No-mold casting method and equipment capable of automatically draining sand

A technology of moldless casting and molding equipment, which is applied in the field of moldless casting, which can solve the problems of increasing the production cost of moldless casting, manual cleaning is time-consuming and laborious, and complex equipment, so as to solve the problem of waste sand accumulation and clamping tools, and save manpower and material resources , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

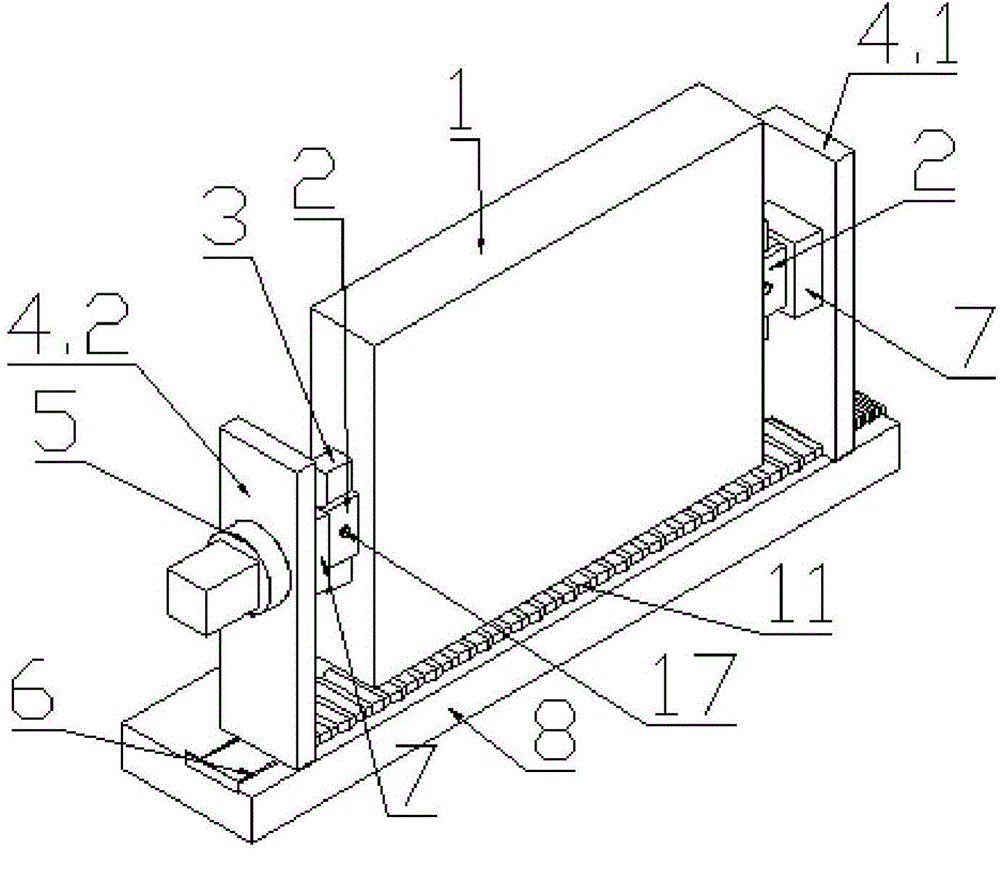

[0019] The invention provides a moldless casting molding method capable of automatic sand discharge, in which the processed surface of the sand mold is inclined or vertically arranged, and the sand mold is cut and processed by a numerical control cutting device. During the processing, the cut waste sand is Under the action of its own gravity, it will naturally fall into the sand discharge tank. A moldless casting molding method that can automatically discharge sand can be realized by a moldless casting molding equipment that can automatically discharge sand.

