Preparation method of graphene oxide/iron disulfide composite nano particles

A technology of composite nano-particles and iron disulfide, applied in the direction of iron sulfide, chemical instruments and methods, carbon compounds, etc., can solve high-demand problems, achieve good dispersion, good application prospects, and simple and easy-to-control production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In an ice bath, 0.015 g of graphite powder was dispersed into 25 mL of concentrated sulfuric acid with a mass fraction of 98%, and potassium permanganate (KMnO 4 ), the added potassium permanganate (KMnO 4 ) to graphite in a mass ratio of 3:1-4:1, stir evenly, and when the temperature rises to 30°C, add 45 mL of deionized water and 15 mL of 30% H 2 o 2 , stirred evenly, centrifuged, and washed repeatedly with 5% hydrochloric acid solution, deionized water and acetone to obtain graphene oxide nanosheets.

Embodiment 2

[0025] (1) 0.2 g ferrous chloride tetrahydrate (FeCl 2 4H 2 O) Dissolve in 20 mL deionized water, stir until dissolved to obtain solution Ⅰ;

[0026] (2) Add 10 mL of PVA solution (3% mass fraction) and 0.05 g of PVP to solution I, stir well, then add 5 mL of 0.75 mol / L sodium hydroxide dropwise to obtain solution II;

[0027] (3) Add 0.2 g of sulfur powder to solution II, stir and dissolve to obtain solution III;

[0028] (4) Add 50 mg graphene oxide to solution Ⅲ, and ultrasonically disperse until uniform to obtain a solution ;

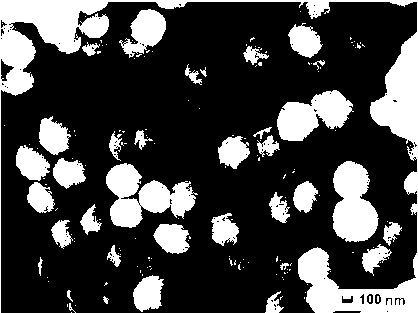

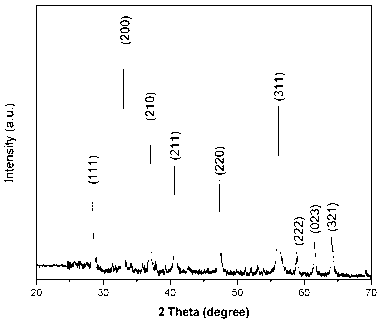

[0029] (5) the solution Under the environment of 180°C, the hydrothermal reaction was carried out for 12 h, and iron disulfide nanoparticles were obtained after cooling and centrifuging. The microscopic morphology of the prepared samples was observed by scanning electron microscopy, and the results were as follows figure 1 As shown, the sample is a spherical structure with uniform size and good dispersion, with an average diameter of about 30...

Embodiment 3

[0031] (1) 0.3 g ferrous chloride tetrahydrate (FeCl 2 4H 2 O) Dissolve in 20 mL deionized water, stir until dissolved to obtain solution Ⅰ;

[0032] (2) Add 10 mL of PVA solution (3% mass fraction) and 0.1 g of PVP to solution I, stir well, then add 5 mL of 0.75 mol / L sodium hydroxide dropwise to obtain solution II;

[0033] (3) Add 0.2 g of sulfur powder to solution II, stir and dissolve to obtain solution III;

[0034] (4) Add 50 mg graphene oxide to solution Ⅲ, and ultrasonically disperse until uniform to obtain a solution ;

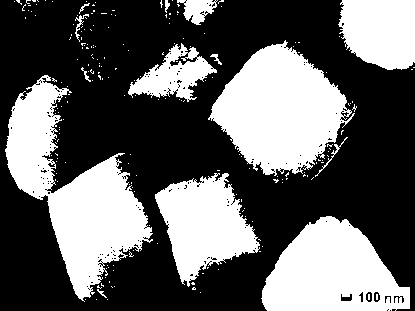

[0035] (5) Solution Under the environment of 200°C, the hydrothermal reaction was carried out for 24 h, and the graphene / iron disulfide composite nanoparticles were obtained after cooling and centrifugation. The microscopic morphology of the prepared samples was observed by scanning electron microscopy, and the results were as follows figure 2 As shown, the sample is an octahedral structure with uniform size and good dispersion, and the avera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com