Fuel injector

A fuel injector and fuel injection technology, applied in fuel injection devices, charging systems, combustion engines, etc., can solve problems such as fluctuations and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0022] A first embodiment of the present invention will be described.

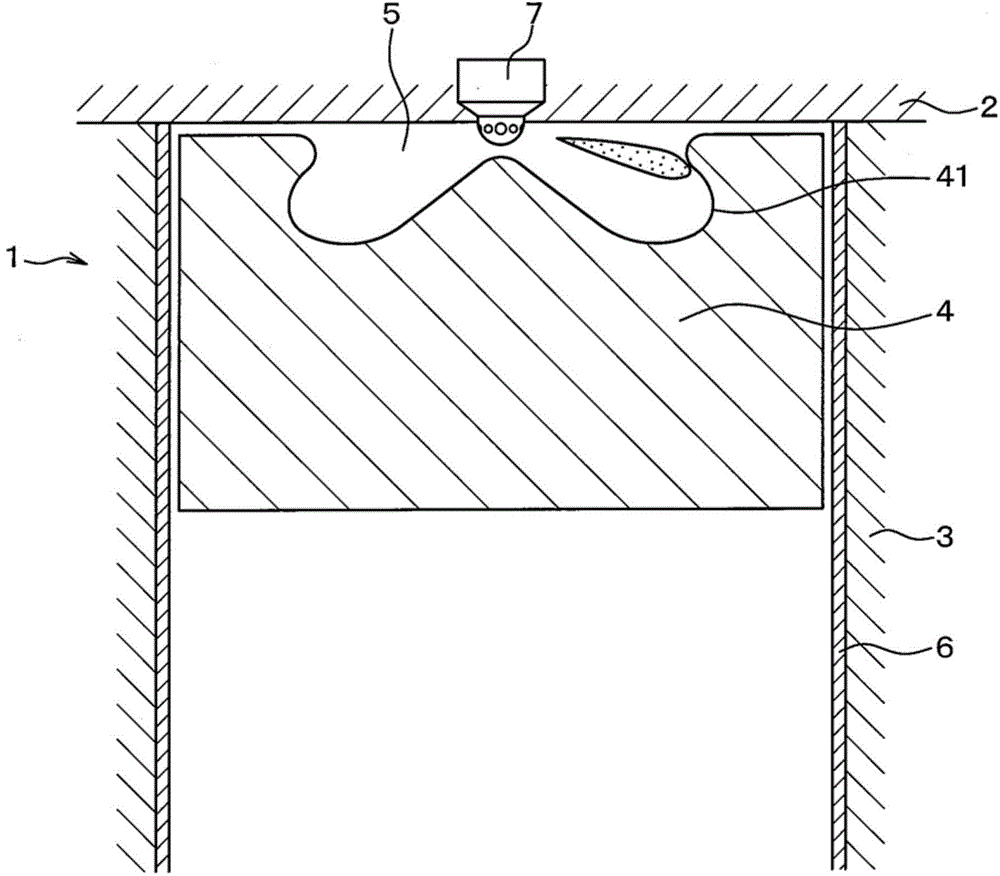

[0023] Such as figure 1 As shown, an internal combustion engine 1 comprises a cylinder head 2 , a cylinder block 3 and a piston 4 which form a combustion chamber 5 . According to this embodiment, the internal combustion engine 1 is a compression ignition type internal combustion engine.

[0024] A cylinder liner 6 is provided on the inner peripheral portion of the cylinder block 3 . The top of the piston 4 is provided with a cavity 41 which is part of the combustion chamber 5 .

[0025] The fuel injector 7 is placed at a position of the cylinder head 2 adjacent to the central axis of the combustion chamber 5 . The fuel injector 7 is connected to a common rail (not shown) accumulating high-pressure fuel and injects the high-pressure fuel into the combustion chamber 5 . Specifically, the fuel injector 7 injects high-pressure fuel supplied from the common rail into the cavity 41 .

