FeS2 film and preparation method thereof

A thin film and seed layer technology, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problems of low photoelectric conversion efficiency and poor light absorption performance, so as to increase the effective light absorption area and improve photoelectricity. Conversion efficiency and the effect of simple synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

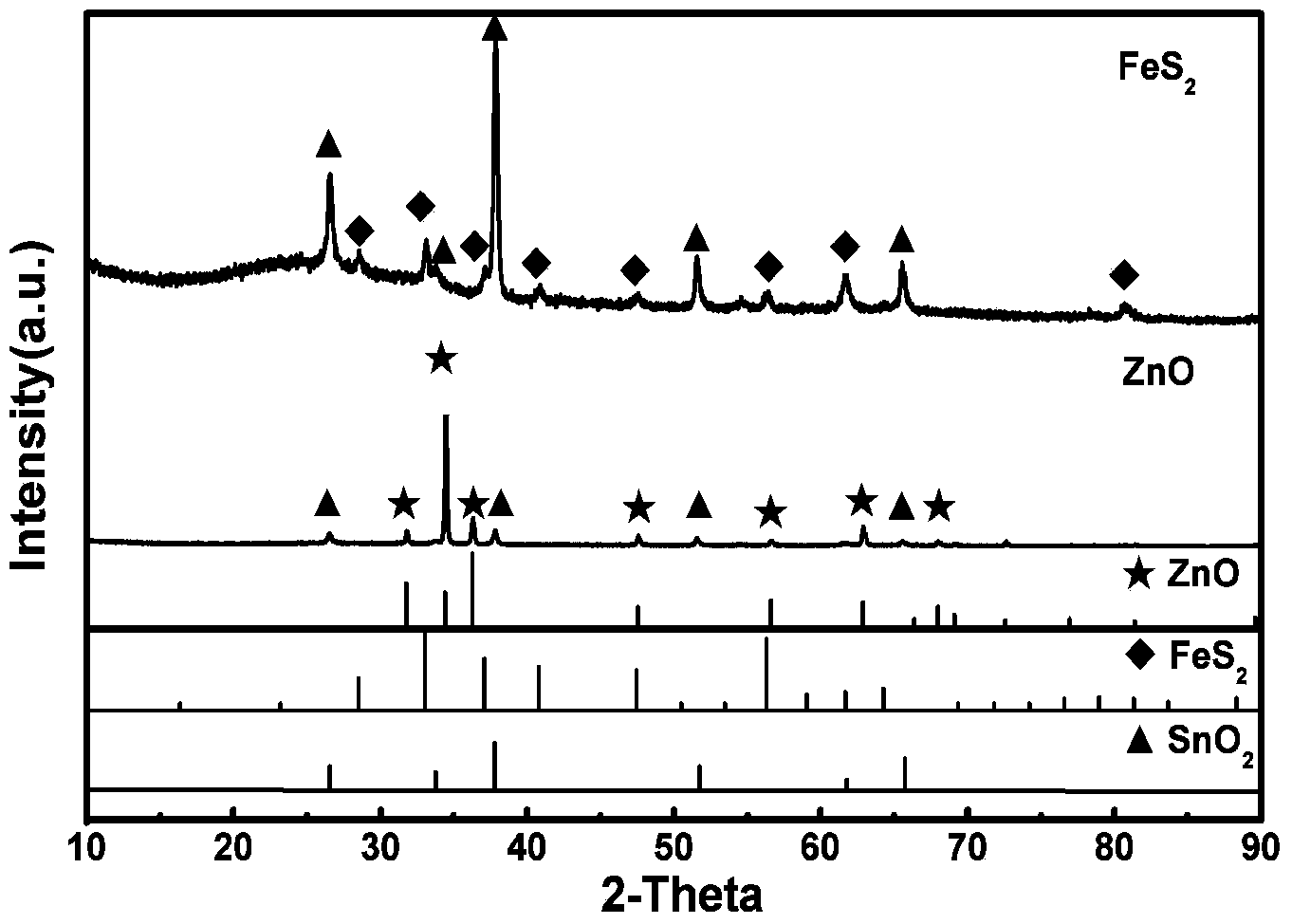

[0039] combined with Figure 1-6 , to further illustrate the present invention:

[0040] a FeS 2 The preparation method of thin film, comprises the following steps:

[0041] 1) Substrate pretreatment: In this example, the size is The conductive glass is used as the substrate, but the size of the substrate is not limited to the example of this embodiment. The substrate was ultrasonically cleaned in acetone solution for 15 minutes, then ultrasonically cleaned in absolute ethanol for 15 minutes, and finally ultrasonically cleaned in deionized water for 15 minutes; the cleaned substrate was dried in a constant temperature drying oven at 100°C, and the dried Base spare;

