Preparation method of ferrous disulfide-graphene composite nano lubricant

A graphene composite and ferrous disulfide technology, applied in the field of nanomaterials, can solve complex problems, achieve low reaction temperature, mild and pollution-free preparation process, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

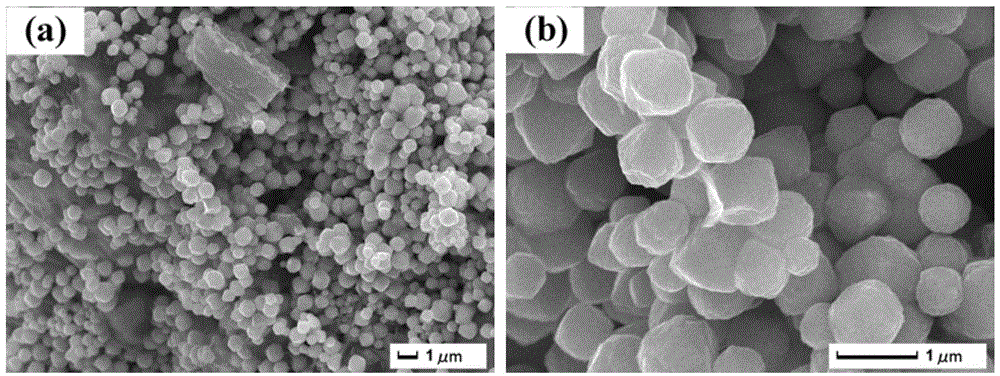

[0014] Dissolve 0.1g of graphene in 20ml of deionized water and ultrasonically for 1h, then add 0.3g of polyvinylpyrrolidone (PVP) and 0.2g of ferric chloride respectively, after completely dissolving, add 5ml of NaOH solution with a concentration of 0.5M dropwise, and then Add 0.2 g of thiourea, and stir magnetically for 30 min. The solution was transferred to a 50ml stainless steel reaction kettle with polytetrafluoroethylene lining and kept at 180°C for 16h. Cool to room temperature, wash by centrifugation, and vacuum-dry in a vacuum oven at 60°C for 8 hours to obtain a black powder.

Embodiment 2

[0016] The difference from Example 1 is that polyvinylpyrrolidone is replaced by cetyltrimethylammonium bromide.

Embodiment 3

[0017] Embodiment 3: the difference from embodiment 1 is that the consumption of graphene is 0.2g, and the dispersant is cetyltrimethylammonium bromide.

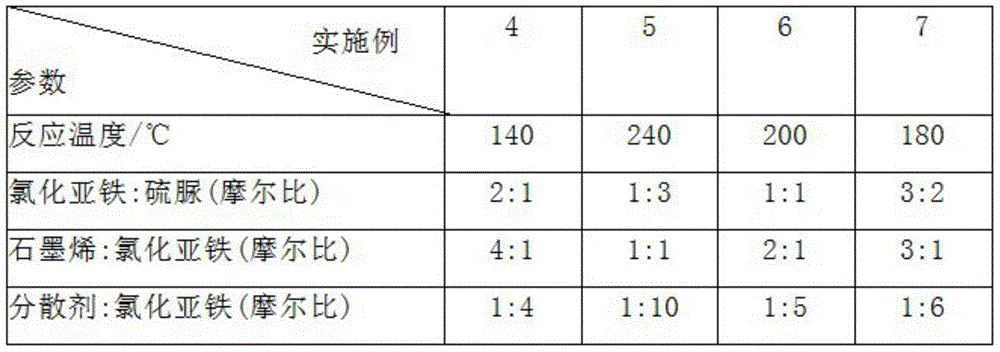

[0018] The consumption of the component that embodiment 4 to embodiment 7 adopts and process parameter are as shown in table 1:

[0019] Table 1

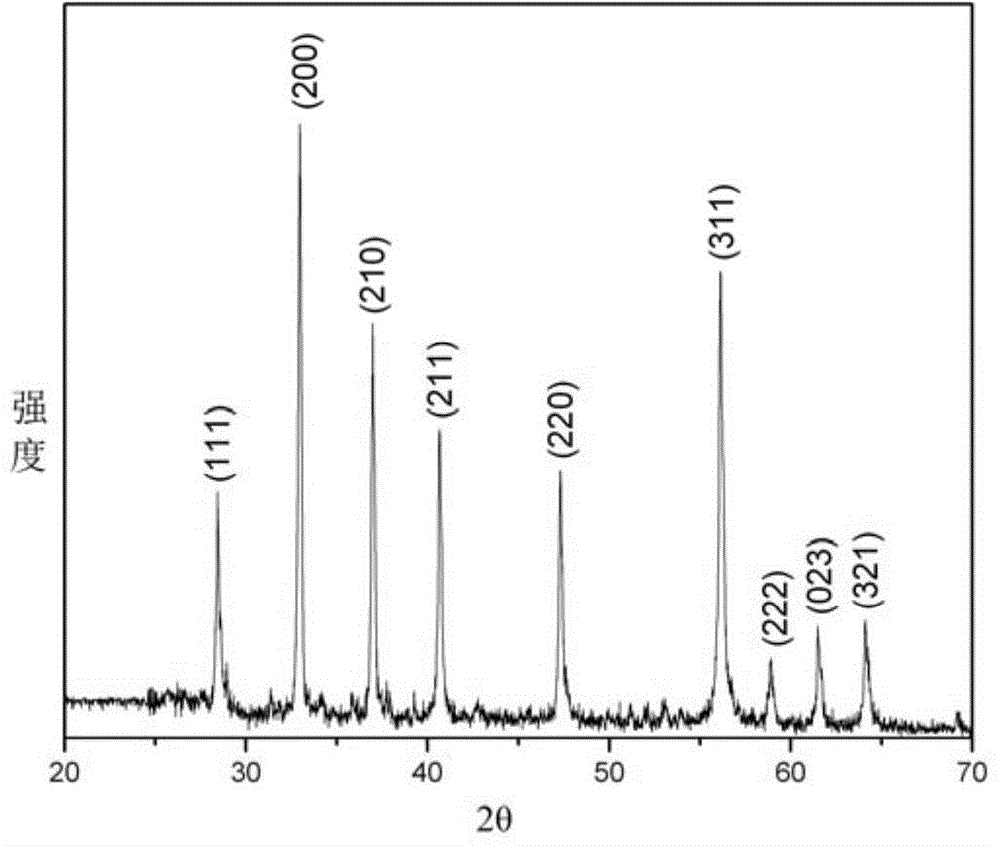

[0020] Due to the small amount of graphene, only a part of the graphene thin layer structure can be seen, and the peak of graphene in XRD cannot be detected).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com