Ferrous disulfide/carbon composite cathode material of primary lithium battery and preparation method and application thereof

A technology of iron disulfide and positive electrode materials, which is applied in the direction of battery electrodes, secondary batteries, electrochemical generators, etc., and can solve the problems of low conductivity of iron disulfide materials, poor high-current discharge characteristics, and low battery discharge efficiency, etc. Problems, achieve good high current discharge characteristics, increase the effective specific surface area, and improve the effect of electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

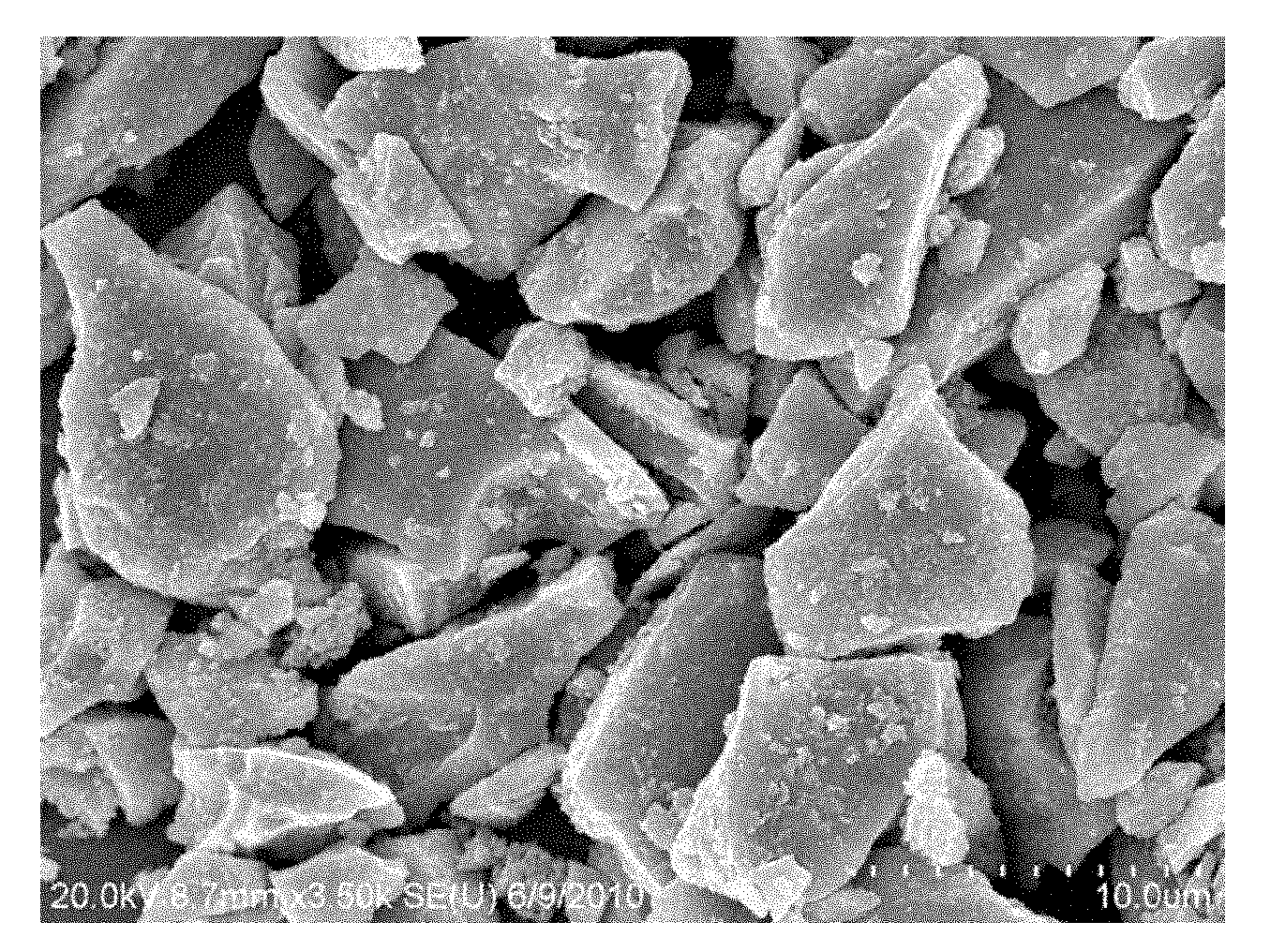

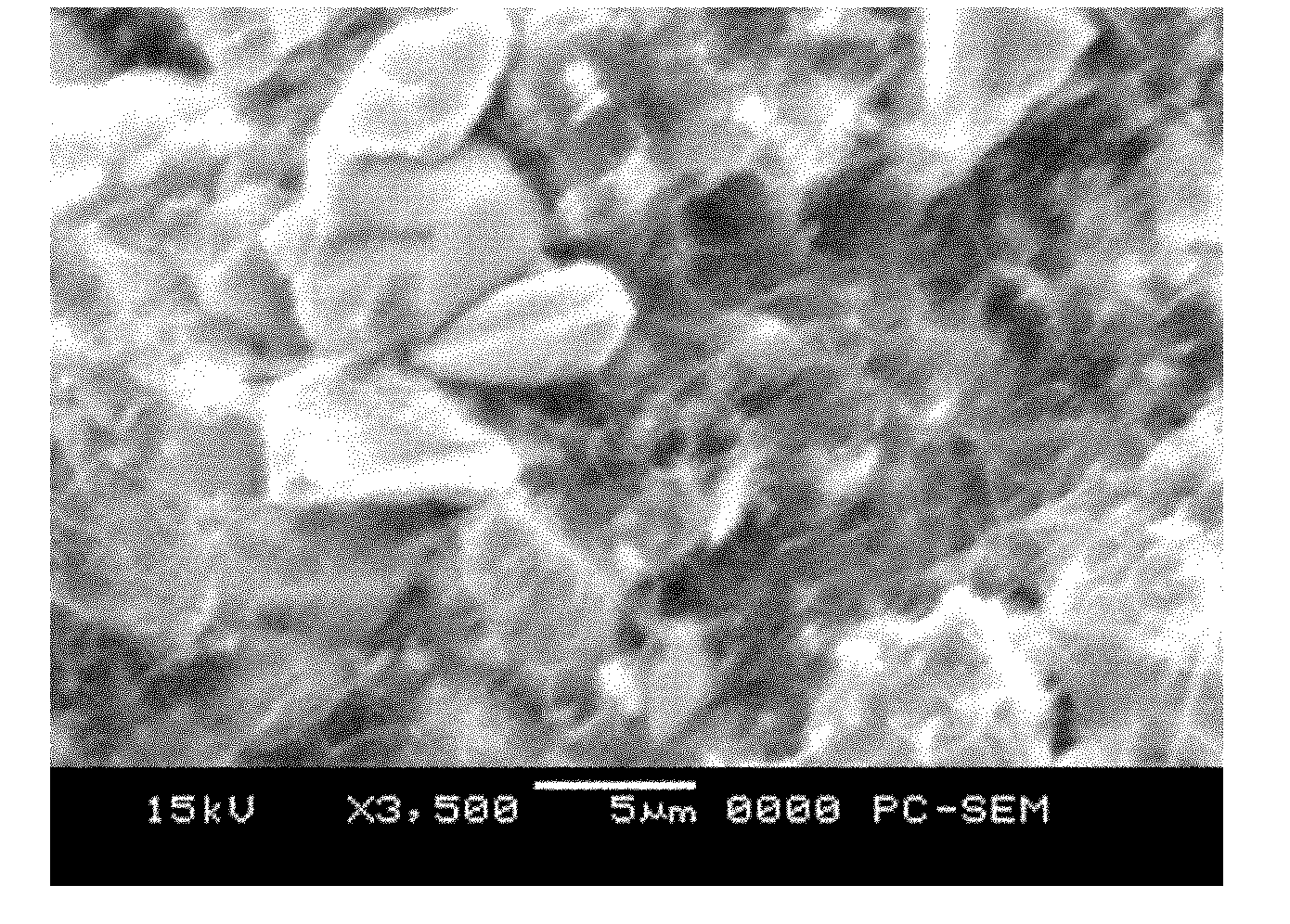

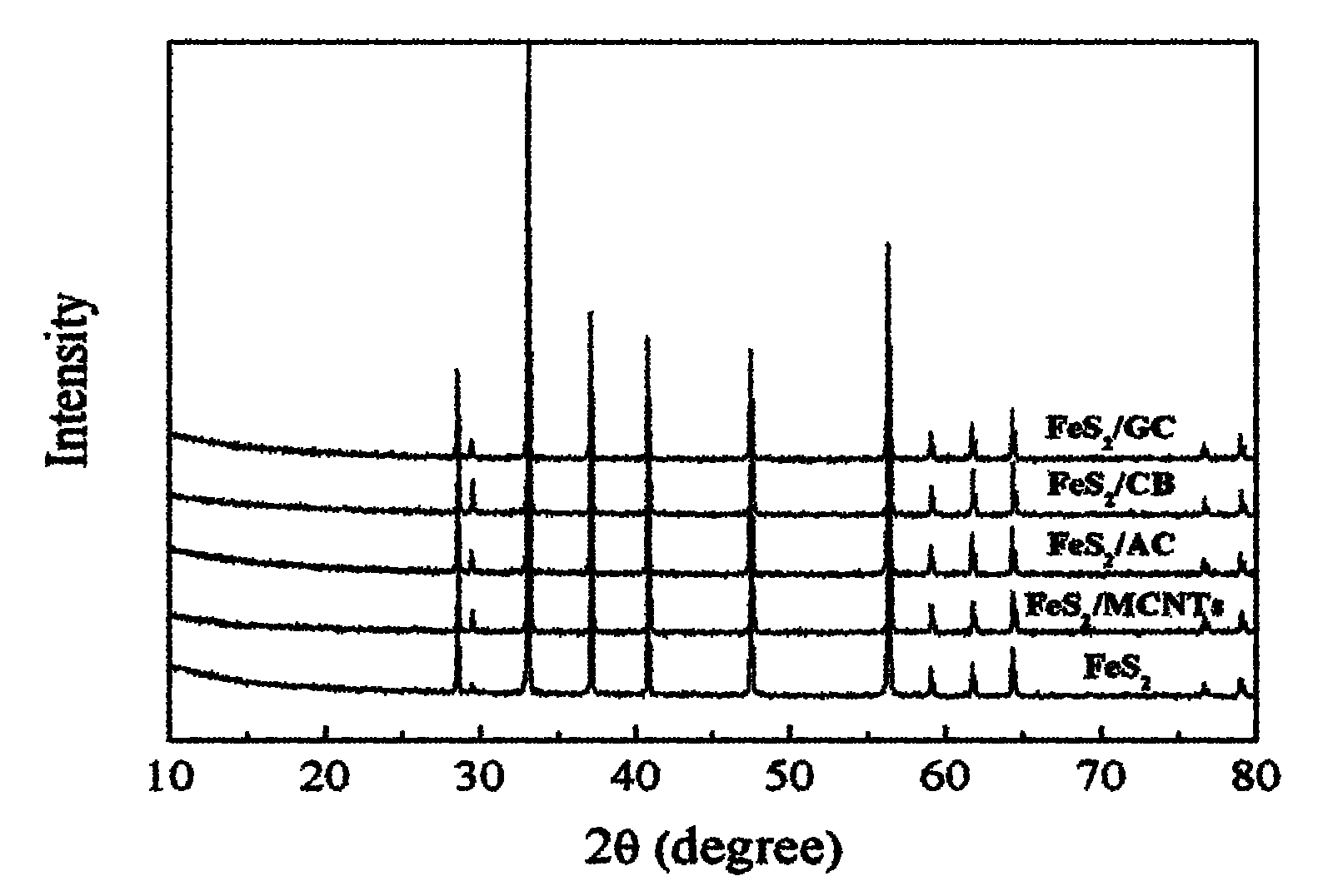

[0023] Embodiment 1: iron disulfide / carbon composite positive electrode material for a primary lithium battery, in which the iron disulfide / carbon composite positive electrode material contains 55% by mass of iron disulfide and 45% by mass of carbon element.

[0024] The preparation method of iron disulfide / carbon composite positive electrode material for primary lithium battery has the following steps:

