Preparation method of pyrite-type ferrous disulfide micron/nano crystalline material with controllable morphology

A technology of ferrous disulfide and nanocrystalline materials, applied in the direction of iron sulfide, nanotechnology, nanotechnology, etc., to achieve low cost, simple preparation process, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

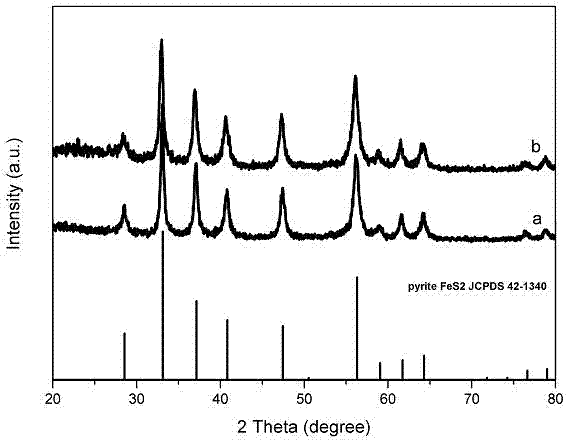

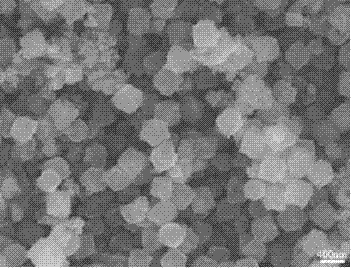

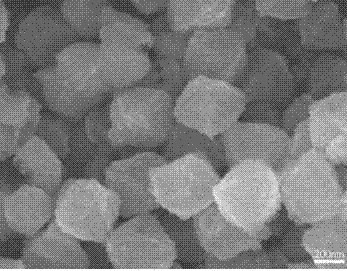

Image

Examples

Embodiment 1

[0036] Example 1 A method for preparing a pyrite-type ferrous disulfide micro / nanocrystalline material with controllable morphology, comprising the following steps:

[0037] (1) Stir the solvent dimethyl sulfoxide (DMSO) and pass nitrogen gas with a purity of 98.5% or more, and then add the compounding agent thioglycolic acid (TGA) at a concentration of 2.4 μl / mL at a concentration of 0.003 g / mL. mL of surfactant polyvinylpyrrolidone (PVP), mixed and stirred to obtain solution A.

[0038] Among them: the volume ratio (mL / mL) of thioglycolic acid and dimethyl sulfoxide is 1:5; the volume ratio (mL / mL) of polyvinylpyrrolidone and dimethyl sulfoxide is 1:2.

[0039] Surfactant polyvinylpyrrolidone has a molecular weight of 10,000.

[0040] (2) In solution A, add iron source with a concentration of 0.01mol / L—ferrous chloride and an aqueous solution of sodium thiosulfate with a concentration of 0.03mol / L in sequence, pass nitrogen with a purity of more than 98.5% and stir vi...

Embodiment 2

[0044] Example 2 A method for preparing a pyrite-type ferrous disulfide micro / nanocrystalline material with controllable morphology, comprising the following steps:

[0045] (1) Stir the solvent dimethyl sulfoxide (DMSO) and pass through the argon gas with a purity of 98.5% or more, and add the compounding agent thioglycolic acid (TGA) at a concentration of 2.4 μl / mL at a concentration of 0.009 g / mL surfactant polyvinylpyrrolidone (PVP), mixed and stirred to obtain solution A.

[0046] Among them: the volume ratio (mL / mL) of thioglycolic acid and dimethyl sulfoxide is 1:10; the volume ratio (mL / mL) of polyvinylpyrrolidone and dimethyl sulfoxide is 1:6.

[0047] Surfactant polyvinylpyrrolidone has a molecular weight of 1,300,000.

[0048] (2) Add iron source with a concentration of 0.02 mol / L—ferrous sulfate and an aqueous sodium thiosulfate solution with a concentration of 0.06 mol / L in sequence in solution A, pass argon gas with a purity of more than 98.5% and stir vi...

Embodiment 3

[0052] Example 3 A method for preparing a pyrite-type ferrous disulfide micro / nanocrystalline material with controllable morphology, comprising the following steps:

[0053] (1) Stir the solvent dimethyl sulfoxide (DMSO) and pass nitrogen gas with a purity of 98.5% or more, and add the compounding agent thioglycolic acid (TGA) at a concentration of 2.4 μl / mL at a concentration of 0.006 g / mL. mL of surfactant polyvinylpyrrolidone (PVP), mixed and stirred to obtain solution A.

[0054] Among them: the volume ratio (mL / mL) of thioglycolic acid and dimethyl sulfoxide is 1:7; the volume ratio (mL / mL) of polyvinylpyrrolidone and dimethyl sulfoxide is 1:4.

[0055] Surfactant polyvinylpyrrolidone has a molecular weight of 100,000.

[0056] (2) In solution A, add iron source with a concentration of 0.015 mol / L—ferrous chloride and an aqueous solution of sodium thiosulfate with a concentration of 0.045 mol / L in sequence, pass nitrogen with a purity of more than 98.5% and stir vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com