High-efficiency thin-film solar component battery structure and implementation method thereof

A thin-film solar energy and battery technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of limited inverter types, unfavorable system integration, and high output voltage, so as to save installation time, enhance flexibility, and have effective output voltage Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

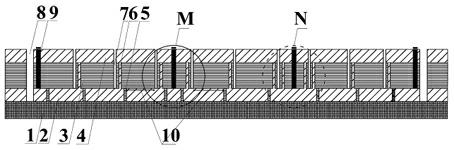

[0020] This embodiment is an amorphous silicon single-junction thin-film solar module in which each photovoltaic unit is connected in series to form three groups of photovoltaic cells. image 3 , 4 , 5, 6.

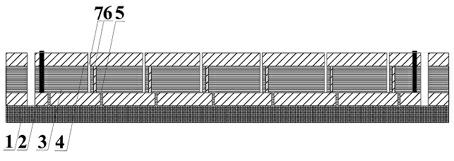

[0021] A high-efficiency thin-film solar module cell structure, ( image 3 ) including substrate glass 1, front electrode film layer 2, photoelectric absorption layer 3, back electrode film layer 4, encapsulation film and back plate, by adjusting laser scribed front electrode film layer isolation trench 5, photoelectric absorption layer isolation trench channel and current lead-out channel 6, the number of scribing times and the scribing position of the back electrode film layer isolation channel 7, so that the battery structure of the thin film module is adjusted from the series structure between each photoelectric unit to each photoelect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com