Device and method for applying a reactive mixture consisting of at least two components to a substrate

A technology of reaction mixture and carrier material, applied in the direction of coating, device for coating liquid on the surface, spraying device, etc., can solve the problems of cost increase, small spray angle, large material loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

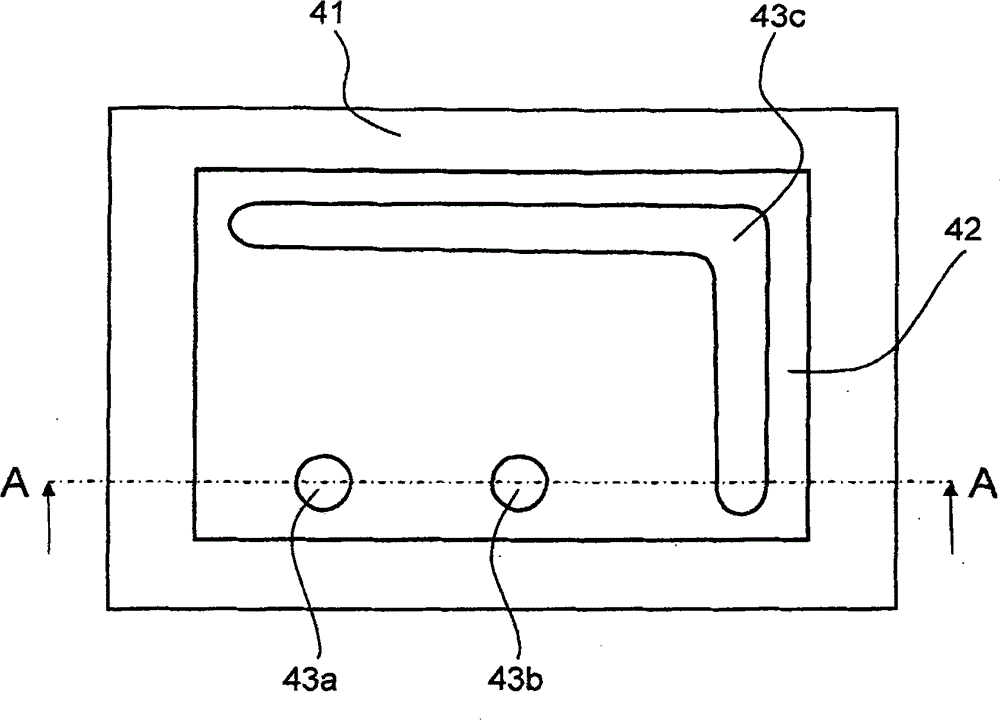

[0024] figure 2 The illustrated carrier material 41 is a rectangular fiber mat in the present exemplary embodiment. A substantially rectangular area is sprayed on this fiber mat 41 with a polyurethane material 42 . The sprayed polyurethane material 42 penetrates into the fiber mat. A further material application in the form of a first circular material application 43 a , a second circular material application 43 b and an essentially L-shaped material application 43 c are arranged on the surface coated with the polyurethane material 42 . The material coated with the further material is likewise a polyurethane material, which in this case has fibers incorporated therein. The fiber mat sprayed in this way is then placed in a mold for hardening. Portions of the outwardly projecting regions 42 of the fiber mat 41 are cut away, either before or after hardening of the material, to ultimately result in the desired composite structural member.

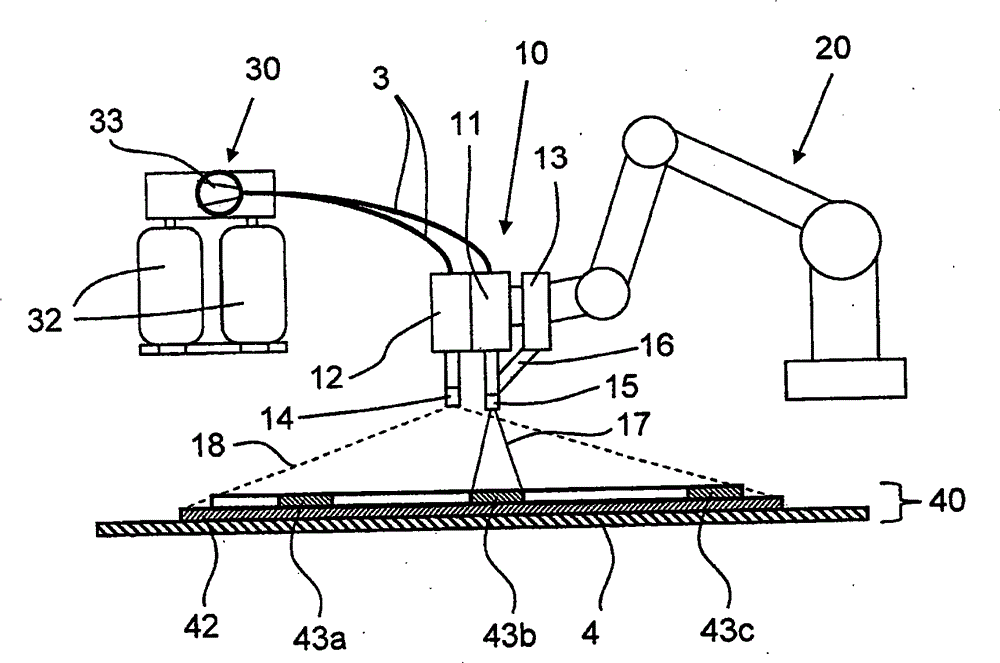

[0025] figure 1 shows the method a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com