Patents

Literature

57results about How to "Short conveying distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

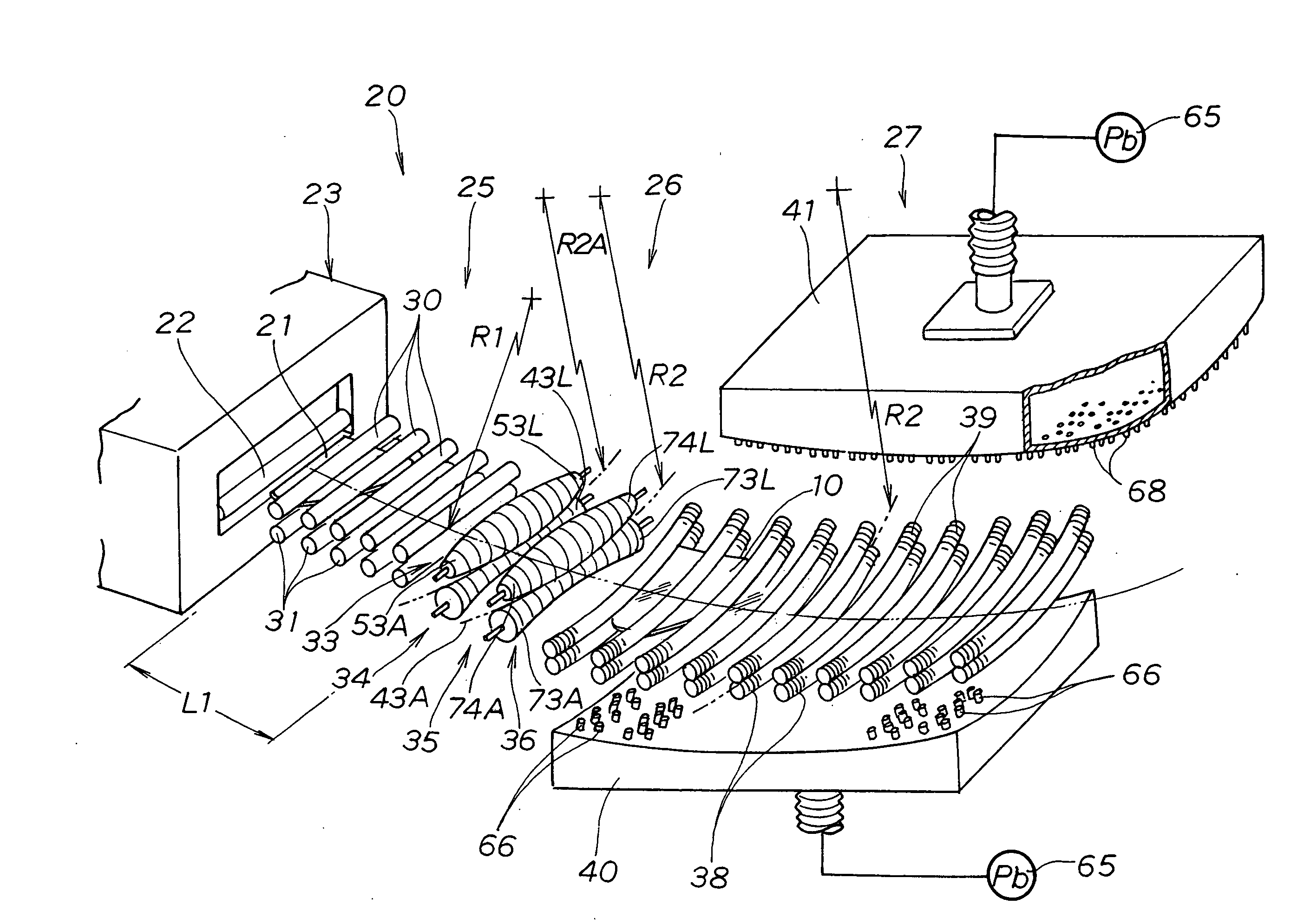

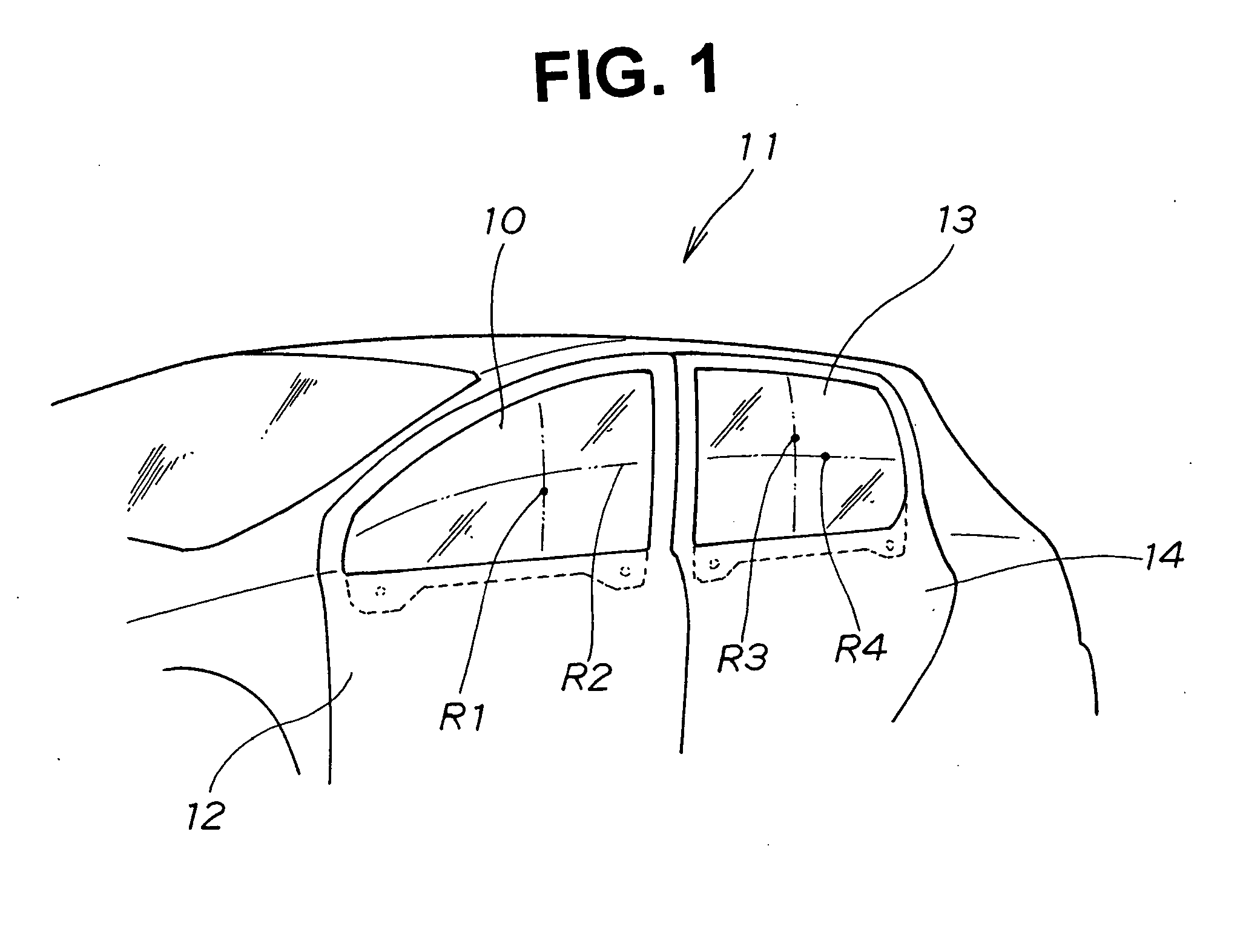

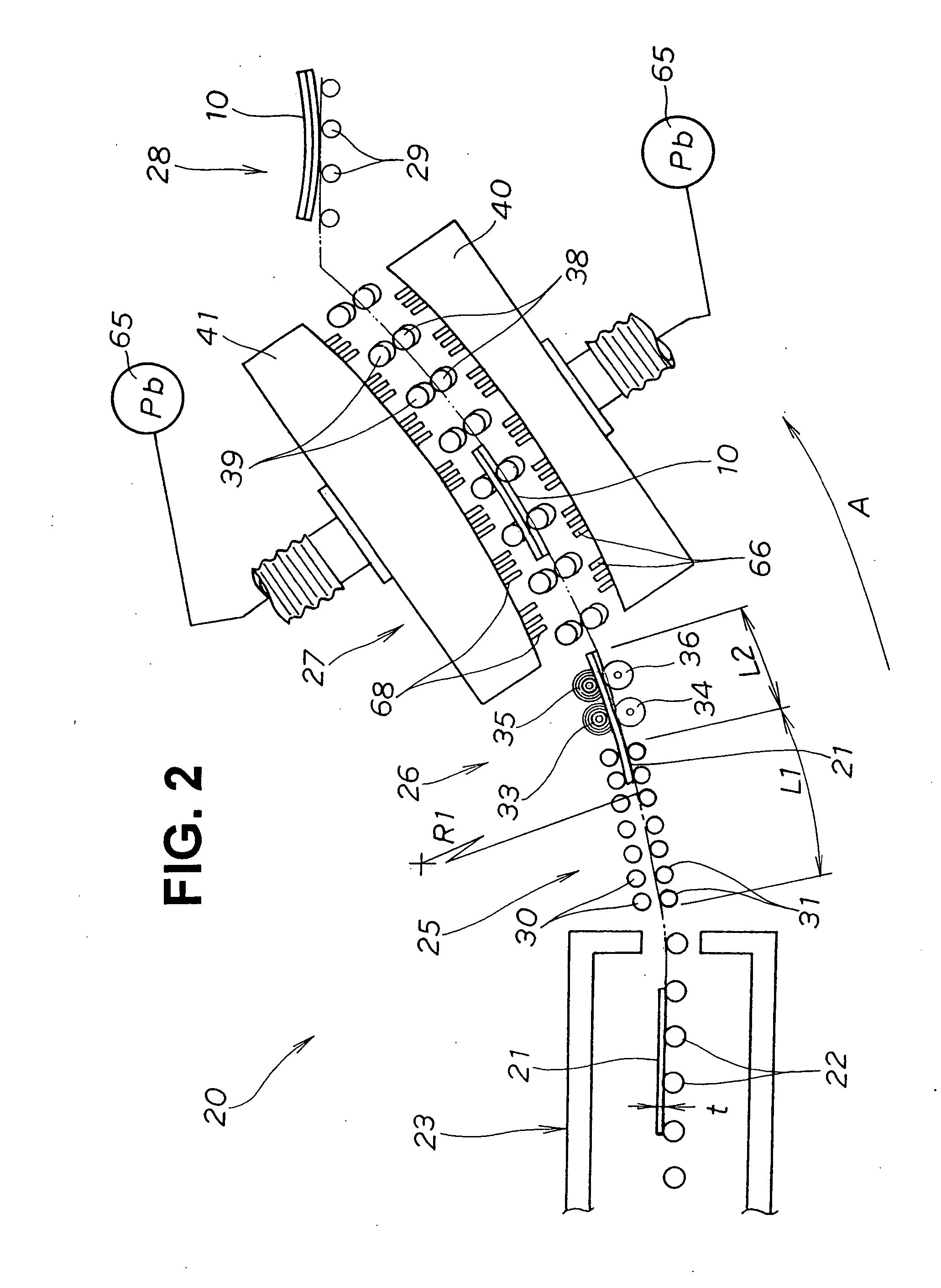

Method and device for forming multi-curved glass sheet

InactiveUS20050061032A1Rapid coolingPrecise supportGlass transportation apparatusGlass rolling apparatusFlat glassMechanical engineering

Owner:NIPPON SHEET GLASS CO LTD

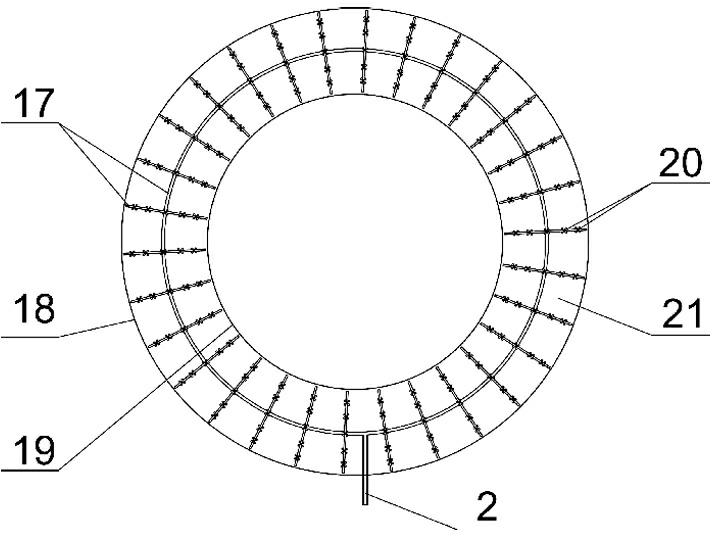

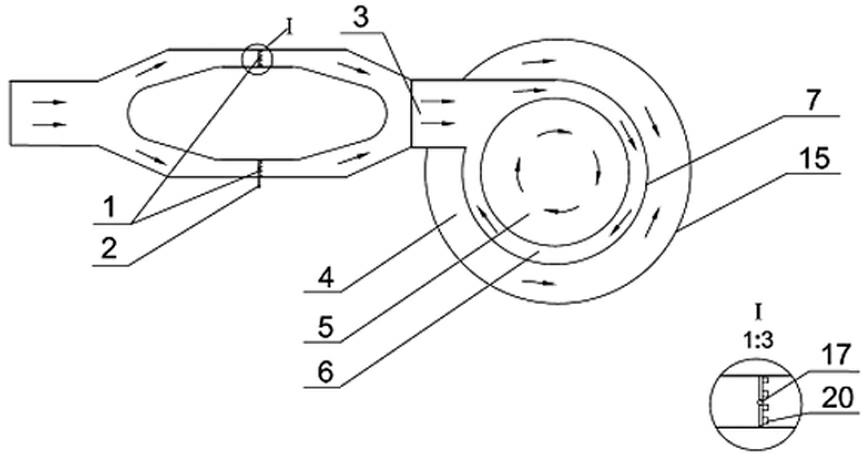

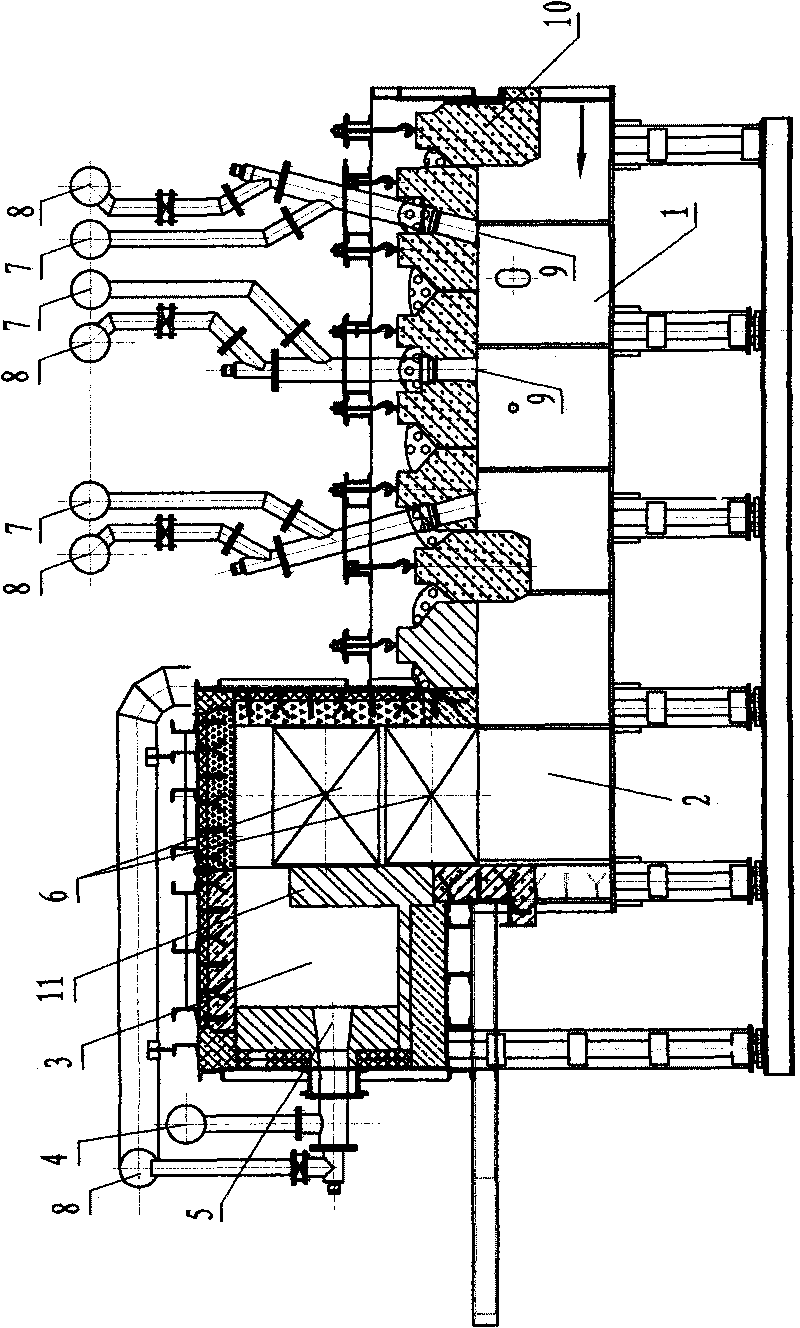

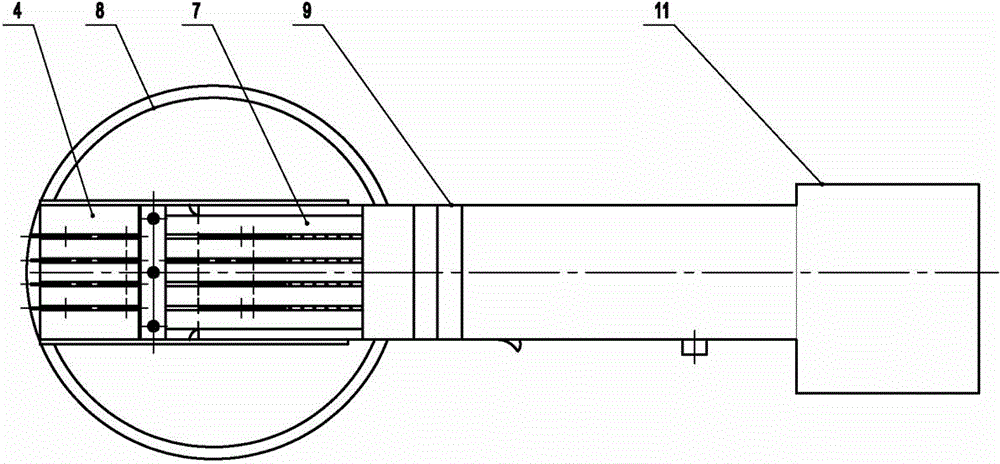

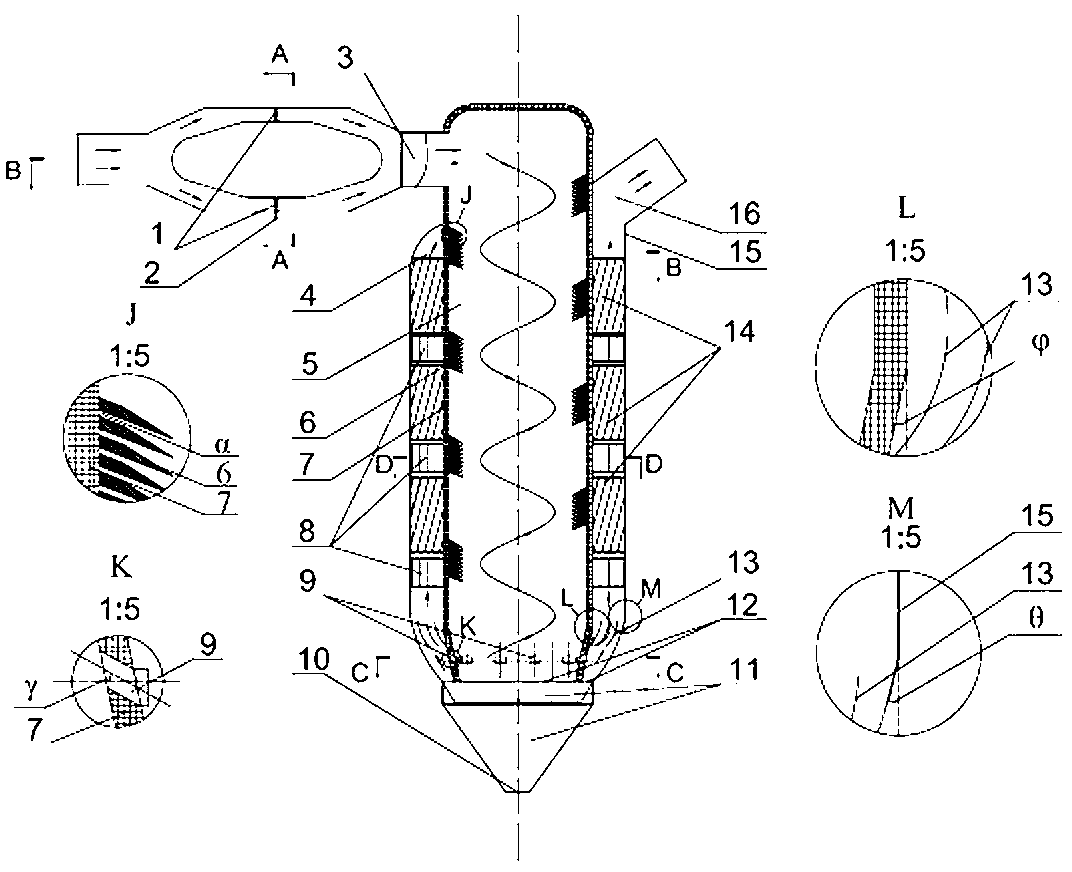

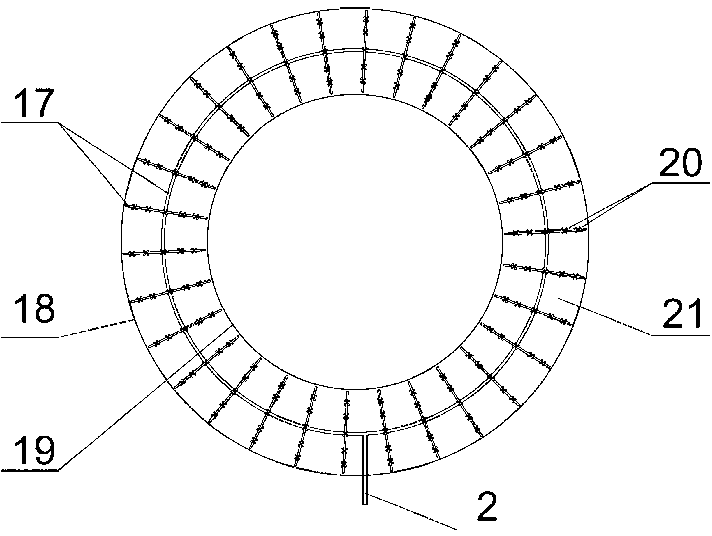

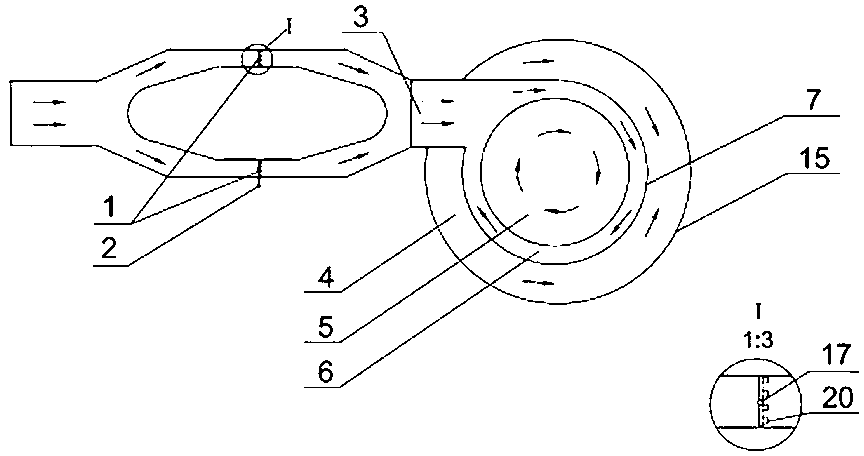

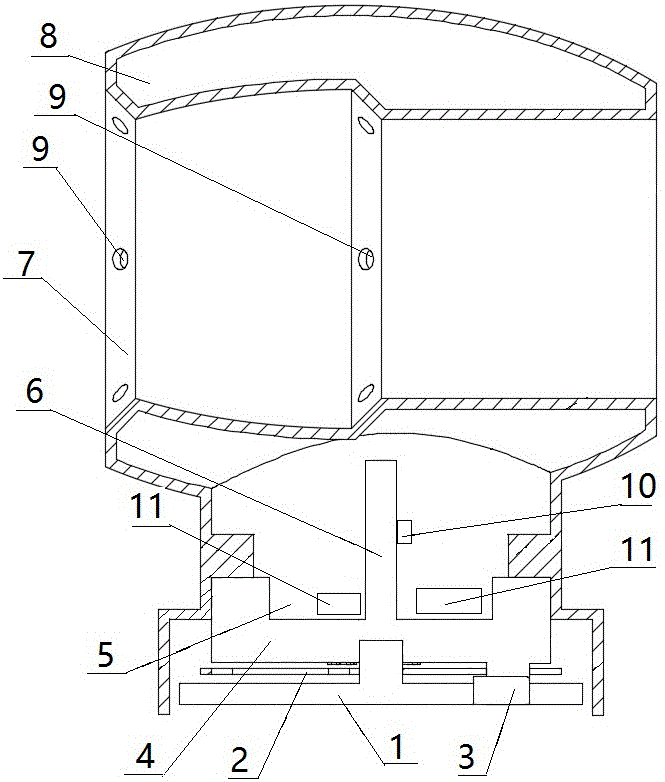

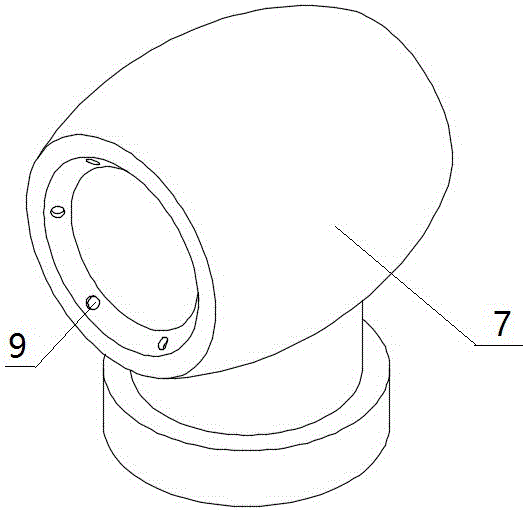

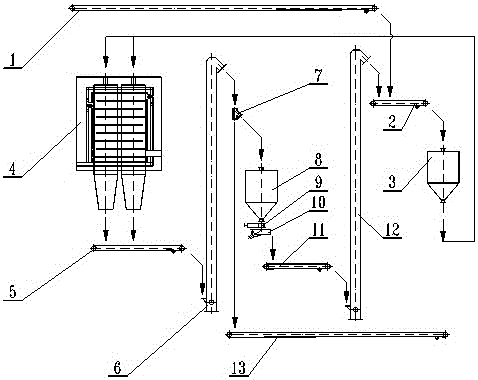

Dedusting-denitrating integrated device

ActiveCN102614779ASimple structureSimple control systemDispersed particle filtrationFlue gasProcess engineering

The invention discloses a dedusting-denitrating integrated device which comprises a flue gas channel, a mixed flue gas inlet and a shell consisting of an outer cylinder and an inner cylinder, and a ash hopper at the bottom of the shell, wherein the inner cylinder is mainly used for dedusting and ammonia mixing, the outer cylinder is mainly used for containing a denitrating catalyst bed, the crosssection of the flue gas channel is ring-shaped, and ammonia spray grilles are distributed in the flue gas channel in a radial manner so that the required NH3-to-NO ratio can be reached more easily. The device provided by the invention can be used for dedusting before carrying out denitrating, a catalyst can be effectively prevented from being worn, poisoned and blocked and the service life of thecatalyst can be prolonged. Under the condition that the length of the device is not increased, the ammonia mixing time is prolonged and ammonia mixing can be performed fully; heat absorbing spiral plates and cooling rectifier plates are arranged in both the inner cylinder and the outer cylinder to share heat of flue gas at the inlet, and therefore the heat loss of flue gas can be reduced, the denitrating efficiency can be improved and the catalyst is prevented from being sintered and inactivated under the action of superheated flue gas.

