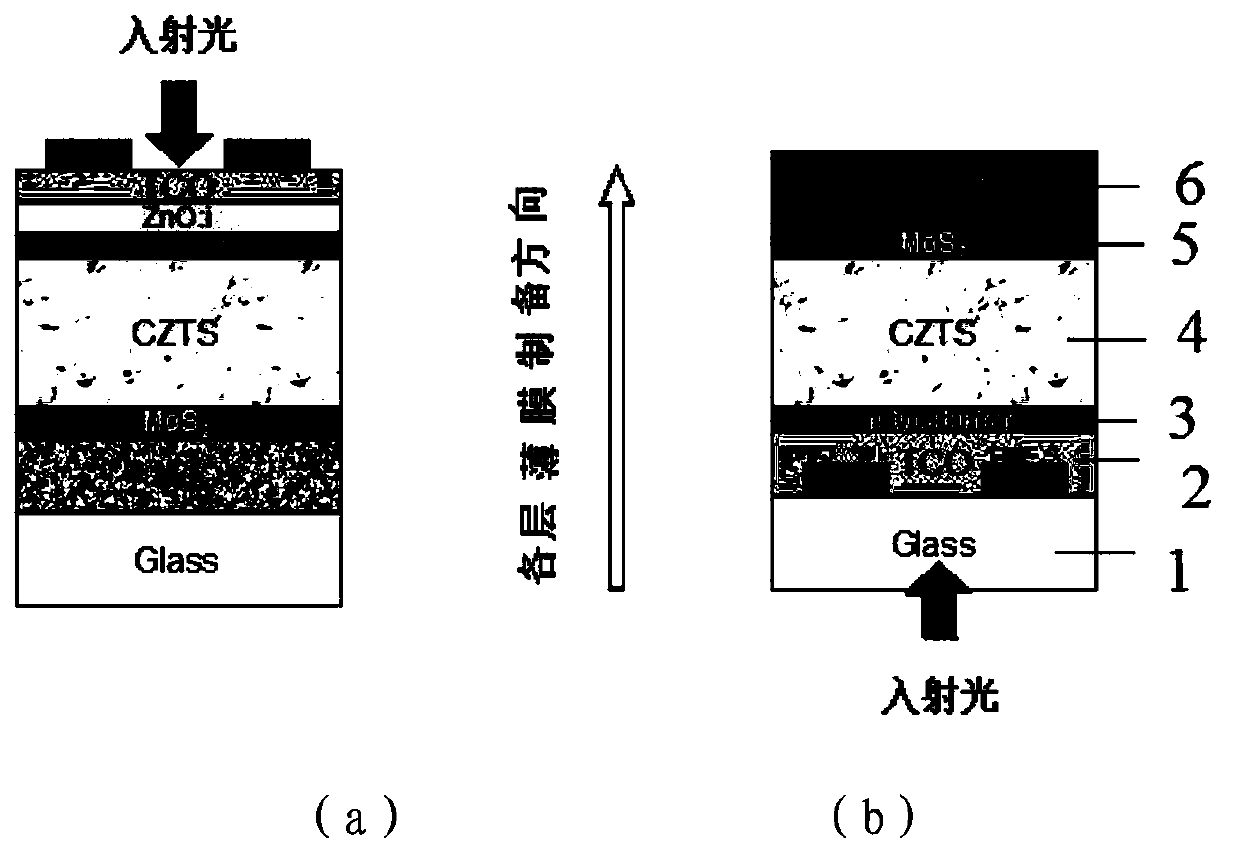

Laminated structure of copper-zinc-tin-sulfur film solar cell and preparation method thereof

