Non-contact micro arc polishing process and device thereof

A non-contact, micro-arc technology, applied in the field of material processing, can solve problems affecting mechanical properties such as fatigue strength of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

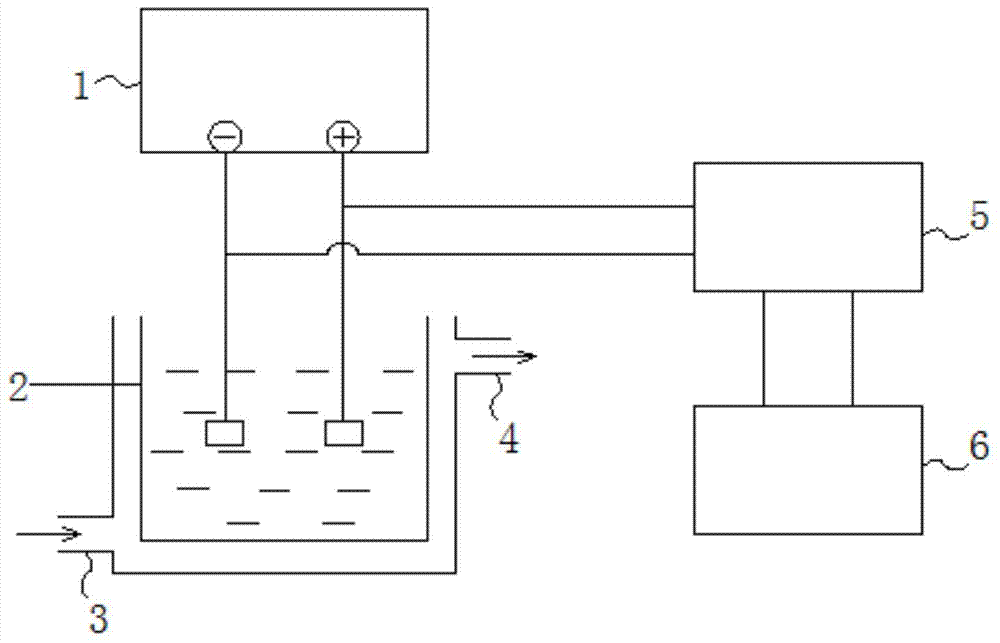

[0026] In this embodiment, an aluminum alloy sample is used, and the steps of micro-arc polishing are as follows:

[0027] Step (1): configuration electrolyte, the present embodiment uses (NaPO 3 ) 6 As the main electrolyte, NaOH solution is used as an additive at the same time. The volume of the solution is 80L, the total concentration of the solution is 40g / L, and the NaOH is 1.2g / L. Stir evenly and adjust the pH value to 7-10.

[0028] Step (2): Design the cathode and anode parameters, use stainless steel as the cathode material, the cross-sectional shape is circular, and the diameter is 30×30mm, and the cathode is aligned with the aluminum alloy so that the distance between the electrodes is 30mm.

[0029] Step (3): Control the flow field environment. According to the requirements of polishing and removal, this embodiment adopts a top-down fluid pipeline, and the flow field velocity is controlled at 0.8m / s.

[0030] Step (4): Set the power supply parameters, select the c...

Embodiment approach 2

[0035] In this embodiment, a magnesium alloy sample is used, and the steps of micro-arc polishing are as follows:

[0036] Step (1): Configure the electrolyte. In this embodiment, silicate is used as the main electrolyte, and NaHCO 3 The solution is an additive, the added concentration is 3g / L, the solution volume is 80L, the total concentration of the solution is 40g / L, and the mixture is evenly stirred.

[0037] Step (2): Adjust the distance between the cathode and the anode. The cathode is a square stainless steel plate with a size of 150mm×250mm, so that the cathode is aligned with the anode magnesium alloy, and the pole spacing is 80mm.

[0038] Step (3): Control the flow field environment. According to the requirements of polishing and removal, this embodiment adopts a top-down fluid pipeline, and the flow field velocity is 1m / s.

[0039] Step (4): Set the power supply parameters, select the constant voltage mode for the power supply mode, the pulse frequency is 20KHz, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com