Iron disulfide positive electrode material, preparation method thereof and alkali metal ion battery

A technology of iron disulfide and positive electrode materials, which is applied in the direction of secondary batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of serious volume effect, low electronic conductivity, and short service life, so as to alleviate the volume effect and improve the conductivity , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

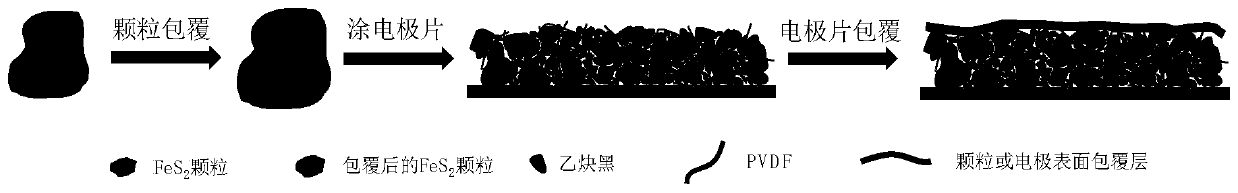

[0044] In this embodiment, the polymer monomer, dopant, and oxidant are pyrrole, sodium p-toluenesulfonate (TsONa), and ferric chloride, respectively. Double coating (material coating and electrode coating) is used to improve the electrochemical performance of iron disulfide. The polymerization of pyrrole is used for both coatings. The specific steps are as follows:

[0045] (1) Add iron disulfide, conductive polymer monomer solution and oxidizing agent solution successively to the polymer dopant solution, stir and then centrifuge to obtain the pre-product; conductive polymer monomer, polymer dopant, oxidizing agent and disulfide The molar ratio of iron is 1:2:3:10; the pre-product is alternately washed three times with absolute ethanol and deionized water, and dried in an oven at 80°C for later use;

[0046] (2) mixing and grinding the pre-product with a conductive additive and a binder, coating the obtained mixture on a copper foil and then drying it at 80° C. to obtain an e...

Embodiment 2

[0051] In this example, the polymer monomers are pyrrole and aniline, the dopant is sodium dodecylbenzenesulfonate (SDBS), the oxidant is ferric chloride, and the electrochemical performance of iron disulfide is improved by double coating The first chemical polymerization uses polypyrrole to coat the active material, and the second electrochemical polymerization uses polyaniline to coat the electrode sheet. The specific steps are as follows:

[0052] (1) Add iron disulfide, conductive polymer monomer solution and oxidizing agent solution successively to the polymer dopant solution, stir and then centrifuge to obtain the pre-product; conductive polymer monomer, polymer dopant, oxidizing agent and disulfide The molar ratio of iron is 1:0.1:2:100; the pre-product is alternately washed three times with absolute ethanol and deionized water, and dried in an oven at 80°C for later use;

[0053] (2) Mix and grind the pre-product with conductive additives and binders, coat the obtained...

Embodiment 3

[0058] In this example, the polymer monomers are pyrrole and thiophene, the dopant is sodium dodecylbenzenesulfonate (SDBS), the oxidizing agent is iron nitrate, and double coating is used to improve the electrochemical performance of iron disulfide. The first chemical polymerization uses polypyrrole to coat the active material, and the second electrochemical polymerization uses polythiophene to coat the electrode sheet. When coating the electrode sheet, no conductive additives are added, and the conductivity of the conductive polymer is used to meet the conductivity requirements. Specifically Proceed as follows:

[0059] (1) Add iron disulfide, conductive polymer monomer solution and oxidizing agent solution successively to the polymer dopant solution, stir and then centrifuge to obtain the pre-product; conductive polymer monomer, polymer dopant, oxidizing agent and disulfide The molar ratio of iron is 1:0.5:1.25:1; the pre-product is alternately washed three times with absol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com