Owner:HUNAN UNIV

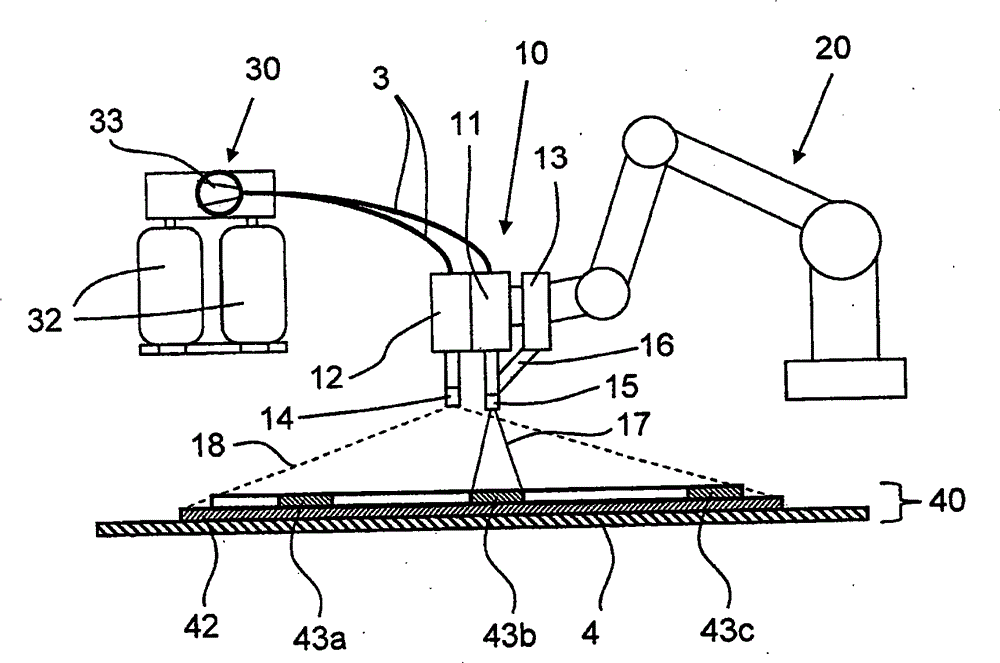

Device and method for applying a reactive mixture consisting of at least two components to a substrate

Owner:KRAUSSMAFFEI TECH GMBH

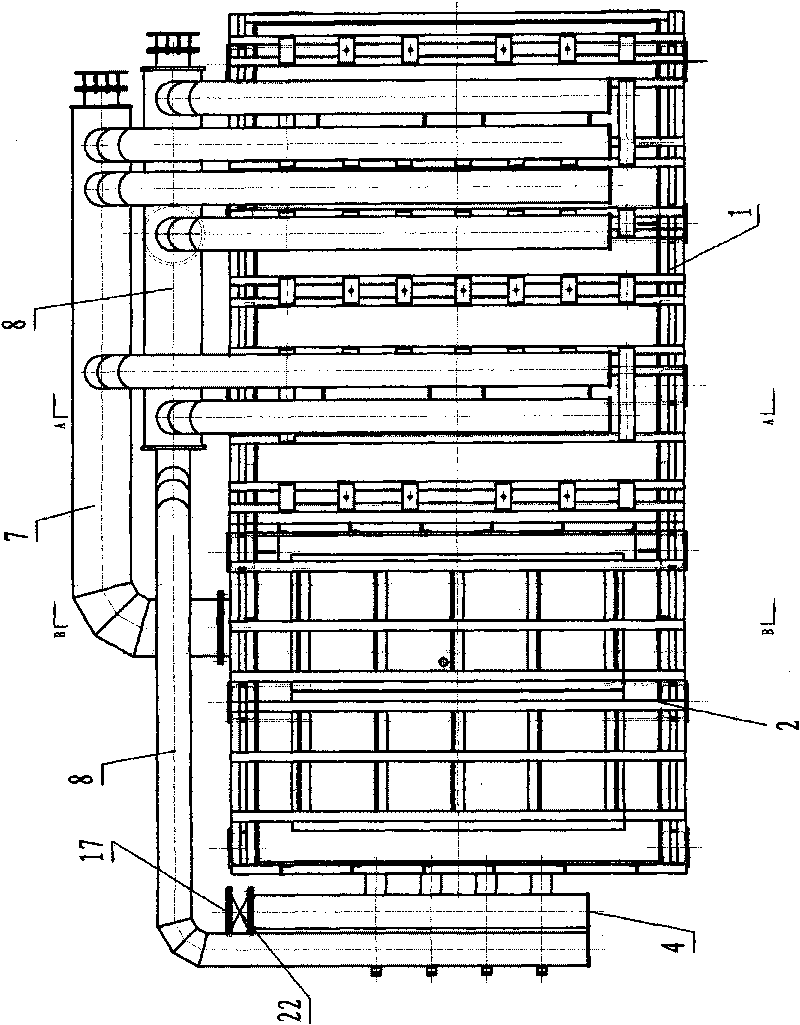

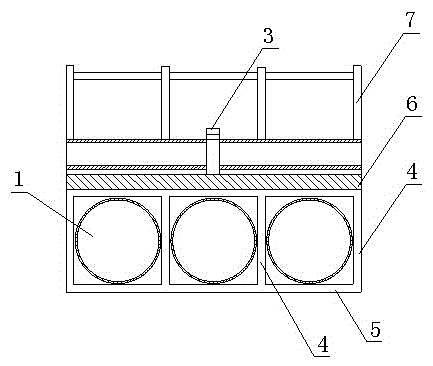

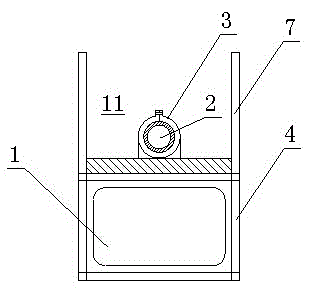

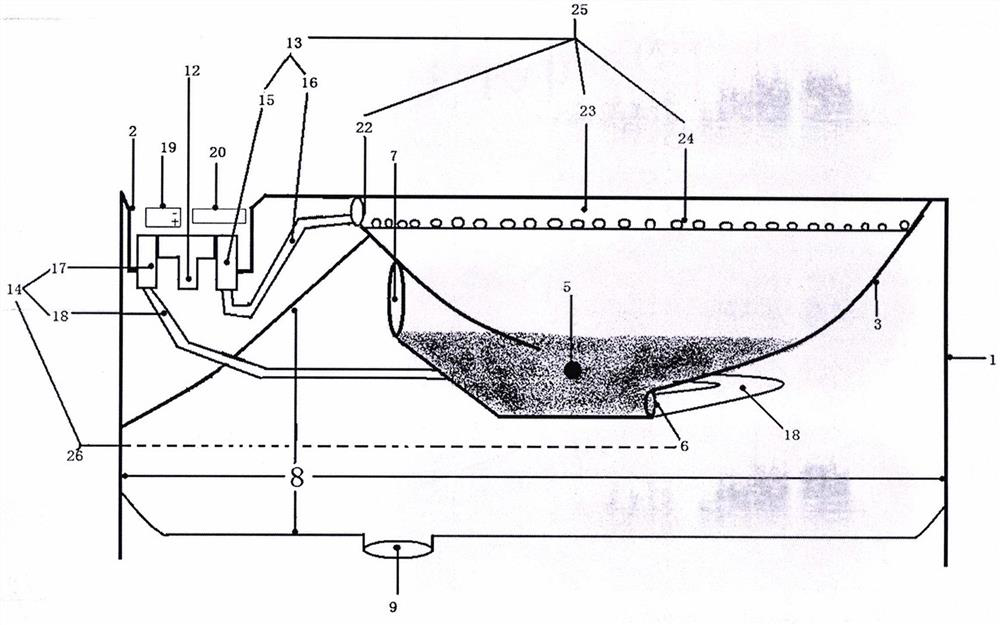

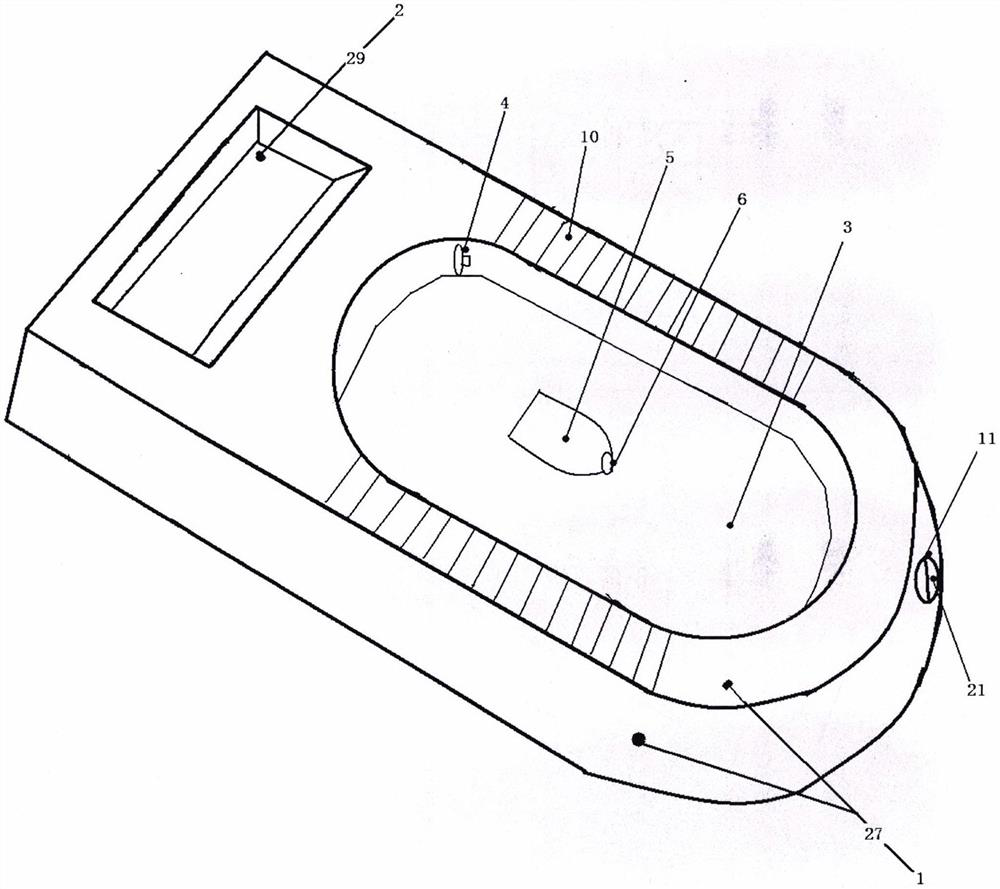

Single preheating, sintering, igniting and heat insulating furnace

The invention relates to a single preheating, sintering, igniting and heat insulating furnace with the advantages of simple structure, little pollution, obvious energy saving effect and high safety. The furnace comprises an igniting section and a heat insulating section, wherein the igniting section and the heat insulating section are connected into a whole and are arranged on a sintering machine table. The heat insulating section comprises an air preheating furnace, and an air heat exchanger is arranged in the air preheating furnace. The igniting section comprises a plurality of burning nozzles, and each burning nozzle is connected with a blast furnace gas pipe and a hot air pipe. A cold air inlet and a cold air input tube of the air heat exchanger are connected, and a fan is arranged on the cold air input tube. A hot air outlet of the air heat exchanger is connected with an inlet of the hot air tube. The air heat exchanger is arranged on a trolley. When the single preheating, sintering, igniting and heat insulating furnace is in working, the sintering compound of the waste gas trolley outputted by the air preheating furnace is insulated, and sucked into a large fume passage by the sintering compound surface of the trolley. The large fume passage is connected with the hot waste gas heat energy recovery system and the waste gas treating system to recover and utilize heat energy and remove harmful elements of sulphur and the like in the waste gas.

Owner:常州市黑山烧结点火炉制造有限公司

Heavy-denier flat yarn continuous spinning process

InactiveCN102978722ASmall spanShort conveying distanceNew-spun product collectionFilament manufactureYarnSmall footprint

The invention discloses a heavy-denier flat yarn continuous spinning process. The process comprises the following steps of viscose metering molding, washing, baking and rolling, drawing molded yarns onto a small processing roll and a big processing roll through a yarn guide rod, sequentially performing regenerating, washing, desulfurizing, Ph value-adjusting, oiling and baking processes on the yarns on the small processing roll and the big processing roll, and rolling the baked yarns on a winding head under the action of a yarn guide wheel, wherein before the yarns are drawn to the small processing roll and the big processing roll, acid liquid on the yarns is scraped in a foam acid-scraping way. Continuous spinning can be finished on one set of spinning equipment, the breakage is low, the occupation area of the equipment is small, the acid bath loss is low, the continuity is higher, spindle positions are not mutually affected, and the produced heavy-denier flat yarns are high in quality, the rate of finished products and yield.

Owner:YIBIN HIEST FIBER +1

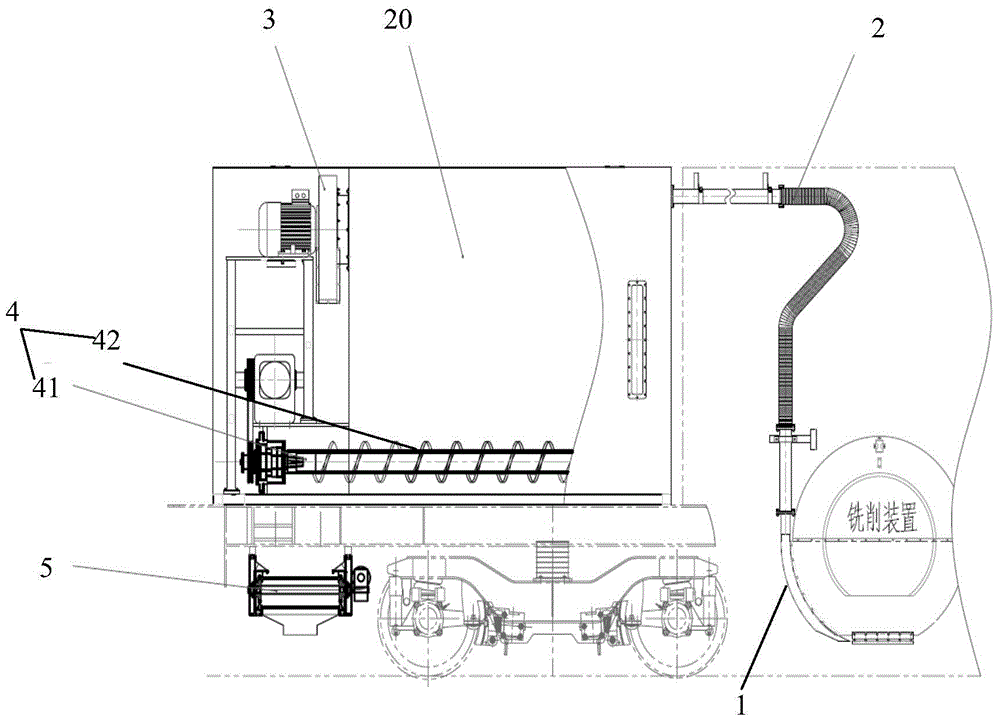

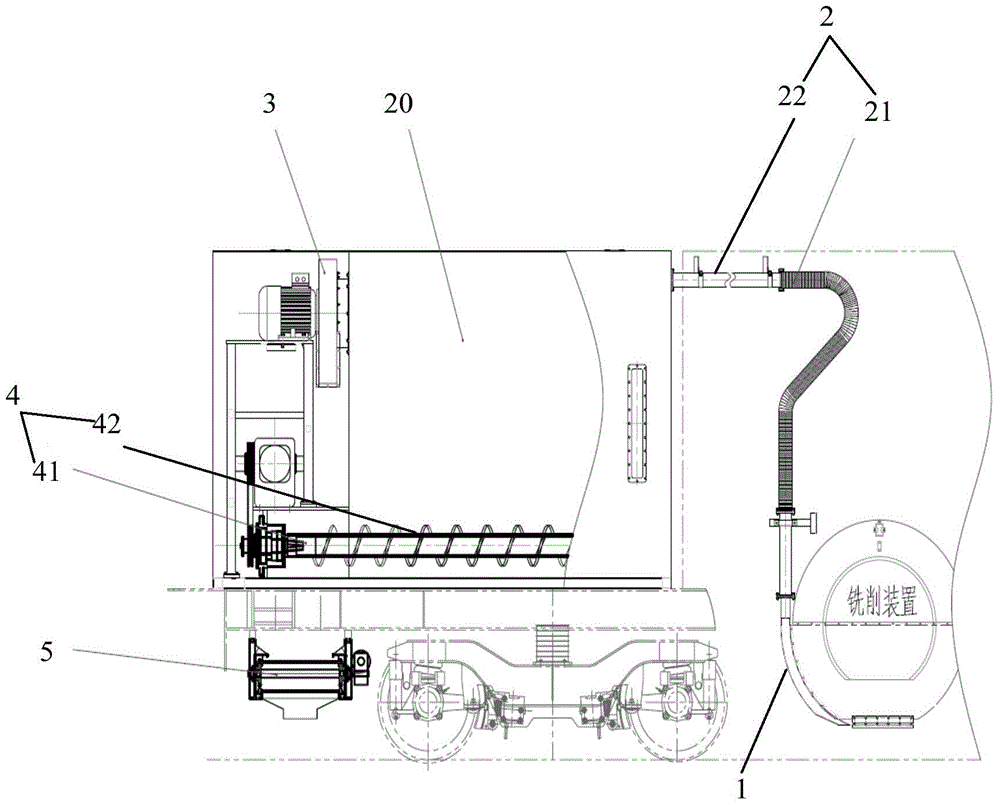

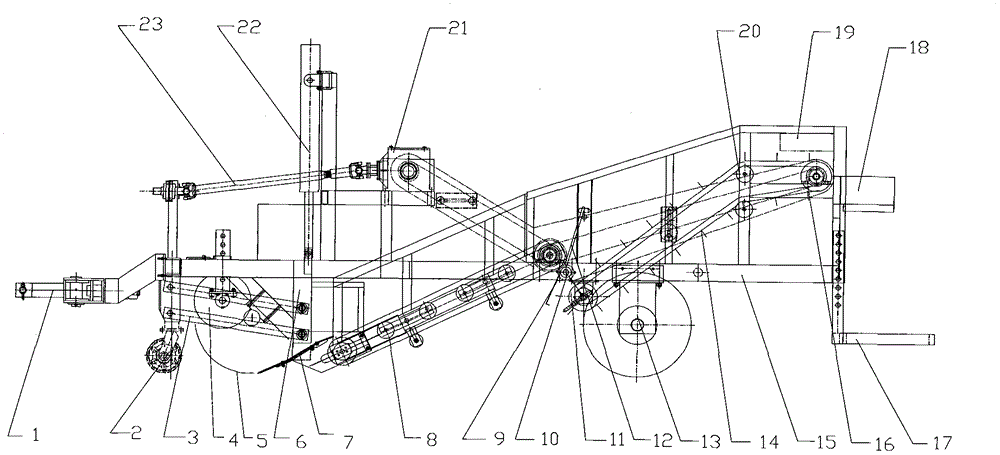

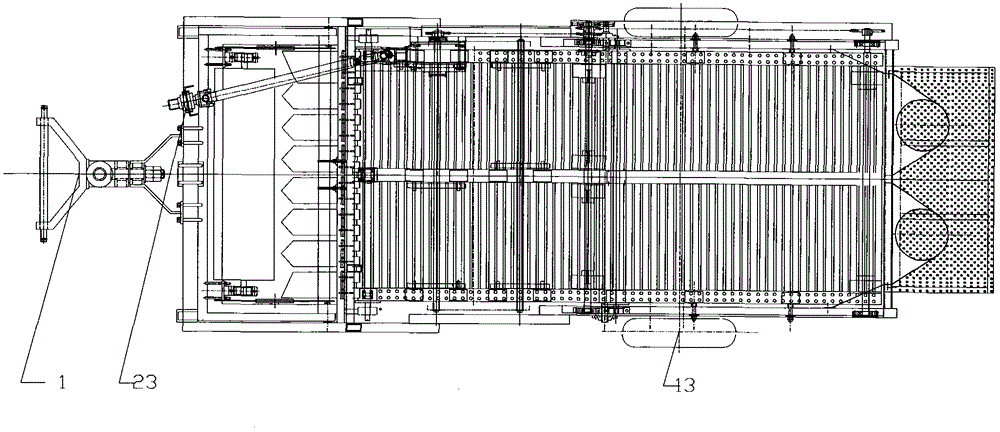

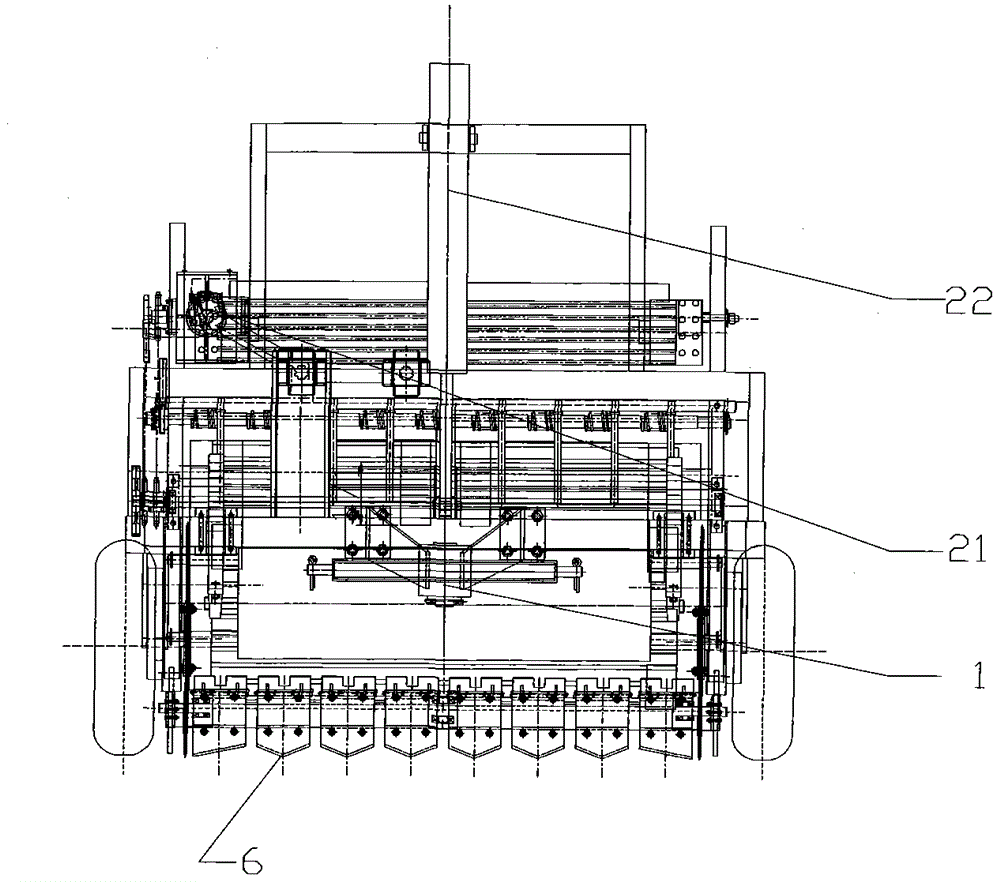

Chip collecting device

InactiveCN104526451AReduce points of failureExtend your lifeMaintainance and safety accessoriesDischarge efficiencyEngineering

The invention provides a chip collecting device which comprises a chip collecting system, a chip collecting box and a chip discharging system. The chip collecting system comprises a chip collecting shoe, a chip collecting pipeline and an induced draft fan. The chip collecting shoe is fixed to a milling device, one end of the chip collecting pipeline is connected with the chip collecting shoe, and the other end of the chip collecting pipeline is connected with a first connector of the chip collecting box. The induced draught fan is connected with a second connector of the chip collecting box and used for forming negative pressure in the chip collecting box, and iron chips are collected into the chip collecting box through the chip collecting pipeline. The first connector is opposite to the second connector. The chip discharging system comprises a spiral conveyor and a conveying belt, and the spiral conveyor is used for conveying the iron chips in the chip collecting box to the part outside the chip collecting box. The spiral conveyor comprises a motor and a spiral rod, the motor is connected with the spiral rod, the spiral rod is driven to rotate, the motor is arranged outside the chip collecting box, the spiral rod stretches in the chip collecting box through a third connector of the chip collecting box, and the conveying belt is fixed below the spiral conveyor. The chip collecting device is simple in structure and high in chip discharging efficiency.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

