Solid oxide fuel cell tail gas treatment system and treatment method

A solid oxide and fuel cell technology, applied in fuel cells, electrical components, circuits, etc., can solve problems such as low energy utilization, achieve the effects of reducing emissions, energy-saving utilization, and avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 Solid Oxide Fuel Cell Exhaust Gas Treatment System Based on Solid Oxide Electrolyzer

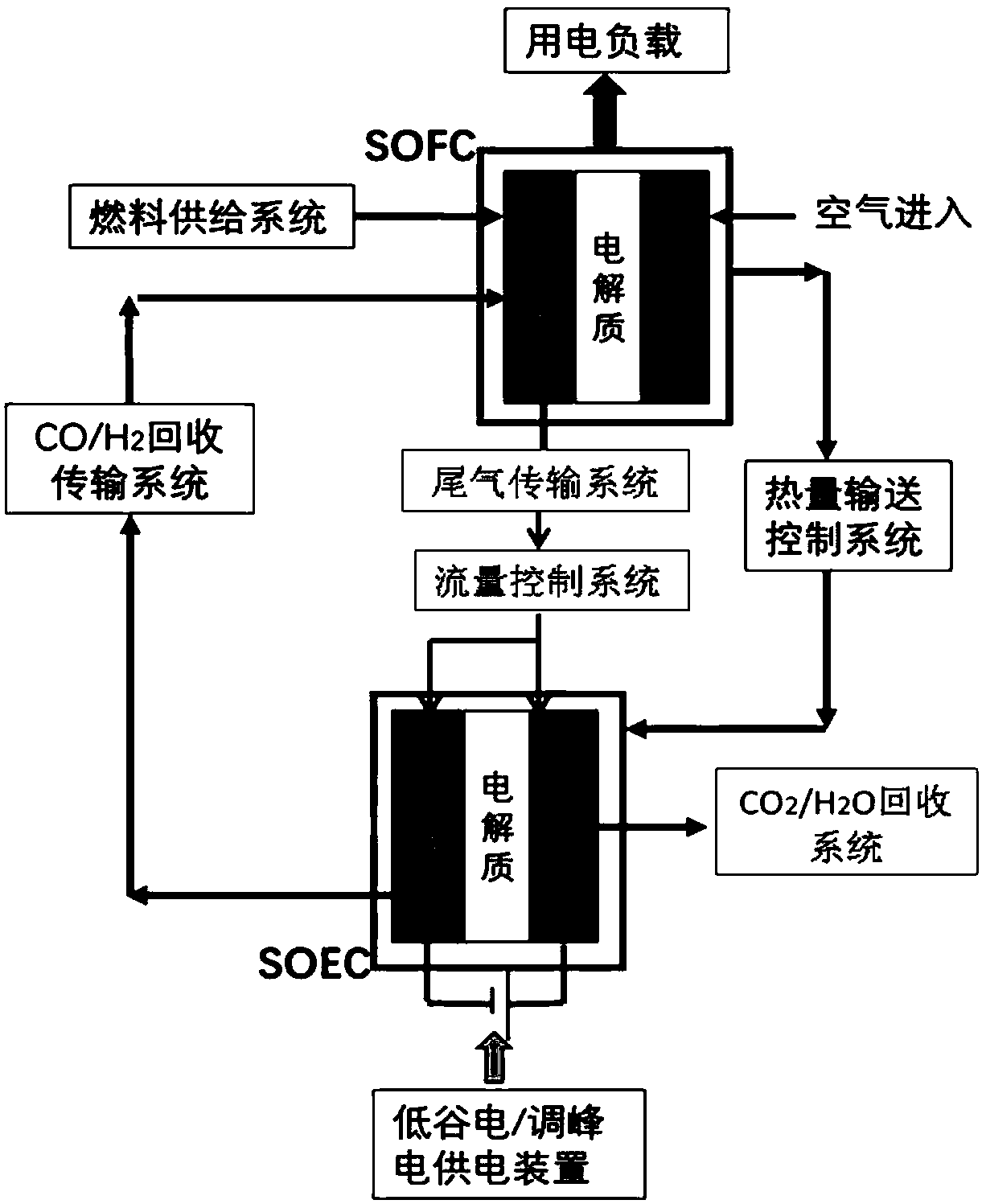

[0046] Solid oxide fuel cell tail gas treatment system based on solid oxide electrolytic cell, including solid oxide fuel cell, solid oxide electrolytic cell, heat transfer control system, tail gas transfer system, CO / H 2 Recovery transfer system, CO 2 / H 2 O Recovery system, fuel supply system, power load and low-peak / peak-shaving power supply device. The solid oxide fuel cell is connected with the electric load, and the generated electric energy is delivered to the electric load; the fuel supply system is connected with the anode of the solid oxide fuel cell, and provides fuel gas for the solid oxide fuel cell; the solid oxide fuel cell The anode of the battery is connected to the anode and cathode of the solid oxide electrolytic cell through the tail gas transmission system, and a flow control system is set between the tail gas transmission system and the solid oxide el...

Embodiment 2

[0047] Example 2 Solid Oxide Fuel Cell Tail Gas Treatment Method 1 Based on Solid Oxide Electrolyzer

[0048] S1, the air is passed into the cathode side of the solid oxide fuel cell, and the oxygen in the air is reduced to oxygen ions by the electrolyte.

[0049] S2. At this time, the fuel gas gas is passed into the anode side of the solid oxide fuel cell through the fuel supply system, and the oxygen ions permeated by the electrolyte enter the anode and H 2 combined to form H 2 O, combined with CO to form CO 2 , producing CO 2 and H 2 O, and release electrons to the external circuit for power generation, which is connected to the converter and electric load.

[0050] S3, the exhaust gas produced by the solid oxide fuel cell anode has CO 2 and H 2 In addition to O, there is also part of the unreacted fuel gas, and the tail gas is transported to the solid oxide electrolytic cell anode and cathode by the tail gas transmission system, and at the anode, the H in the tail ga...

Embodiment 3

[0052] Example 3 Solid Oxide Fuel Cell Tail Gas Treatment Method 2 Based on Solid Oxide Electrolyzer

[0053] S1, the air is passed into the cathode side of the solid oxide fuel cell, and the oxygen in the air is reduced to oxygen ions by the electrolyte.

[0054] S2. At this time, the fuel gas gas is passed into the anode side of the solid oxide fuel cell through the fuel supply system, and the oxygen ions permeated by the electrolyte enter the anode and H 2 combined to form H 2 O, combined with CO to form CO 2 , producing CO 2 and H 2 O, and release electrons to the external circuit for power generation, which is connected to the converter and electric load.

[0055]S3, the exhaust gas produced by the solid oxide fuel cell anode has CO 2 and H 2 In addition to O, there are some unreacted fuel gases, and the tail gas is transported to the anode and cathode of the solid oxide electrolytic cell through the tail gas transmission system. A flow control system is arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com