Bidirectional luminescent heat radiation LED

A light-emitting diode, two-way technology, applied in lighting and heating equipment, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve problems such as color temperature change, luminous flux reduction, carbonization and blackening, and achieve color temperature without occurrence Change, working life extension, effect of life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

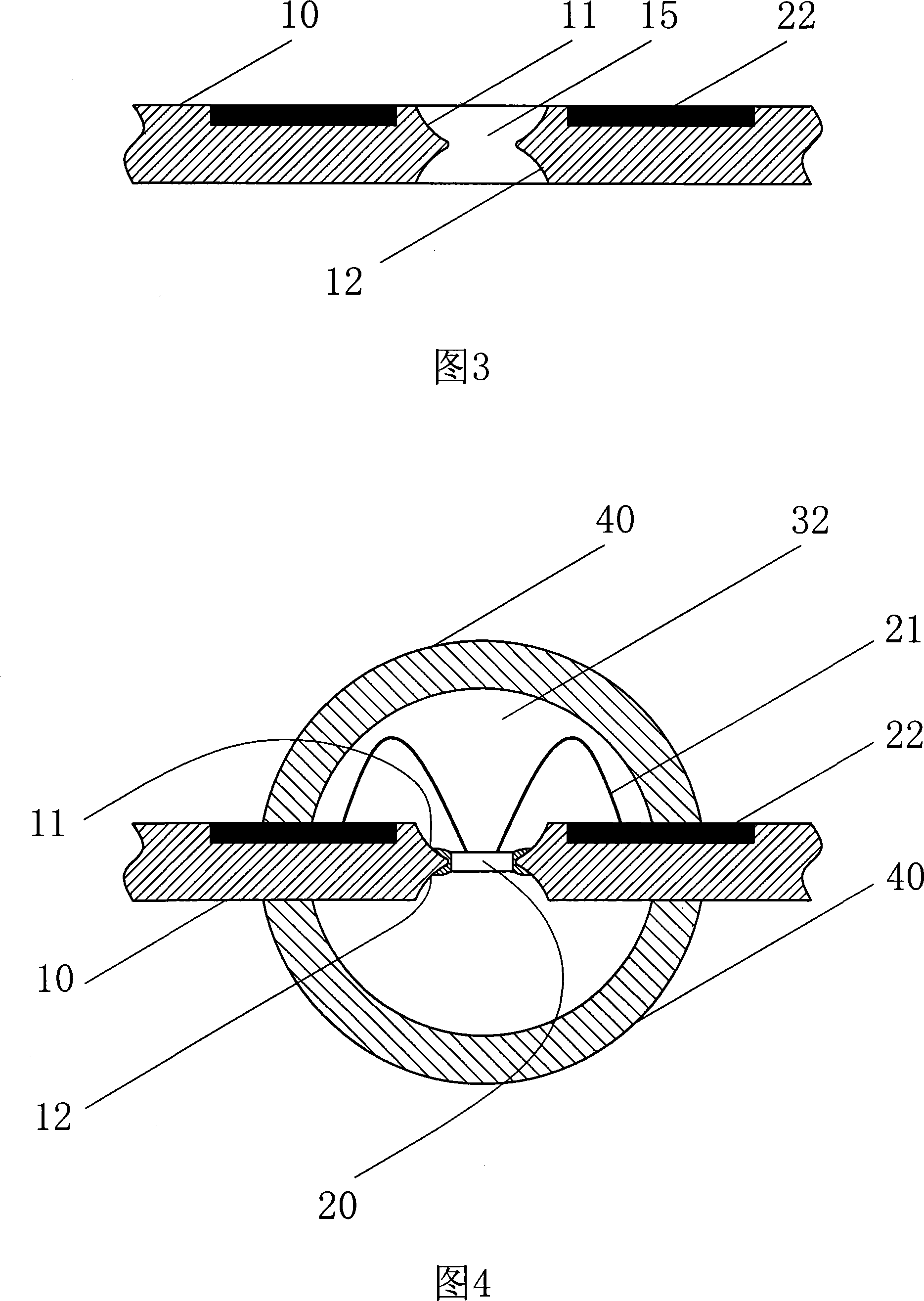

[0030] Embodiment 1: Refer to Fig. 3-4: the light-emitting diode of two-way light emission and heat dissipation is that the positive and negative electrodes on the light-emitting diode chip 20 are respectively drawn out with lead wires 21 and connected with the guide pins 22 extending outside the lens cover 40, the lens The cover 40 can cover the chip 20 , and at least one chip 20 is fixed in the through hole 15 on the substrate 10 .

[0031] The above-mentioned wafer 20 is a wafer of red light, yellow light, blue light, green light or orange light.

[0032] The upper and lower ends of the above-mentioned through hole 15 are two outwardly expanding cup-shaped bottomless grooves 11 , 12 .

[0033] The above-mentioned substrate 10 is made of PCB-based or copper-based or aluminum-based or iron-based materials.

[0034] A cavity 32 may be provided between the lens cover 40 and the medium 30, and the cavity 32 is filled with an inert gas of nitrogen, helium, neon, argon, or xenon....