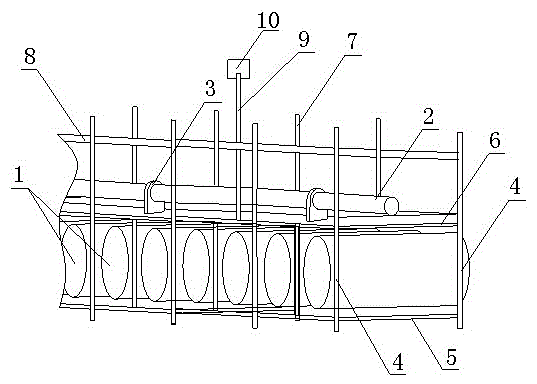

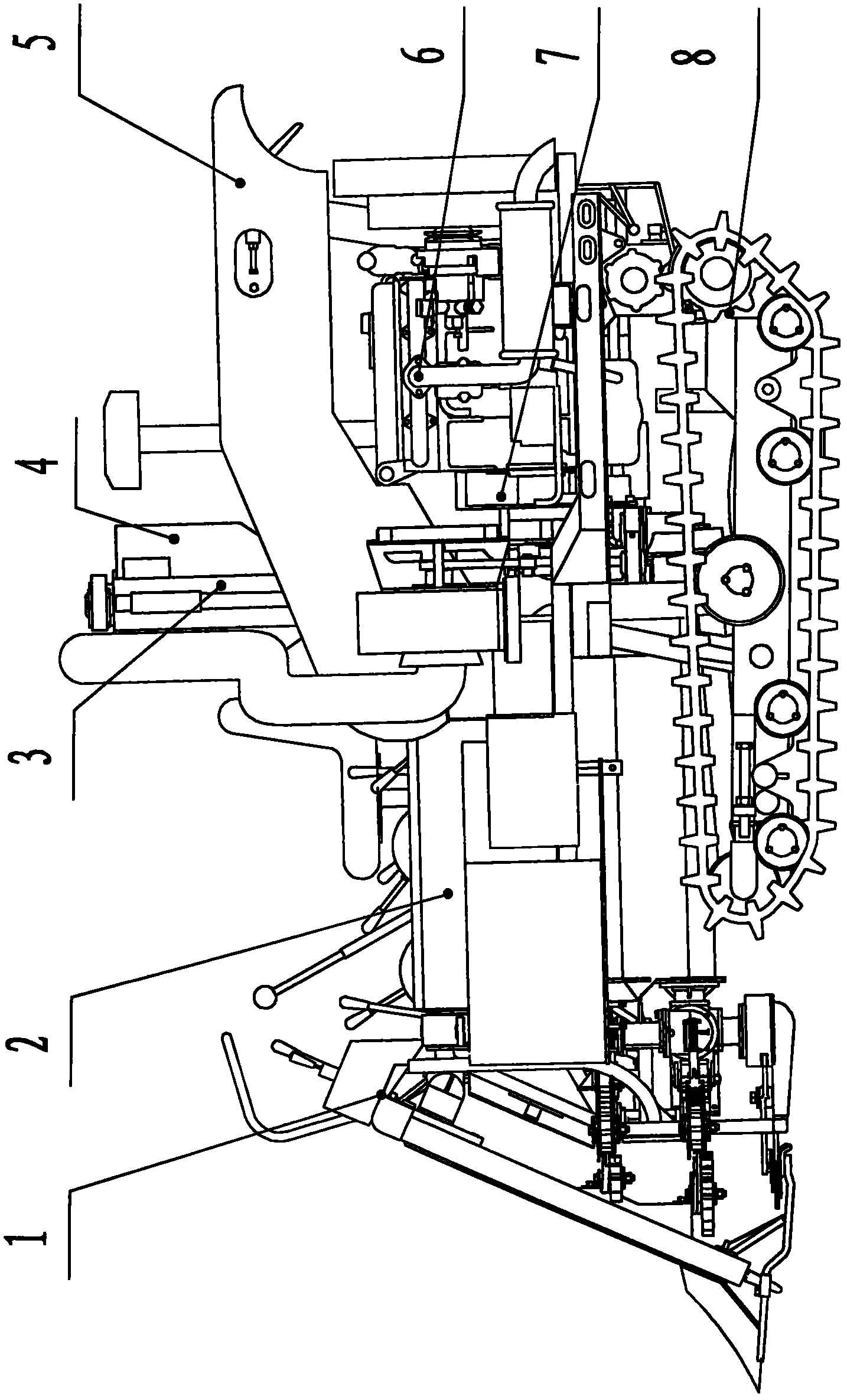

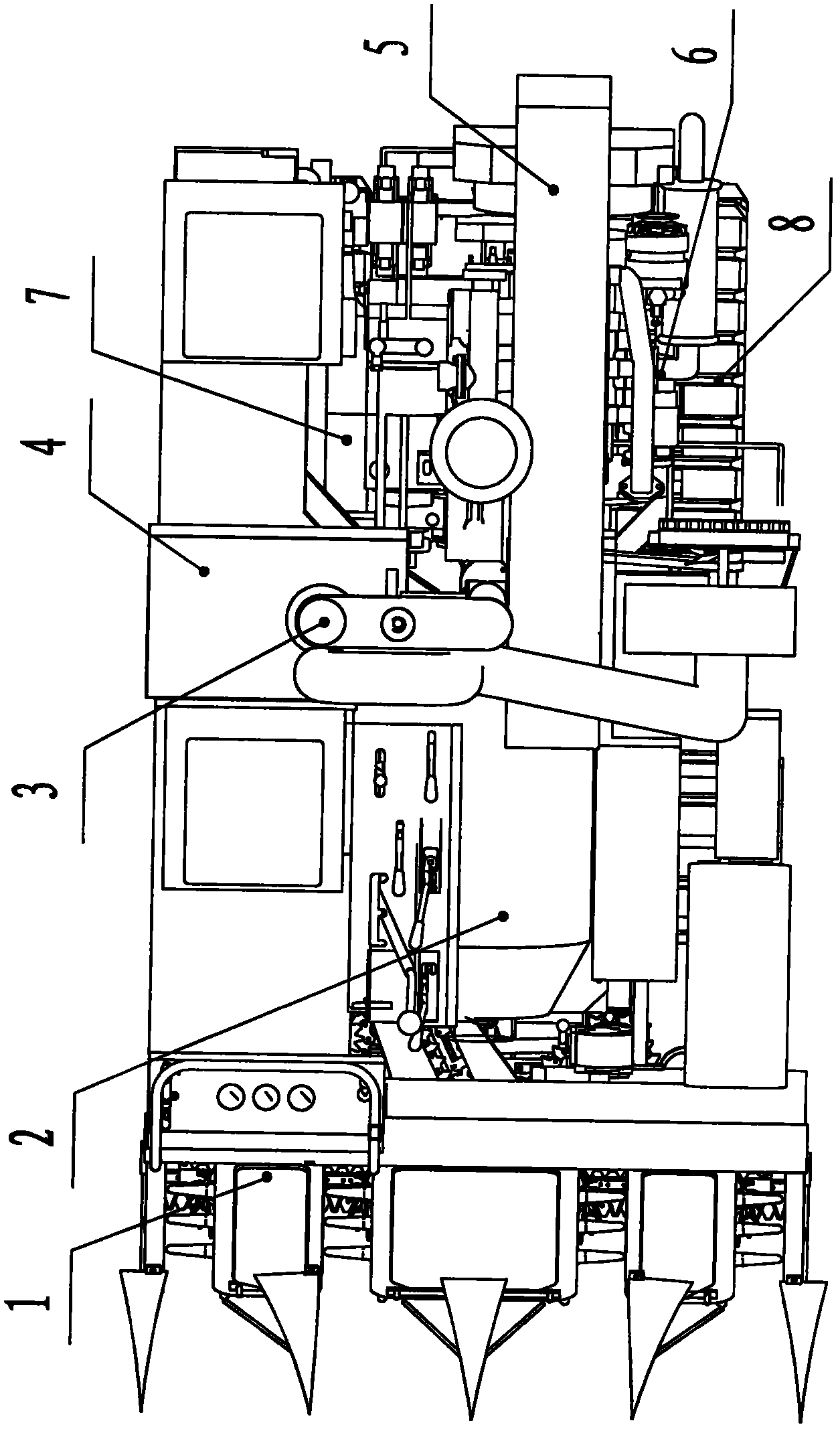

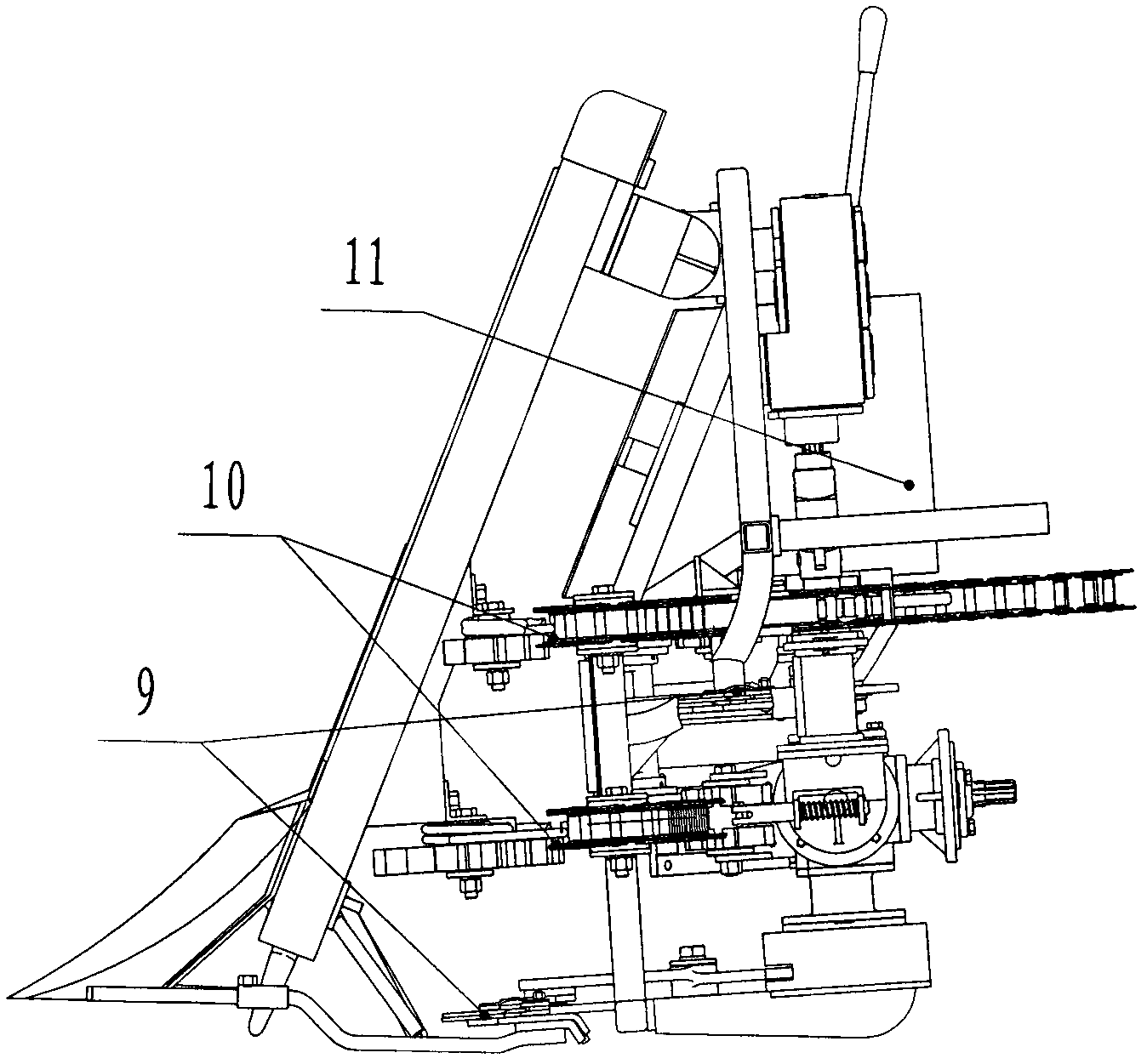

Bagging potato combined harvester

InactiveCN104396423AReduce mechanical damageEasy to separateDiggersDrive shaftAgricultural engineering

The invention relates to the field of agricultural machinery and particularly relates to a bagging potato combined harvester. The combined harvester comprises a rack, a digging shovel, a stalk separation unit and a potato tuber lifting delivery unit. The combined harvester is characterized in that a traction unit is arranged at the front end of the rack, and the whole harvester is connected with a pull rod through the traction unit. A hydraulic lifting oil cylinder is arranged on the upper portion of the rack and is hinged to the upper portion of the digging shovel. A transmission is arranged above the rack and is connected with a transmission shaft. A stopping support wheel, a soil and potato separation delivery unit, the potato tuber lifting delivery unit and a traveling unit are arranged below the rack successively. A bagging unit and a standing platform are arranged behind the rack. By means of the combined harvester, processes of tuber crop digging, stalk and mulch separation, potato tuber collection bagging and the like can be completed through one step, the work efficiency and the labor productivity of potato harvesting are improved greatly, and the labor intensity of human is further reduced.

Owner:GANSU AGRI UNIV

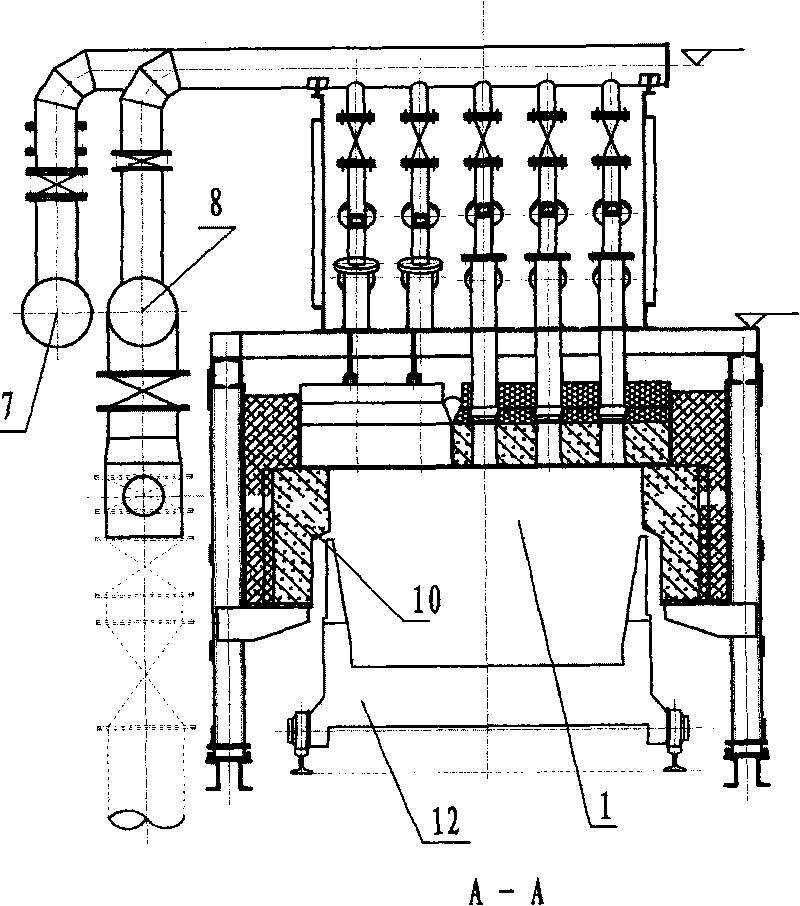

Device and method for quicklime digestion, dedusting and sewage sludge treatment

ActiveCN105800968AAchieve recyclingAvoid wastingCombination devicesSludge treatment by de-watering/drying/thickeningWater bathsSewage

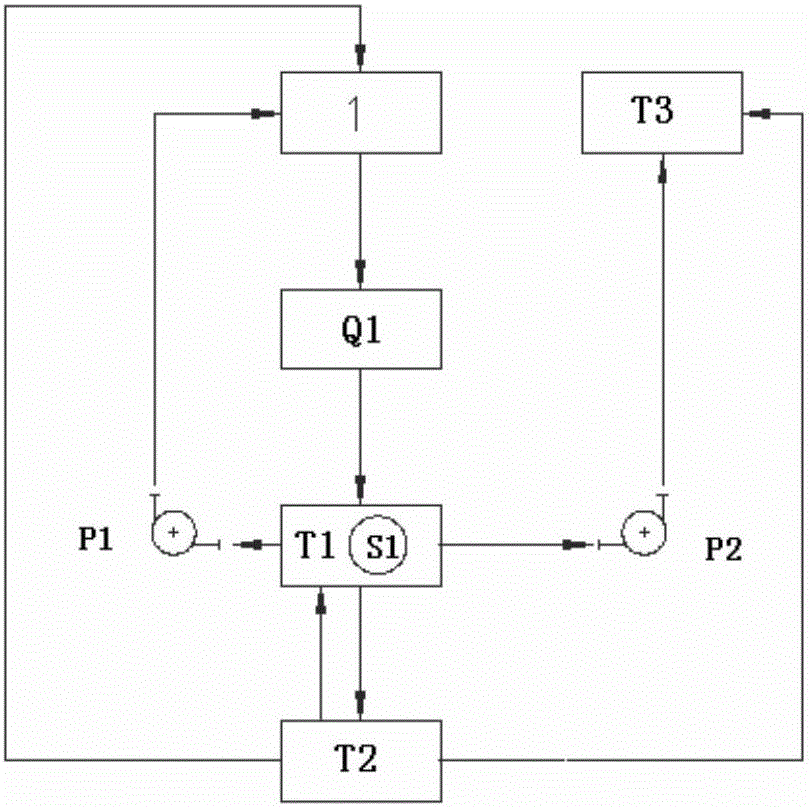

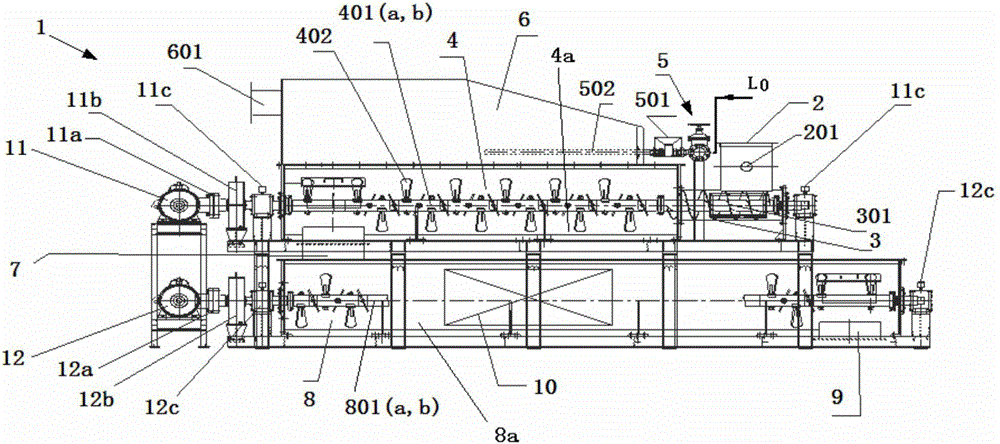

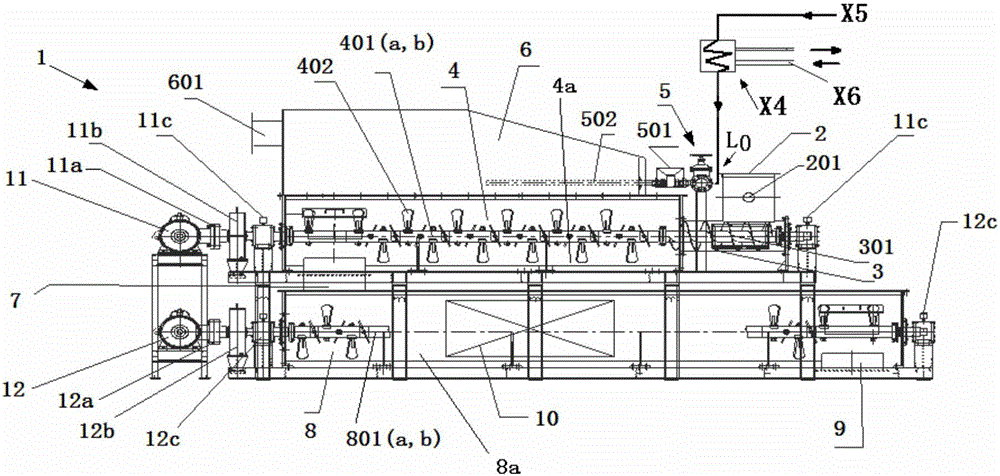

A device for quicklime digestion, dedusting and sewage sludge treatment comprises a quicklime digester (1), a water bath deduster (Q1) and a sewage treatment device, wherein the sewage treatment device comprises a sewage pool, a stirring device arranged on the sewage pool, a sewage pump and a sludge dehydrator. The quicklime digester is provided with a sealing dedusting cover (6) with a dust collecting outer port (601). The water bath deduster (Q1) is communicated with the dust collecting outer port (601) of the digester (1) through a dedusting pipeline (Q4), and the bottom of the water bath deduster (Q1) is provided with a dedusting sewage pipe communicated with the sewage pool. A method for quicklime digestion, dedusting and sewage sludge treatment is further provided.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