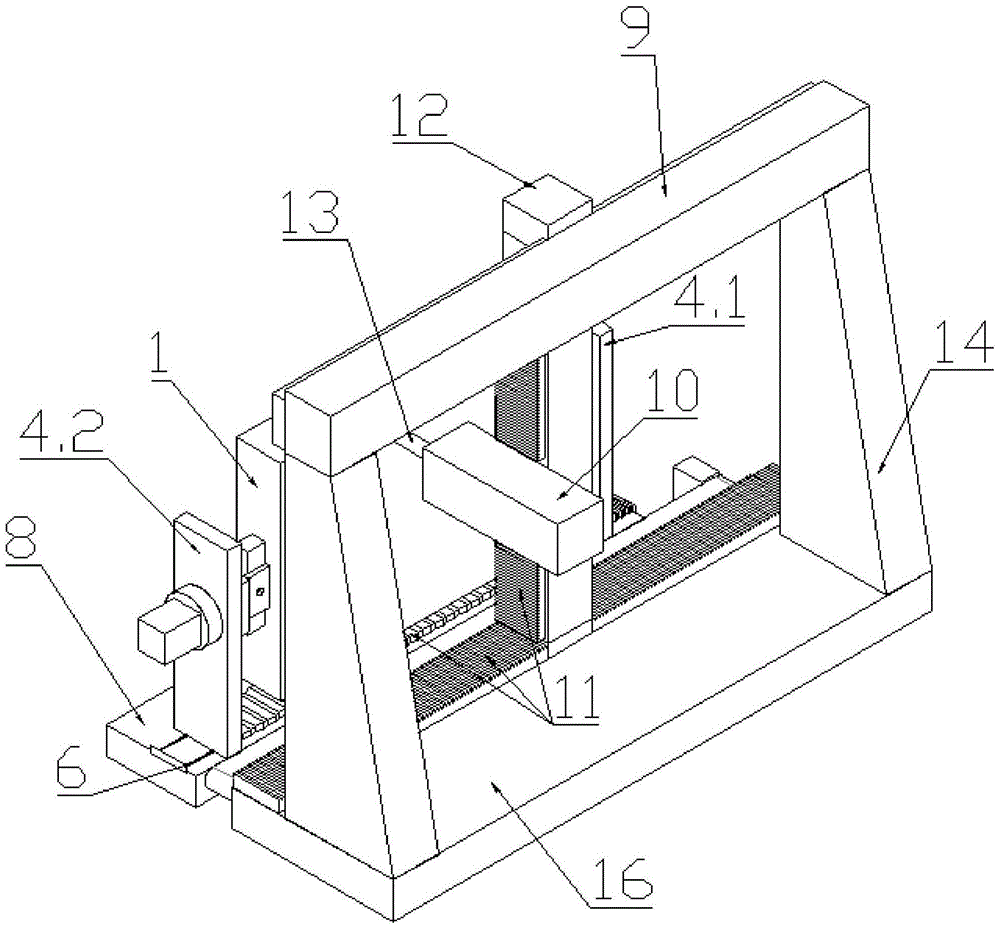

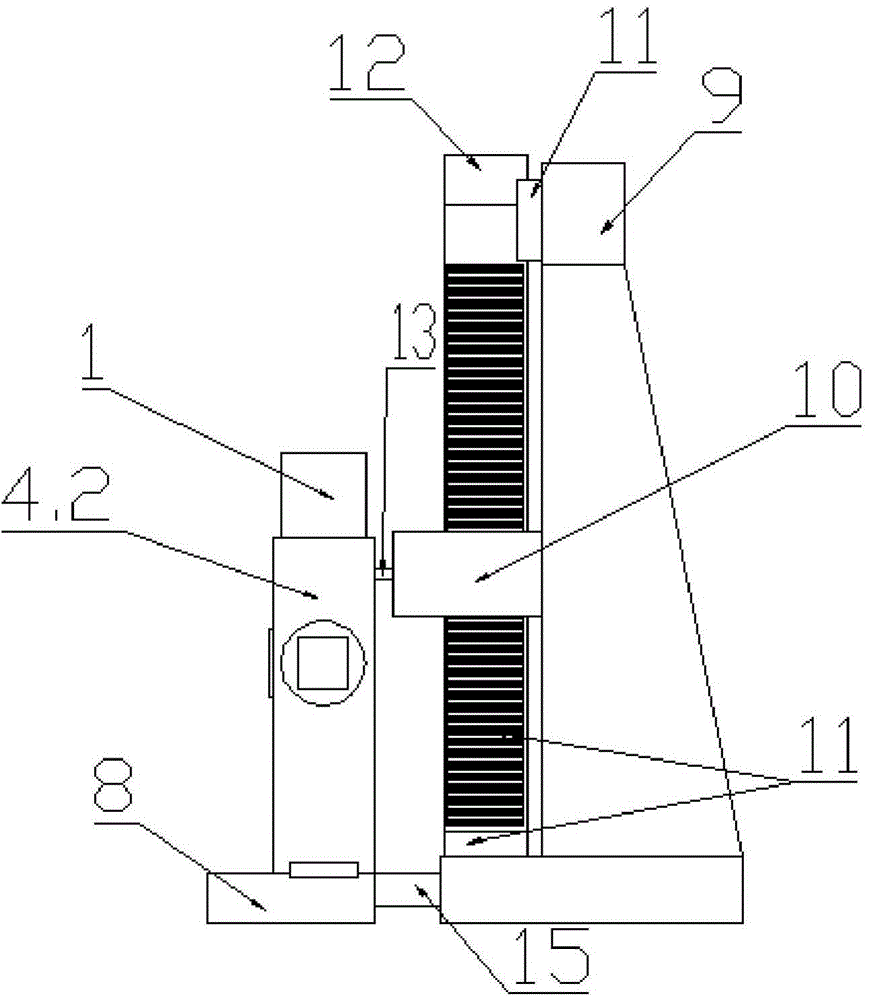

[0020] like Figure 1-Figure 3 As shown, a moldless casting molding equipment capable of automatic sand discharge includes a moldless casting molding machine, a sand box turning table, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com