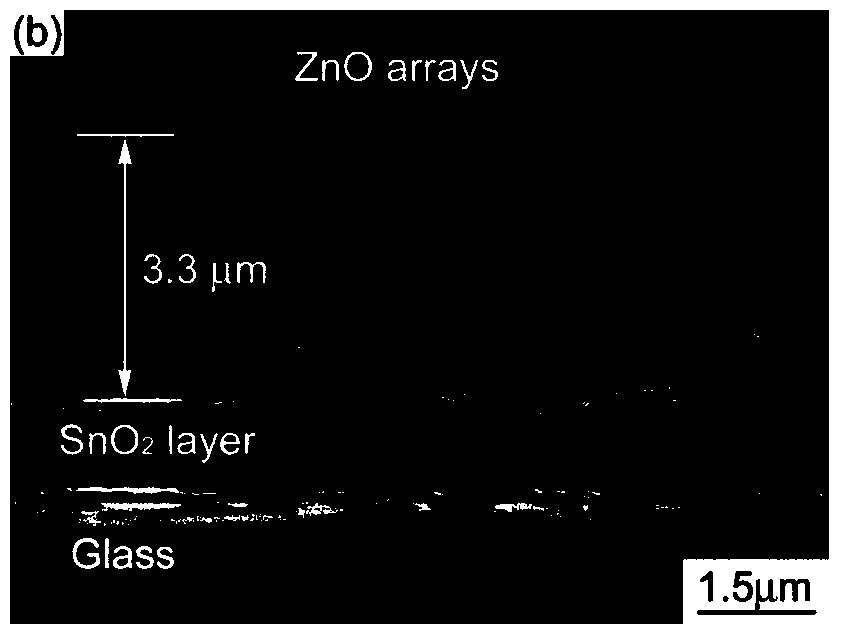

[0042] 2) Add 0.05mol of zinc acetate dihydrate to the beaker, dissolve it with 50ml of ethylene glycol methyl ether, add 3ml of ethanolamine, and stir at a constant temperature of 60°C for 30 minutes until completely dissolved, forming a uniform and transparent seed layer solution; magnetic stirring The pur...

Embodiment 2

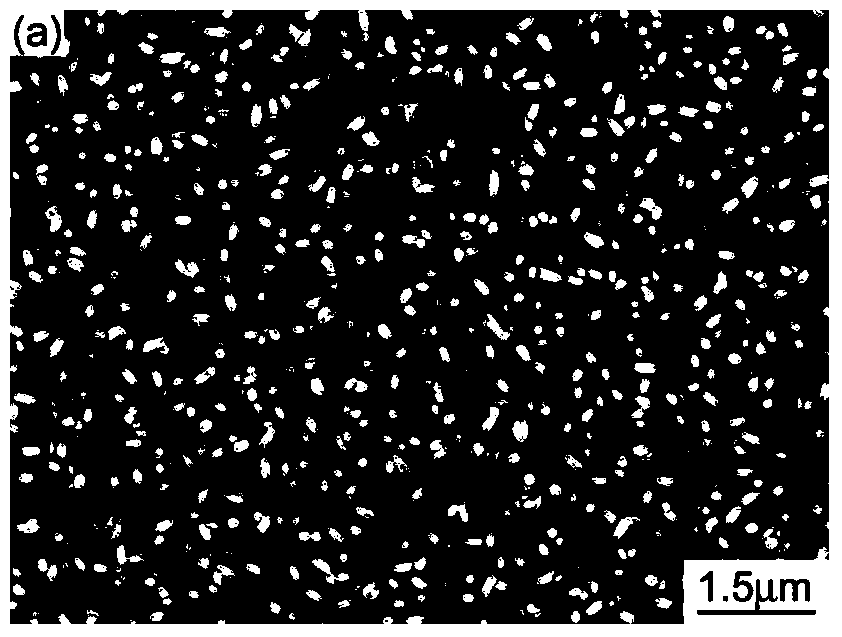

[0051] As shown in Figure 4, a FeS 2 Thin films, including FTO conductive glass substrates covered with FeS 2 array of nanorods, each FeS 2 Nanorods made of FeS 2 accumulation of nanoparticles.

[0052] by FeS 2 One-dimensional ordered FeS composed of nanoparticles 2 The nanorod array structure makes FeS 2 The film has a three-dimensional structure, and the effective light absorption area not only contains FeS 2 the top surface of the nanorods, and includes FeS 2 The outer faces of the nanorods make the FeS 2 The effective light absorption area of the film is much larger than the surface area of the substrate, which can improve the FeS 2 The effective light absorption area of the film has the advantage of improving the light absorption conversion efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com