Air inlet pipe of SCR tail gas processing system and SCR tail gas processing system

A technology for exhaust gas treatment and intake pipes, which is applied to exhaust devices, noise reduction devices, engine components, etc., can solve the problems of large ammonia leakage, low nitrogen and oxygen conversion efficiency, and uneven mixing, so as to improve efficiency and heat preservation effect , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

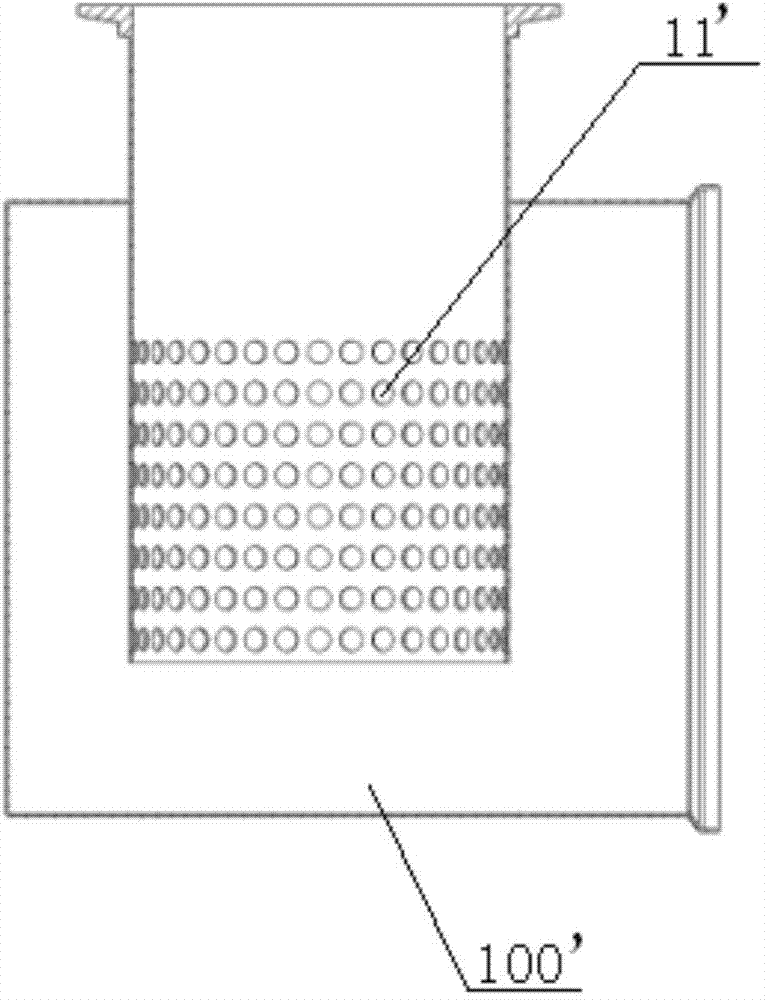

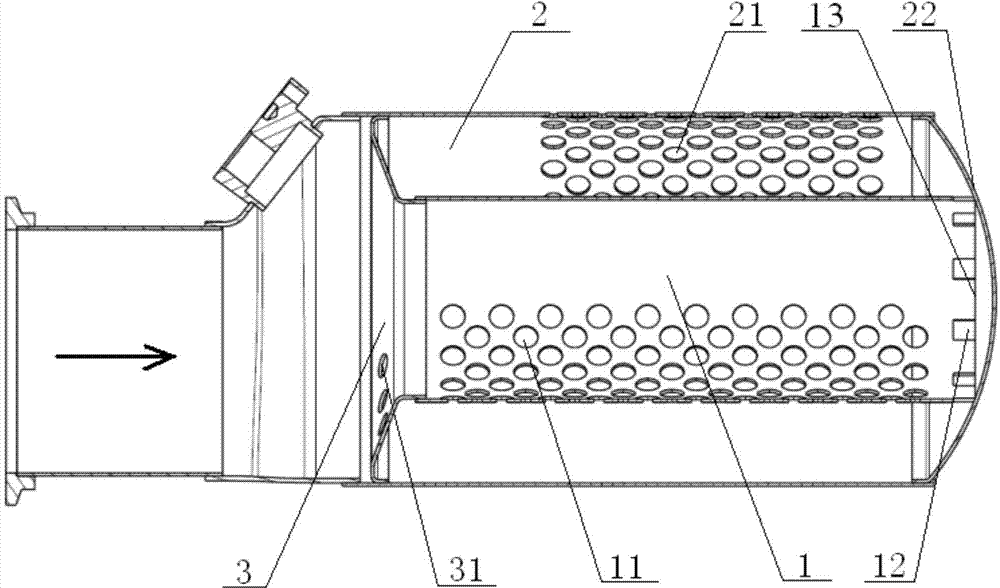

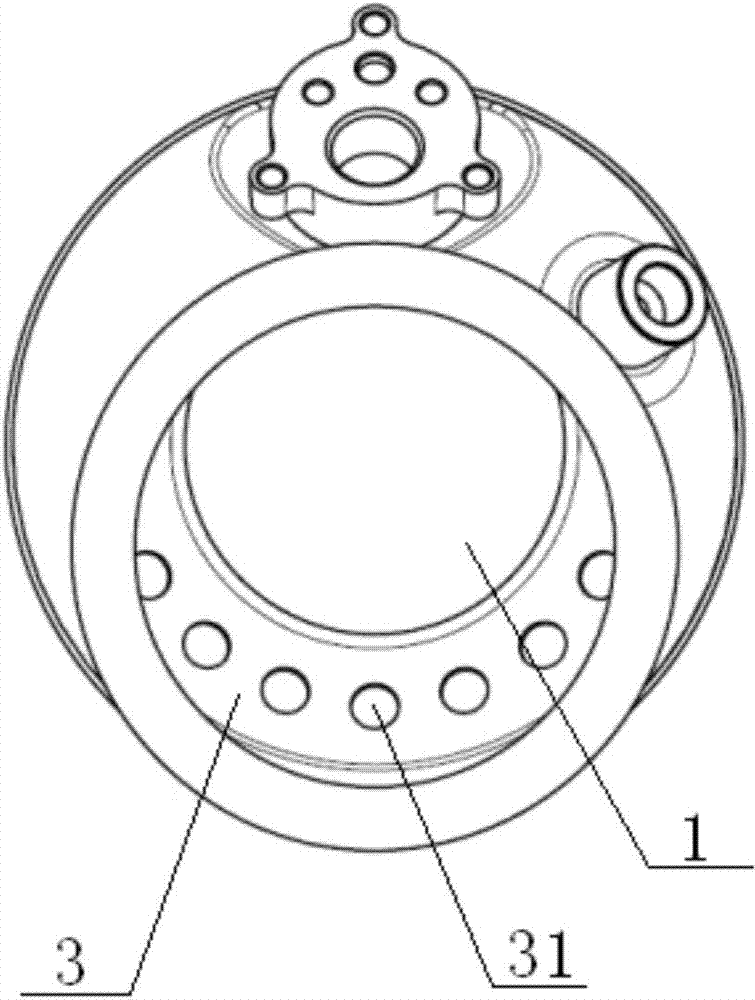

[0037] The core of the present invention is to provide an intake pipe of an SCR exhaust gas treatment system. The intake pipe increases the flow velocity of the airflow by setting a multi-layered guide pipe, thereby reducing the crystallization of urea, and can disturb the airflow, thereby Improve the conversion efficiency of nitrogen oxides. On this basis, another core of the present invention is to provide an SCR exhaust gas treatment system using the above-mentioned intake pipe.

[0038] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] It should be noted that the orientation word "intake end" in this article refers to figure 2 In the left end, the orientation word "bottom" refers to the figure 2 It should be understood that the appearance of these orientation wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com