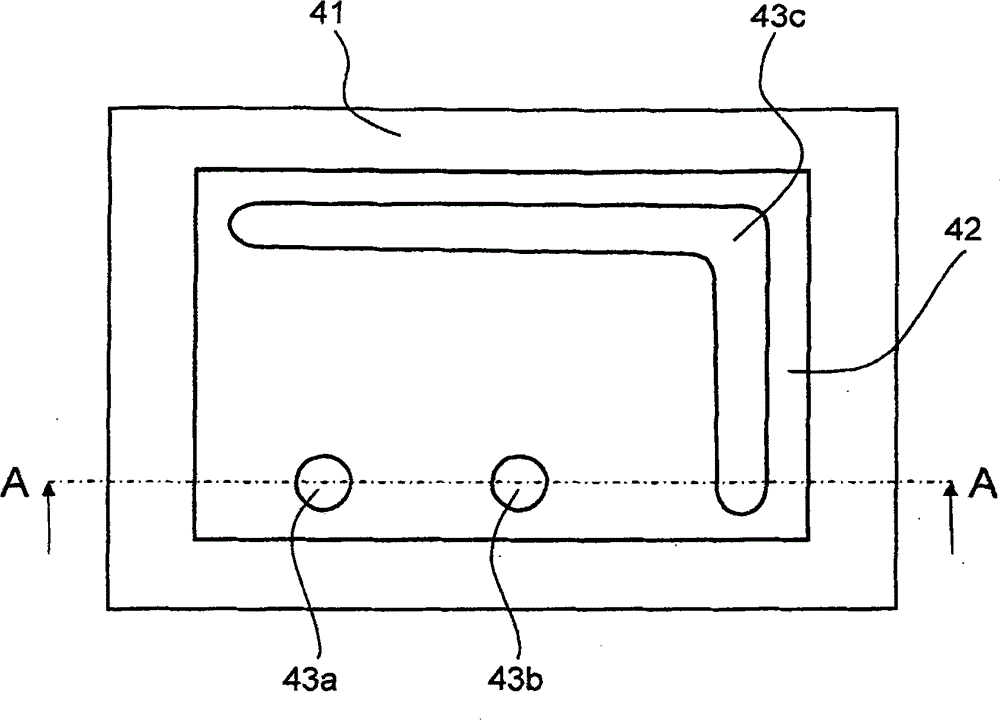

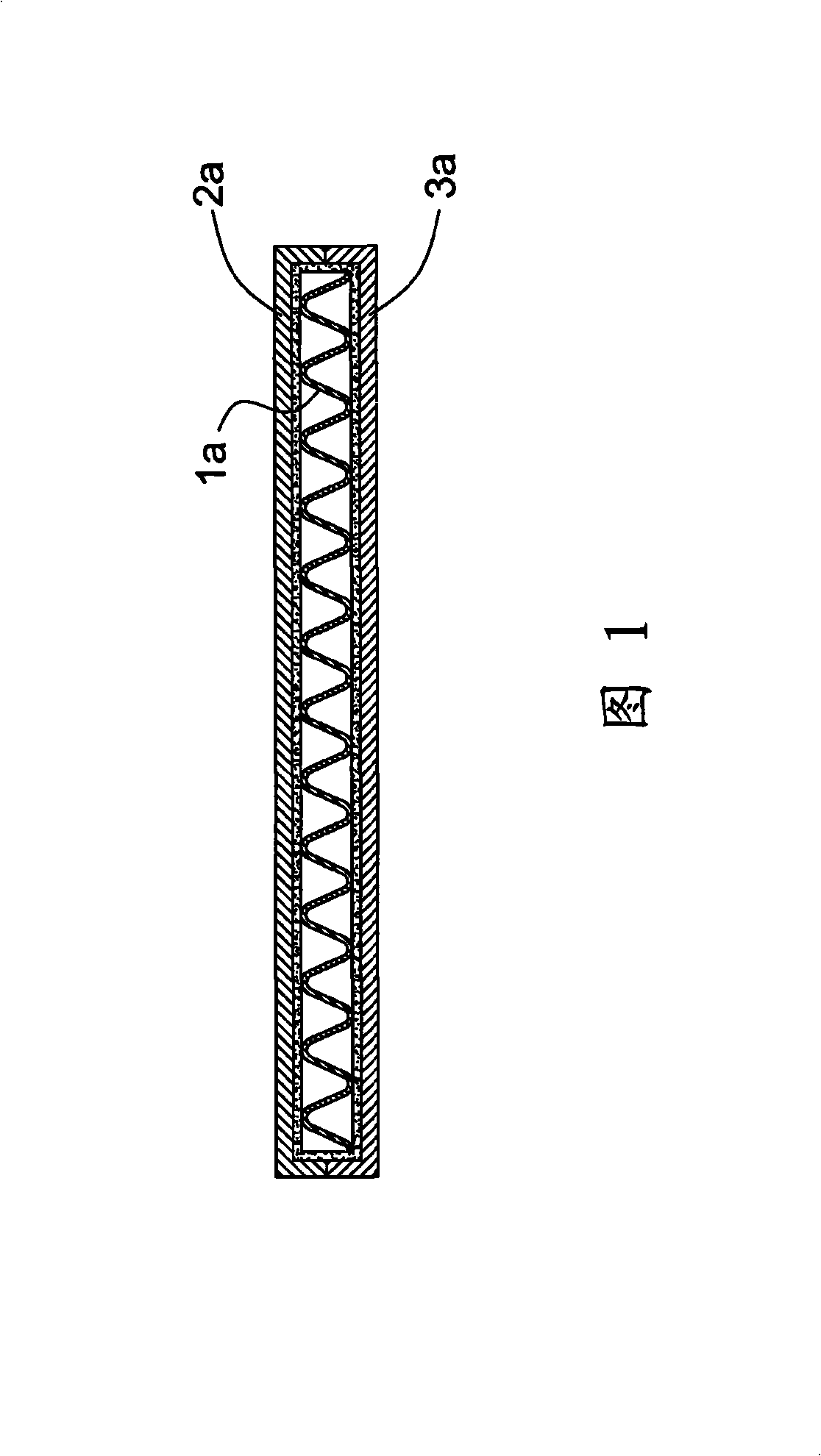

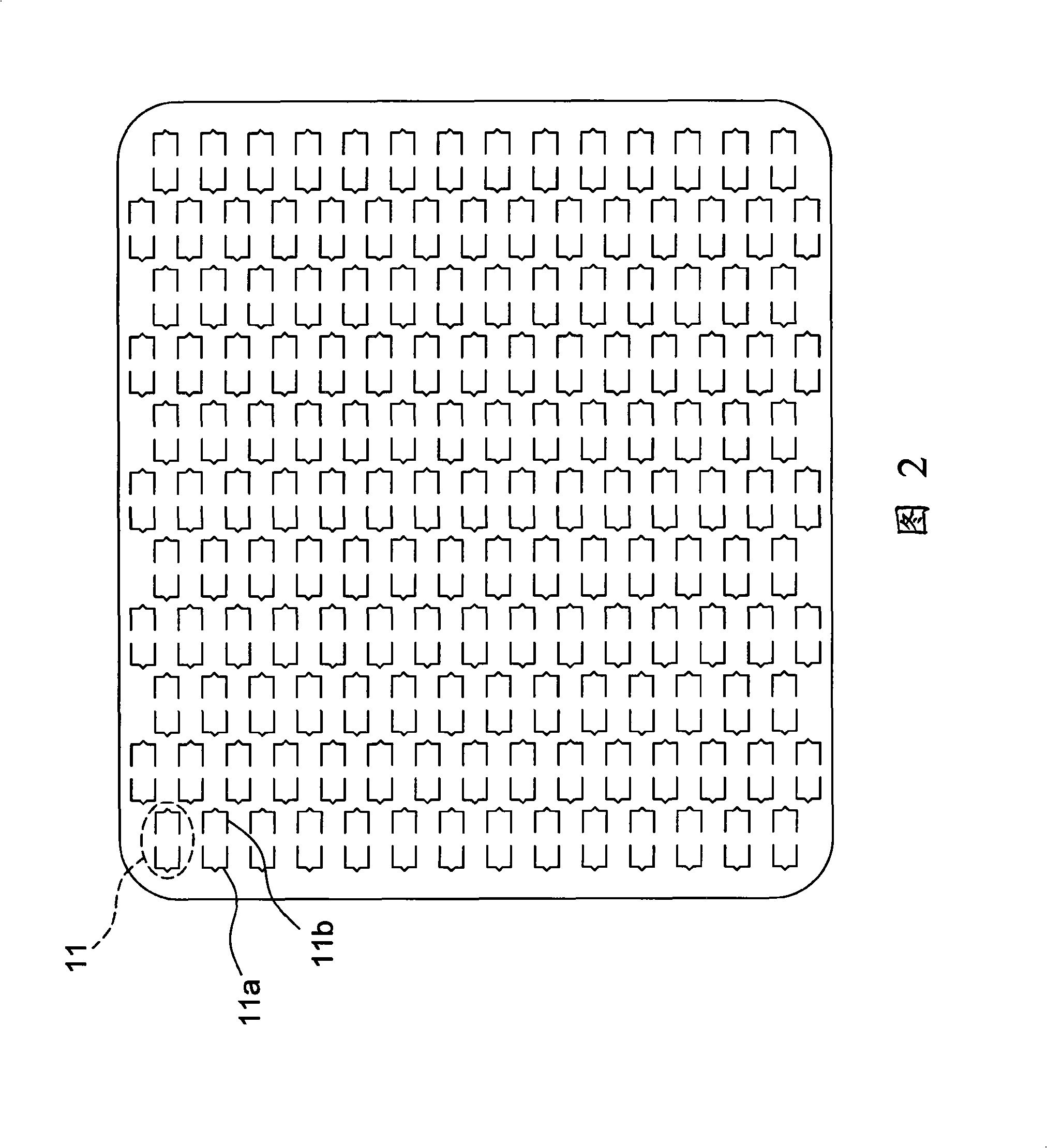

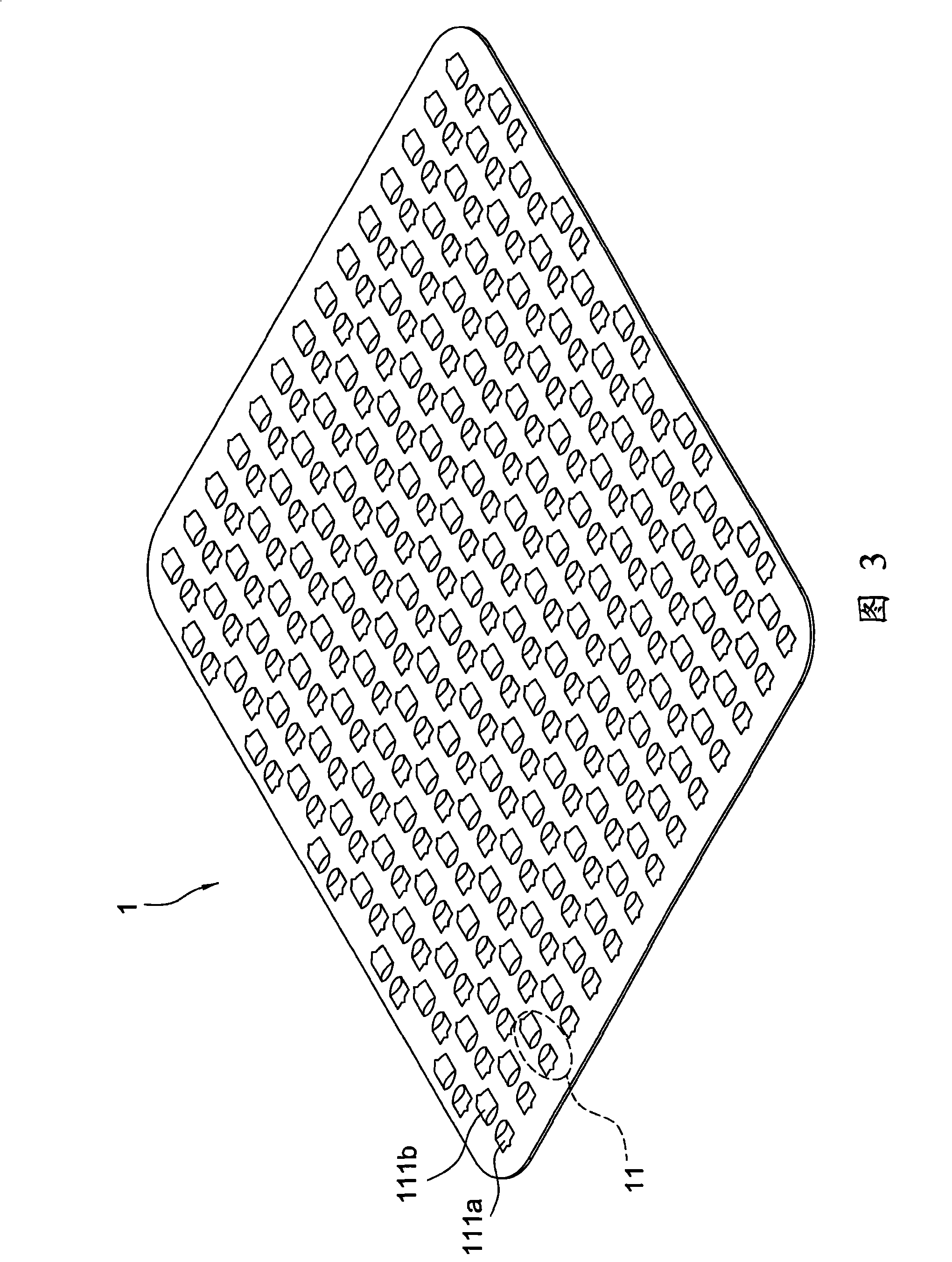

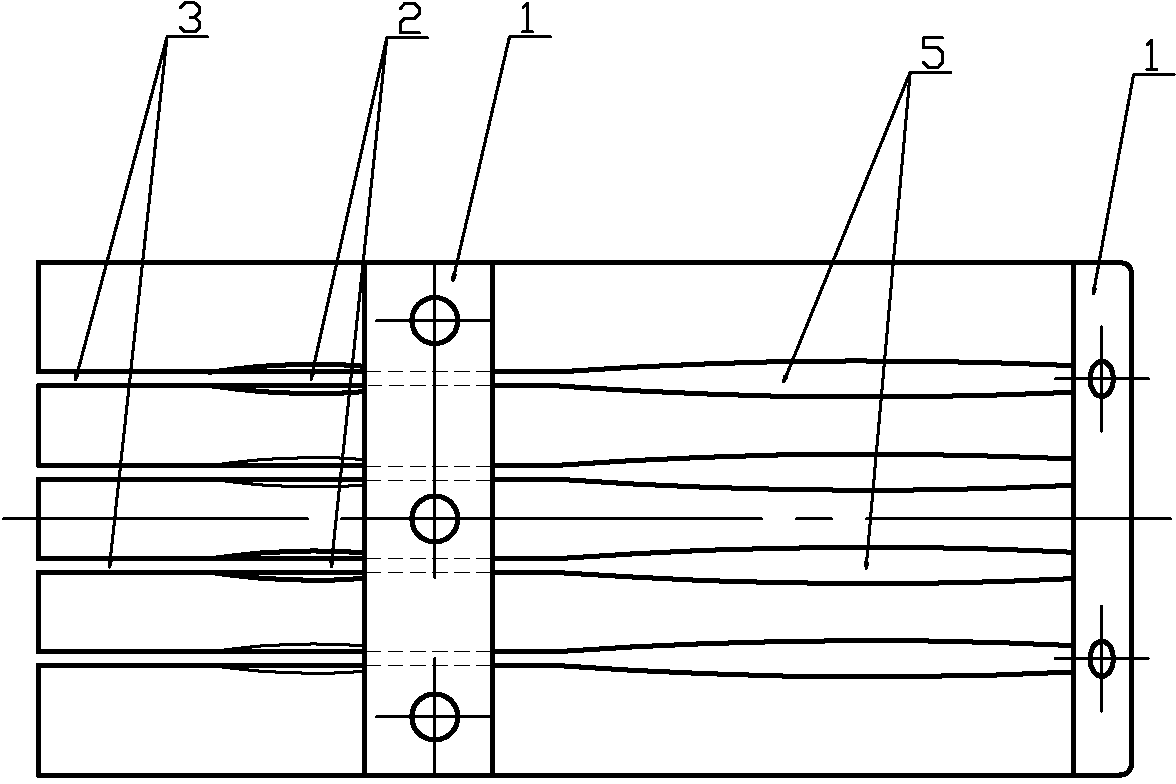

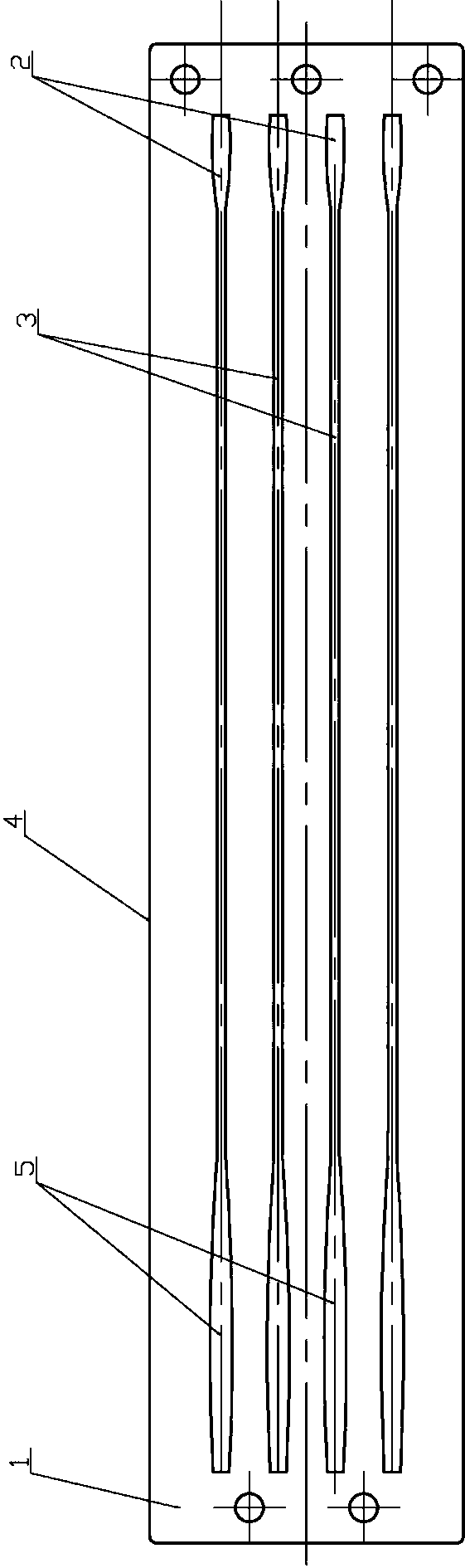

Temperature equalization plate and interlaced capillary structure and method for manufacturing the same

InactiveCN101354222AShort conveying distanceImprove delivery capacitySemiconductor/solid-state device detailsSolid-state devicesPorous layerEngineering

The invention relates to a temperature equalizing plate and a staggered capillary structure thereof and a manufacturing method of the capillary structure. The manufacturing method of the invention mainly includes that: a plurality of groups of grooves with the shape of curly brackets in pairs are cut on a metal plate and then arrayed on the plate in a staggered manner; semi-cylindrical plate bodies are stamped towards different sides on a plate surface space surrounded by each single-side groove of each group of grooves; a porous layer is arranged on the plate surface of the plate and a cylindrical porous body is respectively fixed in each semi-cylindrical plate body; two porous bodies and the semi-cylindrical plate bodies in each group of grooves are reversely and vertically rotated so as to be vertical to the metal plate; finally, the plate and the porous bodies are placed in a shell body together so that two end faces of the porous bodies and the plate body can be respectively contacted with the plate surface of the shell body, namely a temperature equalizing plate is formed.

Owner:贸晖科技股份有限公司

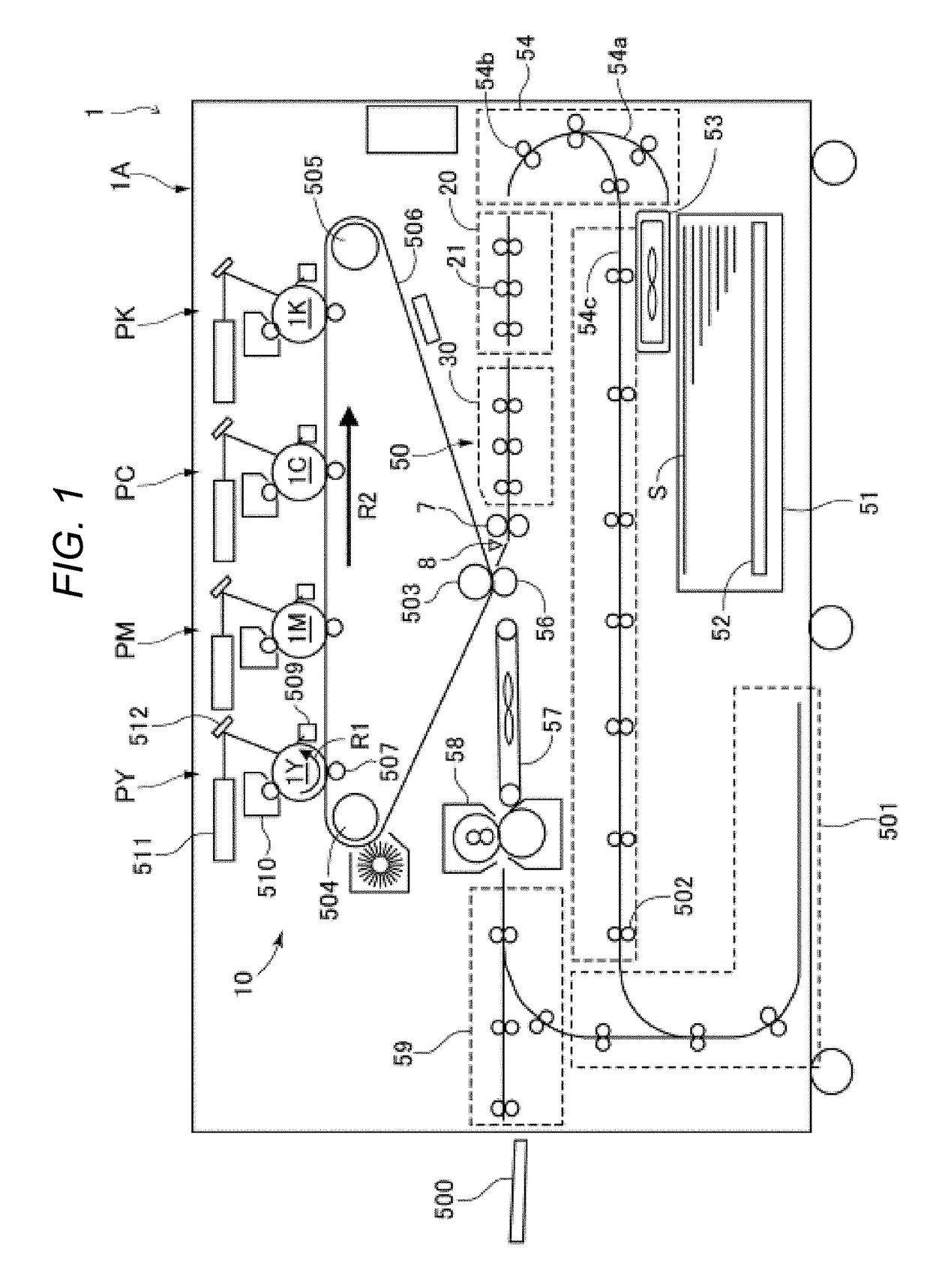

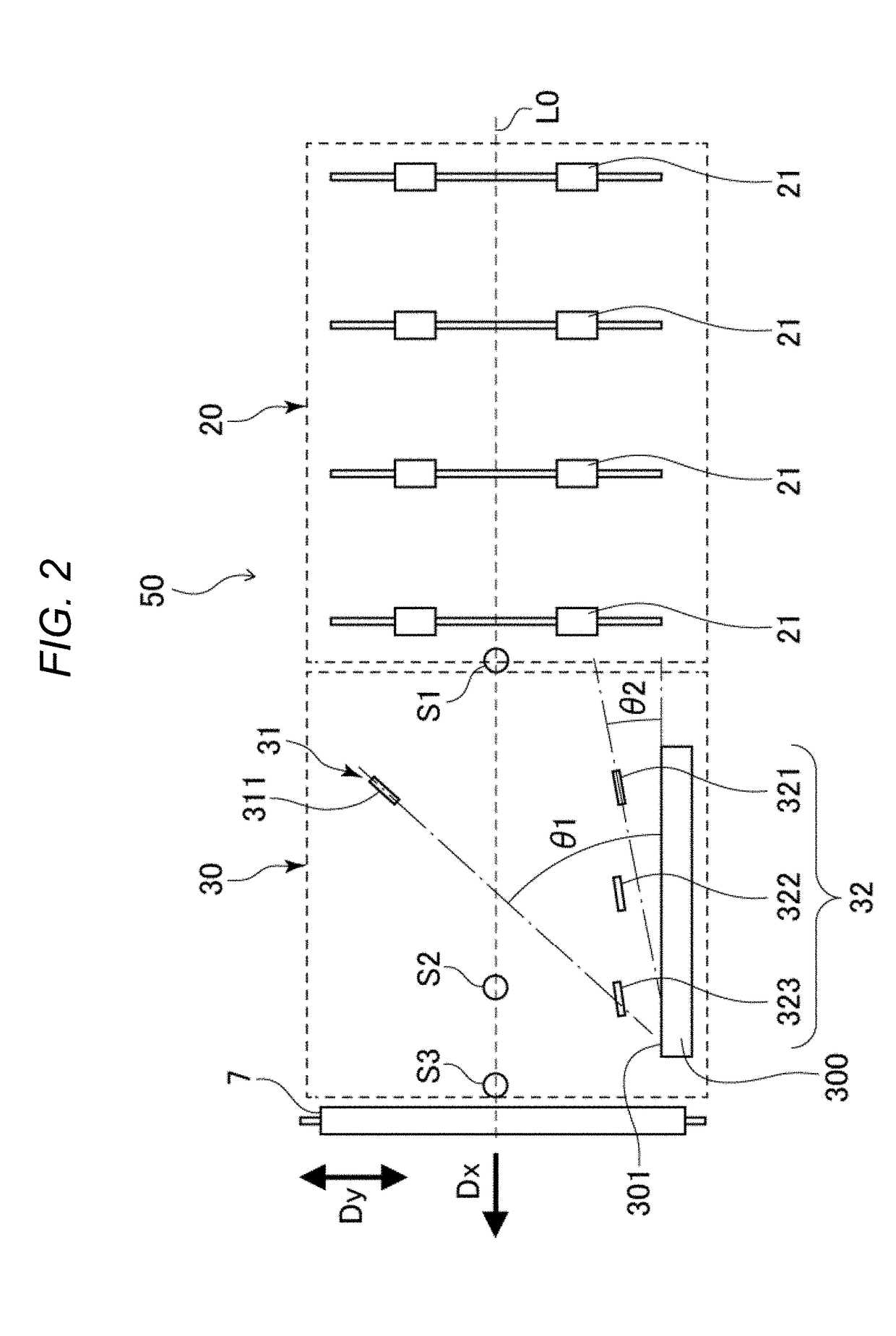

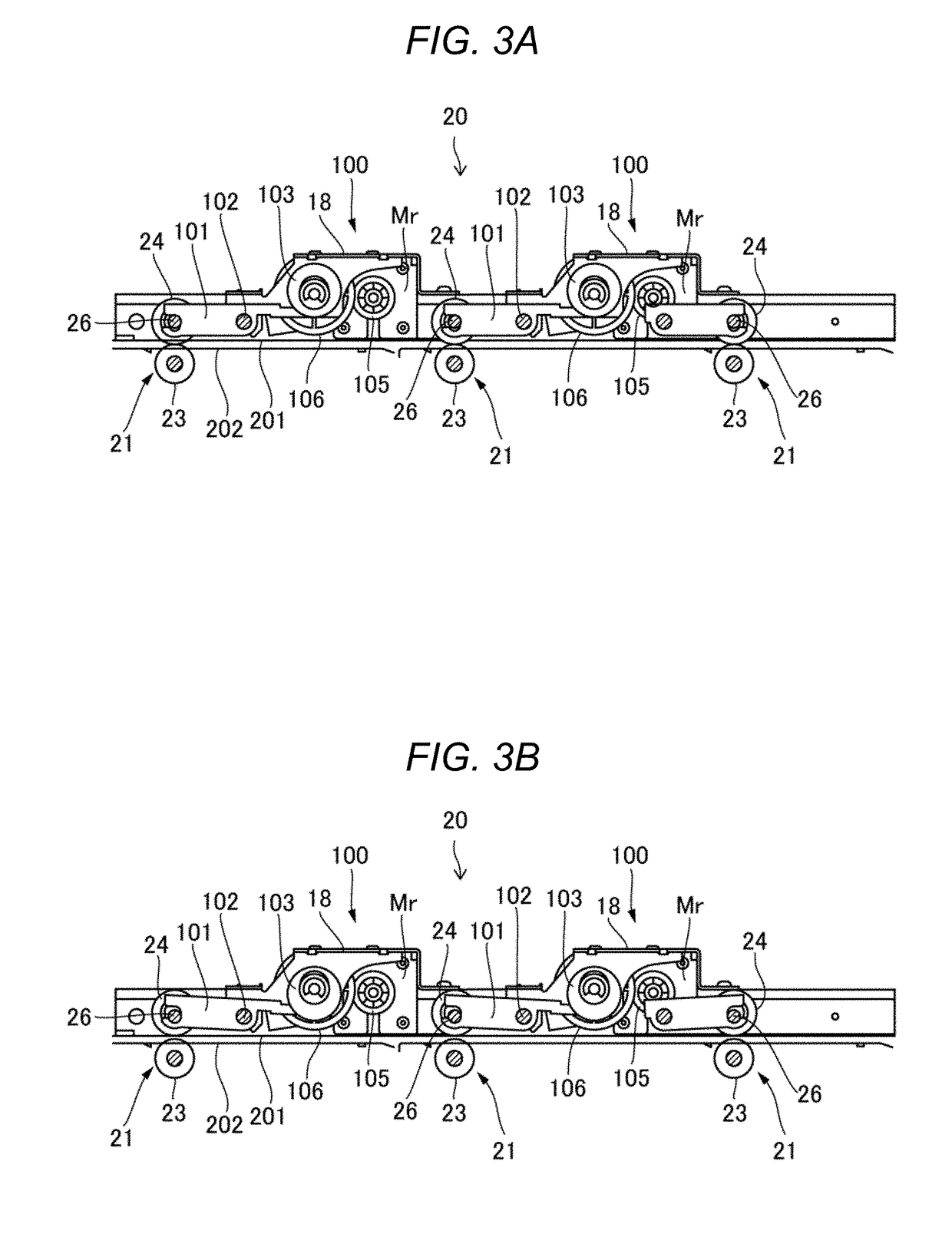

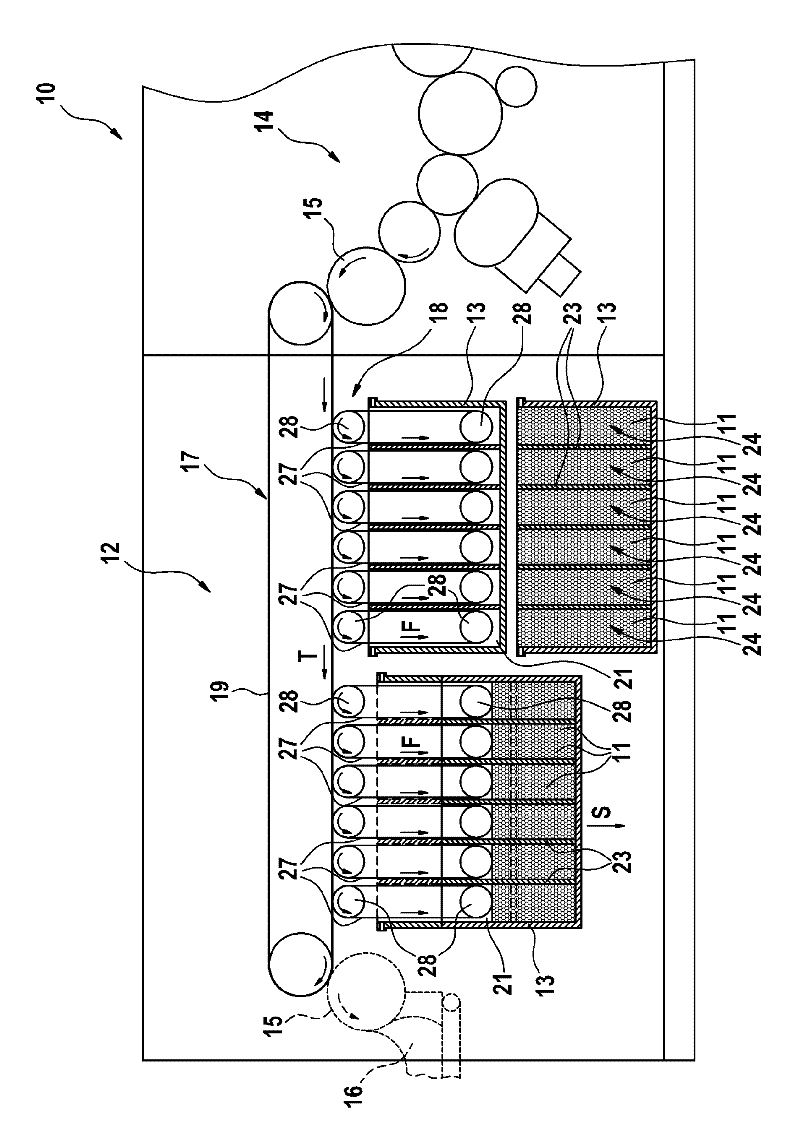

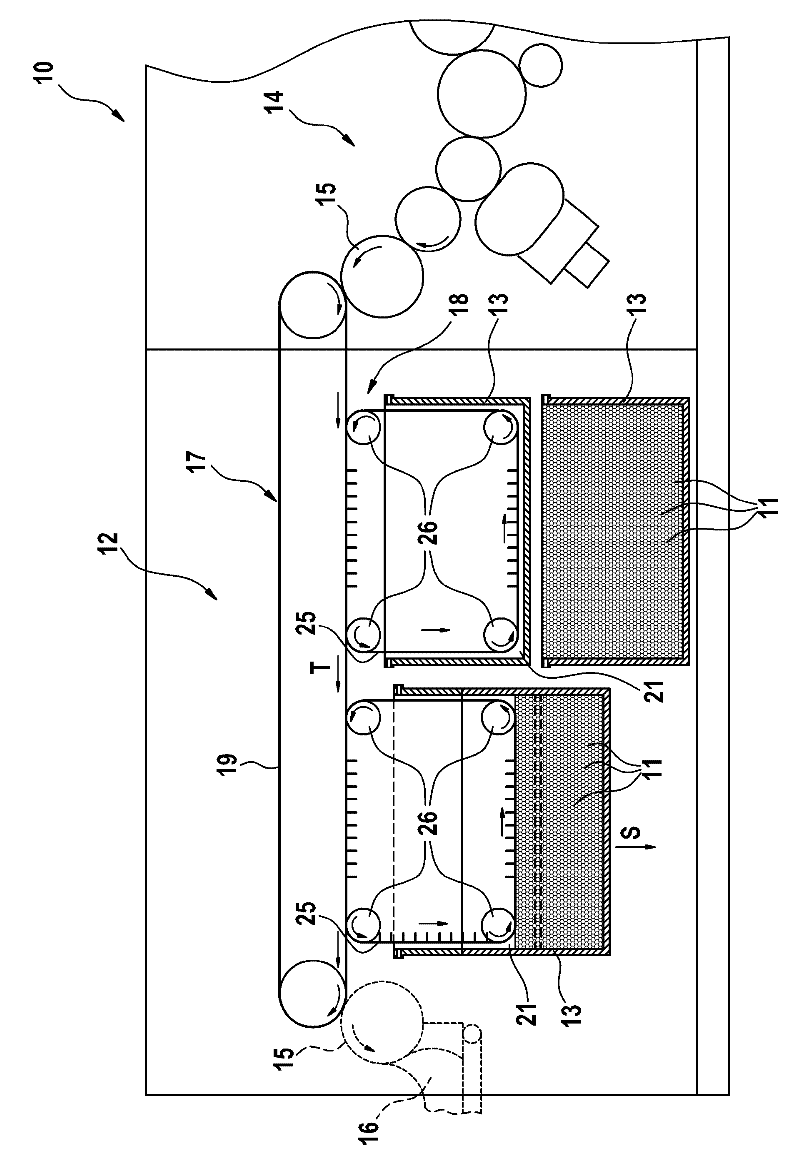

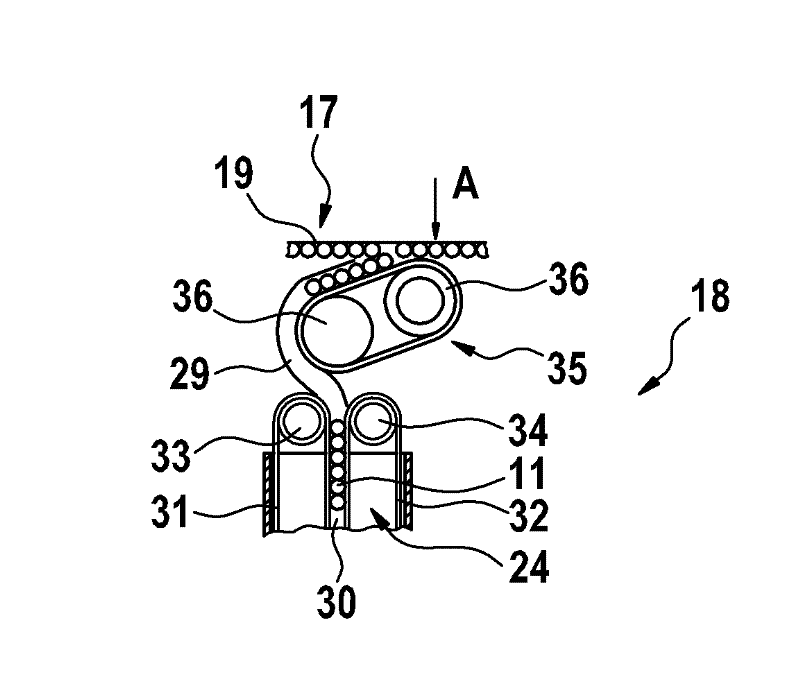

Sheet conveyance apparatus

ActiveUS20190025750A1Prevent bucklingShort conveying distanceElectrographic process apparatusMechanical engineeringEngineering

A sheet conveyance apparatus including: a first oblique-feed unit configured to convey the sheet by imparting to the sheet a force in a first direction inclined relative to the sheet conveyance direction so that the sheet approaches an abutment surface in the width direction as the sheet proceeds downstream in the sheet conveyance direction; and a second oblique-feed unit configured to convey the sheet by imparting to the sheet a force in a second direction inclined relative to the sheet conveyance direction so that the sheet approaches the abutment surface as the sheet proceeds downstream, wherein an angle of the first direction with respect to the sheet conveyance direction is larger than an angle of the second direction with respect to the sheet conveyance direction, and the second oblique-feed unit is disposed at a position closer to the abutment surface than the first oblique-feed unit in the width direction.