[0025] (1) Mix carbon black (abbreviated as CB) or acetylene black with water at a mass ratio of 1:20 to obtain a suspension; ultrasonically disperse the obtained suspension with an ultrasonic power of 800 watts and keep After 5 hours, add pyrite to the suspension, wherein the mass ratio of pyrite to carbon black or acetylene black is 60:40, and after stirring for 8 hours, a mixed paste is obtained; the carbon source material can also be carbon A mixture of black and acetylene black.

[0026] (2) Heat the mixed paste obtained in step (1) to 90°C under the protection of nitro...

Embodiment 2

[0030] Embodiment 2: Iron disulfide / carbon composite positive electrode material for a primary lithium battery. The iron disulfide / carbon composite positive electrode material contains 80% by mass of iron disulfide and 20% by mass of carbon element.

[0031] The preparation method of iron disulfide / carbon composite positive electrode material for primary lithium battery has the following steps:

[0032] (1) Mix activated carbon (abbreviated as AC) or mesoporous carbon with ethanol or methanol or acetone at a mass ratio of 1:40 to obtain a suspension; ultrasonically disperse the obtained suspension with an ultrasonic power of 600 watts, keep 4 hours, add pyrite in the suspension, wherein the mass ratio of pyrite to activated carbon or mesoporous carbon is 85:15, after stirring for 5 hours, a mixed paste is obtained; carbon black material can be It is a mixture of activated carbon and mesoporous carbon, and the dispersant can also be a mixture of two or three of ethanol, methano...

Embodiment 3

[0035] Embodiment 3: Iron disulfide / carbon composite positive electrode material for a primary lithium battery. The iron disulfide / carbon composite positive electrode material contains 98% by mass of iron disulfide and 2% by mass of carbon element.

[0036] The preparation method of iron disulfide / carbon composite positive electrode material for primary lithium battery has the following steps:

[0037](1) After mixing carbon nanotubes (abbreviated as MCNTs) or graphene sheets or glucose (abbreviated as GC) or sucrose or starch or p-aminobenzoic acid and N-methylpyrrolidone in a mass ratio of 1:100 , to obtain a suspension; the obtained suspension was ultrasonically dispersed, and the ultrasonic power was 700 watts, and kept for 3 hours, and pyrite was added to the suspension, wherein pyrite and carbon nanotubes or graphene sheets The mass ratio is 98:2, and the mass ratio of pyrite to glucose or sucrose or starch or p-aminobenzoic acid is 97:3. After stirring for 8 hours, a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com