Soybean milk machine control method

A control method and technology of soymilk machine, applied in the direction of computer control, program control, general control system, etc., can solve the problems of motor temperature rise, many limitations, high cost, increase time length, simplify power-off memory circuit, Ensure intelligent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

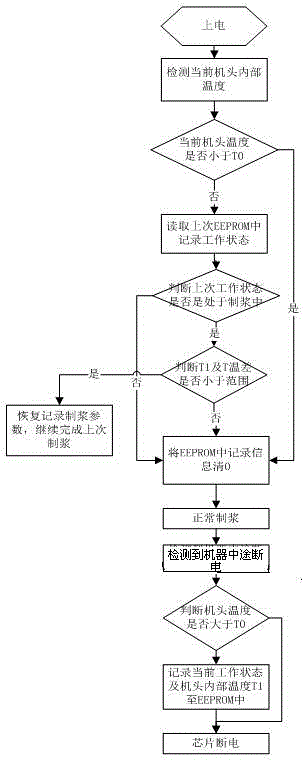

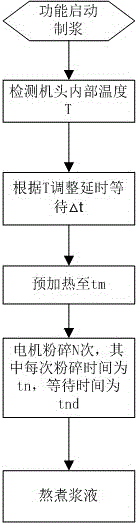

[0027] The present invention relates to a control method for a soymilk machine. The soymilk maker includes a machine head and a cup body. In the cooking stage, the motor for driving the crushing device is arranged in the machine head, wherein a temperature detection device for detecting the ambient temperature T of the machine head is provided in the machine head, and the temperature detection device is electrically connected with the control chip. The temperature threshold T0 is preset in the control chip, and the control chip adjusts the pulping process of the soybean milk machine according to the ambient temperature T of the machine head and the temperature threshold T0. In this embodiment, the control chip controls the pulping process of the soybean milk machine to enter the heating stage after a delay of Δt according to the relationship between the ambient temperature T of the machine head and the temperature threshold T0. Wherein the temperature threshold T0≥40°C.

[00...

Embodiment 2

[0036] The difference between this embodiment and the above-mentioned embodiment is that the crushing stage includes multiple intermittent operations of the motor, wherein the nth motor operation time is tn, and the intermittent waiting time is tnd. The relationship between the threshold T0, adjust the intermittent waiting time tnd. When T≥T0, tnd≥120s.

[0037] In this embodiment, when the ambient temperature T<temperature threshold T0, the interval waiting time tnd is generally equal and generally 30s. Of course, it is the same as the embodiment 1. This waiting time depends on different functional programs and the characteristics of the ingredients. Different options are different, generally set within 120s, so as to be able to control the pulping time as a whole. Therefore, in this embodiment, when the ambient temperature T is greater than the temperature threshold T0, the interval waiting time is set to 120s. As long as it is greater than such a temperature value, it can ...

Embodiment 3

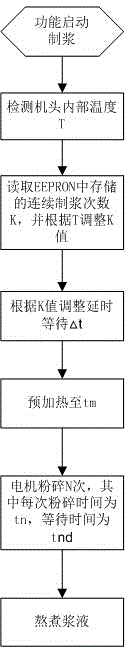

[0043] The difference between this embodiment and the above-mentioned embodiment is that the number K of continuous pulping of the soybean milk machine is also stored in the control chip, and the control chip updates the number K of continuous pulping according to the relationship between the ambient temperature T of the machine head and the temperature threshold T0 , when T≤T0, the number of continuous pulping K is updated to 0; when T≥T0, the number of continuous pulping K is updated to K+1. The control chip enters the heating stage after adjusting the delay Δt according to the number K of continuous pulping. Set the basic waiting time t0, each adjustment coefficient is t, Δt=t0+t*k.

[0044] That is to say, in this embodiment, by detecting the ambient temperature, it is judged whether the soymilk machine is continuously making pulp. When the ambient temperature TT0, the K value is accumulated. According to the accumulation of the K value, the number of continuous operations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com