Anode material and anode plate of lithium-iron disulfide battery and method for preparing same

A technology for iron disulfide batteries and positive electrode materials, which is applied in iron sulfide, electrode manufacturing, battery electrodes, etc. It can solve the problems of poor voltage platform and high-current discharge performance, high battery open circuit voltage, and high processing costs, and achieve a stable voltage platform. , Improve electrical conductivity and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Preparation of iron disulfide nanocrystals

[0038] 150ml concentration is 4mol / L FeSO 4 After stirring the aqueous ethanol solution, add dropwise the solution containing 150ml concentration of 8mol / L (NH 2 ) 2 CS and 5ml of PVP in ethanol aqueous solution, then add 6g of high-purity sulfur powder, mix thoroughly, and adjust the pH value to 7-8 with sulfuric acid aqueous solution of pH=1.0. After continuing to stir, put the mixed solution in a high-pressure reactor, add a certain amount of ethanol until the volume is above 95%, then seal the reactor, keep it warm at 200°C for 36 hours, filter, and use Carbon disulfide, deionized water, absolute ethanol and dilute sulfuric acid were repeatedly washed several times to remove excess sulfur, dried and dehydrated, and ground to obtain iron disulfide nanocrystals.

Embodiment 2

[0039] Example 2: Preparation of iron disulfide nanocrystals

[0040] 150ml concentration is 4mol / L FeSO 4 After stirring the aqueous ethanol solution, add dropwise the solution containing 150ml concentration of 8mol / L (NH 2 ) 2 CS and 5ml of PVP in ethanol aqueous solution, then add 6g of high-purity sulfur powder, mix thoroughly, and adjust the pH value to 5-6 with pH=12 sodium hydroxide aqueous solution. After continuing to stir, put the mixed solution in a high-pressure reactor, add a certain amount of ethanol until the volume is above 95%, then seal the reactor, keep it warm at 200°C for 36 hours, filter, and use Carbon disulfide, deionized water, absolute ethanol and dilute sulfuric acid were repeatedly washed several times to remove excess sulfur, dried and dehydrated, and ground to obtain iron disulfide nanocrystals.