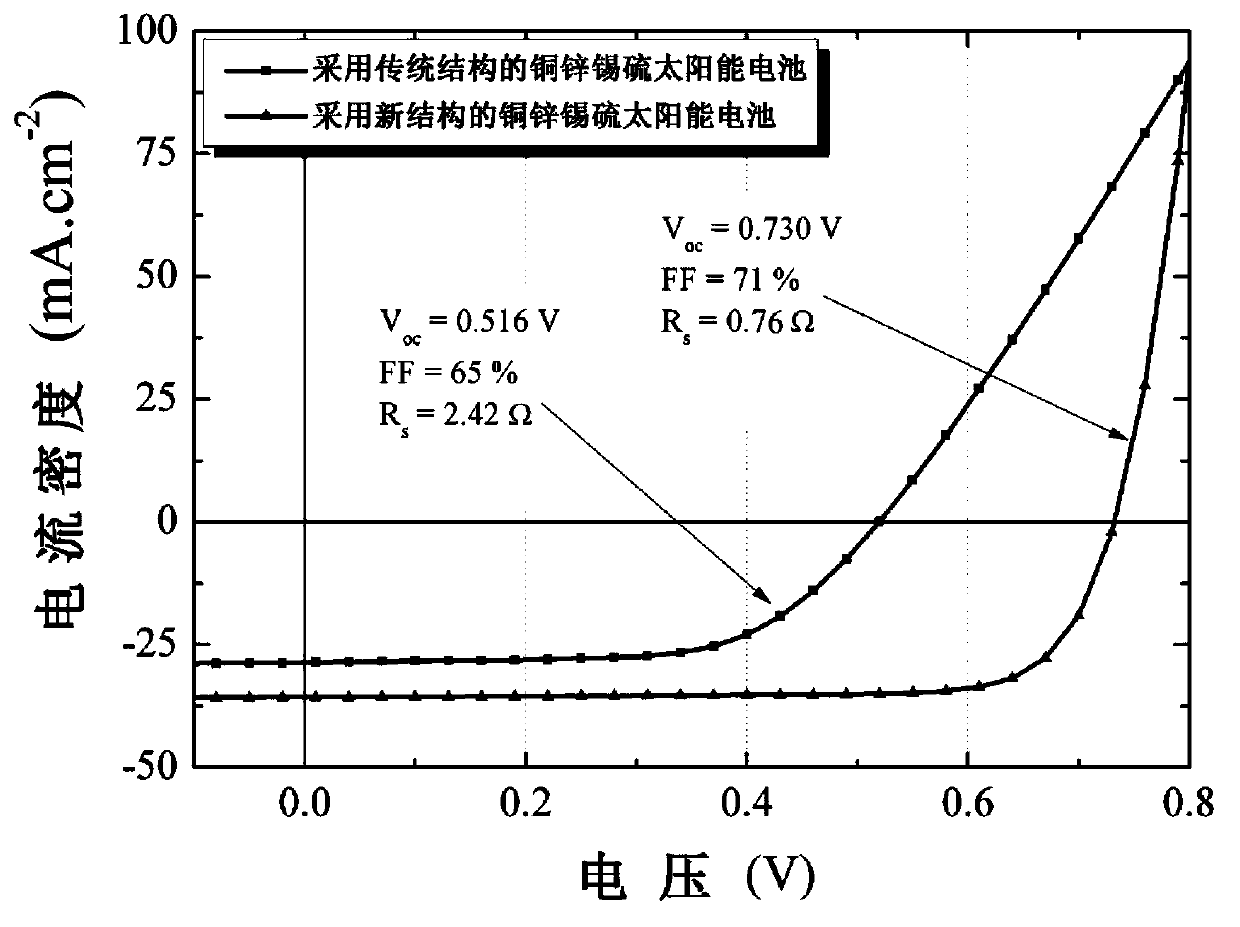

A solar cell, copper-zinc-tin-sulfur technology, applied in the manufacture of circuits, electrical components, final products, etc., can solve problems such as low open circuit voltage and fill factor, and achieve the effect of increasing series resistance and flat and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Step 1. In the order of acetone, methanol, and isopropanol, clean a square substrate glass with a side length of 2 cm with high light transmittance (light transmittance > 80%) with the above three reagents for analytical purity, and blow dry with nitrogen .

[0036] Step 2. Evaporating silver / nickel alloy grids on the glass substrate by vacuum evaporation method.

[0037] Step 3. Next, magnetron sputtering is used to sputter an indium tin oxide (ITO) transparent conductive layer on the silver / nickel alloy grid side of the glass substrate, with a layer thickness of 150 nanometers.

[0038] Step 4, depositing an n-type cadmium sulfide buffer layer on the indium tin oxide layer with a chemical bath method, with a layer thickness of 50 nanometers.

[0039] Step 5, continue to prepare a uniform and dense p-type copper-zinc-tin-sulfur absorption layer on the n-type buffer layer by thermal injection spraying method, with a layer thickness of about 2 microns, thereby forming a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com