Organic sulfur compound anode material, and aluminum ion battery and anode piece for aluminum ion battery

A composite cathode material, aluminum ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low overall capacity, affecting the capacity of carbon-sulfur composite materials, etc., to improve product qualification rate, good market prospects, The effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

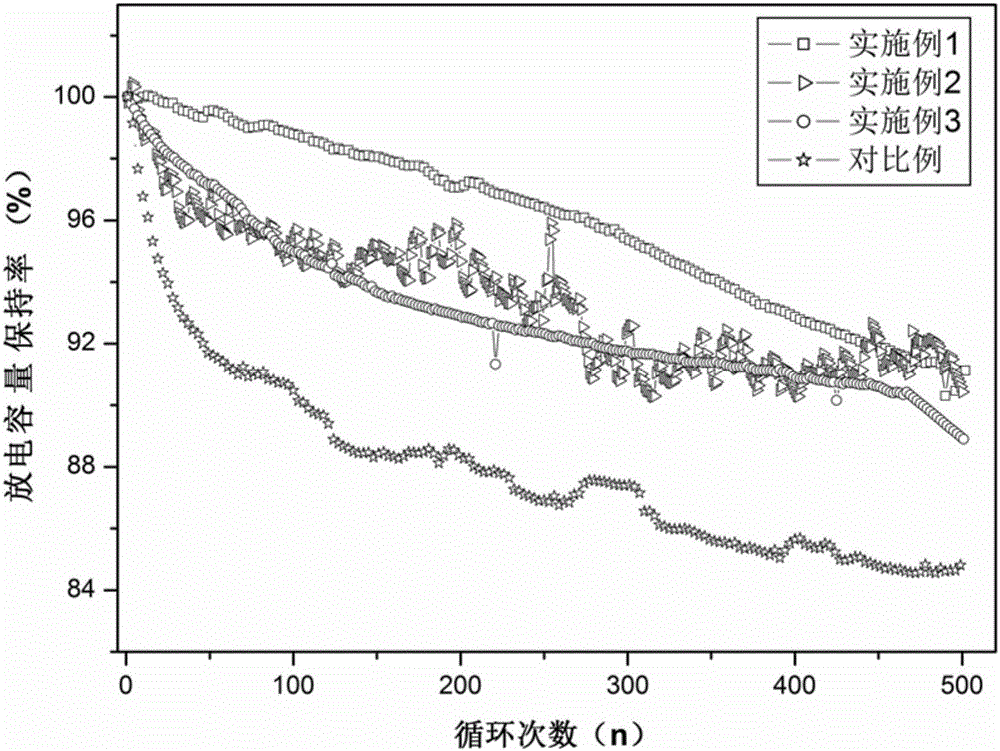

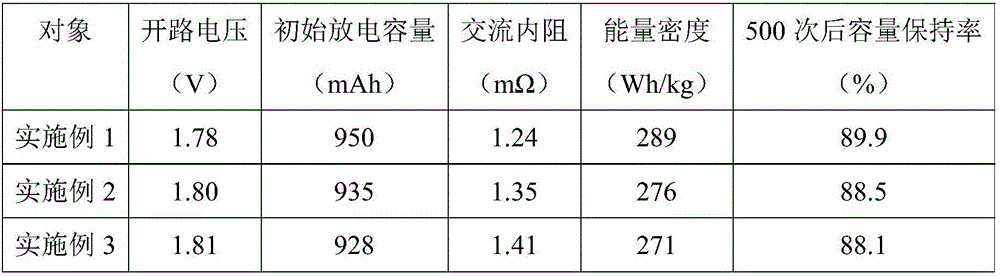

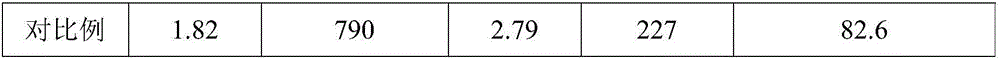

Examples

Embodiment 1

[0035] The organosulfur composite positive electrode material of this embodiment is prepared by the following method:

[0036] Dissolve 30g of polypropylene carbonate (high molecular polymer) in 300g of dimethyl carbonate, stir at a low speed for 15min to obtain a polymer solution, add 10g of vulcanized polyacetylene powder (C:S=1:3) to the In the above polymer solution (mass ratio of high molecular polymer to organic sulfur powder is 30:10), after stirring for 30 minutes, filter the filter residue, wash it with deionized water, and then dry it at 70°C under the protection of argon , to obtain the organic sulfur composite cathode material.

[0037] The aluminum ion battery positive pole sheet of the present embodiment is prepared by the following method:

[0038] 1) Composite binder preparation: Take 40g of polyacrylic acid, 15g of polypropylene glycol, 40g of polyvinylidene fluoride, and 5g of vinyl carbonate and add them into a high-speed disperser and stir and mix for 1 ho...

Embodiment 2

[0041] The organosulfur composite positive electrode material of this embodiment is prepared by the following method:

[0042]Dissolve 10g of polymethyl acrylate (high molecular weight polymer) in 300g of diethyl carbonate, stir at a low speed for 15min to obtain a polymer solution, add 5g of carbyne polysulfide powder (C:S=1:2) to the In the above polymer solution (mass ratio of polymer to organic sulfur powder is 10:5), after stirring for 30 minutes, filter the filter residue, wash it with deionized water, and then dry it at 70°C under the protection of argon , to obtain the organic sulfur composite cathode material.

[0043] The aluminum ion battery positive pole piece of the present embodiment is prepared by the following method:

[0044] 1) Composite binder preparation: Take 30g of polyacrylic acid, 19g of polypropylene glycol, 50g of polyvinylidene fluoride, and 1g of vinyl carbonate and add them into a high-speed disperser and mix them for 1 hour to obtain a composite ...

Embodiment 3

[0047] The organosulfur composite positive electrode material of this embodiment is prepared by the following method:

[0048] 50g of polymethyl methacrylate (macromolecular polymer) was dissolved in 500g of ethyl methyl carbonate, stirred at a low speed for 15min to obtain a polymer solution, and 20g of polythiopolystyrene powder (C:S=1: 5) Add it into the polymer solution (mass ratio of high molecular polymer to organic sulfur powder is 50:20), stir for 30 minutes, filter the filter residue, wash it with deionized water, and then heat it at 70°C under argon gas. drying under protection to obtain the organosulfur composite cathode material.

[0049] The aluminum ion battery positive pole piece of the present embodiment is prepared by the following method:

[0050] 1) Composite binder preparation: take 50g of polyacrylic acid, 20g of polypropylene glycol, 25g of polyvinylidene fluoride, and 5g of vinyl carbonate and add them into a high-speed disperser and stir and mix for 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com