Owner:CANON KK

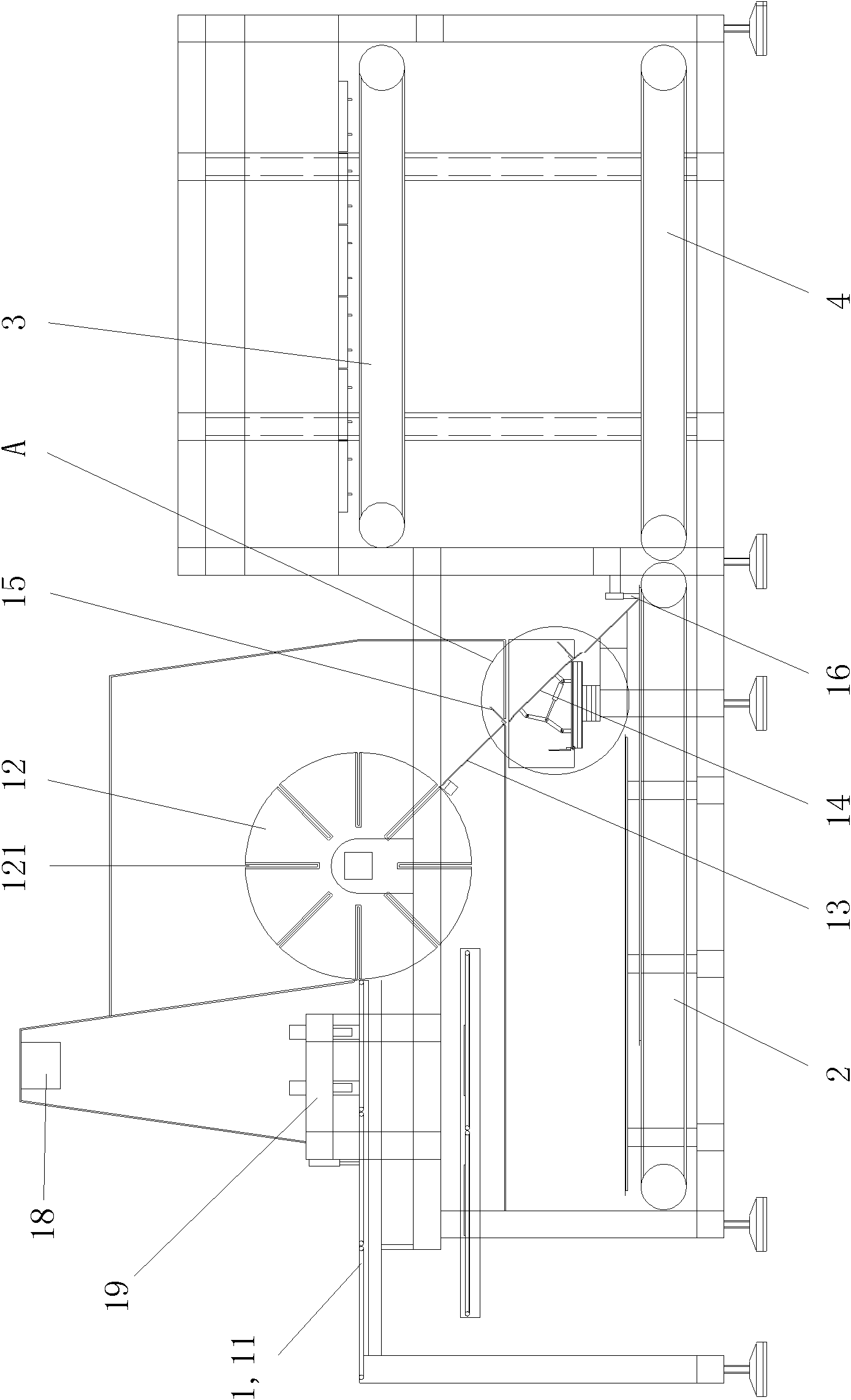

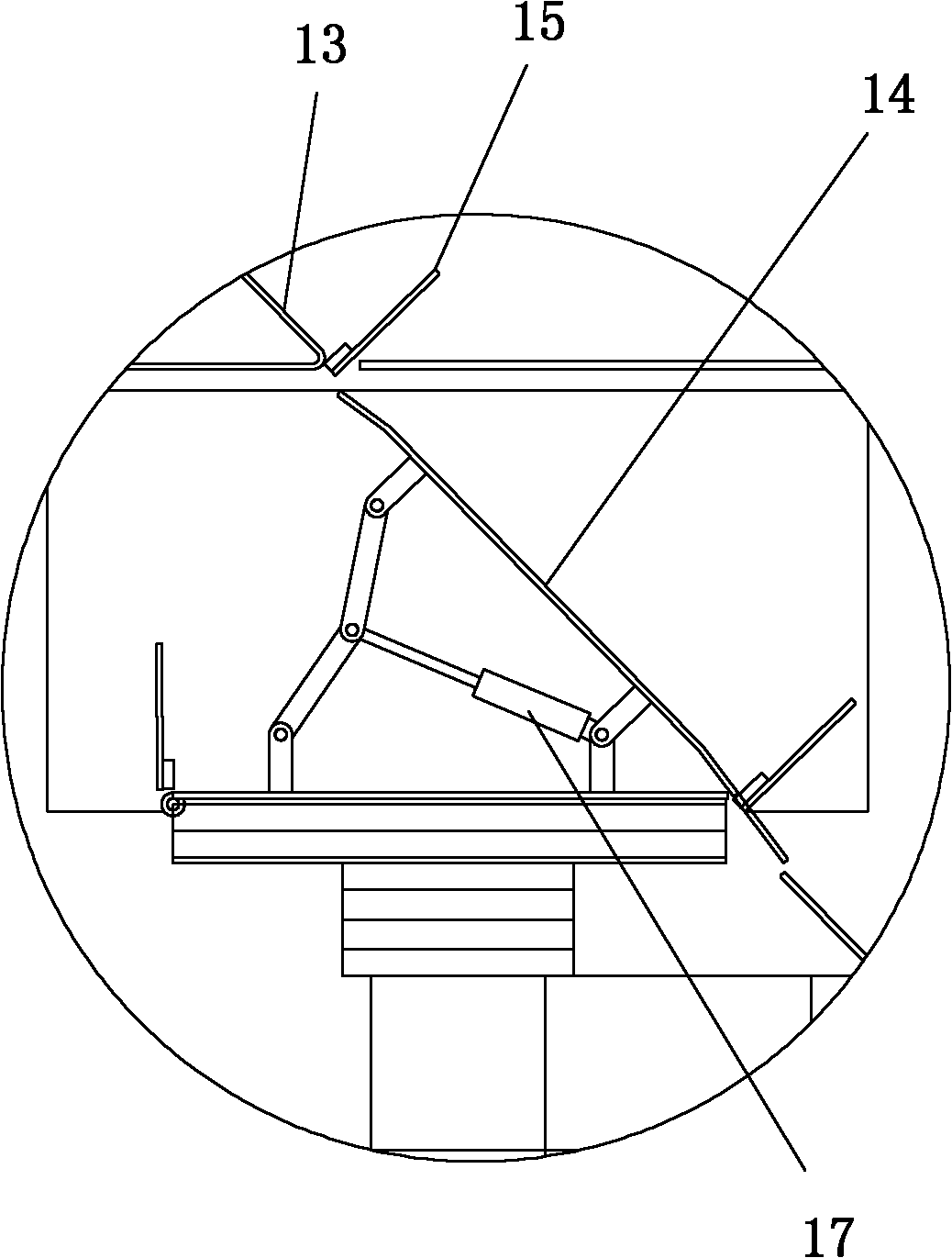

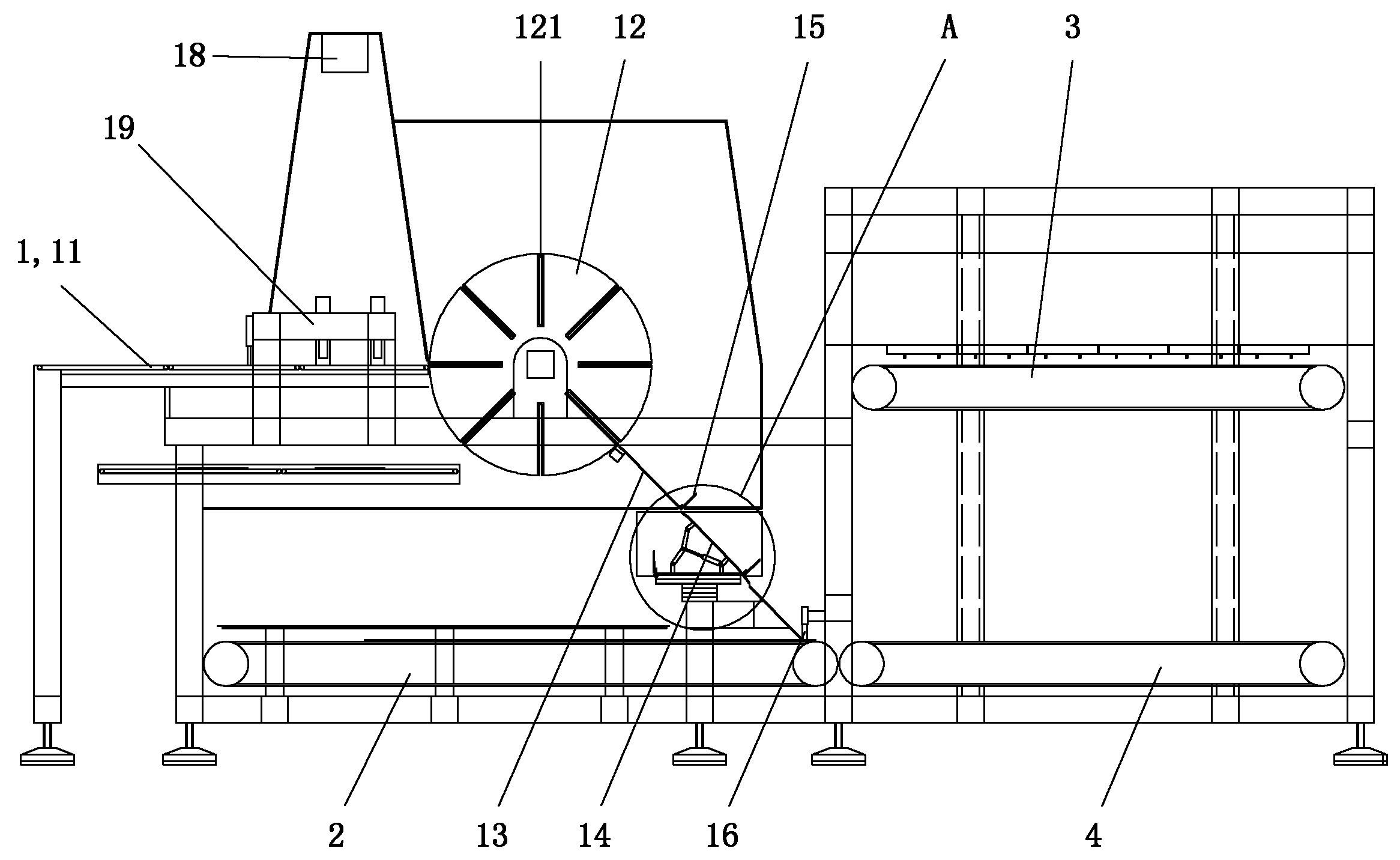

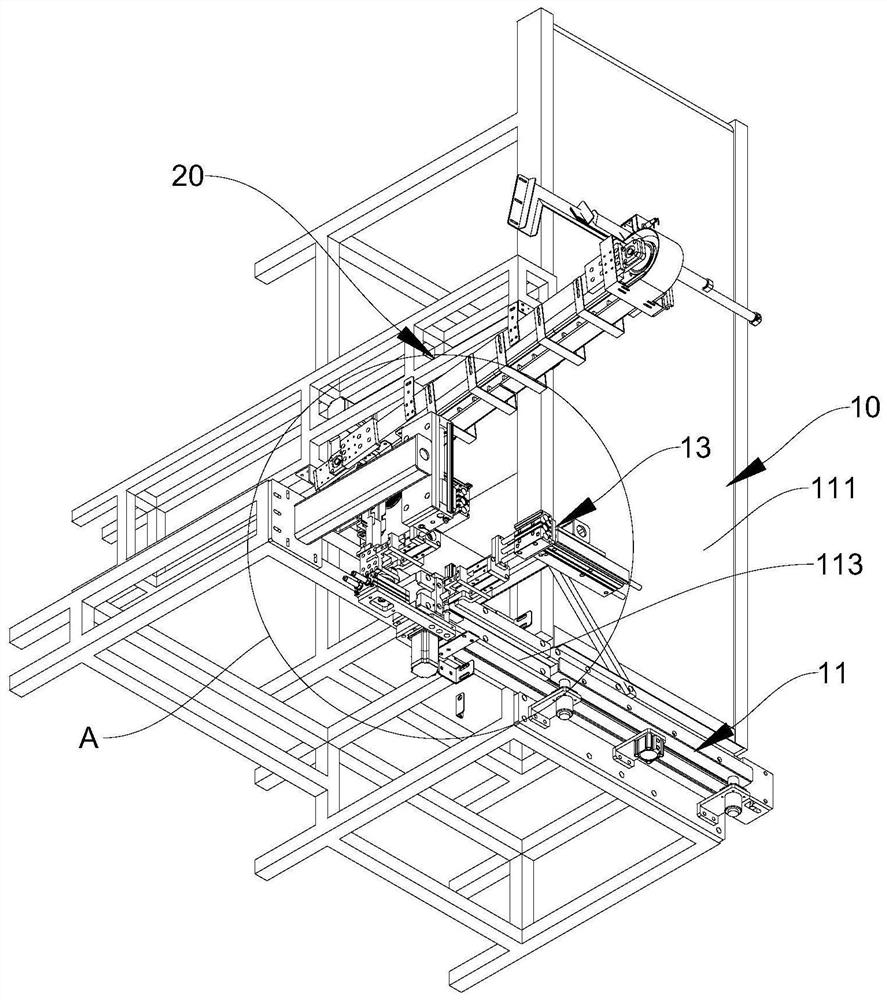

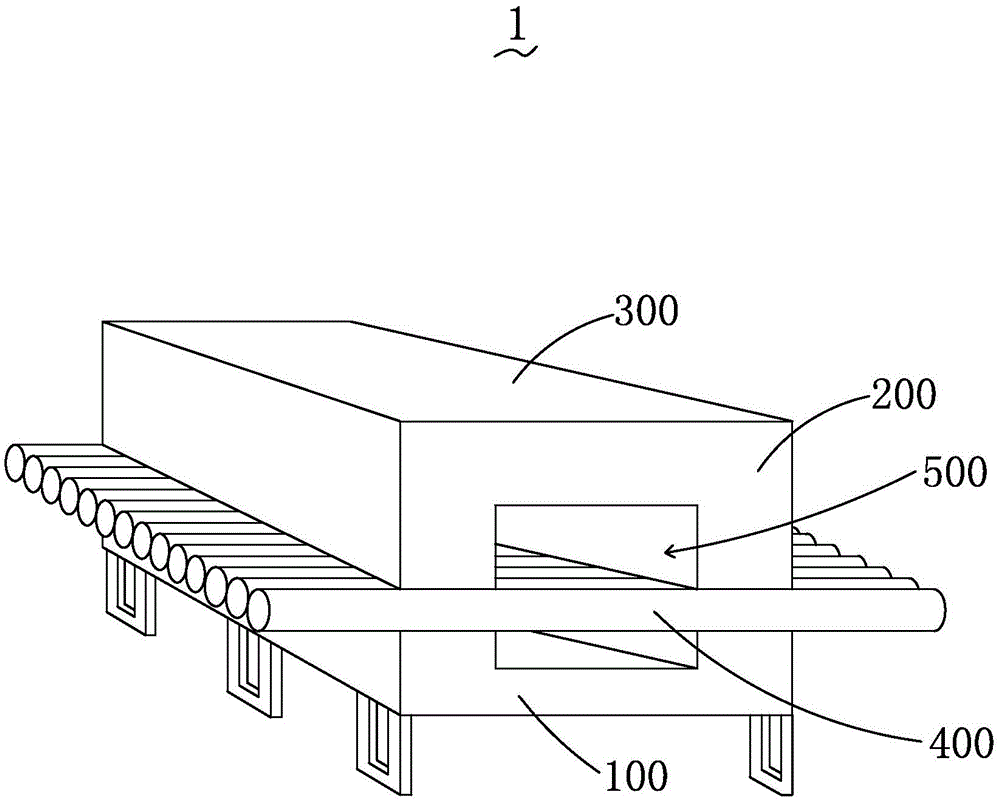

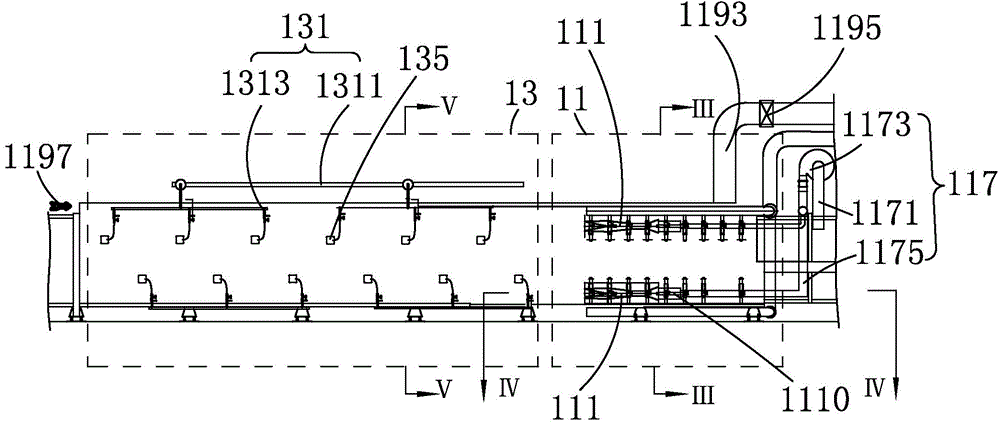

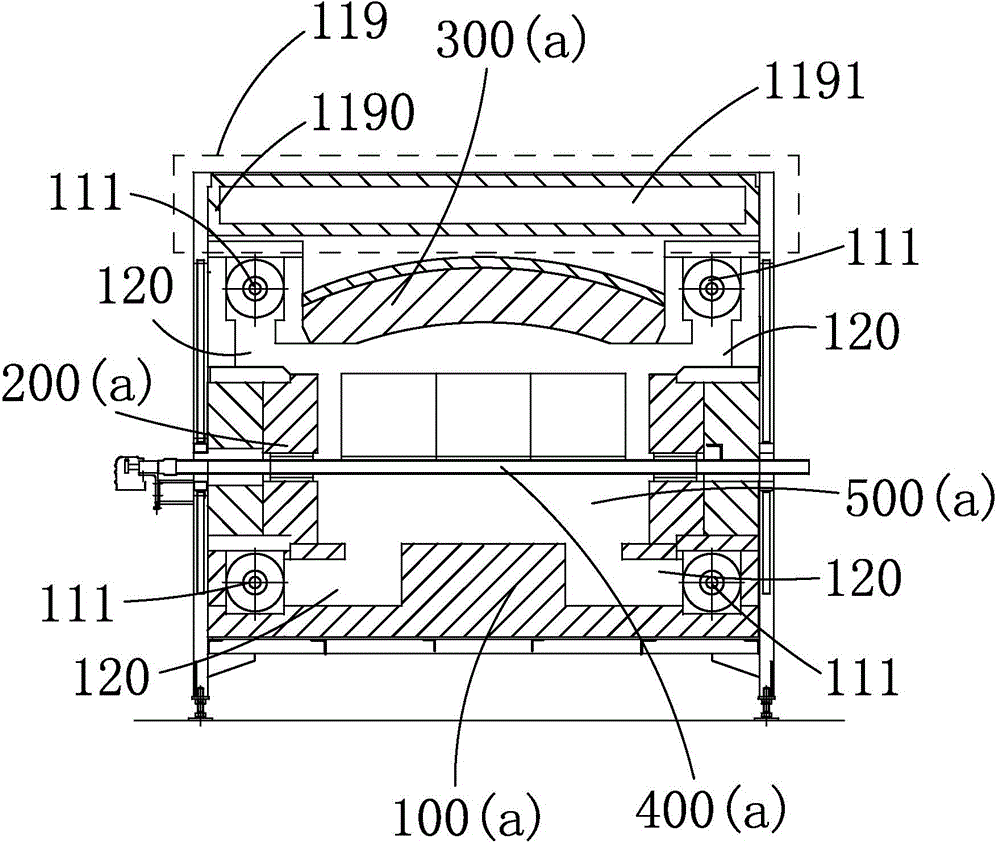

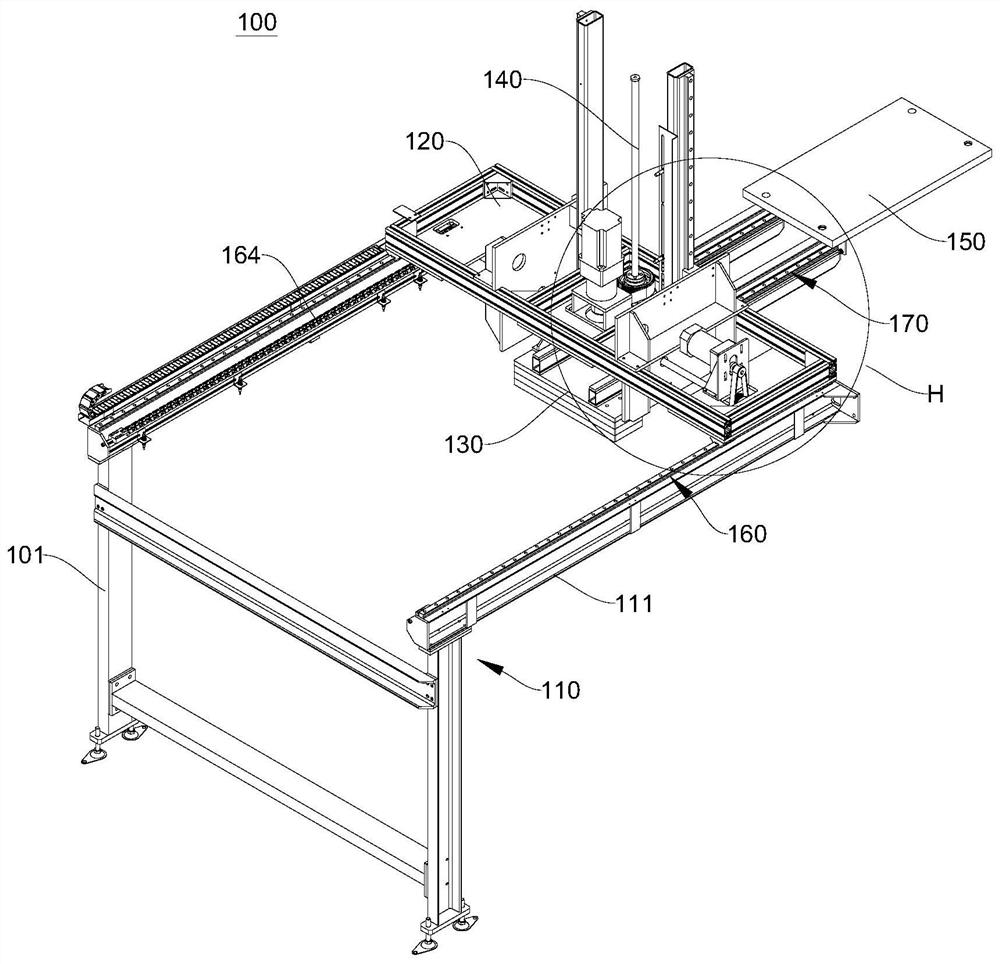

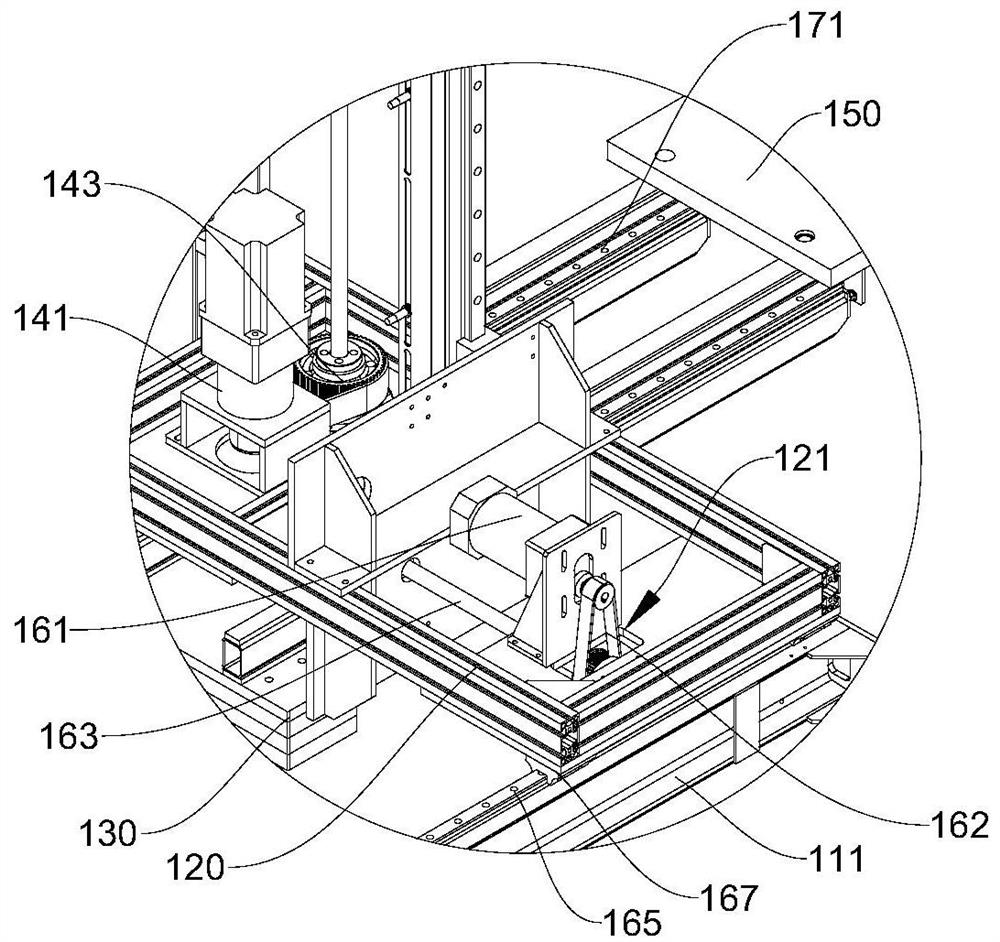

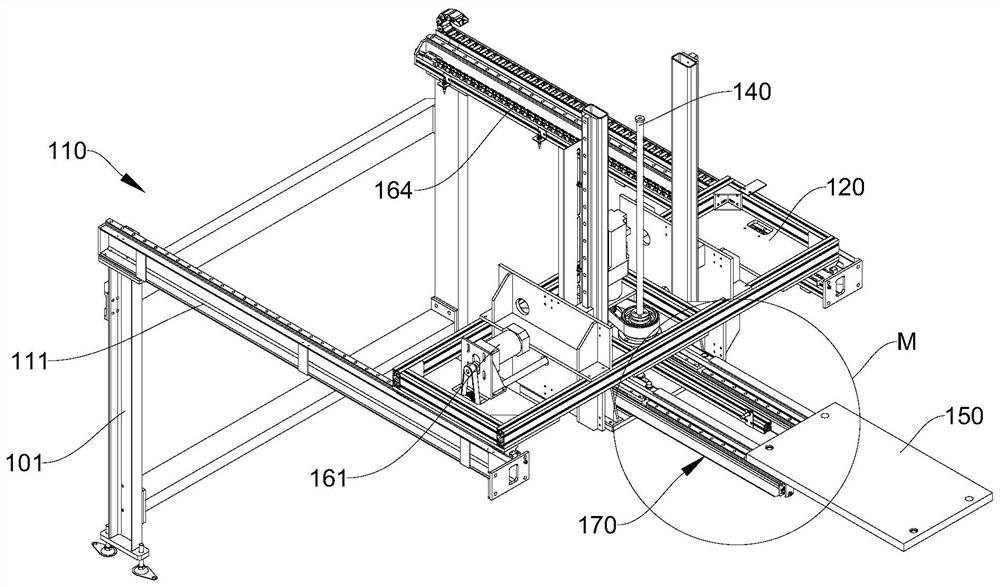

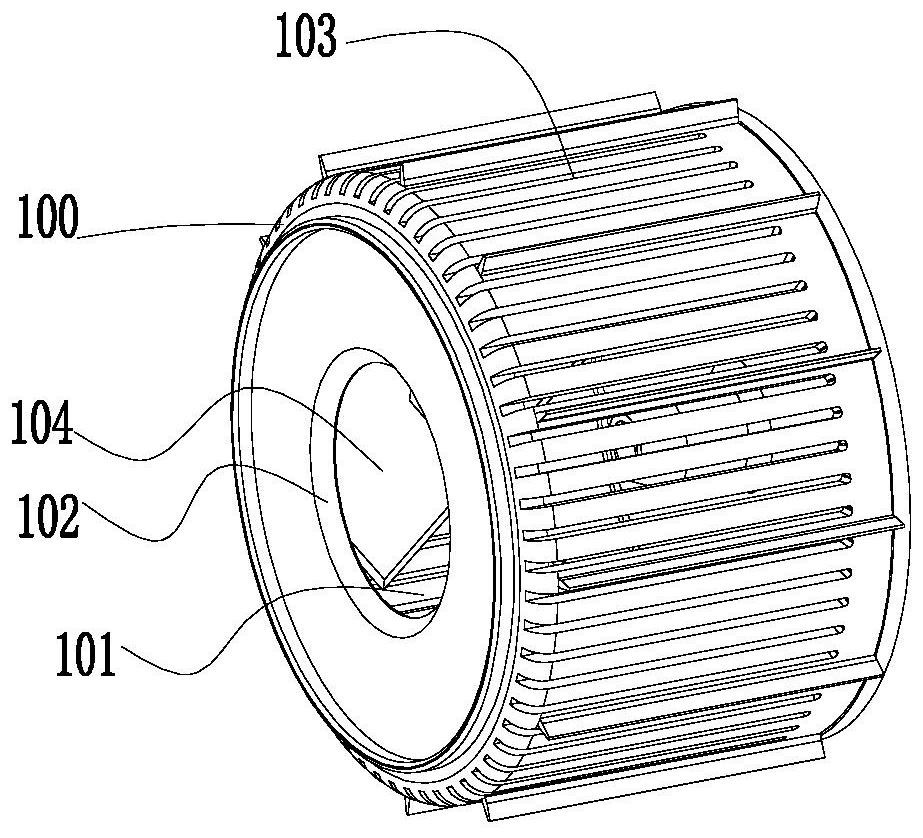

Rotation cage type automatic laying machine of solar cell serial slices

InactiveCN102468368AShort conveying distanceImprove efficiencyFinal product manufactureSemiconductor devicesEngineeringWorkstation

The invention relates to a rotation cage type automatic laying machine of solar cell serial slices, which comprises a cell serial slice conveying system, a ethylene-vinyl acetate (EVA) glass substrate laying and conveying system and a converge welding and conveying system, wherein the cell serial slice conveying system comprises a cell serial slice conveying belt, a cell serial slice overturning and temporarily-storing rotation cage, an inclined sliding frame and a steering bracket, the cell serial slice overturning and temporarily-storing rotation cage is rotatably arranged and is provided with cell serial slice temporarily-storing grooves, and during rotation of the cell serial slice overturning and temporarily-storing rotation cage, the cell serial slice temporarily-storing grooves can circularly rotate to reach a first workstation butted with cell serial slice conveying belt and rotate to reach a second workstation butted with the inclined sliding frame. With the matching of the rotation cage, the sliding frame and the steering bracket, the rotation cage type automatic laying machine is short in conveying distance and high in efficiency, no external force is applied to the cell serial slices during laying, the process is stable and safe, the arrangement is accurate, and the whole equipment relatively occupies small space and is reasonable in design.

