Whole-feed combine harvester with double-cutting vertical header and harvesting method thereof

A combined harvester and full-feeding technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of high spare parts and maintenance costs, complex transmission mechanism for conveying stalks, and high manufacturing costs, and achieve reduction Effects of vibration and noise amplitude, moderate center of gravity, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

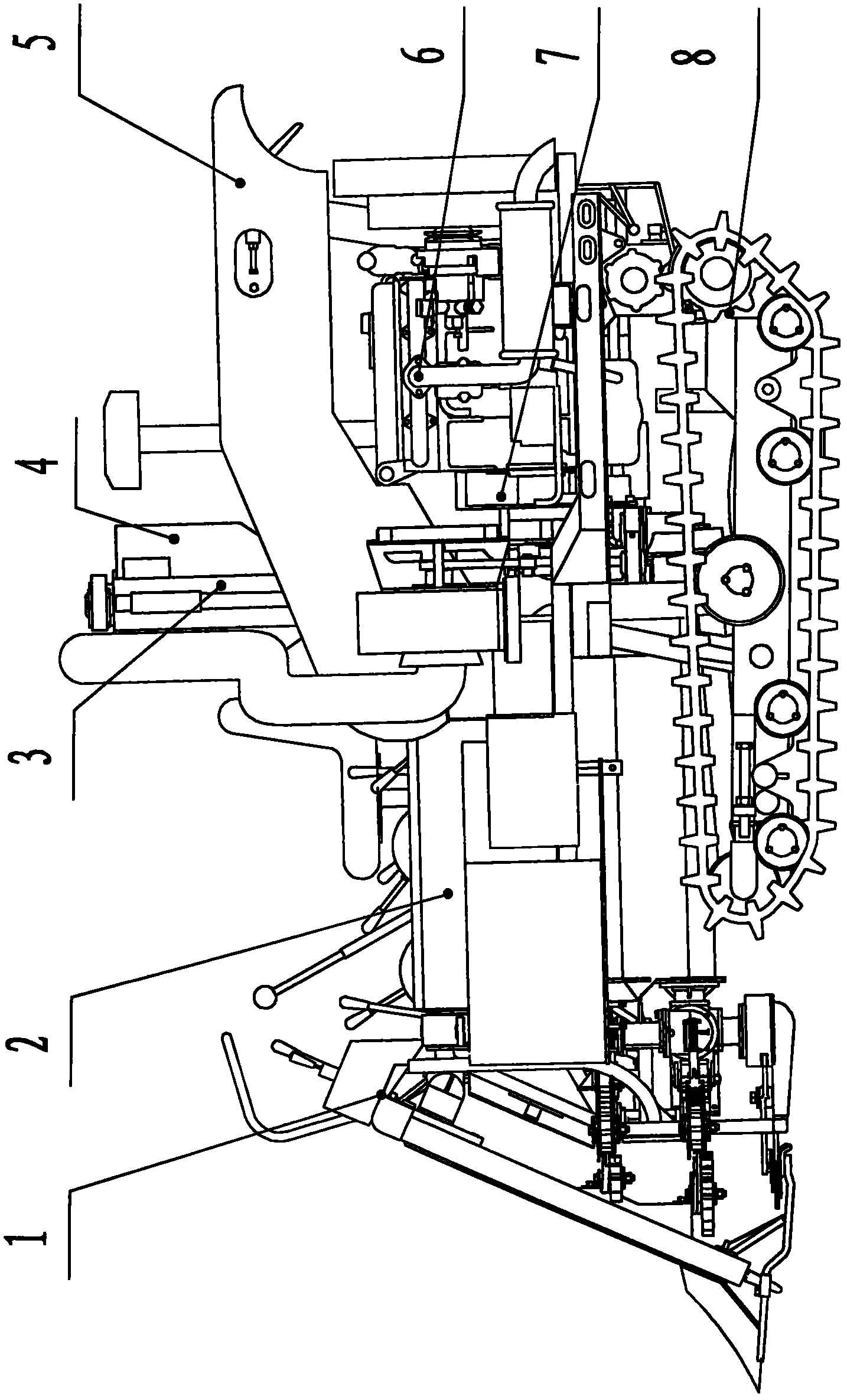

