Method for synthesizing pyrite type ferrous disulfide by hydro-thermal method

A technology of pyrite type and iron disulfide, which is applied in the direction of iron sulfide, can solve the problems of small particle size and good dispersibility, and achieve the effect of small particle size, good dispersibility and no poisonous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

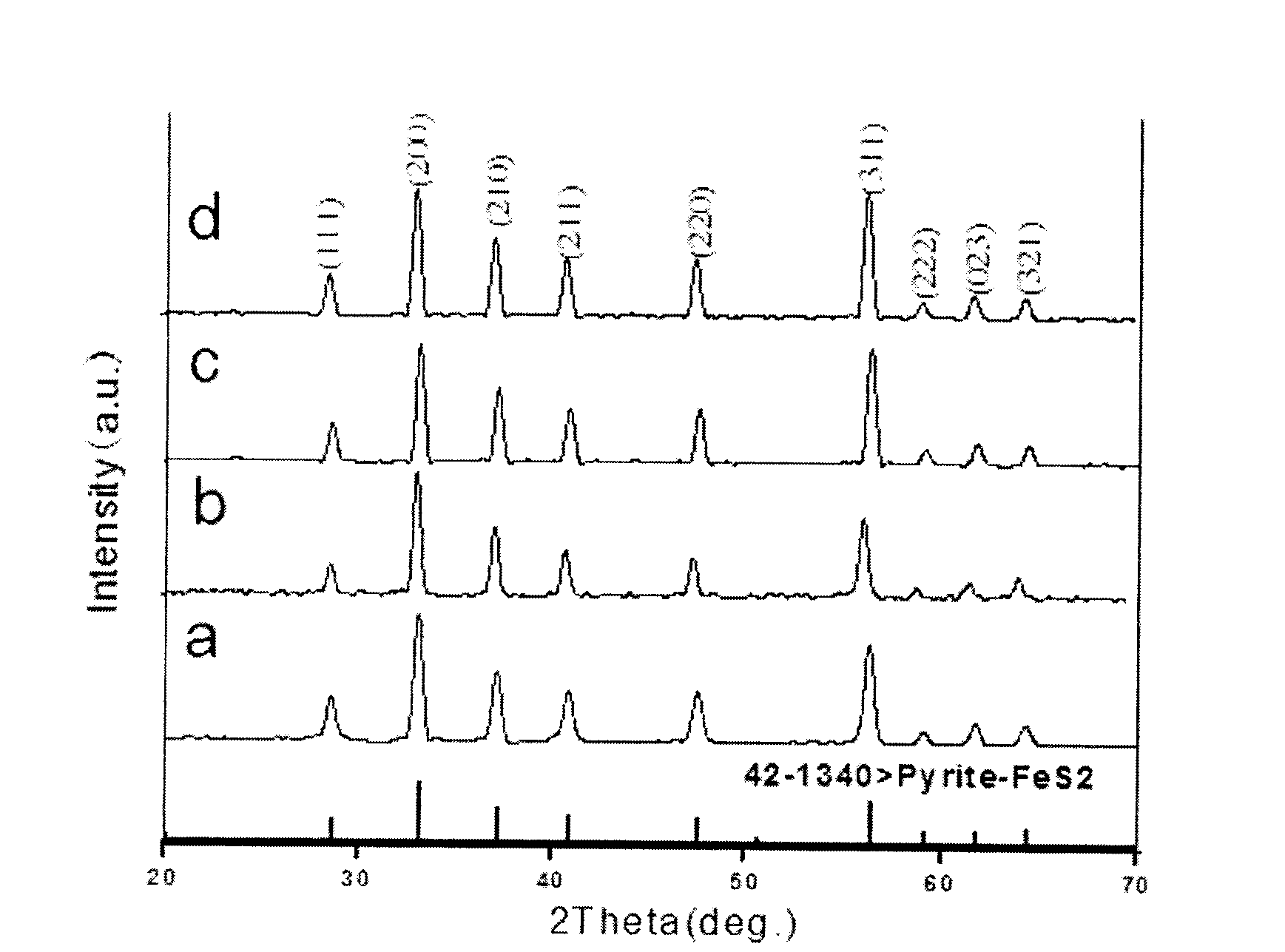

[0026] By n(FeCl 2 ): n(Na 2 S): n (S) = 1: 2: 1 molar ratio is mixed with an appropriate amount of deionized water, the mixture is heated until the elemental sulfur is completely dissolved to obtain a mixed solution, and then the mixed solution is transferred to a 100ml hydrothermal kettle, With 2.0mol / L NaOH solution and 1.4mol / LH 2 SO 4 solution to adjust the pH value of the mixed solution to 5, add deionized water to the hydrothermal kettle until the final volume of the reaction solution is 80ml; then perform a constant temperature hydrothermal reaction at 160°C for 24 hours; after naturally cooling down to room temperature, use dilute Sulfuric acid, boiling Na 2 S solution, distilled water wash, obtain pyrite type iron disulfide; figure 1 Middle a is the XRD pattern of this embodiment product.