Owner:CHANGZHOU SKY SOLAR NEW ENERGY INST

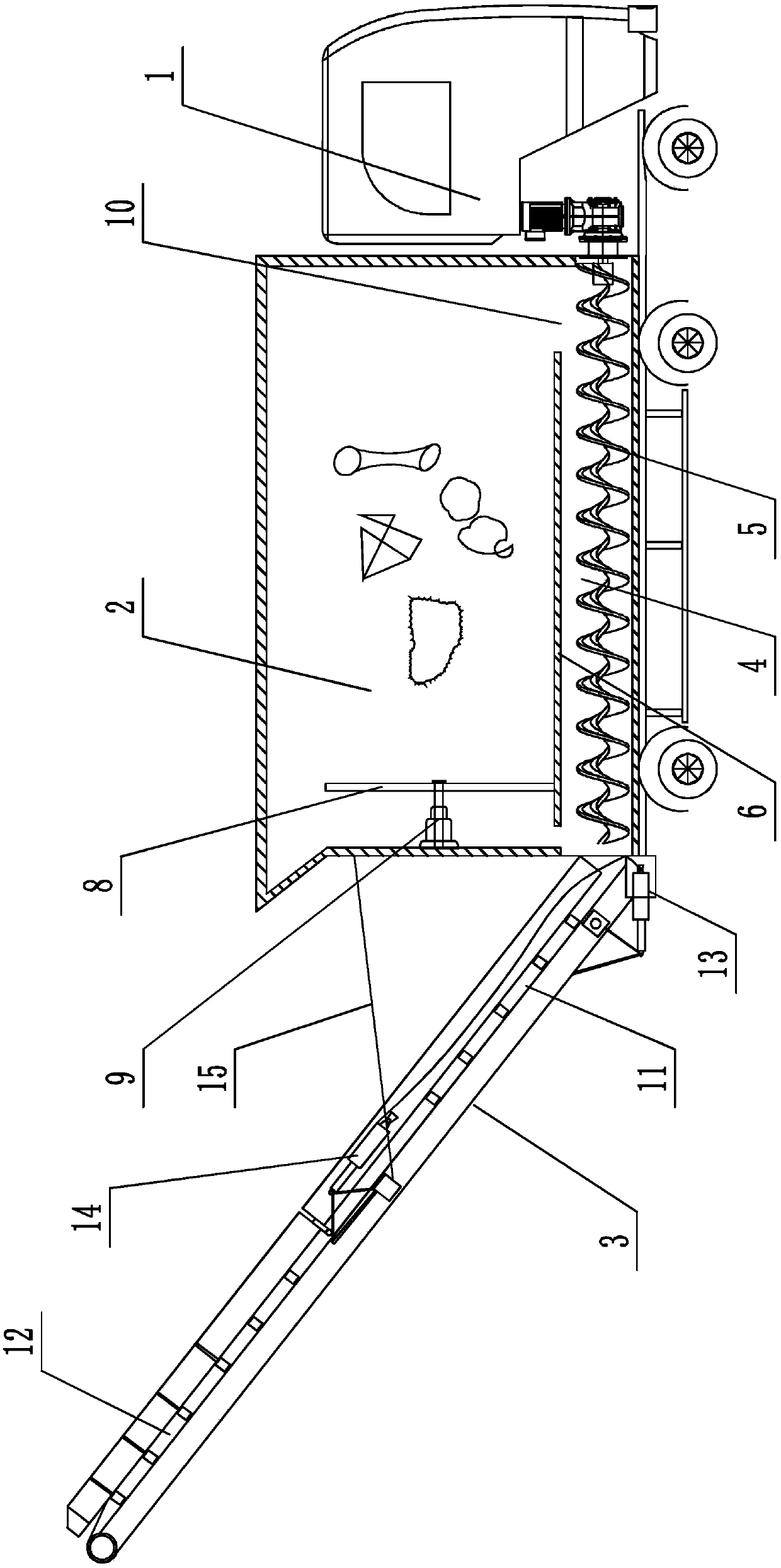

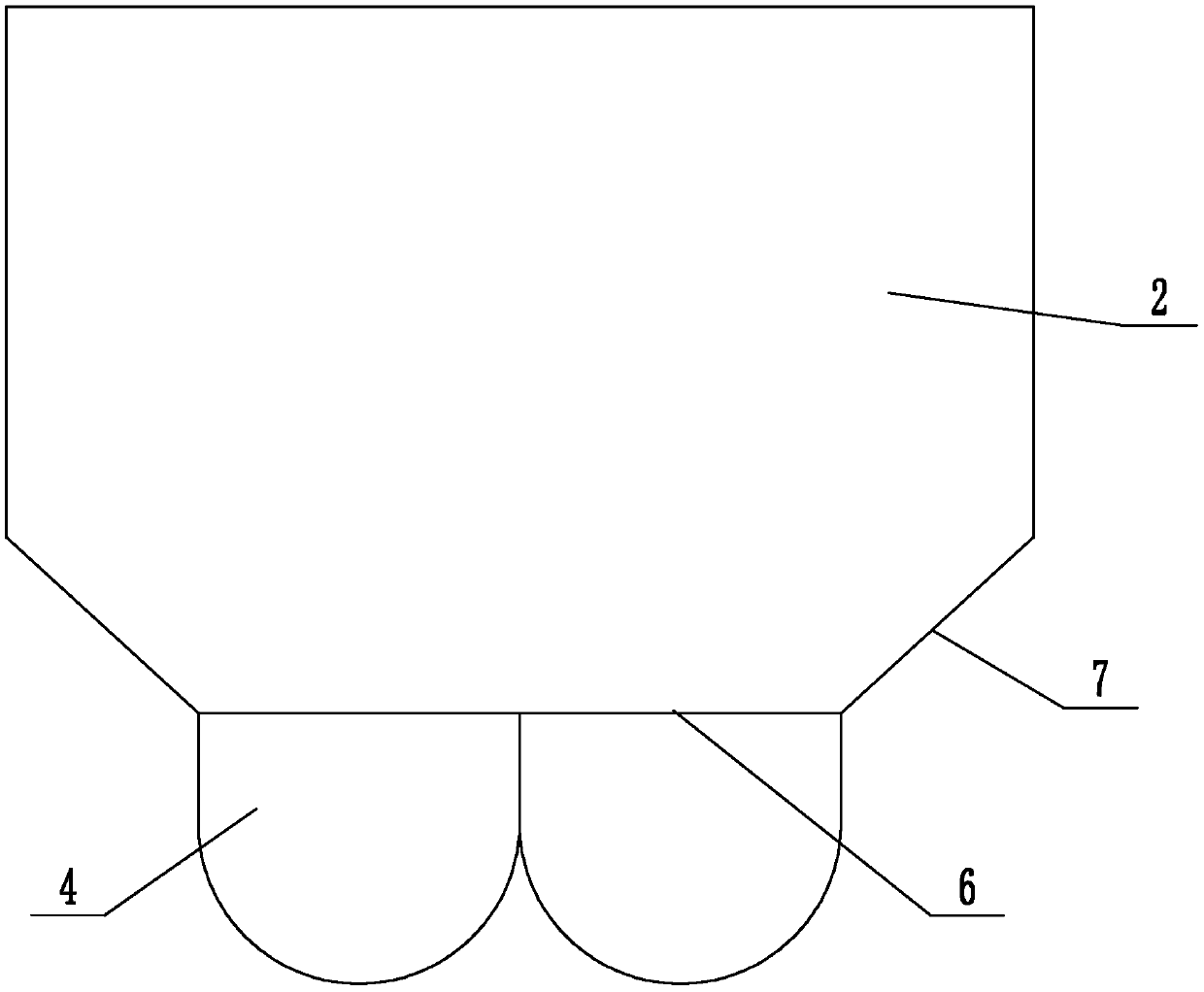

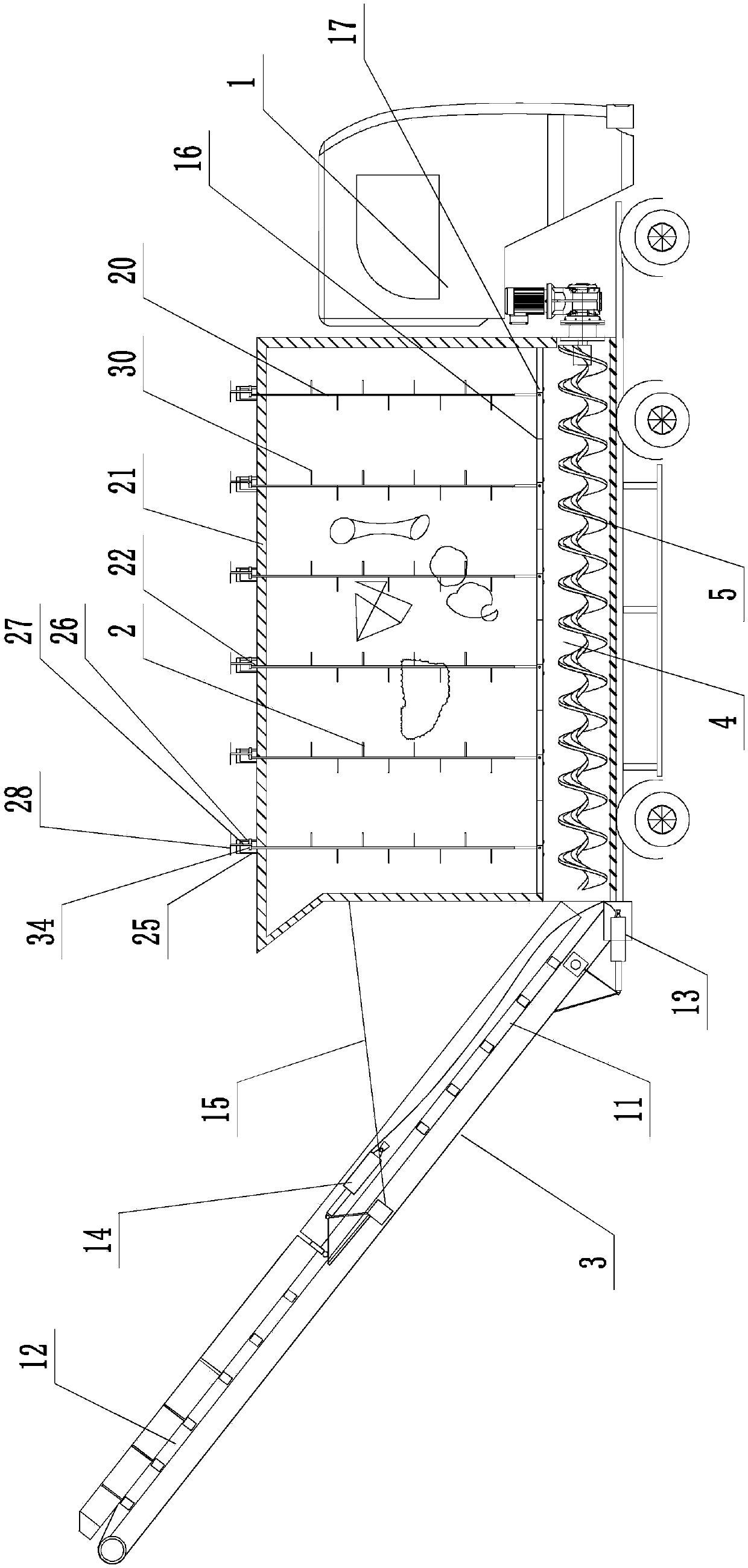

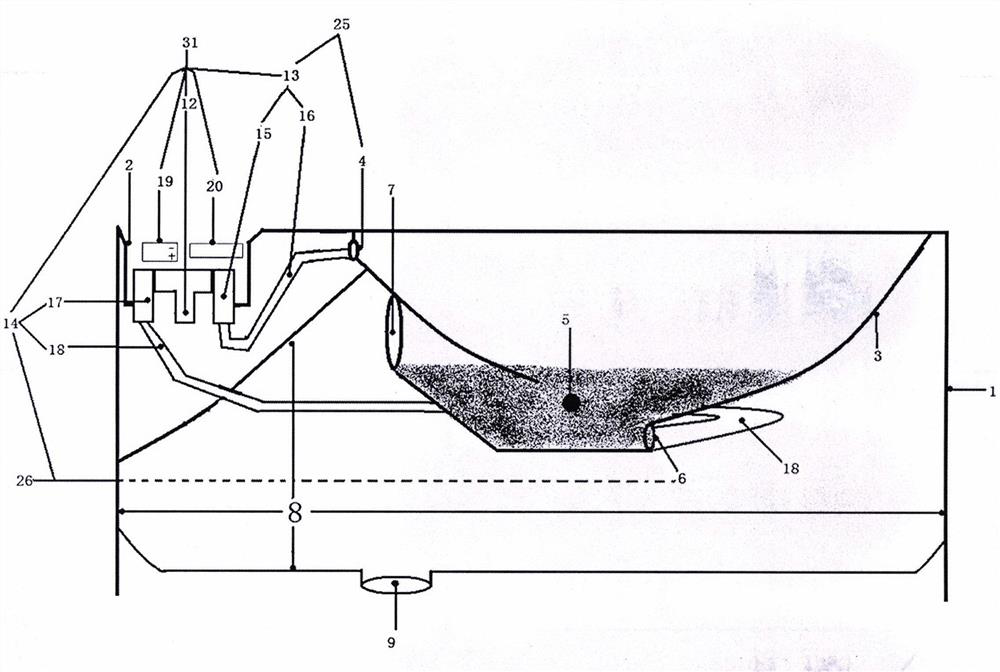

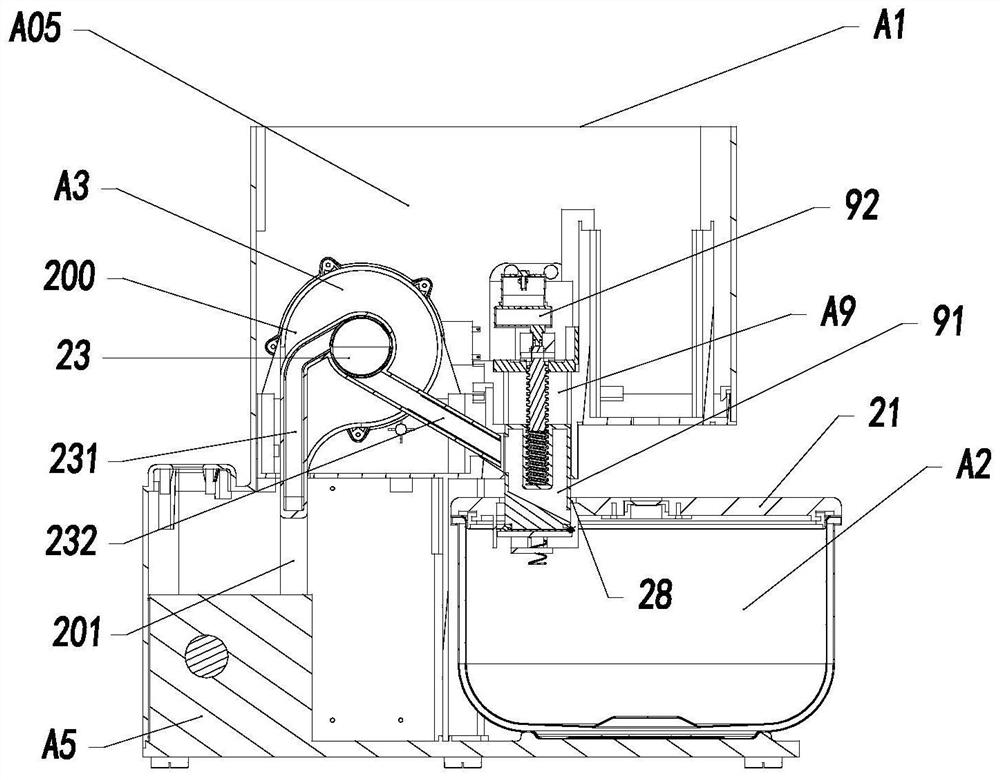

Efficient garbage truck for garbage desiccation and garbage unloading method

ActiveCN109533738ARealize import and exportReduce delivery and transit timeRefuse vehiclesMode of transportLitter

The invention discloses an efficient garbage truck for garbage desiccation and a garbage unloading method and aims to overcome the defects that a combined transportation manner of a travelling crane and a belt conveyor is adopted when garbage is transported during the desiccation process, so that the structure is complicated, the operating cost is high, the occupied area is large and garbage transportation is inconvenient. The efficient garbage truck comprises a vehicle body, wherein a carriage is arranged on the vehicle body; a material conveyer belt with an adjustable dip angle is mounted atthe rear end of the vehicle body; a plurality of feeding channels are arranged at the interior bottom of the carriage; conveying screw rods are mounted in the feeding channels; and the rear end of each of the feeding channels is corresponding to the front end of the material conveyer belt. The efficient garbage truck can feed and discharge garbage during the garbage desiccation process, is uniform in discharging, simple in structure and low in operating cost, avoids the combined transportation manner of the travelling crane and the belt conveyor, reduces the occupied area, shortens the garbage transporting time and lowers the equipment invested cost and the garbage desiccation operating treatment cost.

Owner:杭州科晟能源技术有限公司

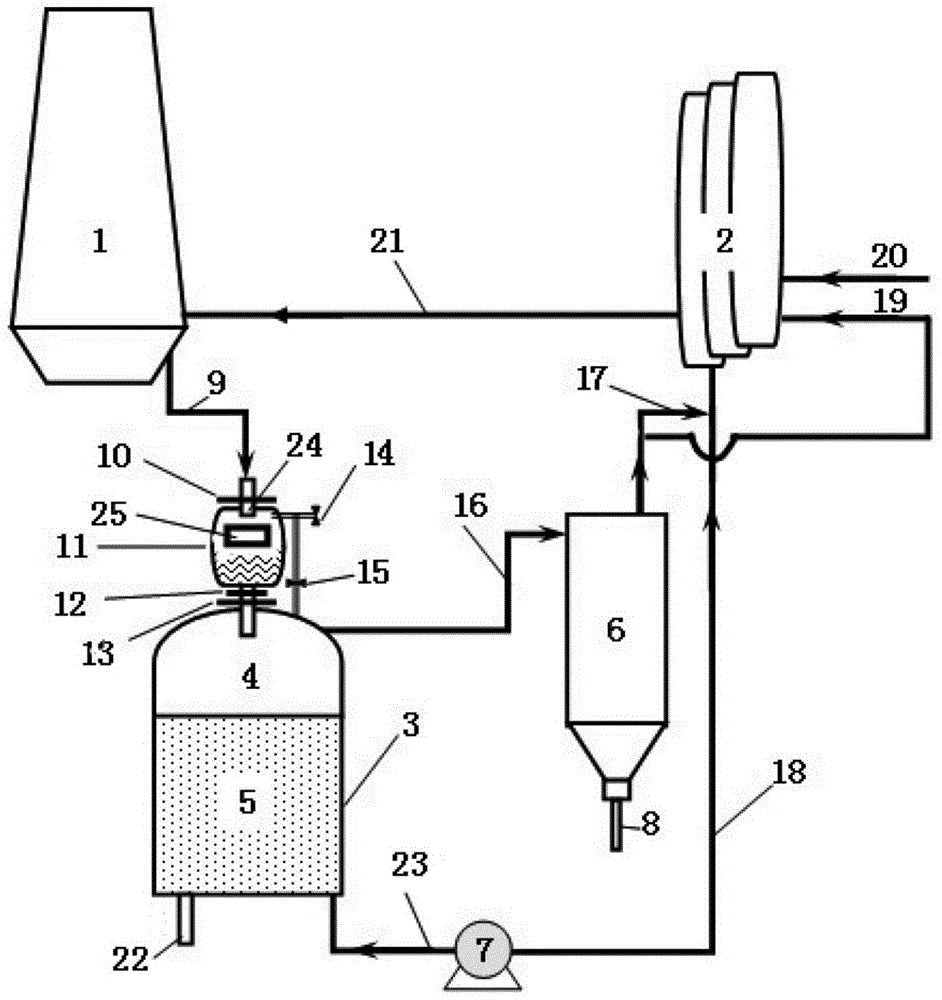

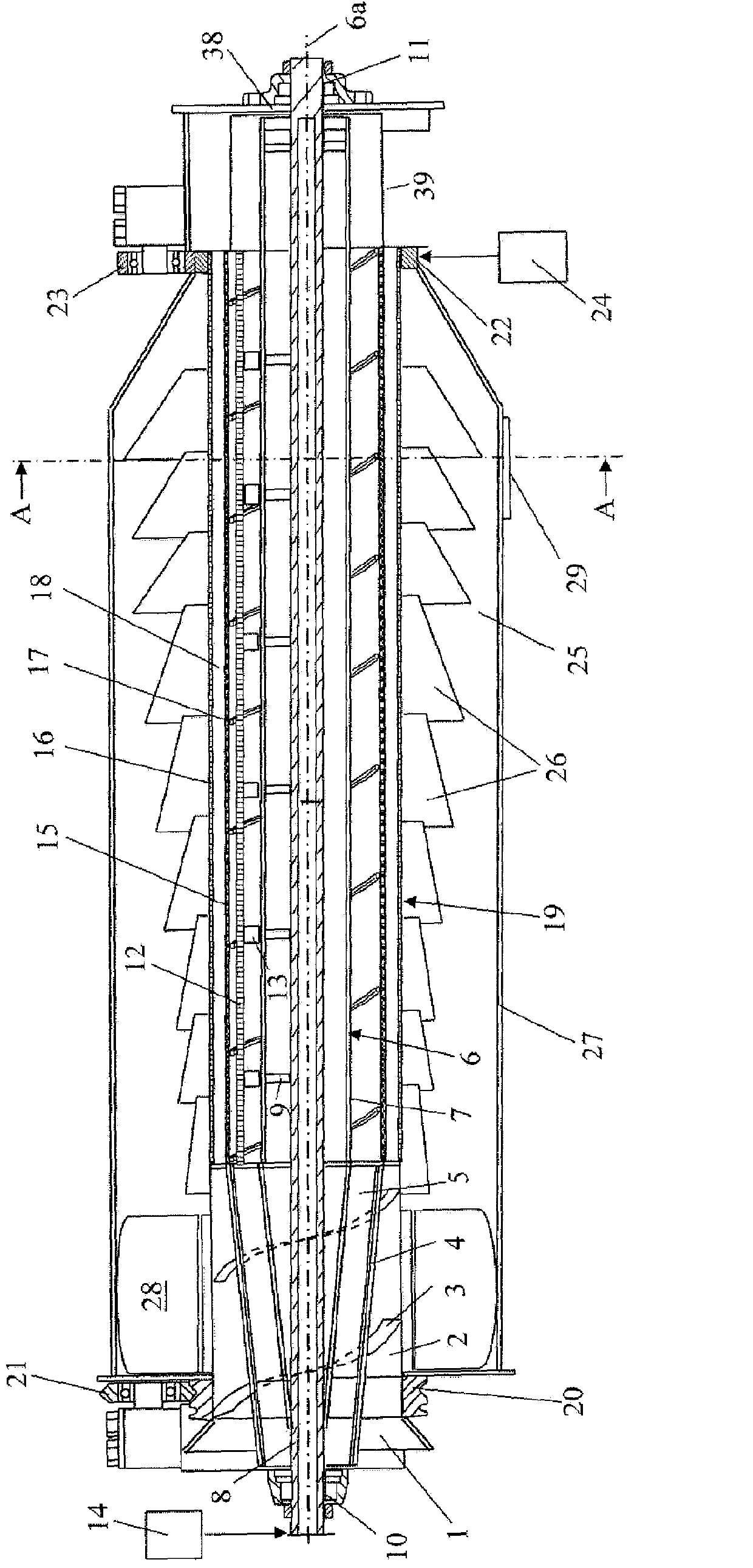

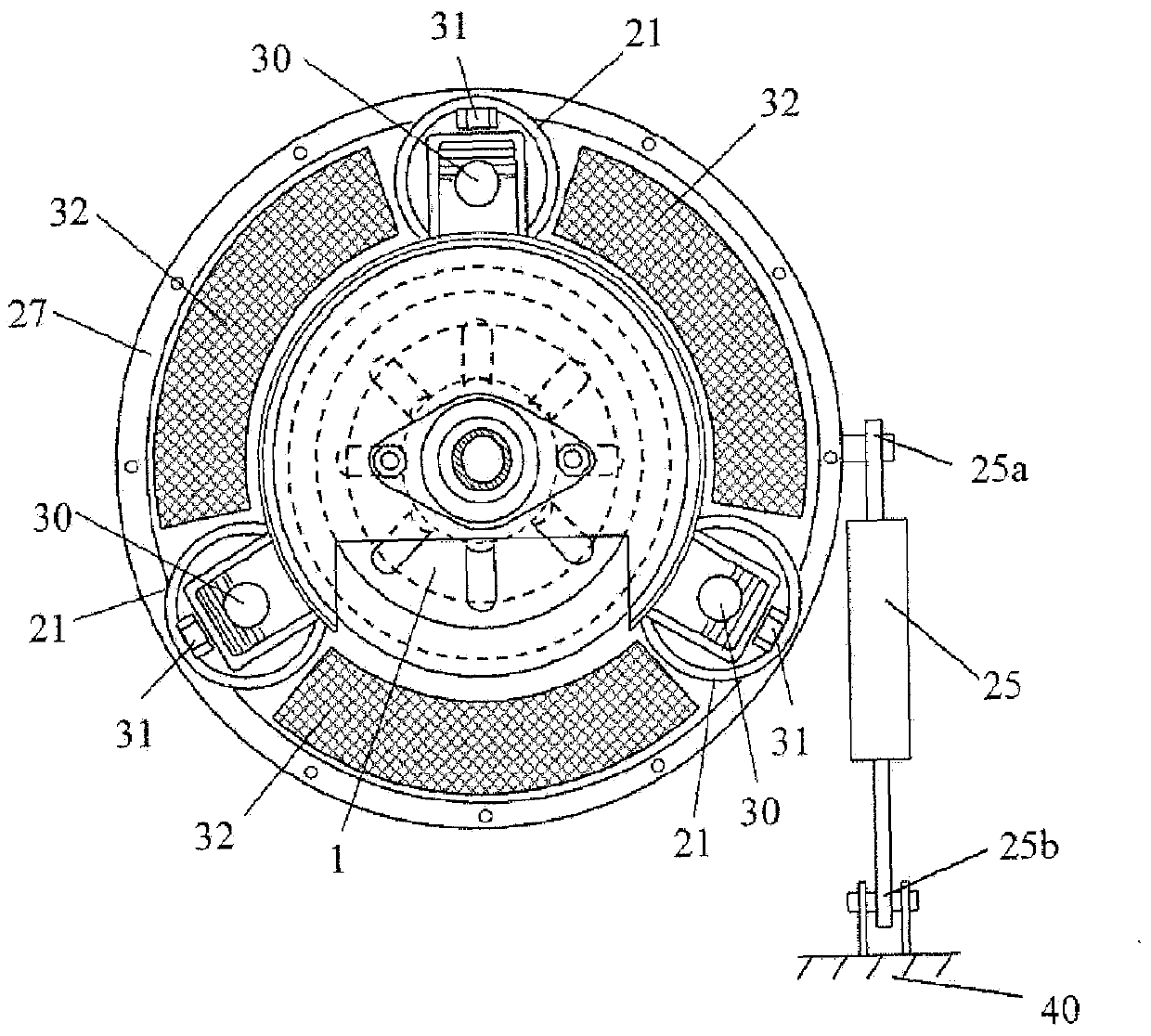

Device for recovering waste heat of blast furnace slag by dry granulation and method for recovering waste heat of blast furnace slag

ActiveCN105112577BImprove heat recoveryHigh heat recovery in the blast furnace processIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodHeat losses

Provided is a device and method for dry granulation recovery of blast furnace slag waste heat, which belongs to the technical field of metallurgical slag heat energy recovery. The device is installed between the blast furnace and the hot blast furnace and consists of a granulating kiln used for dry granulation of blast furnace slag and its accessory piping devices as well as a matching dust collector. Among them, the granulating kiln and its ancillary pipeline devices include: blower, slag introduction tank, upper sealing valve, slag storage tank, sliding water port, lower sealing valve, relief valve, pressure equalizing valve, granulating kiln gas output pipeline, low-temperature granulation Slag discharge pipe, granulating kiln cold air pipe, slag nozzle pipe and granulator. The granulating kiln body is equipped with a granulating area and a heat exchange area. This device can fully recover the latent heat of solidification of molten slag and the sensible heat of high-temperature slag particles. In addition, the hot air generated by waste heat recovery is directly supplied to the blast furnace hot blast stove, which has the advantages of short material transportation distance, low process heat loss, high heat recovery rate, basically no secondary power consumption, and low additional investment.