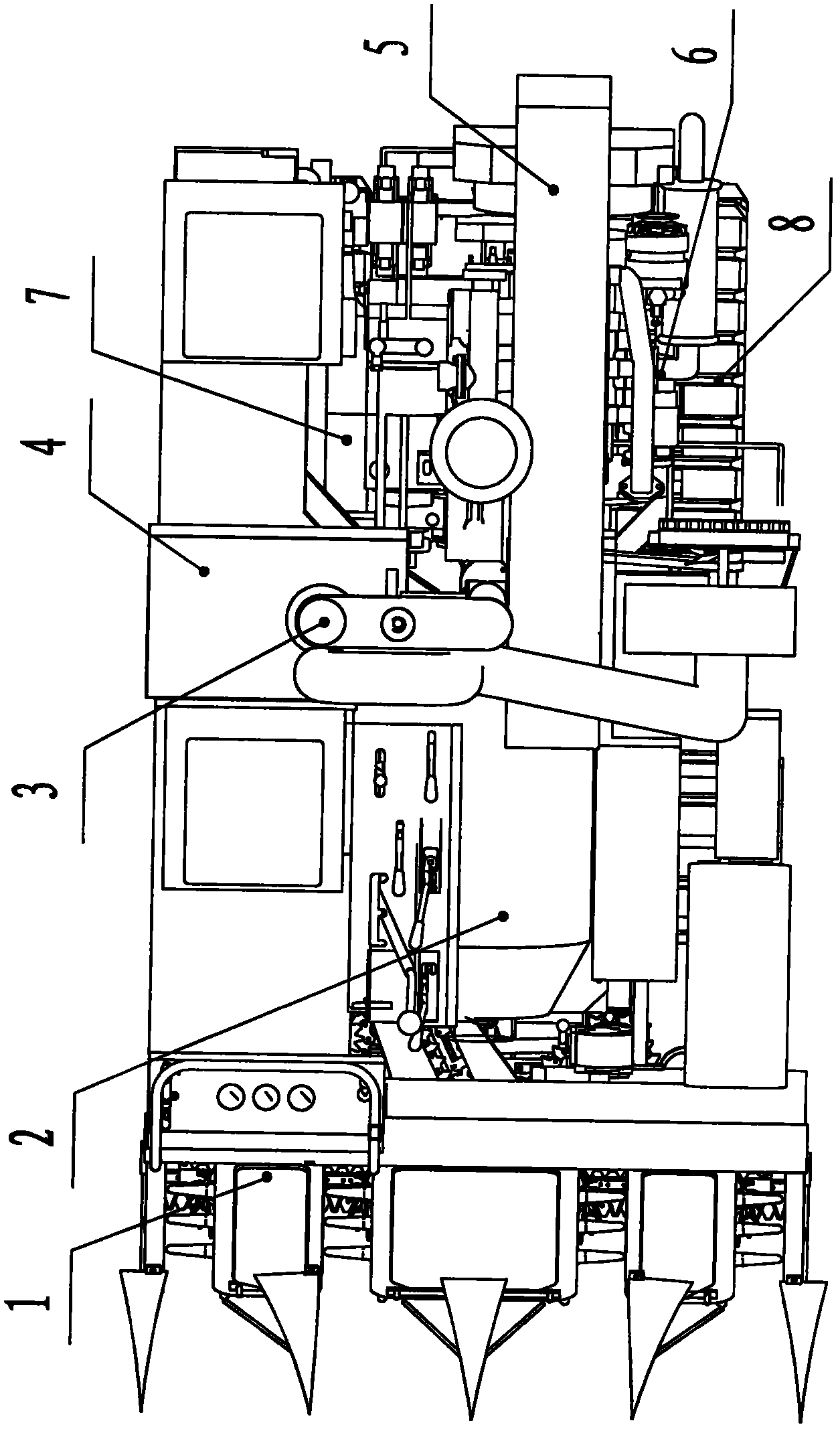

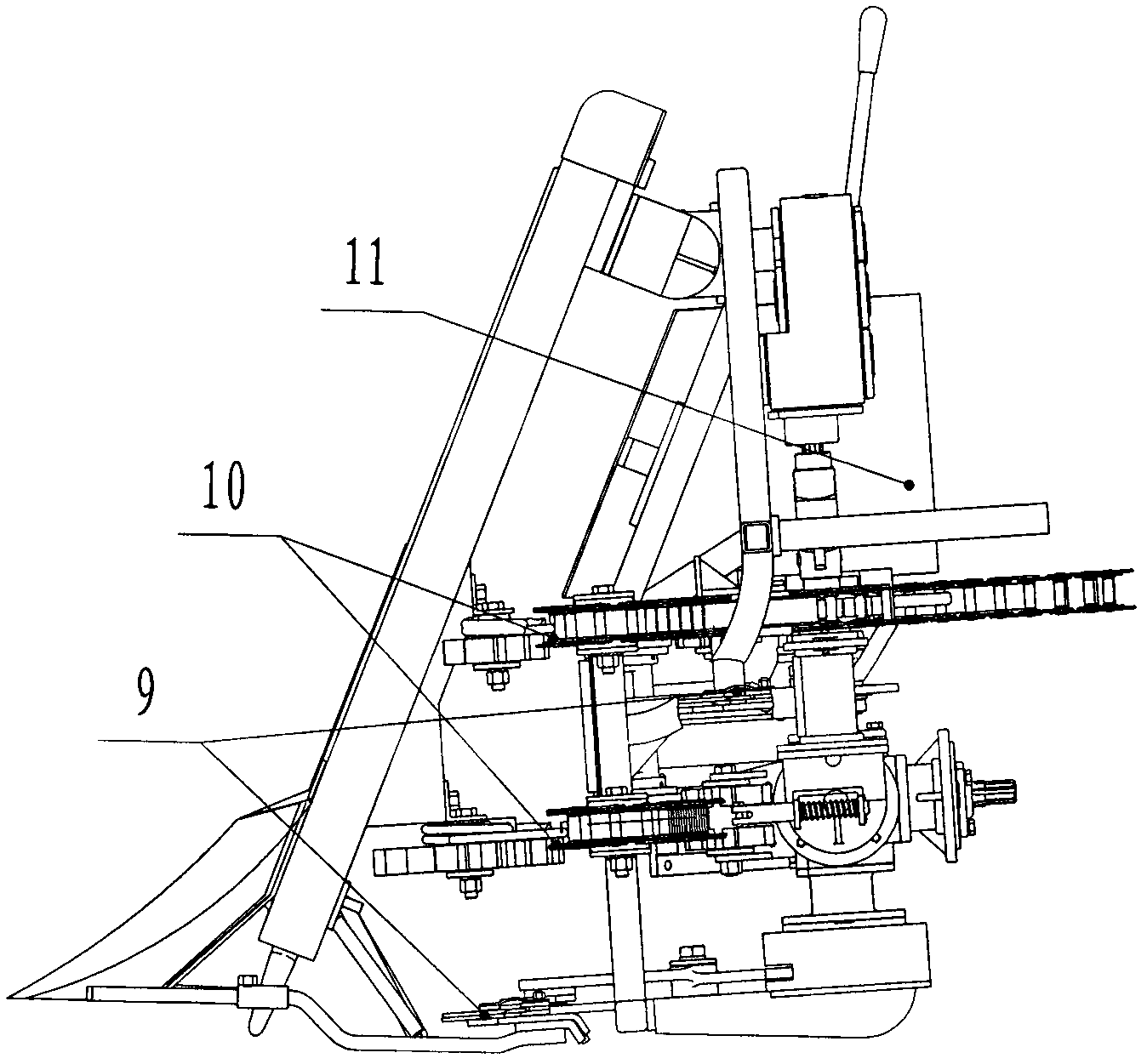

[0018] Such as Figure 1 to Figure 4 As shown, a double-cut vertical header full-feed combine harvester includes a vertical header, a threshing device, a lifting auger, a cleaning device, a miscellaneous discharge device, an engine, a gearbox, and a walking device. A threshing device 2 is longitudinally installed on the front and upper side of the walking device 8, and the threshing device 2 is connected to the vertical header 1 by bolts. On the side, the engine 6 is installed behind the threshing device 2, the engine 6 is connected to the gearbox 7 through the output shaft, the gearbox 7 is located at the upper rear of the traveling device 8, and the miscellaneous removal device 5 is installed longitudinally at the upper rear of the threshing device 2 The rear of the vertical header 1 is installed with two groups of cutters 9 up and down and paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com