Multifunctional food processing platform

A multi-functional food and food processing technology, which is applied in the direction of household machinery for filtering food, household appliances, applications, etc., can solve the problems that the wide load of the driving mechanism cannot be realized, the switching of functions cannot be realized, and the damage of the food processing platform can be reduced. The effect of occupying an area of space, ensuring the service life, and reducing the number of purchases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

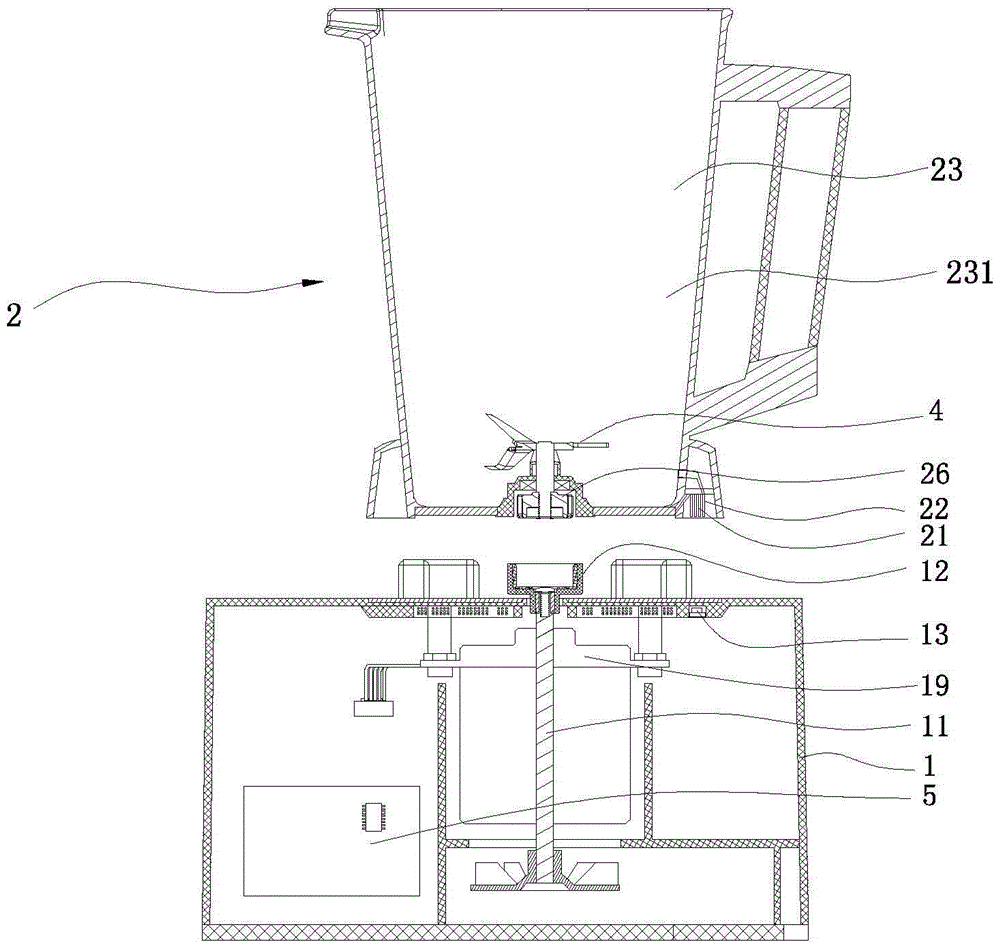

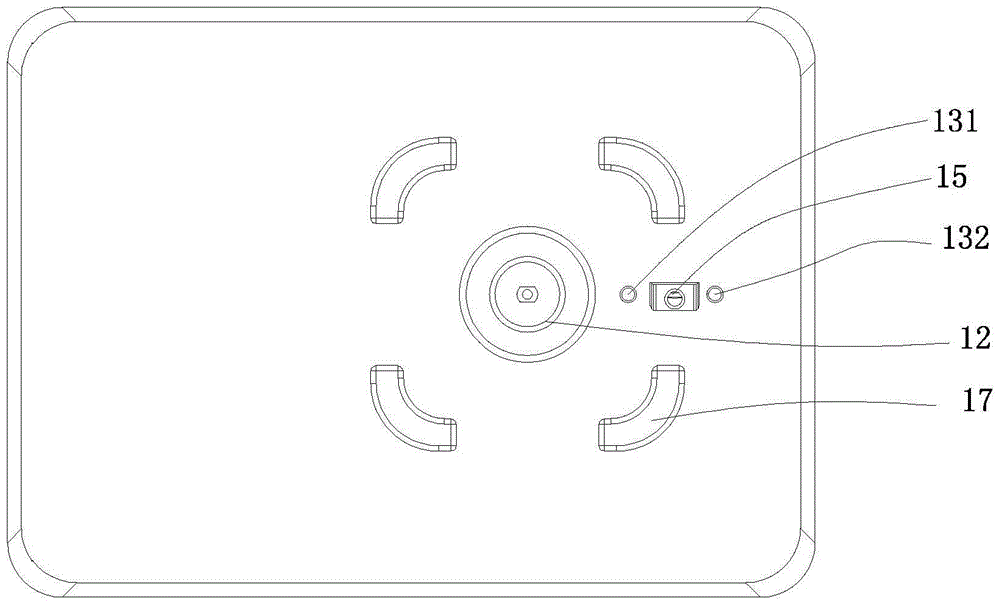

[0048] The multifunctional food processing platform of the present invention, such as figure 1 and figure 2 As shown, a machine base 1 is included, and the machine base 1 is provided with a mounting structure 17 through which the food processing assembly 2 is installed on the machine base 1 . The installation structure 17 is four bumps arranged on the machine base 1, and the food processing assembly 2 is a crushing food processing assembly 23, including a cup body 231 and a stirring and crushing tool 232. The outer shape of the bumps and The inside shape of the bottom of the cup body 231 is matched to facilitate the installation of the cup body 231. The base 1 is provided with a main output mechanism 14, and