Owner:NORTHEASTERN UNIV LIAONING

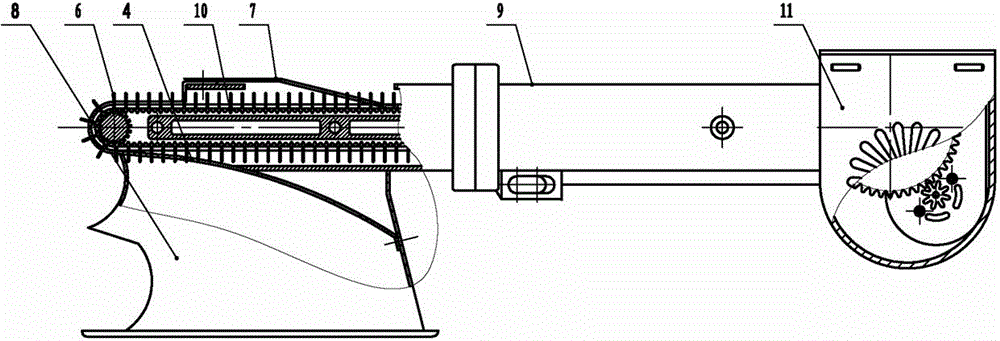

Cotton separation device of cotton picking machine

The invention discloses a cotton separation device of a cotton picking machine, which separates cotton while picking and realizes a good separation effect. Particularly, when collecting the cotton with dew, a shell and a cotton conveying pipe are not blocked easily. The device comprises a shell (9), wherein a belt (10) driven by power is mounted in the shell (9); a picking needle (6) is mounted on the belt (10); and one end of the shell (9) is a picking port. The device is characterized in that a cotton conveying pipe (8) is mounted at the picking port; a cotton separation plate is mounted in the cotton conveying pipe (8) and separates the cotton picked by the picking needle (6) from the picking needle (6); and meanwhile, according to the moving direction of the picking needle (6), the shell (9) is also provided with an auxiliary cotton separation plate behind the cotton separation plate. The device disclosed by the invention has a simple structure; the design of the whole machine is reasonable, and the device is convenient to use; the separation effect of the picking needle and the cotton is good; the cotton conveying distance is short; and particularly, when picking the cotton with dew, the separation effect is good, the shell and the cotton conveying pipe are not easily blocked, the working efficiency is greatly improved, and the device has better practicability.

Owner:YIYANG FUJIA TECH CO LTD +1

Device and method for conveying concrete on water surface of wide river

InactiveCN105064215AShort conveying distanceSpeed up the construction progressBridge erection/assemblyBuilding material handlingSteel tubeBuoyancy

The invention discloses a device and method for conveying concrete on the water surface of a wide river. The device comprises a concrete conveying platform, which is formed by arranging a plurality of cylindrical buoyancy cans with same shapes and sizes in parallel in sequence, wherein the concrete conveying platform comprises a plurality of platform units; each platform unit comprises a buoyancy bracket; each buoyancy bracket comprises a cuboid-shaped bracket frame, which is formed by welding four vertical beams, four cross beams on the top surface and four cross beams on the bottom surface; a cylindrical buoyancy can is arranged in each bracket frame; the four cross beams on the top surface of each buoyancy bracket form a platform working surface; the four vertical beams of each buoyancy bracket extend upwards to form a side beam of the platform working surface; the different platform conveying units are end to end to form the concrete conveying platform; and concrete conveying steel pipes are arranged on the platform working surfaces. According to the device and method for conveying the concrete on the water surface of the wide river, disclosed by the invention, as the concrete is conveyed by means of the water surface of the wide river, the concrete conveying safety is guaranteed, the construction progress is accelerated, the construction quality is improved and the construction cost is reduced.

Owner:CHINA 19TH METALLURGICAL CORP

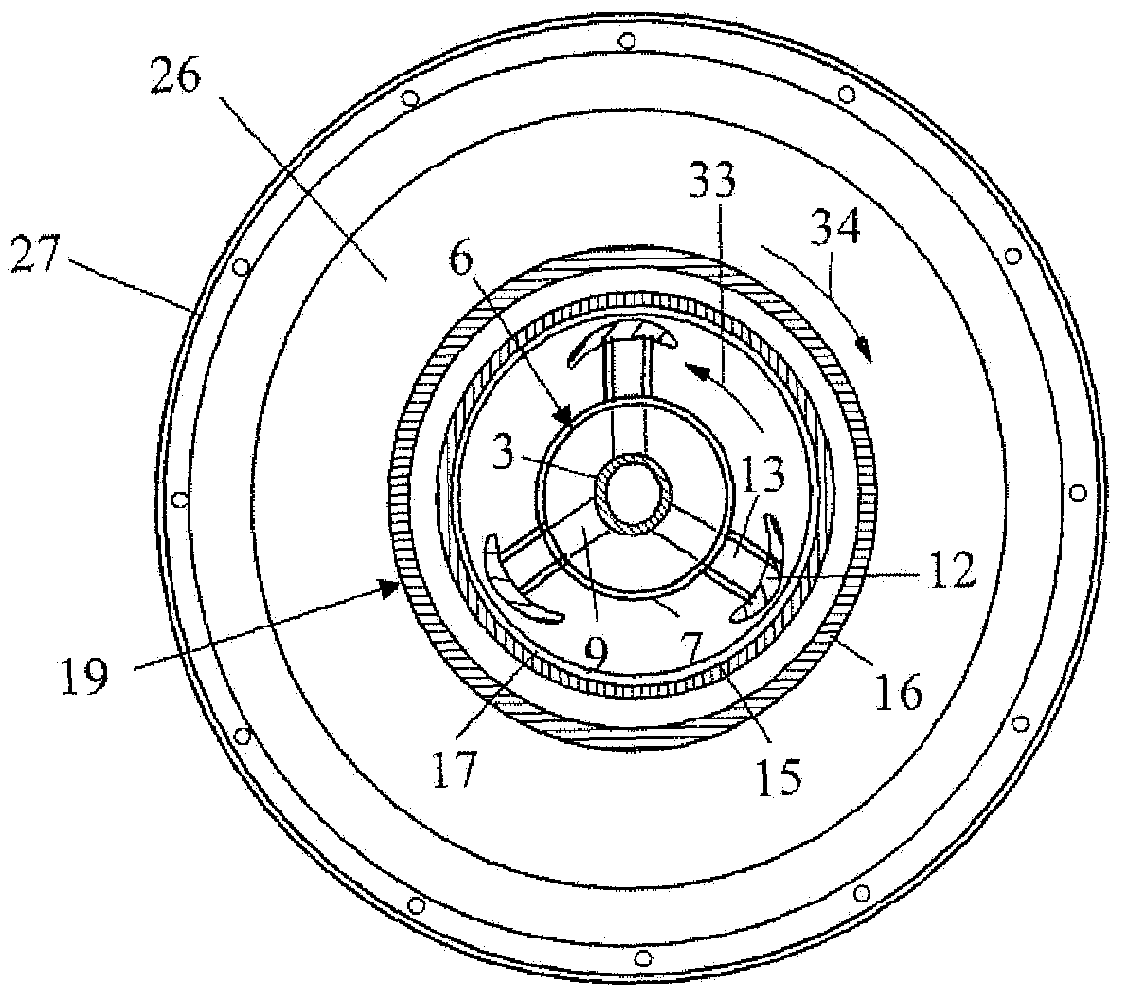

Threshing device

The present invention relates to a threshing device for threshing of a material. The threshing device comprises a threshing part with a first rotatable unit (6) which comprises at least a flail (12) and a concave (15) which surrounds the rotatable unit (6). Preferably, the concave (15) is rotatably arranged in an opposite direction in relation to the first rotatable unit (6). The threshing device comprises a cleaning part with a rotatably mounted sieve (16), which surrounds the concave (15). A fan (28) is arranged to provide an air stream towards the sieve (16) for preventing the cleaned parts of the threshed material to pass through the sieve (16). The air stream is also arranged to transport out the cleaned parts which are collected in a space (18) between the sieve (16) and the concave (15).

Owner:贡纳·俄克罗夫

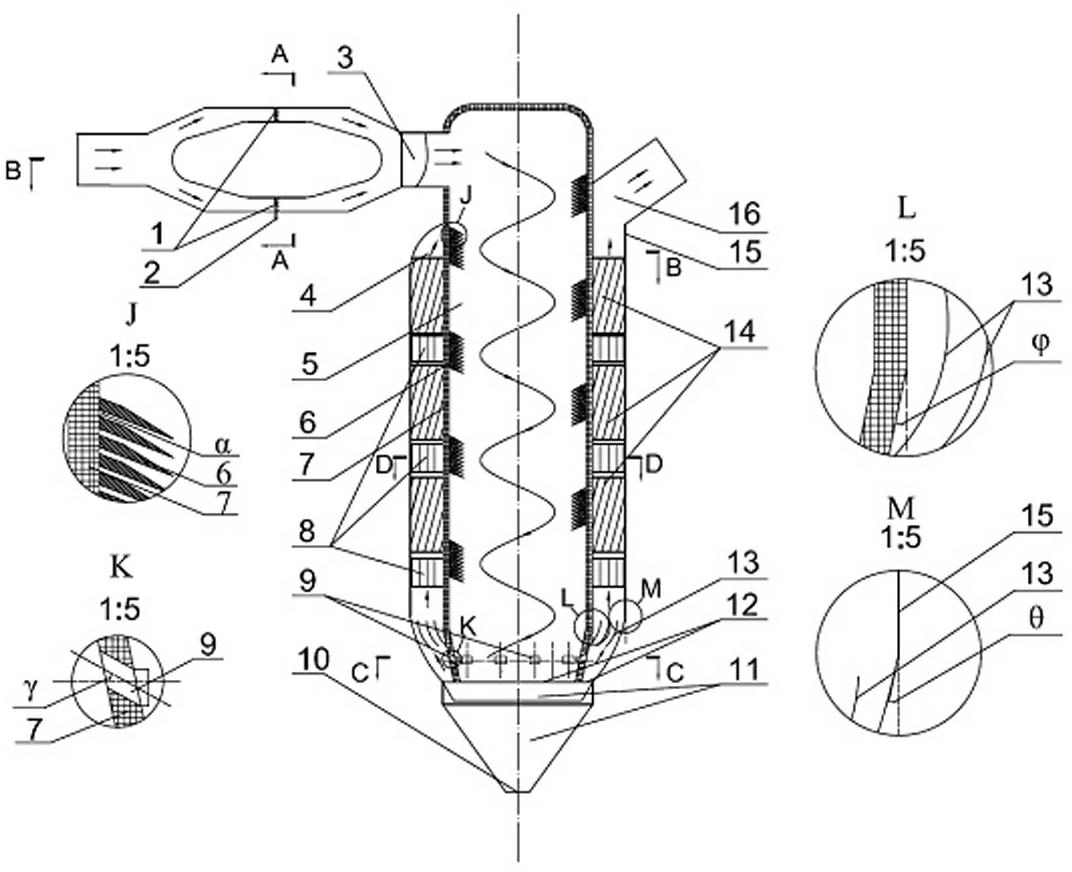

Dedusting-denitrating integrated device

ActiveCN102614779BSimple structureSimple control systemDispersed particle filtrationFlue gasHeat losses

The invention discloses a dedusting-denitrating integrated device which comprises a flue gas channel, a mixed flue gas inlet and a shell consisting of an outer cylinder and an inner cylinder, and a ash hopper at the bottom of the shell, wherein the inner cylinder is mainly used for dedusting and ammonia mixing, the outer cylinder is mainly used for containing a denitrating catalyst bed, the cross section of the flue gas channel is ring-shaped, and ammonia spray grilles are distributed in the flue gas channel in a radial manner so that the required NH3-to-NO ratio can be reached more easily. The device provided by the invention can be used for dedusting before carrying out denitrating, a catalyst can be effectively prevented from being worn, poisoned and blocked and the service life of the catalyst can be prolonged. Under the condition that the length of the device is not increased, the ammonia mixing time is prolonged and ammonia mixing can be performed fully; heat absorbing spiral plates and cooling rectifier plates are arranged in both the inner cylinder and the outer cylinder to share heat of flue gas at the inlet, and therefore the heat loss of flue gas can be reduced, the denitrating efficiency can be improved and the catalyst is prevented from being sintered and inactivated under the action of superheated flue gas.

Owner:HUNAN UNIV

Whole-feed combine harvester with double-cutting vertical header and harvesting method thereof

The invention discloses a whole-feed combine harvester with a double-cutting vertical header, in which the technologies of double cutting, vertical header and whole feeding are combined to form a new grain harvesting method. When the whole-feed combine harvester with the double-cutting vertical header operates, the vertical header cut the grain into a root part, a straw part and a spike part through two groups of cutters, the straw part cut down is discharged from the outer side of the harvester by a seizing device at the lower row; and the spike part is directly sent into a seed husking plant by a seizing device at the upper row and then is delivered to a cleaning device and an impurity remover for treatments. Compared with the prior art, the whole-feed combine harvester has the advantages of low power consumption, low loss and small volume and is economic and practical. The whole-feed combine harvester is suitable for use in southern areas of China.

Owner:GUANGXI CHUNMAO INVESTMENT CO LTD

Anti-blocking induction flushing table type squatting pan

PendingCN111794336AShort blowdown distanceSewage speed is fastUrinalsWater closetsSewage outfallMechanical engineering

The invention provides an anti-blocking induction flushing table type squatting pan and relates to the field of sanitary fittings. The squatting pan comprises a squatting pan body, a urinal, a urinalwater storage area, a urinal sewage draining exit, a sewage draining containing pool, a sewage draining exit and an induction flushing device. The squatting pan is characterized in that the urinal andthe sewage discharging containing pool are located in the squatting pan body, the sewage discharging containing pool is located on the lower layer of the urinal, the urinal is located on the upper layer of the sewage discharging containing pool, and the height of the squatting pan body is larger than the total depth of the urinal and the sewage discharging containing pool; the anti-blocking induction flushing table type squatting pan provided by the invention is not provided with a blow-off pipeline, has the functions of induction flushing and deodorization, and has the characteristics of difficulty in blocking, short blow-off distance, high blow-off speed and low water consumption.

Owner:陈泳杰

Device and method for filling fork supports with rod-shaped items and production machine for rod-shaped items with such a device

InactiveCN102232617AIncrease production capacityIncreased process reliabilityCigarette manufactureEngineeringIntegrated devices

The invention relates to a device and method for filling fork supports with rod-shaped items and a production machine for rod-shaped items with such a device. The rod-shaped items used for tobacco processing are used for filling a device with at least one fork support and preferably two fork supports, the device comprises a mechanism constructed and disposed to be used for receiving items from a device arranged in the front and particularly used at a production machine for the rod-shaped items in a multi-layer and orderly way, a mechanism constructed and disposed to be used for receiving items from the mechanism used for receiving the items and arranged at the front in a multi-layer and orderly way and be used for giving out the items to the fork supports, and a transporting mechanism used for the fork supports. The device is advantaged in that, the mechanism used for receiving the items is completely arranged at the upper part of the fork supports and the mechanism used for receiving and giving out the items is constructed and disposed to be used for filling the fork supports in a fixed direction in a single-layer upper-lower mode. Additionally, the invention relates to a corresponding method and a production machine provided with an integrated device used for filling the fork supports.

Owner:HAUNI MASCHINENBAU AG

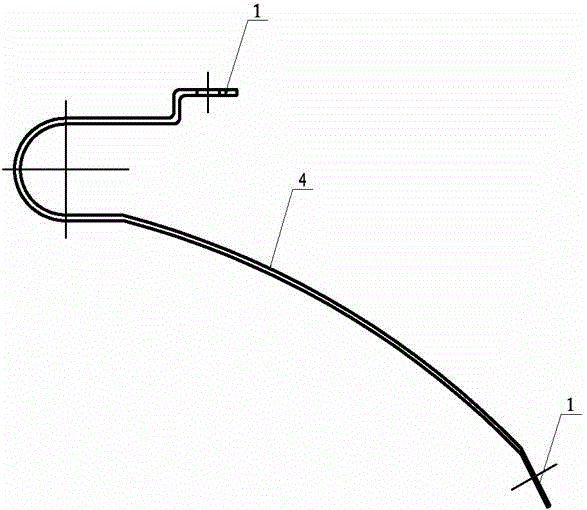

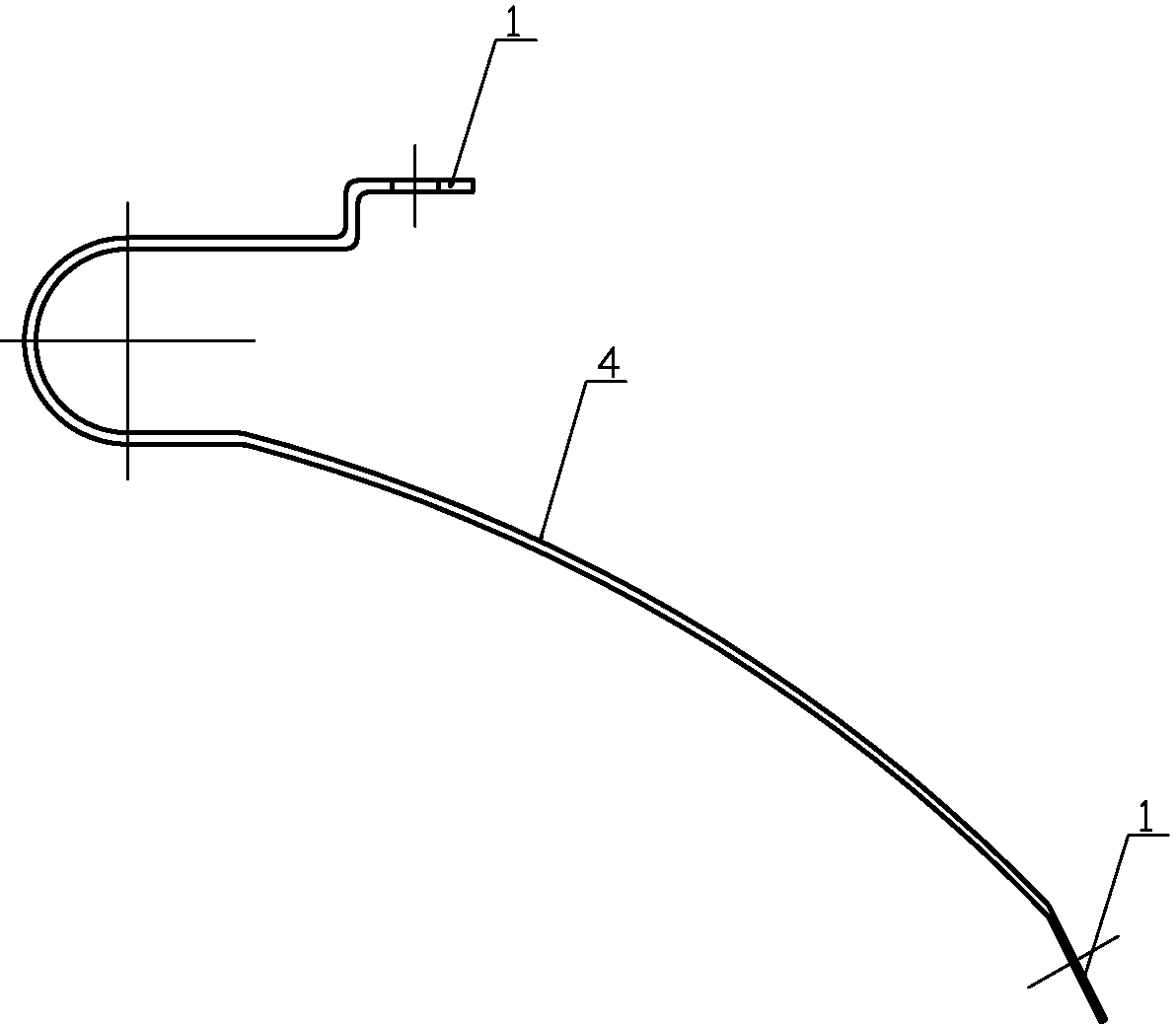

Cotton separating plate of cotton picking machine

The invention discloses a cotton separating plate of a cotton picking machine, which is used for separating cotton while picking and preventing cotton from blocking a cotton conveying tube. The cotton separating plate is characterized by comprising a plate body (4), wherein the plate body (4) is flaky, two ends of the plate body (4) are fixed ends (1) and provided with screw holes for fixing, a groove for a picking needle (6) to pass through is formed on the plate body (4), the width of the groove is 2-3 times of the diameter of the picking needle (6), the groove is respectively a needle inlet segment (2), a cotton picking segment (3) and a cotton separating segment (5) along the moving direction of the picking needle (6), the needle inlet segment (2) is horizontally arranged, the cotton picking segment (3) is arranged in a semicircular manner, and the needle inlet segment (2) is arranged in an arc manner. The cotton separating plate is simple in structure and convenient for use; the separating effect of the picking needle and cotton is good, the cotton conveying distance is short, and blockage is not easy to happen; and the work efficiency is greatly improved. Therefore, the cotton picking machine has better practicability.

Owner:YIYANG FUJIA TECH CO LTD +1

Electron oscillation siphon type automatic spraying system

InactiveCN106423699ASimple structureEasy to manufactureLiquid spraying apparatusSiphonControl system

An electron oscillation siphon type automatic spraying system comprises a background control system, an environment information acquisition unit group and an electron oscillation siphon type sprayer group. The electron oscillation siphon type sprayer group and an environment sensor group are electrically connected to the background control system. Different point position environment information threshold values are preset in the background control system. Environment information acquisition units acquire environment information in real time. The background control system receives the information, and electron oscillation siphon type sprayers execute corresponding operations according to instruction of the background control system. The electron oscillation siphon type automatic spraying system has the beneficial effects that spraying to different points can be independently controlled in real time according to environment requirements, and systematic automatic spraying management is achieved. The spraying system is simple in structure, easy to manufacture, and low in production cost; the minitype spraying system is adopted, so that spraying to the different points can be handled independently; and the spraying system has the characteristics of being easy to construct, low in construction cost and convenient to maintain.

Owner:秦皇岛众鹏科技有限公司

An automated continuous batching device for carbon anode tank calciners

Owner:GUIYANG AL-MG DESIGN & RES INST

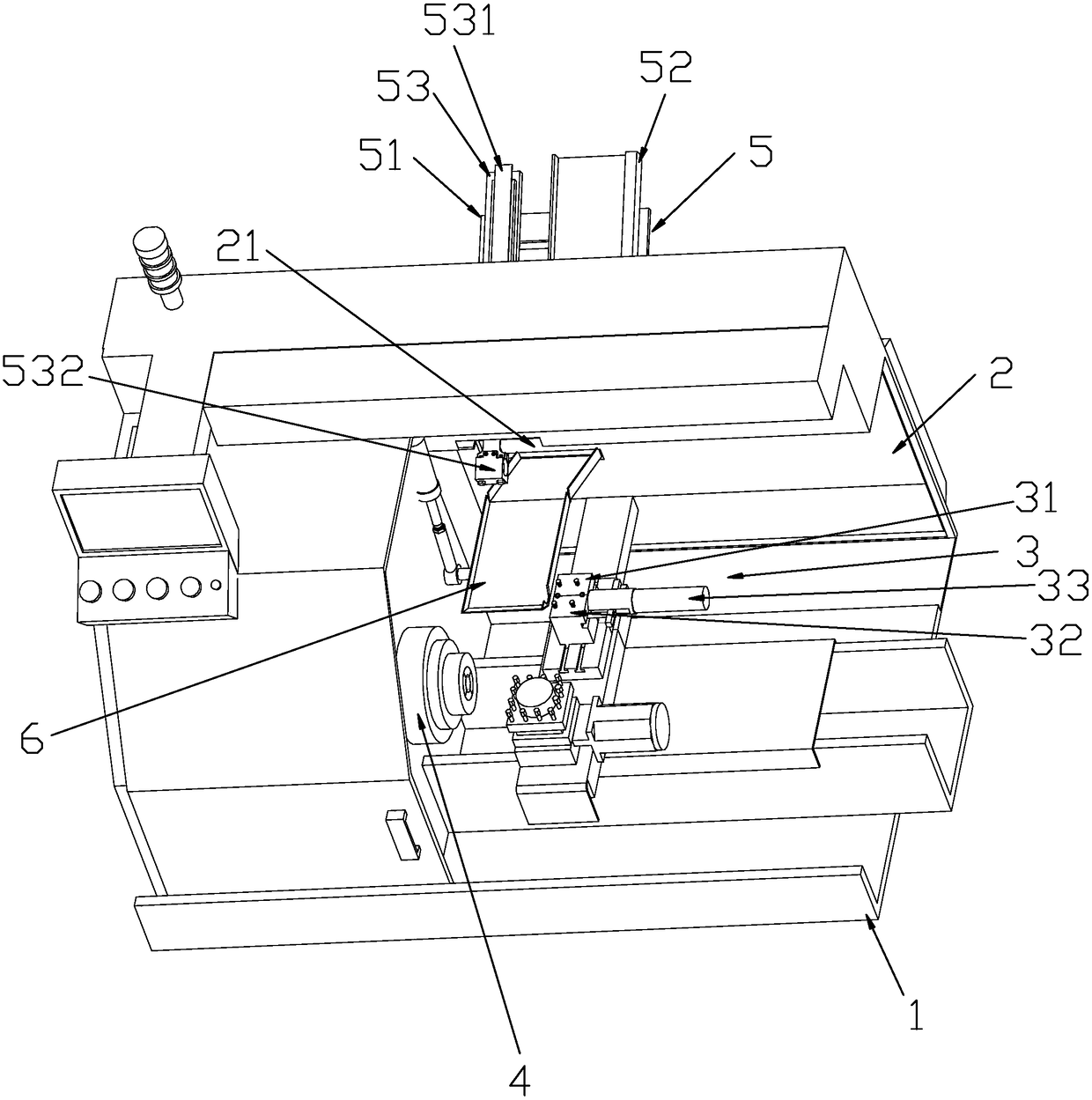

Numerical control machine tool for machining short shaft

PendingCN108127131ARealize automatic collectionSave programming stepsAutomatic conveying/guiding stockNumerical controlReciprocating motion

The invention relates to a numerical control machine tool for machining a short shaft. The numerical control machine tool comprises a numerical control machine tool body, the numerical control machinetool is characterized in that a baffle is arranged on the periphery of the numerical control machine tool body, a clamping station for clamping the short shaft is arranged on the numerical control machine tool body, a machining station for machining the short shaft on the clamping station is arranged at the position, on one side of the clamping station, of the numerical control machine tool body,and a conveying station which moves up and down in a reciprocating mode along a plane where the vertical clamping station is located is arranged above the baffle and between the clamping station andthe machining station. The numerical control machine tool for machining the short shaft has the beneficial effects of being simple in structure, high in conveying efficiency and short in conveying distance, the programming steps of numerical control machine tool programming personnel can be saved, and the production efficiency is effectively improved.