Embodiment 2

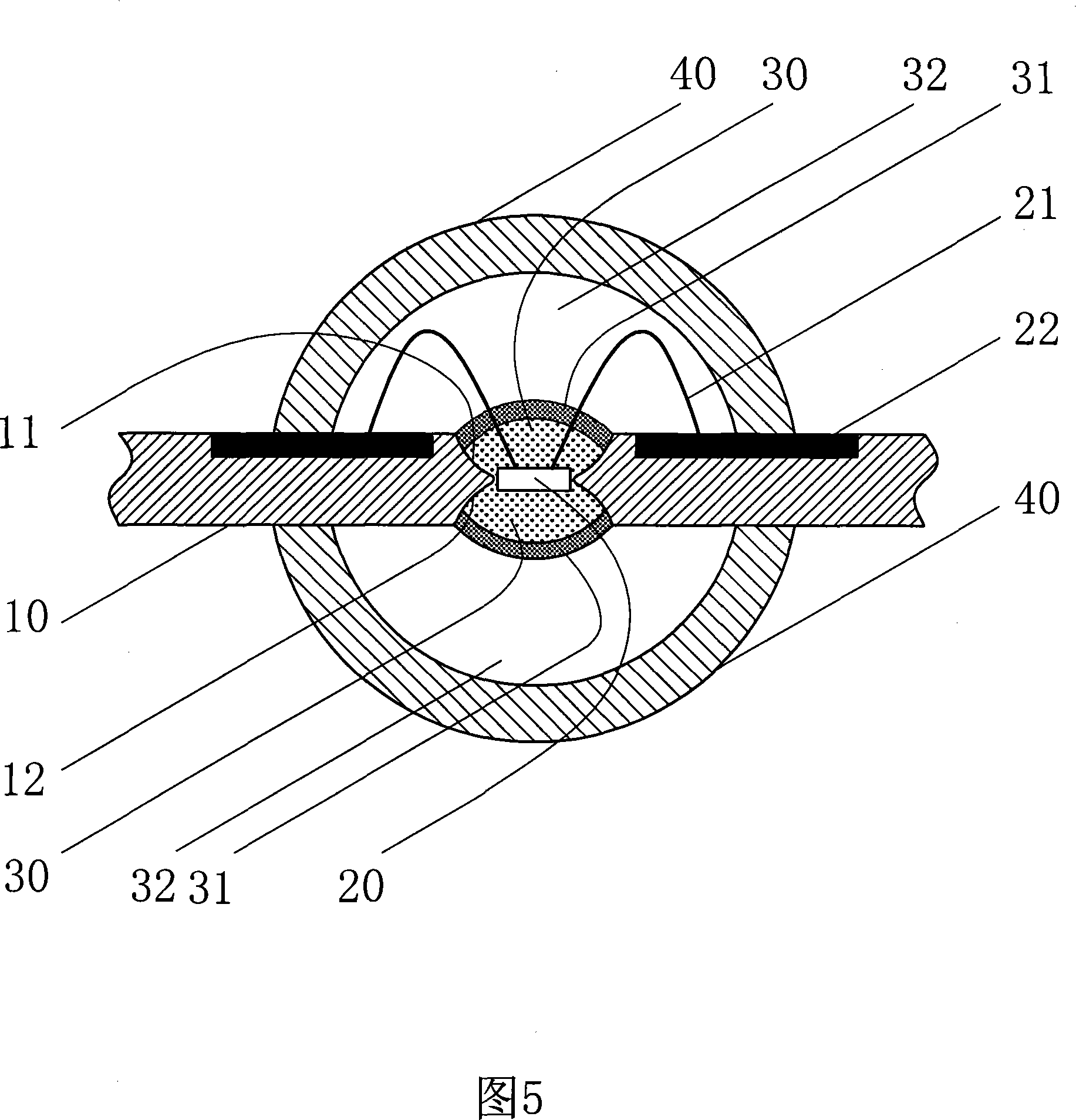

[0036] Embodiment 2: referring to Fig. 5: the basic structure is basically the same as that of Embodiment 1, except that when the wafer 20 is a blue light chip, a light-transmitting, heat-insulating medium 30 is arranged on the outer surface of the blue light chip, and on the outer surface of the medium 30 or a lens A layer of phosphor powder 31 is disposed on the cover 40 .

[0037] The above medium 30 is made of heat-insulating, light-transmitting, UV-resistant silica gel or epoxy resin or ceramics or optical plastics or optical glass materials.

[0038] The phosphor powder 31 disposed on the lens cover 40 is arranged in the interlayer of the lens cover 40 or the inner surface of the lens cover or the outer surface of the lens cover or mixed in the material for making the lens cover 40 .

Embodiment 3

[0039] Embodiment 3: Referring to Fig. 6: the basic structure is basically the same as that of Embodiment 2, except that the above-mentioned one layer of fluorescent powder 31 is arranged on the lens cover 40, that is, arranged in the interlayer of the lens cover 40, of course, the above-mentioned fluorescent powder It is arranged in the interlayer of the lens cover or the inner surface of the lens cover or the outer surface of the lens cover or mixed in the material for making the lens cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com