Capacitor

A technology of capacitors and heat pipes, which is applied in the field of capacitors, can solve problems such as unsolved heat dissipation problems of capacitors, and achieve the effect of reducing temperature difference and increasing ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

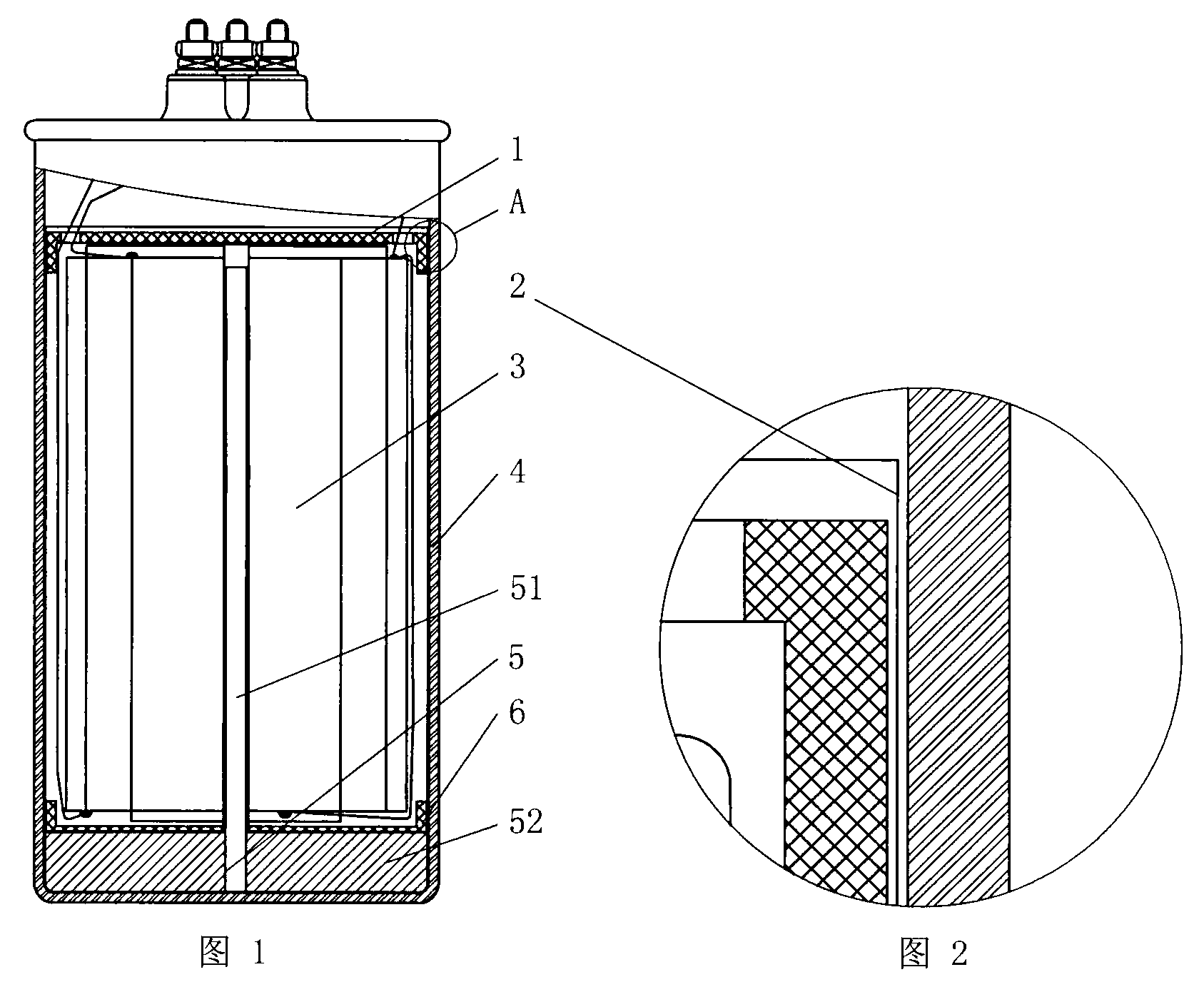

[0018] see figure 1 with figure 2 The capacitor includes an upper positioning sleeve 1, an insulating paper 2, a core 3, a shell 4, a heat pipe device 5, and a lower positioning sleeve 6. The capacitor is cylindrical, and the heat pipe device 5 is composed of a heat pipe 51 and a heat conduction block 52. The heat pipe 51 is located on In the center of the core, the heat conduction block 52 is installed at the lower end of the heat pipe 51. The core is wrapped by the upper positioning sleeve 1, the lower positioning sleeve 6 and the insulating paper 2. The heat pipe 51 is closely connected to the center of the core 3 and the center of the heat conduction block 52 respectively. Contact, the outer cylindrical surface and the bottom surface of the heat conduction block 52 are in close contact with the shell, so that the heat in the center of the core 3 is transferred to the shell 4 through the heat pipe 51 and the heat conduction block 52 for heat exchange with the outside world...

