An automated continuous batching device for carbon anode tank calciners

A tank calciner and carbon anode technology, which is applied in the field of batching devices, can solve the problems that the tank calciner cannot realize automatic continuous batching, the environment and sanitation conditions of the redistribution area are poor, and the continuous operation cannot be performed, so as to achieve continuous production. , the effect of reducing storage and transfer equipment, and improving hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

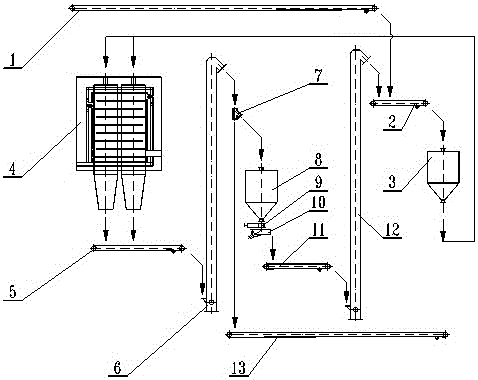

[0010] Such as figure 1 As shown, an automatic continuous batching device for a carbon anode pot calciner includes a pot calciner 4, a pot calciner discharge belt conveyor 5 below the pot calciner 4, and a pot calciner discharge belt conveyor The end of 5 is the first bucket elevator 6, the discharge port of the first bucket elevator 6 is connected with the electro-hydraulic three-way distributor 7, and the outlet end of the electro-hydraulic three-way distributor 7 is respectively connected with the return bin 8 is connected to the belt conveyor 13 of the calcined material storage and transportation system. The bottom end of the return batching bin 8 is an electro-hydraulic flat gate 9. Below the electro-hydraulic flat gate 9 is an electromagnetic vibrating feeder 10, and the electromagnetic vibrating feeder 10 exits. There is a tape quantitative feeder 11 at the material end, and the end of the tape quantitative feeder 11 is a second bucket elevator 12, and the discharge por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com