the main output mechanism 14 outputs power to the food through a coupling. The shaft coupling of the processing assembly 2' comprises a lower shaft coupling 12 arranged on the machine base 1 and an upper shaft coupling 26 arranged on the cup body 231, the said machine ba...

Embodiment 2

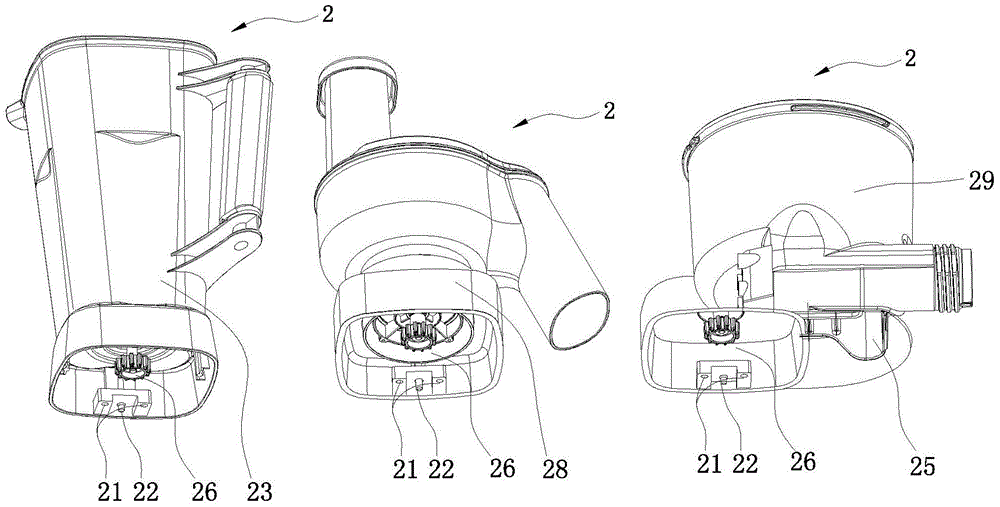

[0062] The difference between this embodiment and embodiment 1 is that, as Figure 4 As shown, the base 1 is provided with 3 output mechanisms, including 1 main output mechanism 14 and 2 auxiliary output mechanisms 18, wherein one auxiliary output mechanism 18 is arranged on the upper end of the base, and it is connected with the stirring extrusion The pressing food processing assembly 29 is connected, and the other auxiliary output mechanism 18 is arranged on one side of the machine base 1, and is connected with the extrusion juice food processing assembly 27, and the auxiliary output mechanism 18 is provided with The deceleration mechanism (not shown in the figure), the sensor 13 is a weak current switch arranged on the upper surface of the base 1, and the trigger mechanism 21 is the first mechanical ejector provided at the bottom of the food processing assembly 2, the first mechanical ejector The contact detection method is used to identify the weak current switch, so there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com