Embodiment 2

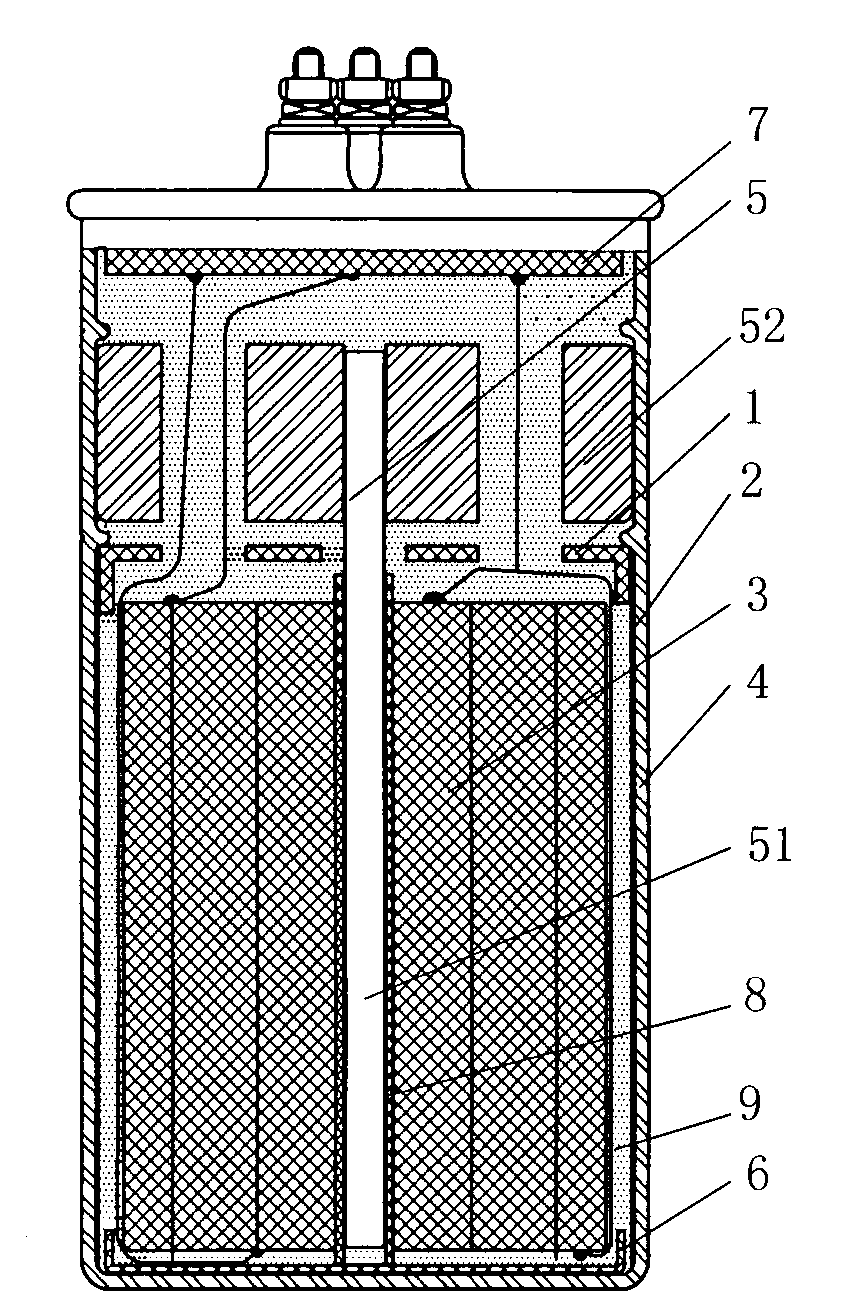

[0020] see image 3 , the capacitor shown is an explosion-proof metallized film capacitor, the metallized film is wound on the mandrel 8 to form the core 3, the top of the capacitor is also provided with an explosion-proof device 7, the heat pipe 51 is located in the mandrel 8, and is connected with the mandrel 8 close contact, the capacitor is cylindrical, and the gap in the shell 4 is filled with filler 9, so that the upper positioning sleeve 1, insulating paper 2, core 3, shell 4, heat pipe device 5, lower positioning sleeve 6 and other components are in the The shell 4 is fixed inside, the heat pipe device 5 is a gravity heat pipe, and the heat conduction block 52 is installed on the upper end of the heat pipe 51. When the core 3 works, the internal temperature of the capacitor rises, and the working fluid at the bottom of the heat pipe 51 is vaporized and raised to the top of the heat pipe 51 , the heat carried by the steam is transferred to the shell 4 through the heat c...