Owner:陈云

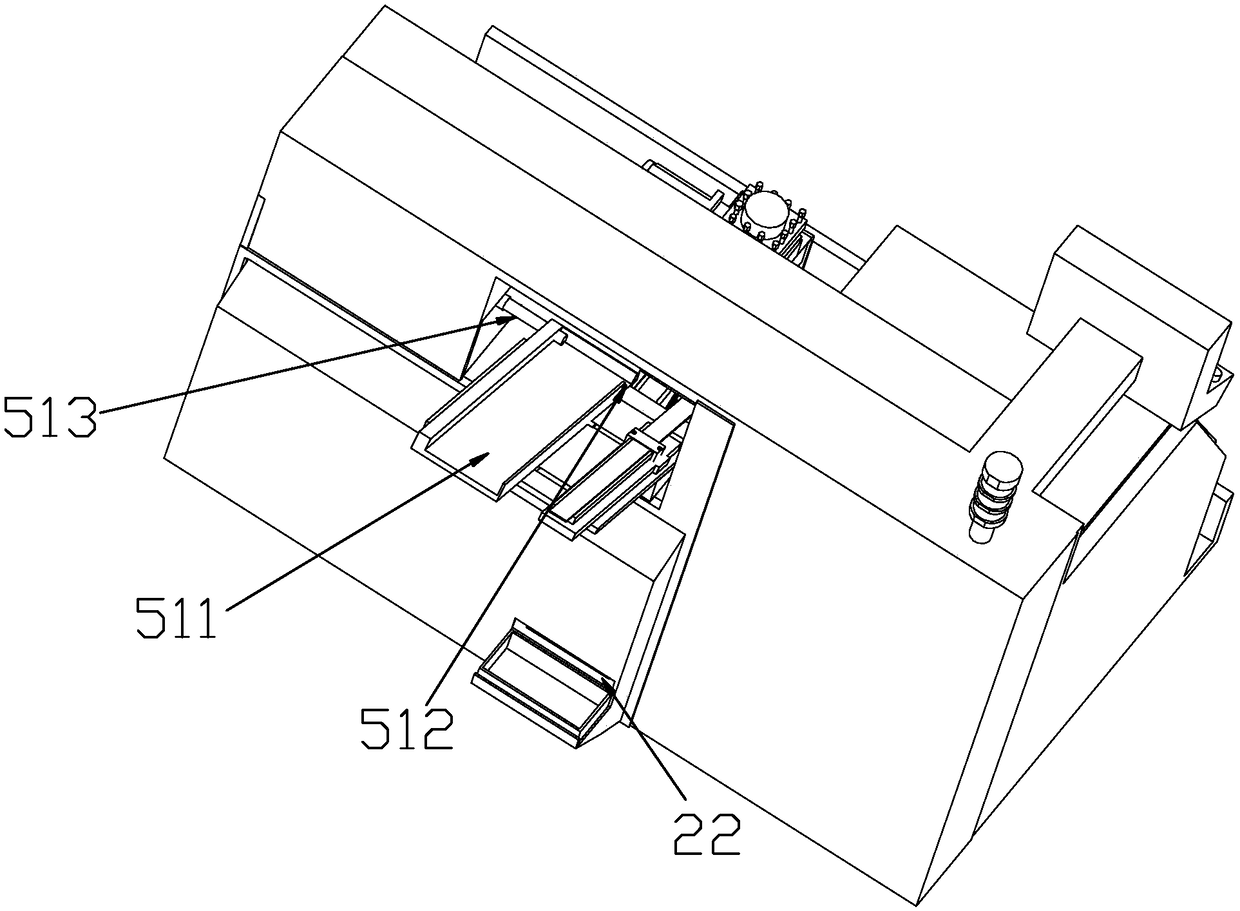

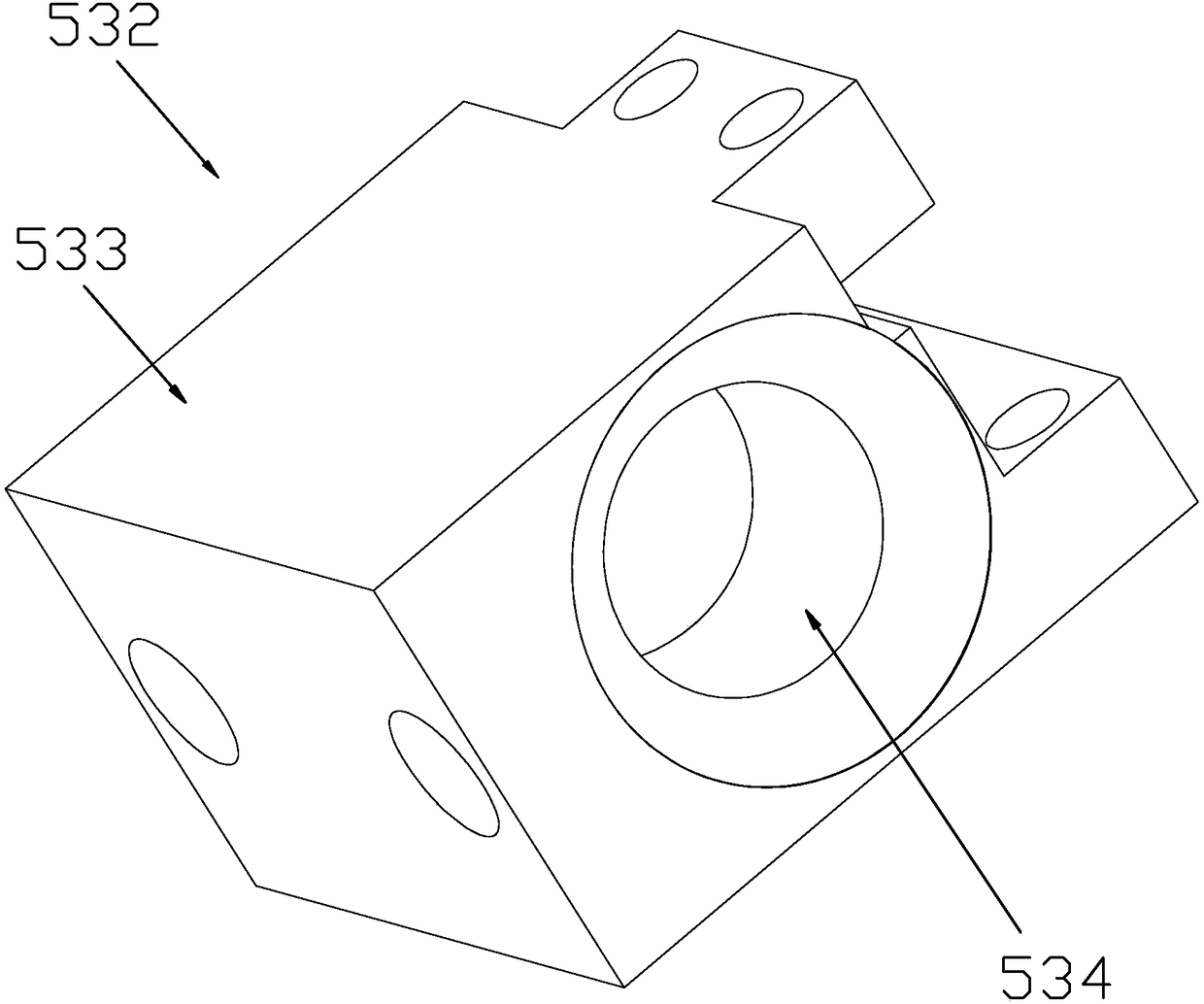

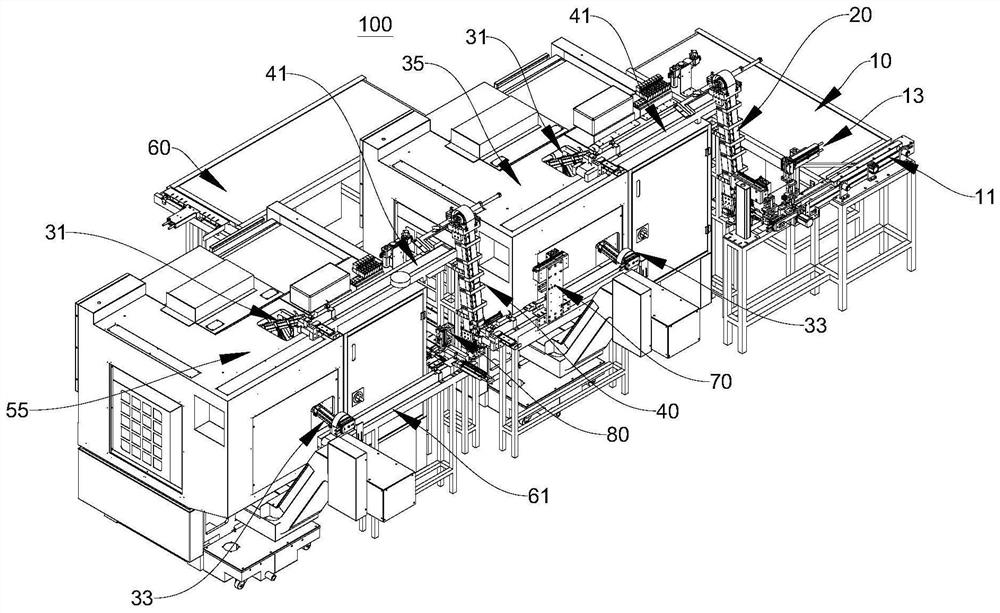

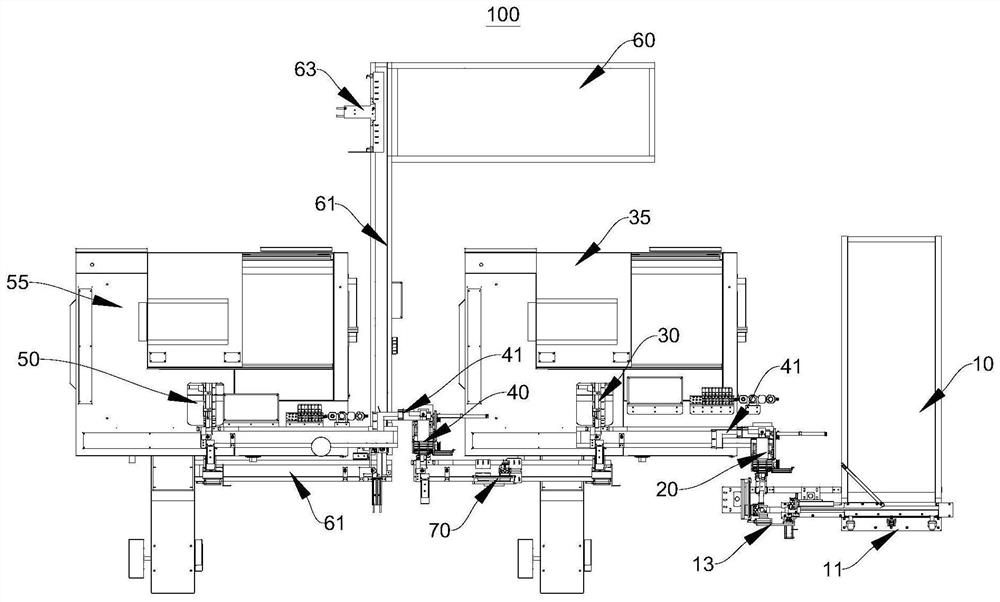

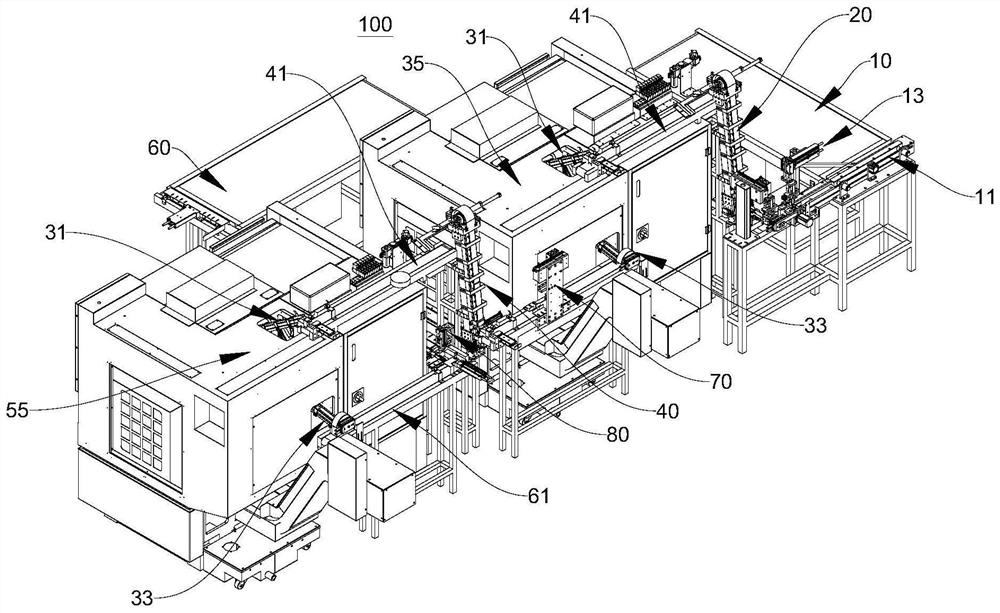

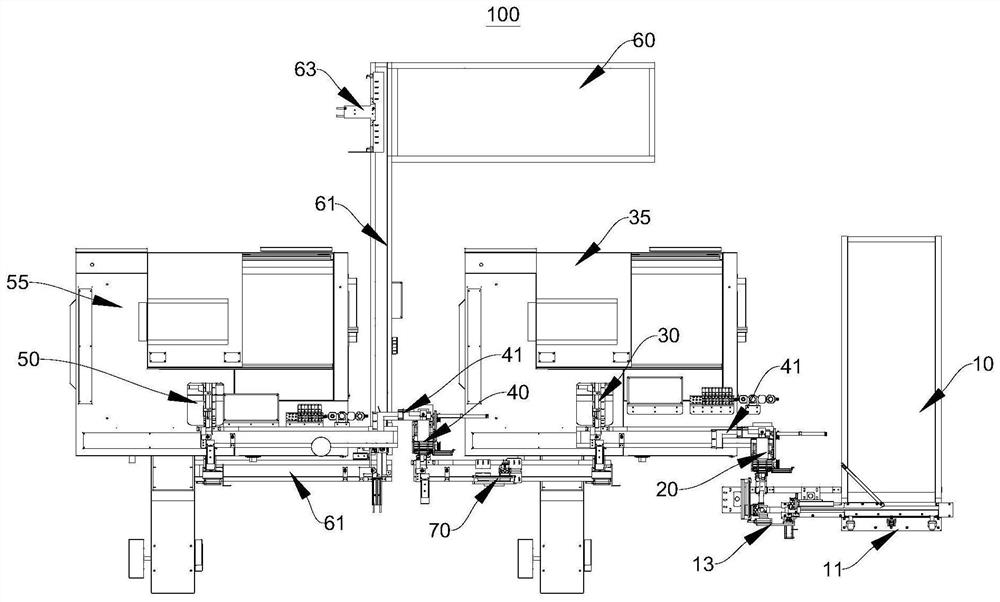

Mechanical automatic machining system for polished shafts

ActiveCN111874596ACompact structureShort conveying distanceSortingConveyor partsMachineMachining system

The invention discloses a mechanical automatic machining system for polished shafts, and relates to the technical field of mechanical automatic machining. The mechanical automatic machining system forthe polished shafts comprises an automatic feeding machine, a first lifting machine, a first feeding assembly, a second lifting machine, a second feeding assembly and an automatic discharging machine. The automatic feeding machine is connected with the first lifting machine, the first lifting assembly is connected with the first feeding assembly, the first feeding assembly is connected with the second lifting machine, the second lifting machine is connected with the second feeding assembly, and the second feeding assembly is connected with the automatic discharging machine. Polished shaft workpieces pass through the automatic feeding machine, the first lifting machine and the first feeding assembly in sequence, and the first feeding assembly conducts machining for the first time. The second lifting machine conveys the polished shaft workpieces machined for the first time to the second feeding assembly, the polished shaft workpieces are machined for the second time, the automatic discharging machine outputs the polished shaft workpieces machined for the second time, automatic machining of the polished shaft workpieces is achieved, and the machining efficiency is improved.

Owner:珠海航特装备制造有限公司

Roller kiln and working method thereof

InactiveCN104807324AMeet delivery requirementsIncrease temperatureCombustion processFurnace typesCombustorEngineering

The invention provides a roller kiln and a working method thereof. The roller kiln comprises an injection mixer, a high temperature waste heat air duct, an injection burner and a waste heat air system; the roller kiln is divided into a preheating section, a firing section and a cooling section along the direction of movement of products; the injection mixer is arranged on the cooling section; the injection burner is arranged on the firing section; the high temperature waste heat air duct is communicated with the cooling section and the firing section; the waste heat air system is arranged at the top of the firing section and the top of the cooling section; the injection mixer is of a concealed venturi tube structure and the injection burner is of a concealed venturi tube structure. According to the roller kiln and the working method thereof, the injection mixer which is of a venturi tube structure is added into the roller kiln so as to directly suck the high temperature waste heat air of a cooling zone of the roller kiln to be pressurized and conveyed to the injection burner of a firing zone and accordingly the high temperature waste heat is well utilized, the sufficient burning is ensured, the energy is saved, and the production workshop environment is improved.

Owner:HUNAN OTLAN IND EQUIP

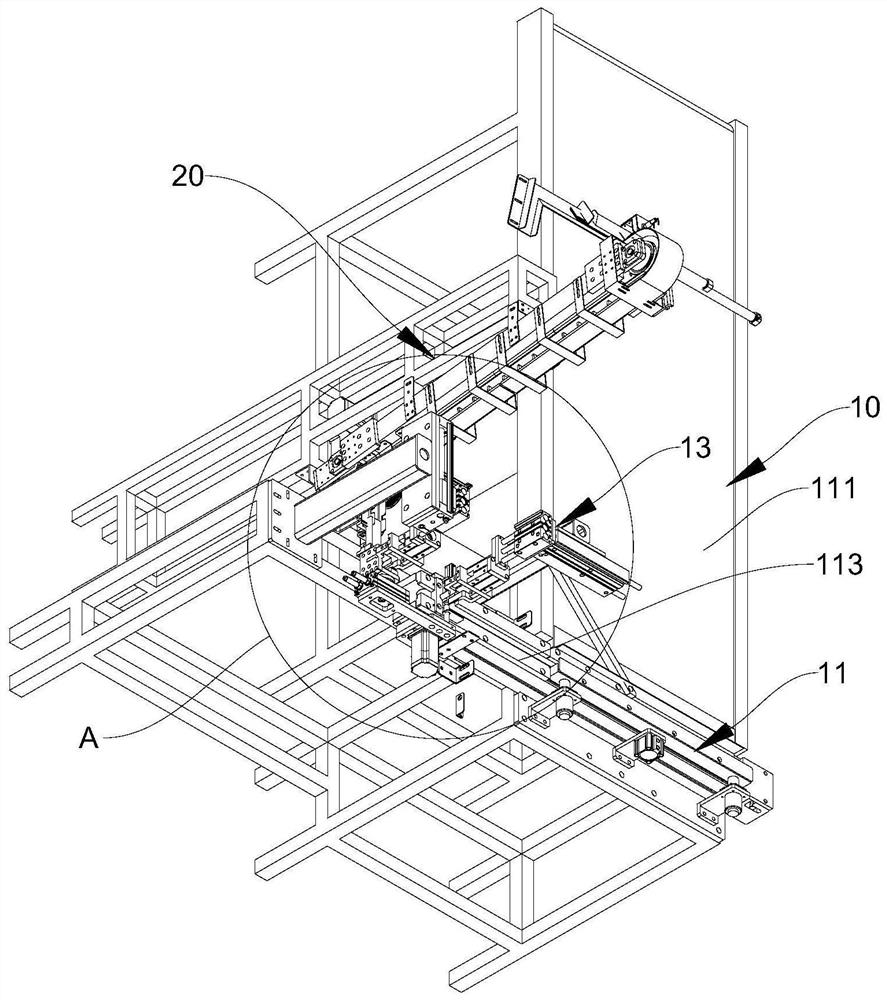

Automatic billet receiving device and four-mold-opening grouting machine

PendingCN111823360AImprove transfer efficiencyAvoid collision damageAuxillary shaping apparatusMechanical conveyorsMachineIndustrial engineering

The invention discloses an automatic billet receiving device and a four-mold-opening grouting machine, and relates to the technical field of grouting machines. The automatic billet receiving device comprises a billet receiving machine frame assembly, a trolley assembly, a billet receiving supporting frame, a lifting module and a billet receiving plate. The trolley assembly is movably arranged on the billet receiving machine frame assembly, the billet receiving supporting frame is fixed to the trolley assembly, the billet receiving plate is movably arranged on the billet receiving supporting frame, and the lifting module is connected with the billet receiving supporting frame to drive the billet receiving supporting frame to rise or fall. According to the automatic billet receiving device,a billet can be taken out and carried, the moving efficiency of the billet is improved, and the yield of the billet is improved.

Owner:广东金马领科智能科技有限公司

Heavy-denier flat yarn continuous spinning process

InactiveCN102978722BSmall spanShorten molding timeNew-spun product collectionFilament manufactureCooking & bakingYarn

The invention discloses a heavy-denier flat yarn continuous spinning process. The process comprises the following steps of viscose metering molding, washing, baking and rolling, drawing molded yarns onto a small processing roll and a big processing roll through a yarn guide rod, sequentially performing regenerating, washing, desulfurizing, Ph value-adjusting, oiling and baking processes on the yarns on the small processing roll and the big processing roll, and rolling the baked yarns on a winding head under the action of a yarn guide wheel, wherein before the yarns are drawn to the small processing roll and the big processing roll, acid liquid on the yarns is scraped in a foam acid-scraping way. Continuous spinning can be finished on one set of spinning equipment, the breakage is low, the occupation area of the equipment is small, the acid bath loss is low, the continuity is higher, spindle positions are not mutually affected, and the produced heavy-denier flat yarns are high in quality, the rate of finished products and yield.

Owner:YIBIN HIEST FIBER +1

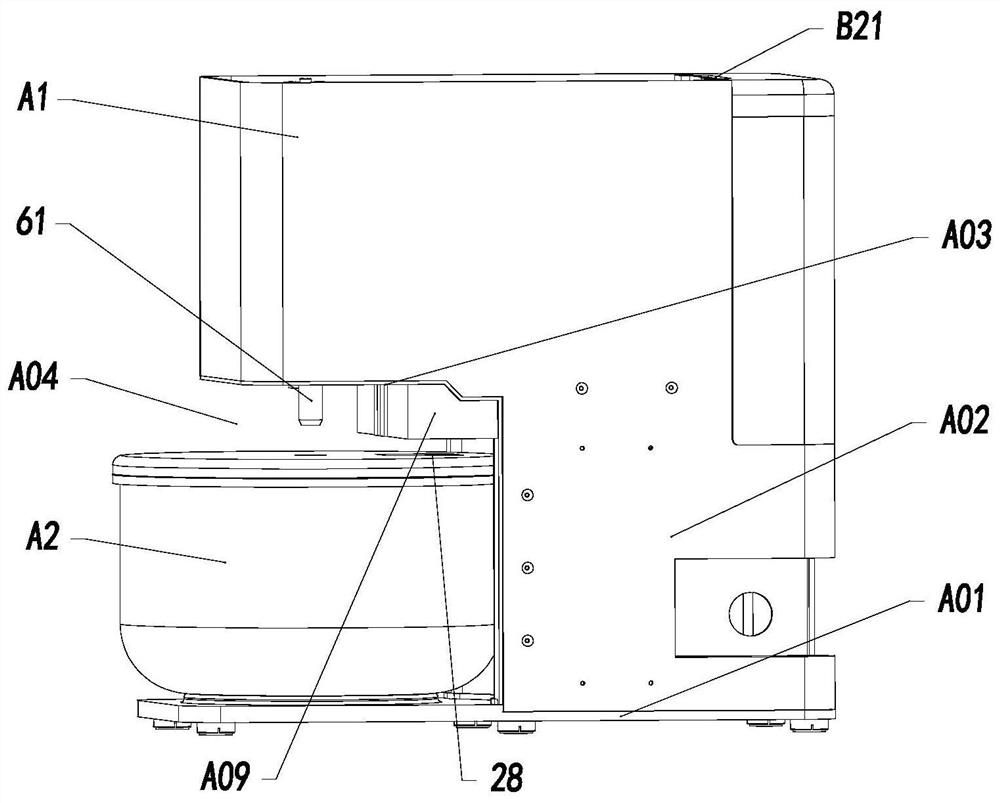

an automatic cooking device

The invention discloses an automatic cooking device, which comprises a pot liner, a pot body and a material cleaning device. The pot liner is used for cooking food, and the material cleaning device is arranged on the pot body; the material cleaning device includes a rotating The rotary bin is used for cleaning materials, and the rotary bin is provided with a material port and a turning blade, and the material port is used for feeding and discharging, and the turning blade is used to control the material In the turning direction of the rotating bin, the body of the pot is also provided with a storage bin, the bottom wall of the storage bin is provided with a first bin opening, the first bin opening is eccentrically arranged on one side of the bottom wall, and An inclined material guide wall inclined towards the first material bin opening is provided on the other side opposite to the first material bin opening, and the rotating bin is located below the inclined material guide wall. The structure of the whole machine of the present invention is more compact.

Owner:JOYOUNG CO LTD

Optical axis mechanical automatic processing system

ActiveCN111874596BCompact structureShort conveying distanceSortingConveyor partsOptical axisEngineering

The invention discloses an optical axis mechanical automatic processing system, which relates to the technical field of mechanical automatic processing. The optical axis mechanical automatic processing system includes an automatic feeding machine, a first hoist, a first feeding assembly, a second elevator, a second feeding assembly and an automatic unloading machine. The automatic feeder is connected to the first elevator, the first lifting assembly is connected to the first feeding assembly, the first feeding assembly is connected to the second elevator, the second elevator is connected to the second feeding assembly, the second feeding assembly is connected to the automatic Unloading machine connection. The optical axis workpiece passes through the automatic feeder, the first hoist and the first feeding assembly in sequence, and the first feeding assembly performs the first processing; the second elevator transports the optical axis workpiece after the first processing to the second feeding assembly , the optical axis workpiece is processed for the second time, and the automatic blanking machine outputs the optical axis workpiece after the second processing, so as to realize the automatic processing of the optical axis workpiece and improve the processing efficiency.

Owner:珠海航特装备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com