Circuit board heat conduction optimization design structure for onboard aviation product

An airborne aviation product, optimized design technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of inability to meet the needs of heat dissipation, poor achievability, etc., to eliminate air gaps, improve temperature rise control, and reduce contact heat. blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

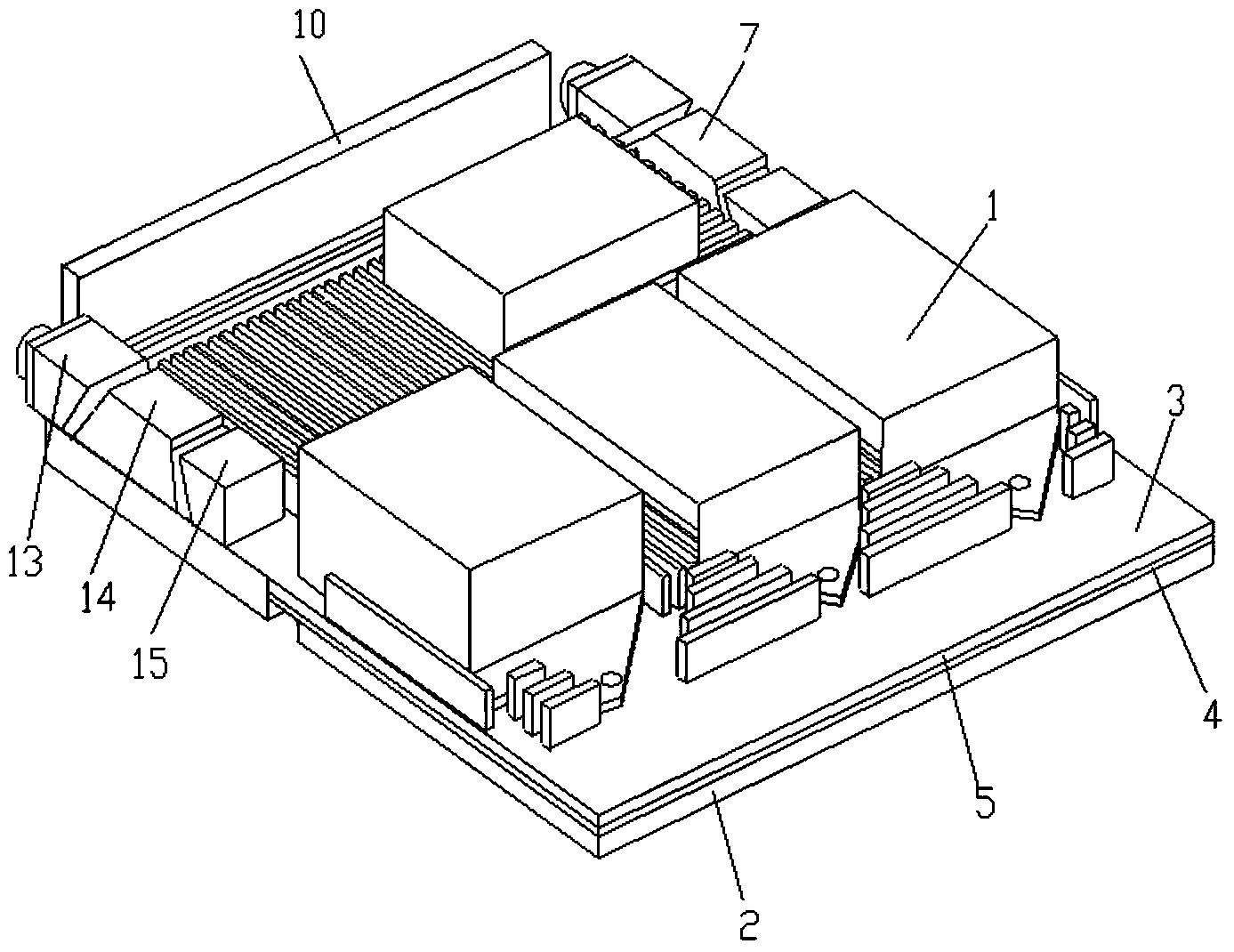

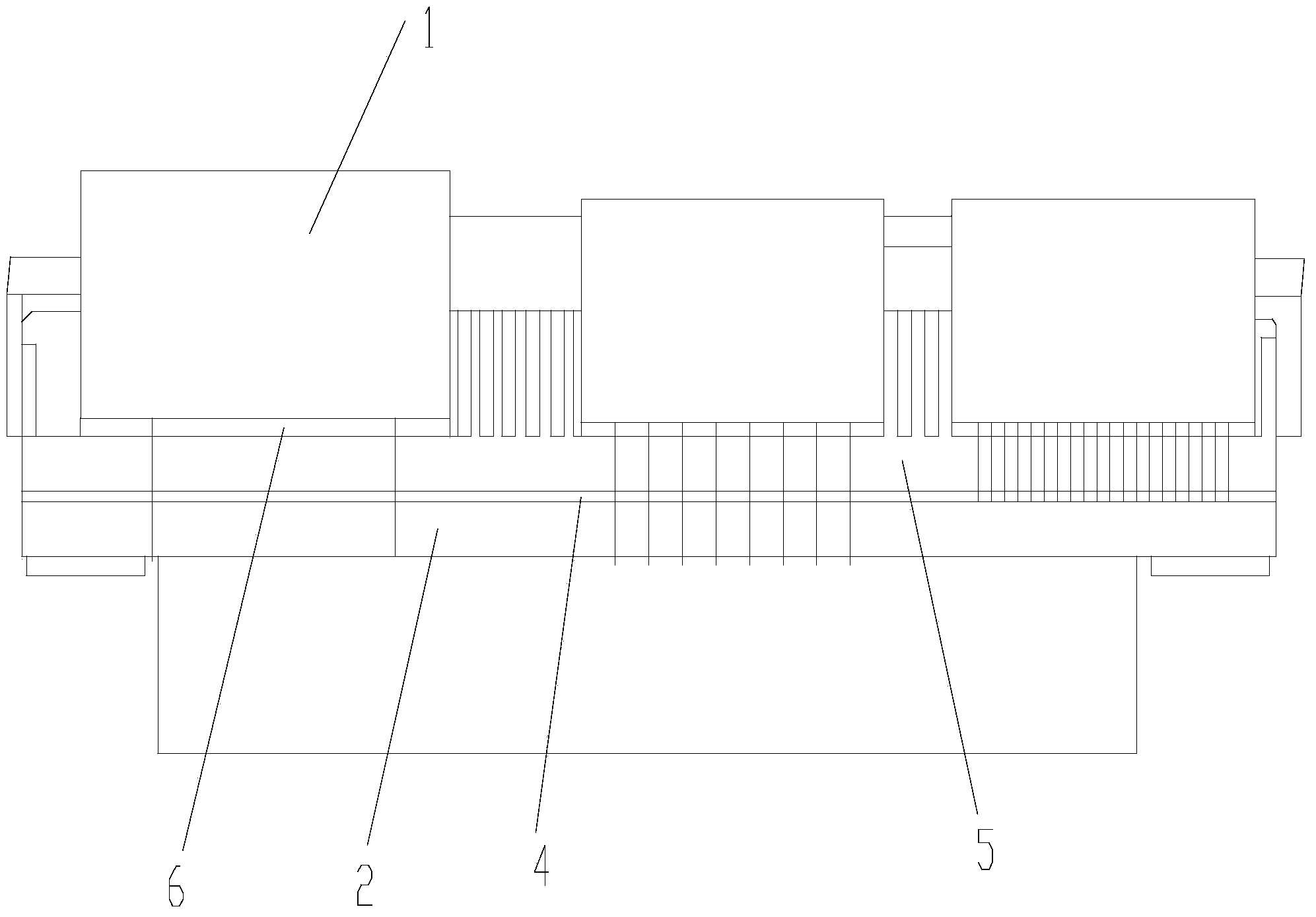

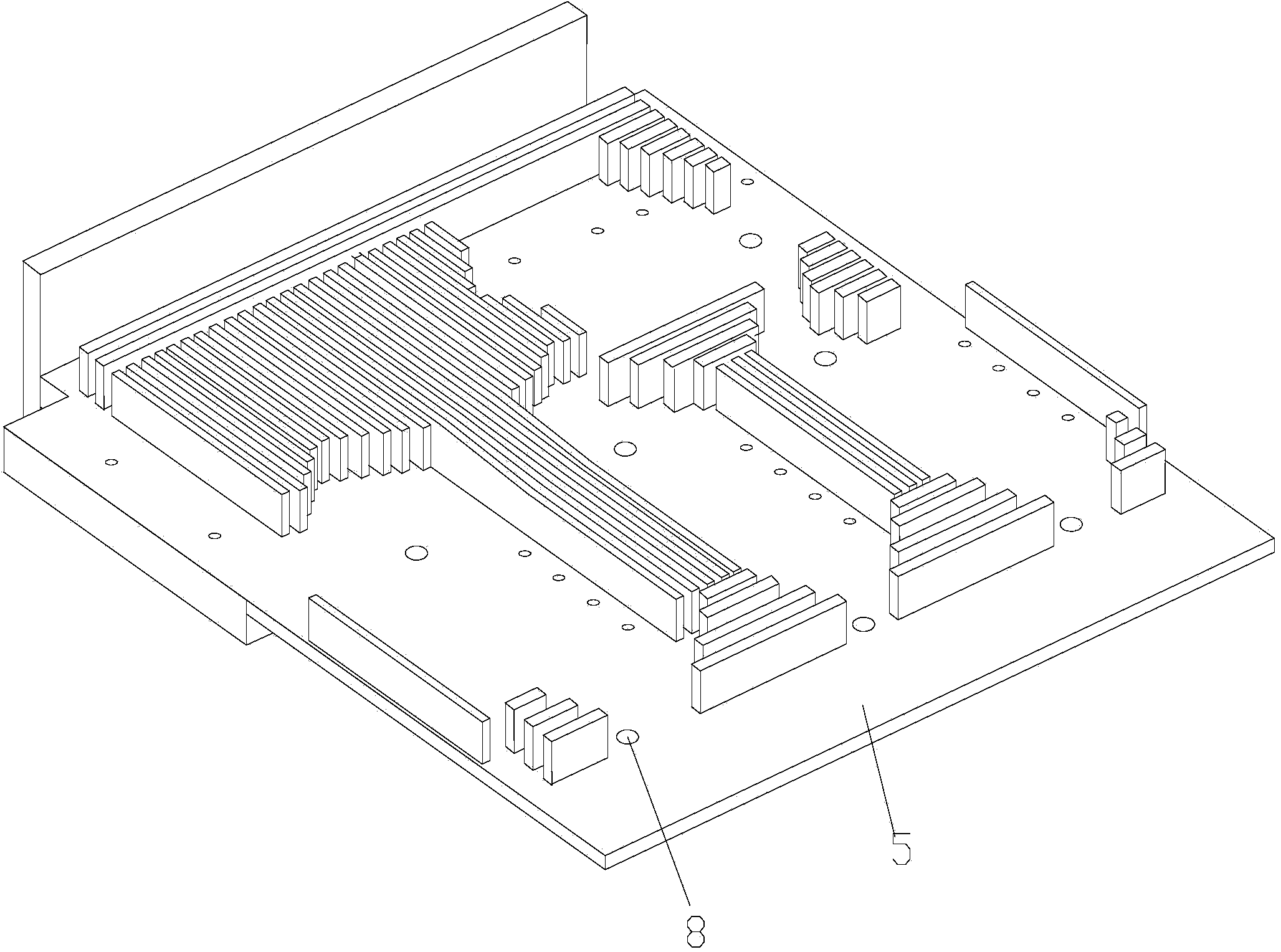

[0024] Attached below Figure 1-5 An embodiment of the present invention is described.

[0025] The circuit board thermal conduction optimization design structure used for airborne aviation products is provided with a heat conducting plate 3 between the high-power and high-heating device 1 and the PCB board 2 . The heat-conducting plate 3 is composed of an insulating partition 4, a heat-conducting aluminum plate 5, and a wedge-shaped pressing mechanism 7. Specifically, the wedge-shaped pressing mechanism 7 is composed of a screw 12, an upper wedge 13, a middle wedge 14, and a lower wedge 15. Composition, a triangular notch is formed between the upper wedge 13 and the lower wedge 15, the middle wedge 14 is an inverted triangle and is incorporated into the triangular notch, the screw 12 passes through the upper wedge 13, the middle wedge 14 and is fixed on The lower wedge-shaped piece 15 on the upper end surface of the heat-conducting aluminum plate 5 is screwed together. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com