Embodiment 3

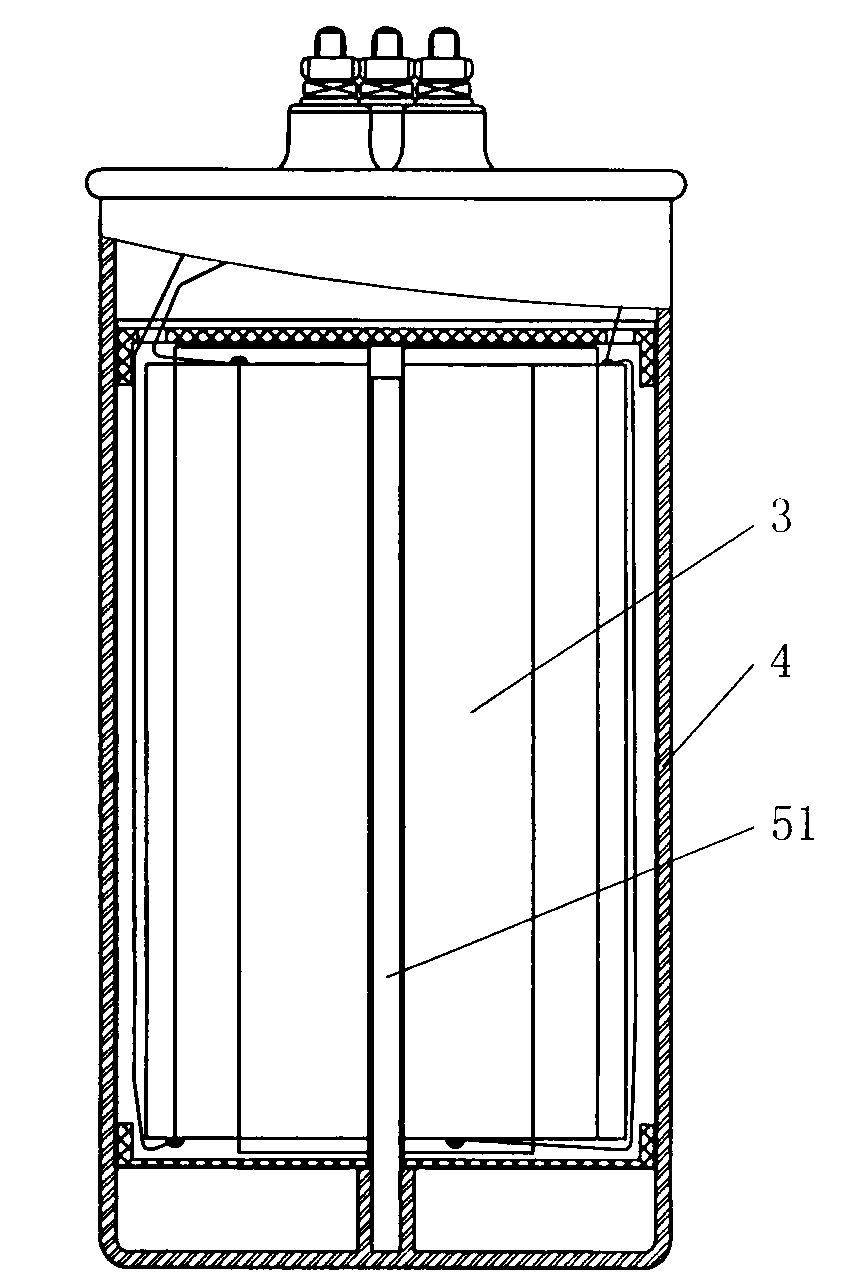

[0022] see Figure 4 , single heat pipe 51 has constituted heat pipe device, and heat pipe 51 is installed in the bottom of shell 4, and heat pipe 51 is in close contact with the surface of the mounting position of shell 4, and the heat of the center of core 3 is directly transferred to shell 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com