Method for preparing wide bandgap nanometer cadmium sulfide thin film

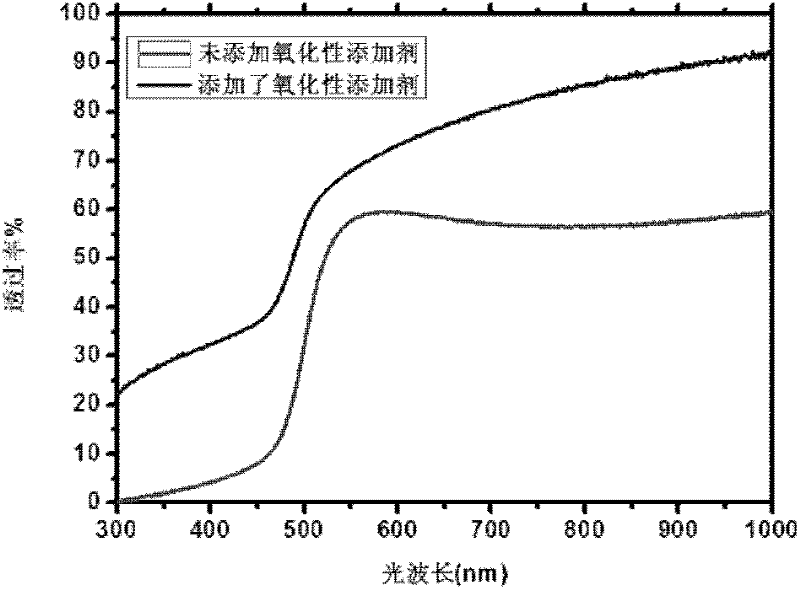

A cadmium sulfide, wide bandgap technology, applied in the field of new energy materials and its preparation, to achieve the effect of reducing short-wave absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Use ITO glass soaked in organic solvent for many days as the substrate, clean the ITO glass with hot alkali solution (NaOH with a pH of 11-13, 50-80°C), and use ultrasonic cleaning technology, and use organic solvent ultrasonic 2-10 Minutes to clean, heated and dried, clamped vertically into the reaction vessel.

[0029] Add 1-10*10-3mol / L cadmium salt (commonly used sulfate, nitrate, chloride, acetate, etc.) 400ml deionized water, as indicated figure 1 Put a magnetic stirrer at the bottom of the container, start the magnetic stirrer and heat it to an appropriate temperature (70-90°C), add an appropriate amount of weak alkali solution (ammonia water) to adjust the pH to 9-11,. The reaction solution of the first step is formed.

[0030] 1. The concentration of liquid oxidizing additive is 1-10*10 -2 mol / L.

[0031] 2. After the weak base solution fully reacts, add 1-10*10 -2 mol / L oxidizing additive, the oxidant is organic peroxide (ROOH) (using peroxymonosulfuric ...

Embodiment 2

[0034] 1. Use ITO glass soaked in organic solvent for many days as the substrate, clean the ITO glass with hot alkali solution, clean it with ultrasonic waves, blow dry it, and put it vertically into the reaction vessel with clips.

[0035] 2. Add 1-10*10 to the container -3 mol / L cadmium salt and 1-10*10 -2 mol / L ammonium salt of the same acid group, then add 200ml deionized water, put a magnetic stirrer at the bottom of the container, start the magnetic stirrer and heat the temperature to an appropriate temperature, add an appropriate amount of ammonia water to adjust the pH value to 7-13.

[0036] 3. Add 1-50*10 after the weak base solution fully reacts -3 mol / L thiourea solution. After reacting for 8-30 minutes, add 1-10*10 -2 mol / L oxidizing additive, the oxidizing agent is organic peroxide (ROOH), organic peroxyacid (RCOOOH), ozone (O 3 ), periodate, 2%~30% hydrogen peroxide (H 2o 2 ), the amount added is 1% to 10% of the molar number of cadmium salt; when adding l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com