Device and method for conveying concrete on water surface of wide river

A concrete and river technology, applied in the erection/assembly of bridges, construction material processing, bridges, etc., can solve the problems of low construction efficiency, waste of construction period, waste of resources, etc., to improve construction quality, short conveying distance, and speed up construction progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

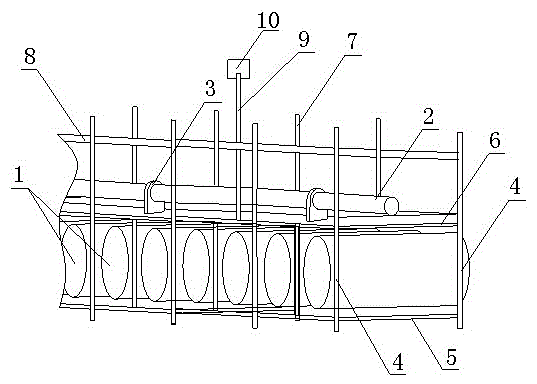

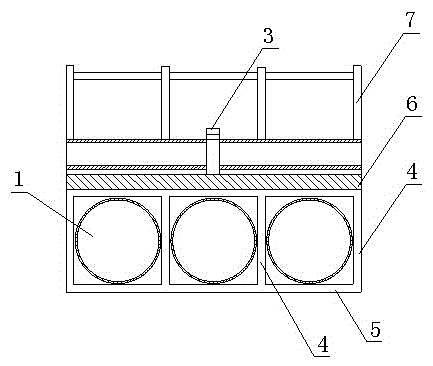

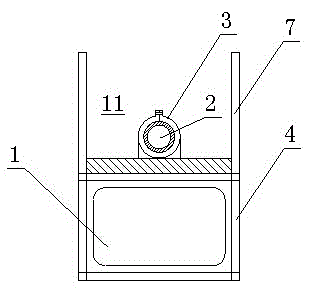

[0025] like figure 1 , 2 , 3, the present invention is a device for conveying concrete on the water surface of a wide river channel, which is characterized in that it comprises a concrete conveying platform formed by arranging a plurality of cylindrical buoyancy barrels 1 with the same shape and size in sequence, and the concrete conveying platform It includes several platform units 11, each platform unit 11 includes a buoyancy support, and the buoyancy support includes four vertical beams 4, four beams 6 on the top surface and four beams 5 on the bottom surface. A cylindrical buoyancy barrel 1 is arranged in the support frame of the buoyancy support, and four beams 6 on the top surface of the buoyancy support form the platform working surface, and the four vertical beams 4 of the buoyancy support extend upward to form the measuring beam 7 of the platform working surface , the different platform conveying units are connected end to end to form a concrete conveying platform, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com