Embodiment 2

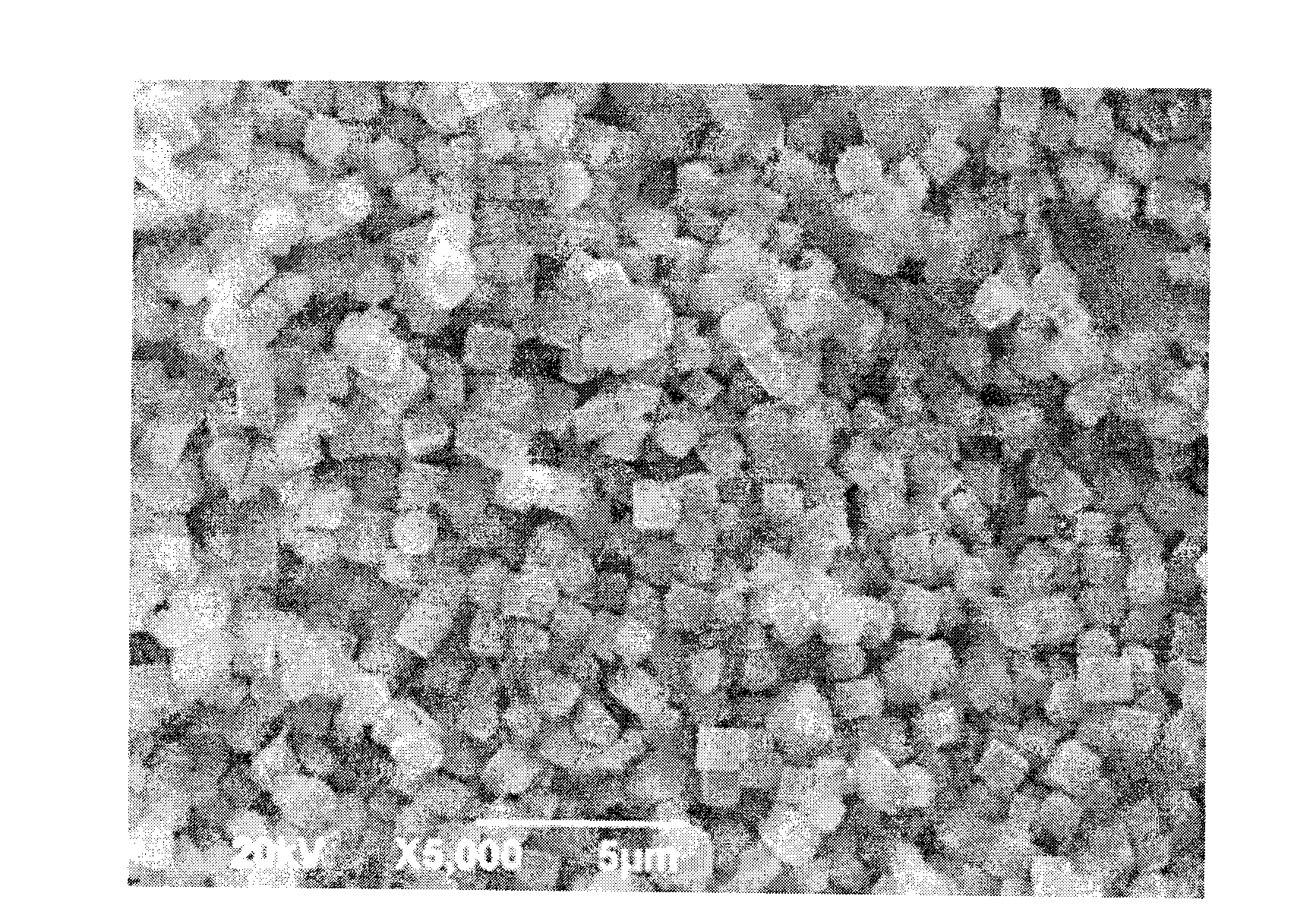

[0028] By n(FeCl 2 ): n(Na 2 S): n (S) = 1: 2: 1 molar ratio is mixed with an appropriate amount of deionized water, the mixture is heated until the elemental sulfur is completely dissolved to obtain a mixed solution, and then the mixed solution is transferred to a 100ml hydrothermal kettle, With 2.0mol / L NaOH solution and 1.4mol / LH 2 SO 4 solution to adjust the pH value of the mixed solution to 9, add deionized water to the hydrothermal kettle until the final volume of the reaction solution is 80ml; then conduct a constant temperature hydrothermal reaction at 200°C for 12 hours; after naturally cooling to room temperature, use dilute Sulfuric acid, boiling Na 2 S solution, distilled water wash, obtain pyrite type iron disulfide; figure 1 Middle b is the XRD collection of collections of this embodiment product, figure 2 It is the scanning electron micrograph of the product of this embodiment.

Embodiment 3

[0030] By n(FeCl 2 ): n(Na 2 S): n (S) = 1: 2: 1 molar ratio is mixed with an appropriate amount of deionized water, the mixture is heated until the elemental sulfur is completely dissolved to obtain a mixed solution, and then the mixed solution is transferred to a 100ml hydrothermal kettle, With 2.0mol / L NaOH solution and 1.4mol / LH 2 SO 4 solution to adjust the pH value of the mixed solution to 12, add deionized water to the hydrothermal kettle until the final volume of the reaction solution is 80ml; then conduct a constant temperature hydrothermal reaction at 140°C for 18 hours; after naturally cooling to room temperature, use dilute Sulfuric acid, boiling Na 2 S solution, distilled water wash, obtain pyrite type iron disulfide; figure 1 Middle c is the XRD pattern of this embodiment product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com