Device and method for filling fork supports with rod-shaped items and production machine for rod-shaped items with such a device

A technology for shaped products and manufacturing machines, which is applied in the field of devices for filling rod-shaped products with fork-shaped brackets and manufacturing machines with this device, which can solve the problems of large interfaces and high requirements for space positions, so as to improve production capacity and improve process reliability. performance, improved process reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

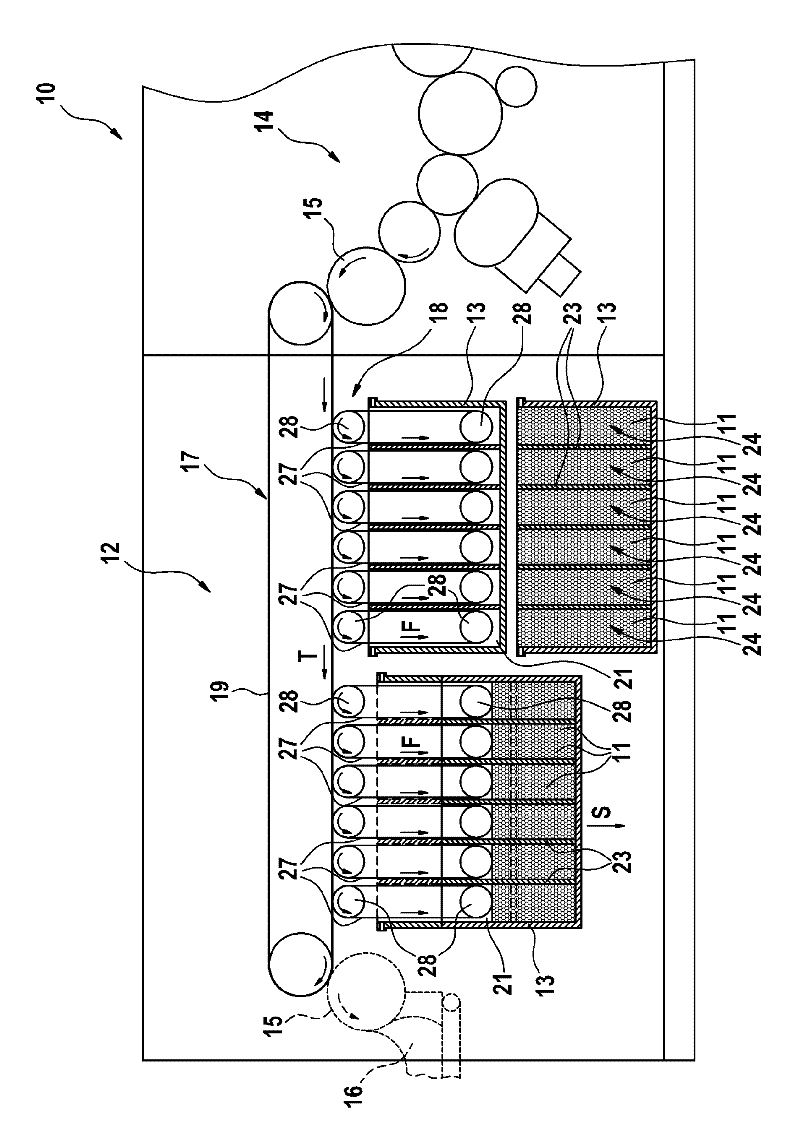

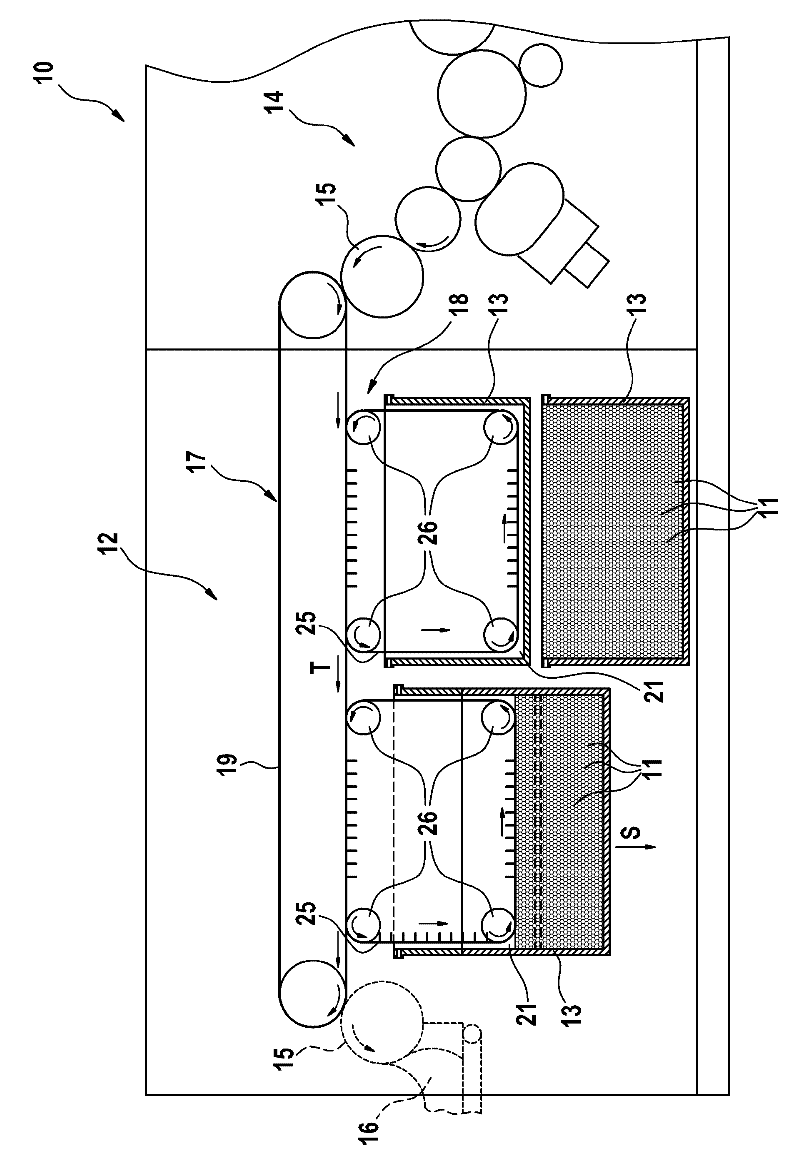

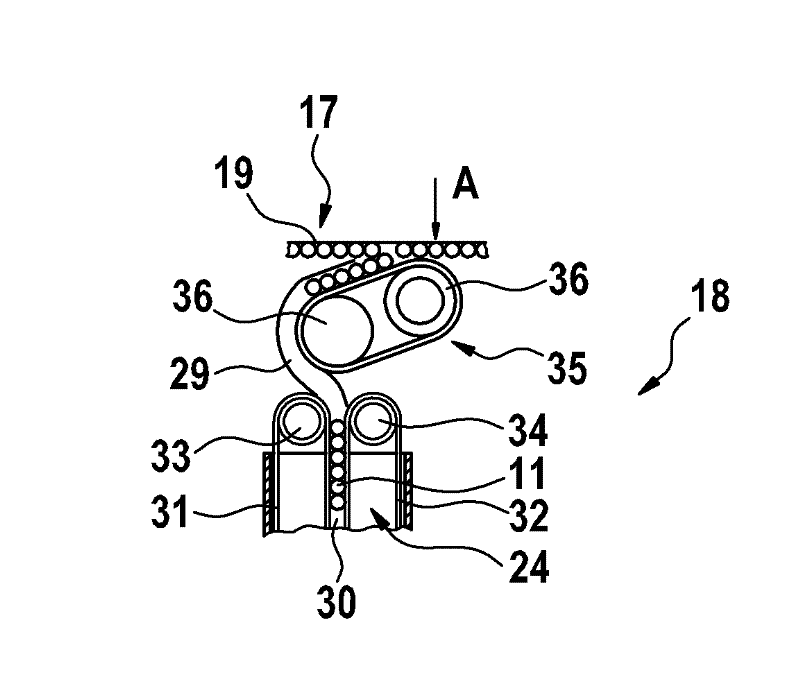

[0031] For a better and easier understanding of the present invention, first with the help of Figures 1 to 3 For the overall device, that is to say the production machine 10 for rod-shaped products 11 with an integrated device 12 for filling the fork / shaft fork 13 (hereinafter only referred to as fork 13 ) with rod-shaped products 11 to describe. The manufacturing machine 10 can be, for example, a tobacco manufacturing machine or a filter manufacturing machine. Cigarettes and filter rods are correspondingly mentioned as rod-shaped articles 11 by way of example. Of course, the device 12 can also be configured as a single device or used in combination with other machines and equipment.

[0032] The manufacturing machine 10 has a roller or drum arrangement 14 terminating in a delivery drum 15 for delivering the manufactured articles 11 . In the embodiment shown, the device 12 for filling the fork carrier 13 is attached to this delivery drum 15 . Optionally (and therefore onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com