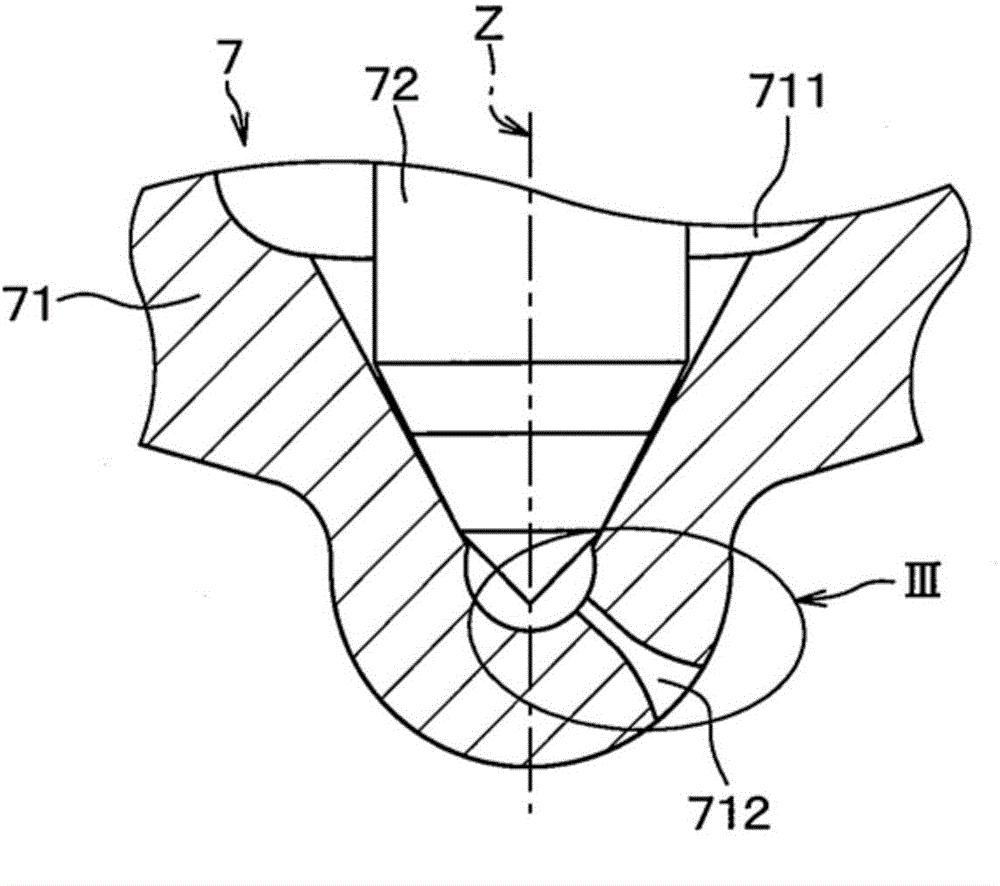

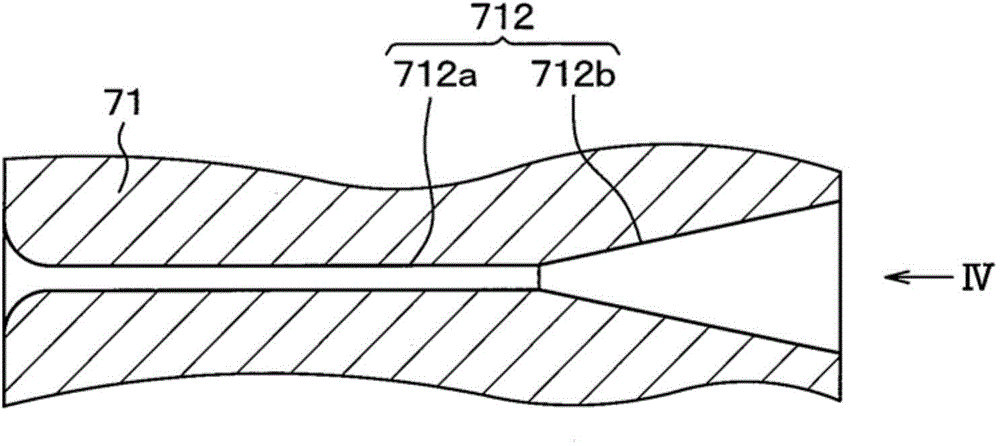

[0026] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com