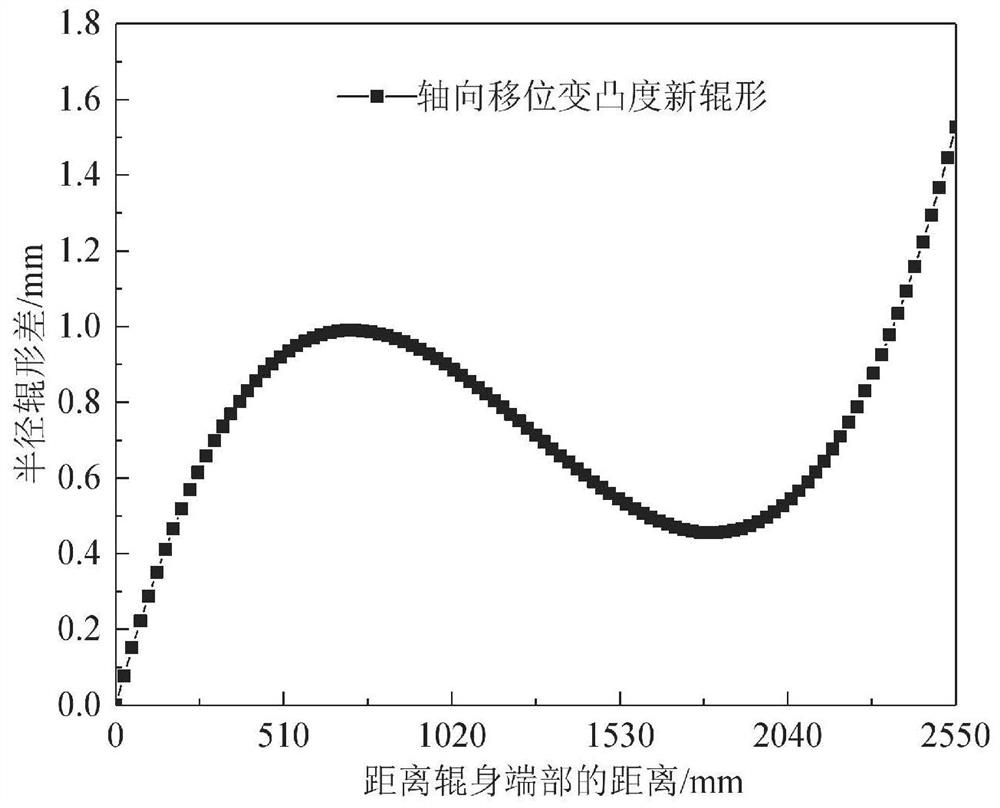

[0046] The embodiment of the present invention solves the technical problem that the roll shape designed by the prior art cannot take into account the quality of the plate shape and the life of the roll by providing the method and device for designing the roll shape with axial displacement and variable crown.

[0047] In order to better understand the technical solutions of the present invention, the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0048] First of all, it should be noted that the term "and / or" that appears in this article is only an association relationship to describe related objects, which means that there can be three kinds of relationships, for example, A and / or B, which can mean that A exists alone, and A exists at the same time. and B, there are three cases of B alone. In addition, the character " / " in this document generally indicates that the related o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com