Temperature equalization plate and interlaced capillary structure and method for manufacturing the same

A capillary structure and manufacturing method technology, applied in heat exchange equipment, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of extended time required for liquid working fluid delivery, limited number of capillary paths, dry burning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A preferred embodiment of the present invention will be described below with reference to the accompanying drawings. However, the relative terms such as "horizontal", "vertical" or "up and down" mentioned in the following descriptions are usually used in conjunction with the viewing angle or direction of the drawings for the convenience of explanation. Unless otherwise specified, they are not absolute or constant state.

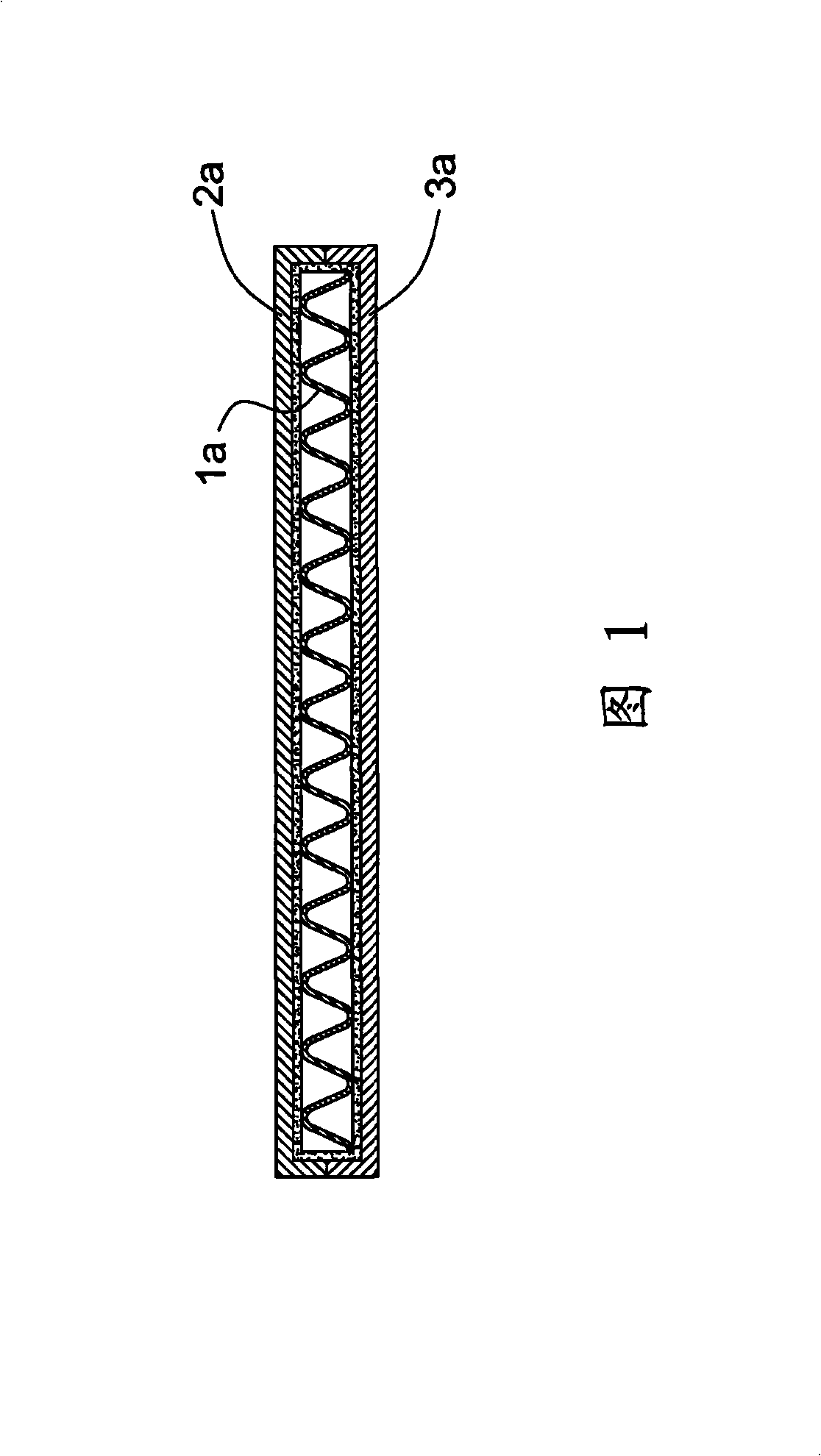

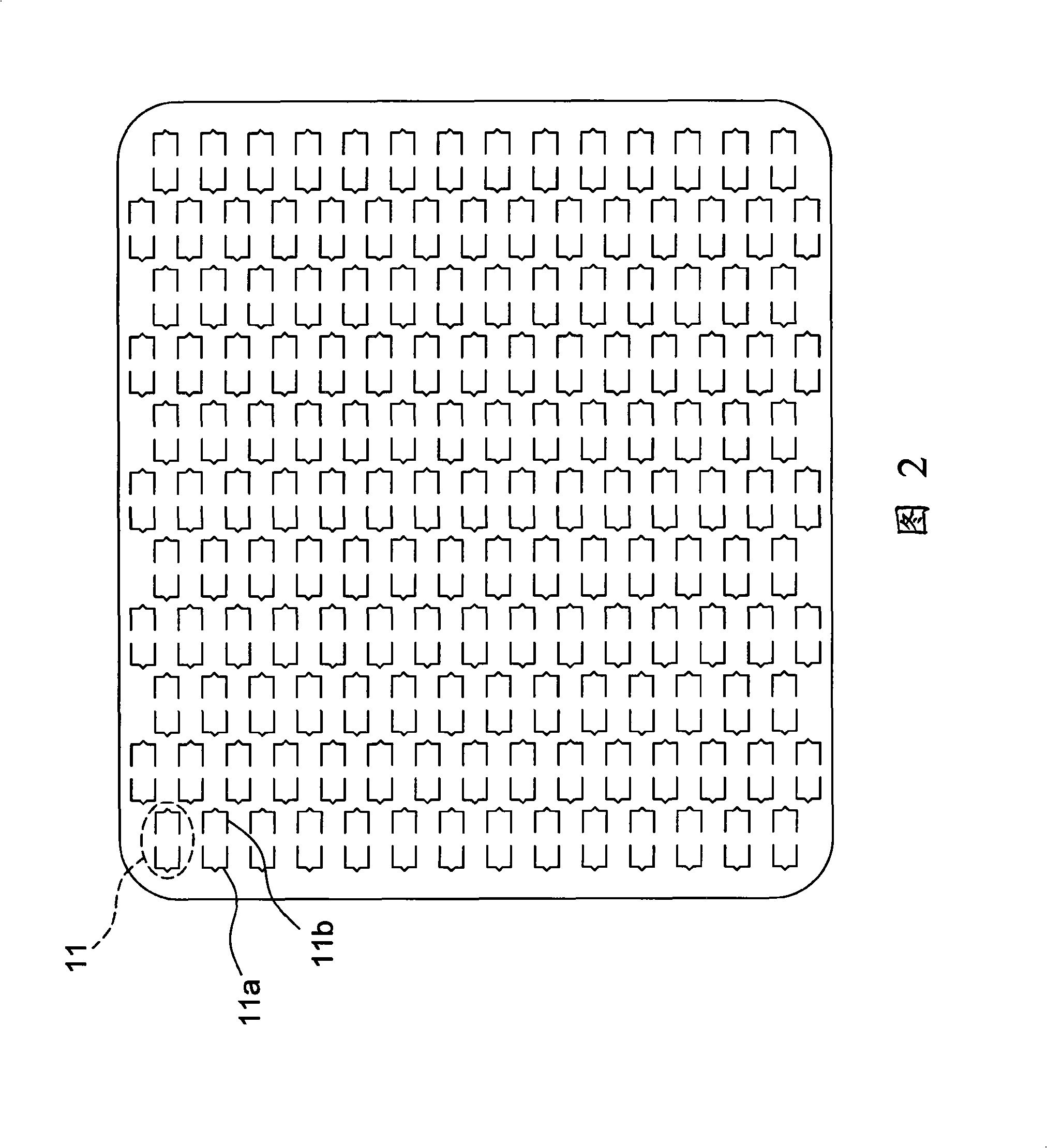

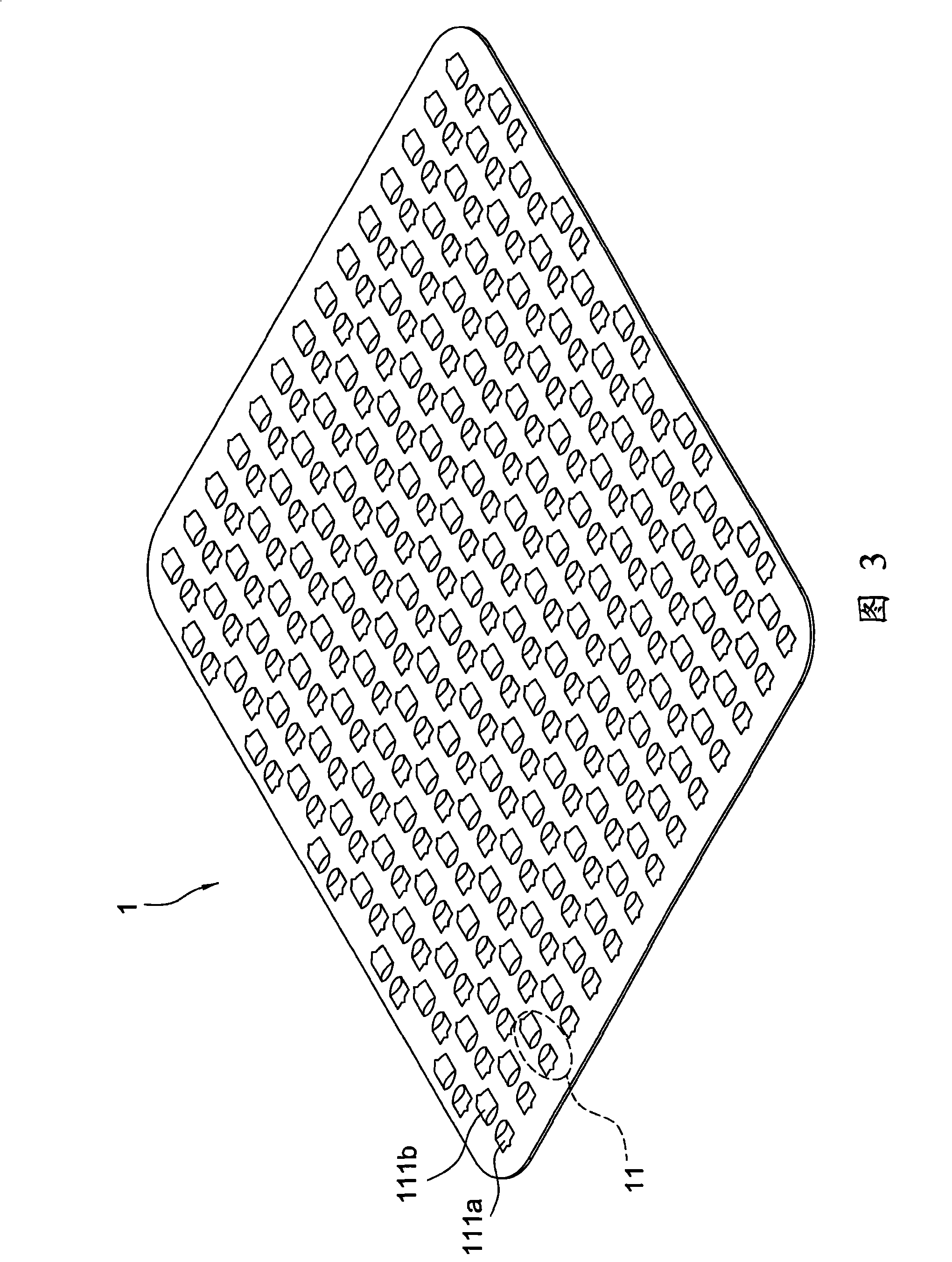

[0045] Fig. 2 is the front view of the first state of the sheet part of the present invention. First, a metal sheet 1 is provided, whose shape corresponds to the temperature chamber to be assembled. It is represented by a rectangle in the figure, and it can also be circular, triangular or other flat shapes. A plurality of pairs of {}-shaped grooves 11 are opened on the plate 1, and each group of grooves 11 is composed of two opposite unilateral grooves 11a, 11b, and their arrangement is in the form of a staggered matrix as shown in the figure It is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com