Embodiment 3

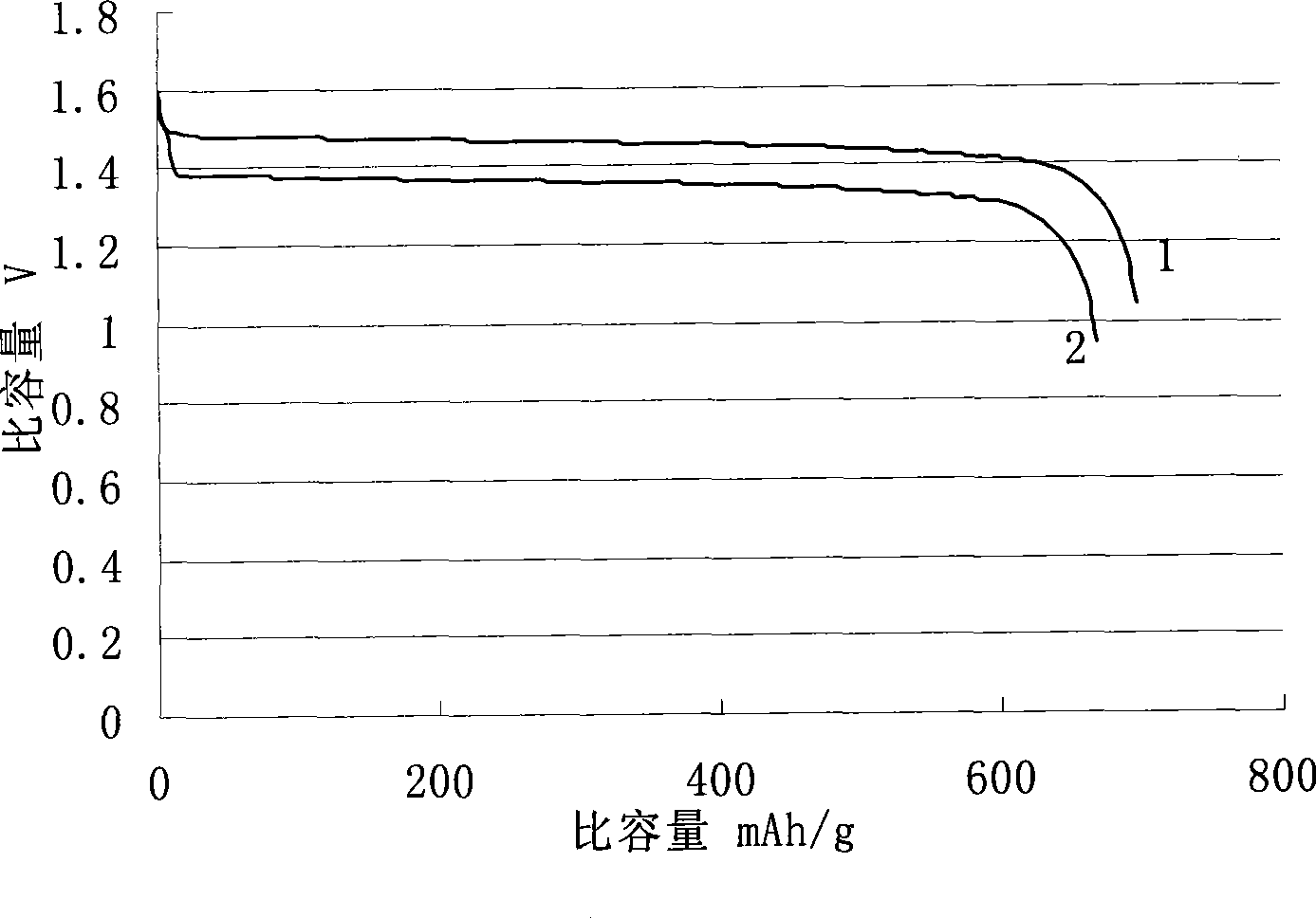

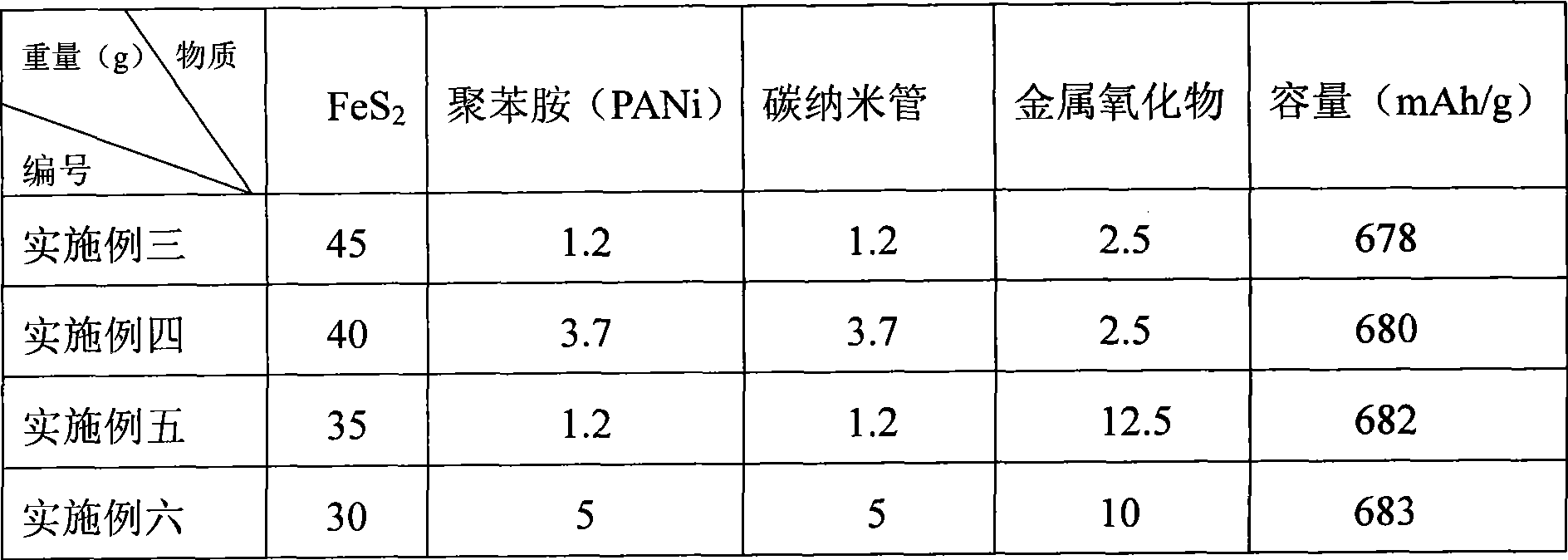

[0042] Take the iron disulfide nanocrystals of Example 1 or Example 2 to prepare a positive electrode sheet for a lithium-iron disulfide battery.

[0043] Get the iron disulfide nanocrystal 45g that makes, add 1.2g polyaniline (PANi) and 1.2g carbon nanotube, 2.5gAl 2 o 3 Metal oxides are mixed to obtain positive electrode materials.

[0044] Disperse the positive electrode material in absolute ethanol, the mass ratio of the positive electrode material to absolute ethanol is 1:1, ball mill in a ball mill for 3 hours to further refine it, and then dry it under vacuum at a temperature of 60°C cooling to room temperature, placing it in a ball mill for ball milling for 3 hours; and then passing through a vibrating sieve with a mesh size of 300 or more to obtain the processed positive electrode material.

[0045] Add 5 g of a mixture of glass fiber and metal copper powder into the treated positive electrode material as a metal binder, stir with an electric mixer for 2 hours, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com