Local passivation contact IBC battery structure and preparation method thereof

A local, passivation film technology, applied in the field of solar cells, which can solve problems such as optical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

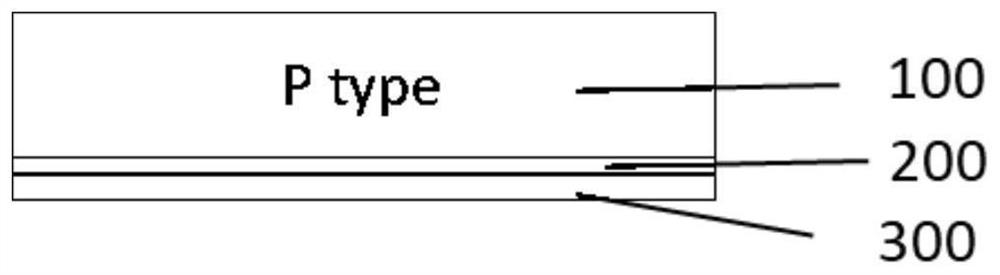

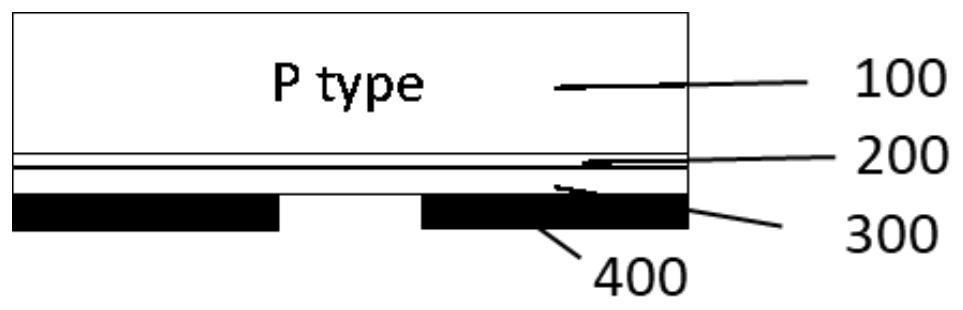

[0024] An IBC solar cell with partial back passivation contact, comprising a P-type crystalline silicon substrate 100, the back surface of the P-type crystalline silicon substrate 100 sequentially includes tunnel oxide layers 200, alternately arranged back surface n+ doped The impurity layer 300 and the p+ doped region 101 at the groove on the back surface, the passivation film 503 on the back surface, and the metal electrode on the back surface; Front surface passivation film 501 and anti-reflection film 502;

[0025] The antireflection film 502 includes SiO 2 and / or Al 2 o 3 dielectric film and SiNx dielectric film or SiOxNy, the SiO 2 The thickness of the dielectric film is 1-5nm, and the Al 2 o 3 The thickness of the dielectric film is 2-20nm, the thickness of the SiNx dielectric film is 40-100nm, and the thickness of the SiOxNy dielectric film is 40-100nm;

[0026] The tunnel oxide layer 200 and the n+ doped layer 300 constitute the emitter region on the back surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com