Production process of lithium-ferrous disulfide battery anode

An iron disulfide battery and manufacturing process technology, which is applied to the electrodes of primary batteries, battery electrodes, circuits, etc., can solve the problems of broken belts and low adhesion of coatings, and achieve powder drop-off, high filling capacity, and large capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

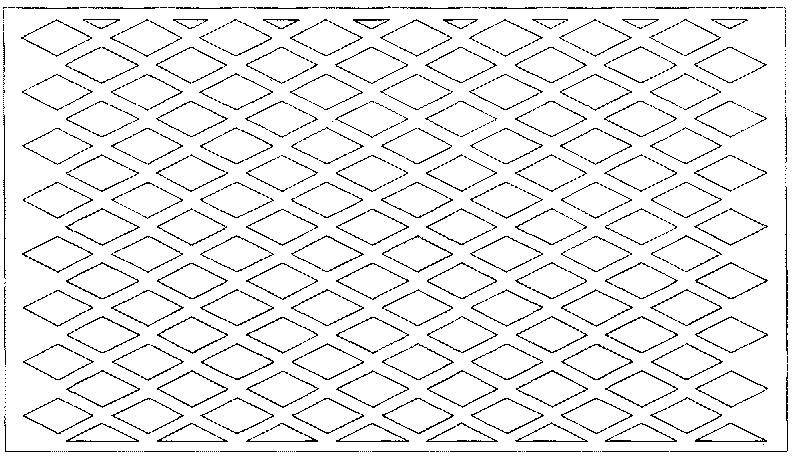

[0040] Use 0.05mm thick stainless steel belt to punch to make stainless steel mesh, rough surface, make the mesh into rhombus, the diagonal length is 1mm and 2mm, arranged in staggered rules, the vertical distance between adjacent sides of each diamond mesh is 0.5mm , the mesh area accounts for about 52% of the stainless steel belt area.

[0041] The stainless steel mesh was washed with deionized water and dried by circulating air.

[0042] Preparation of semi-dry slurry: Mix 93% iron disulfide, 2.5% graphite, 1% acetylene black and 3.5% PTFE by mass, and then add NMP whose mass is 8 times that of PTFE to make a viscous paste Semi-dry slurry.

[0043] The coated stainless steel mesh is dried, and the thickness of the coating after drying is controlled at 0.40mm. Then, the stainless steel mesh is cut into a rectangle of 330mm×42mm, and then rolling and tab welding are performed to form the positive electrode sheet of the AA type battery.

[0044] Please refer to Figure 5 a...

Embodiment 2

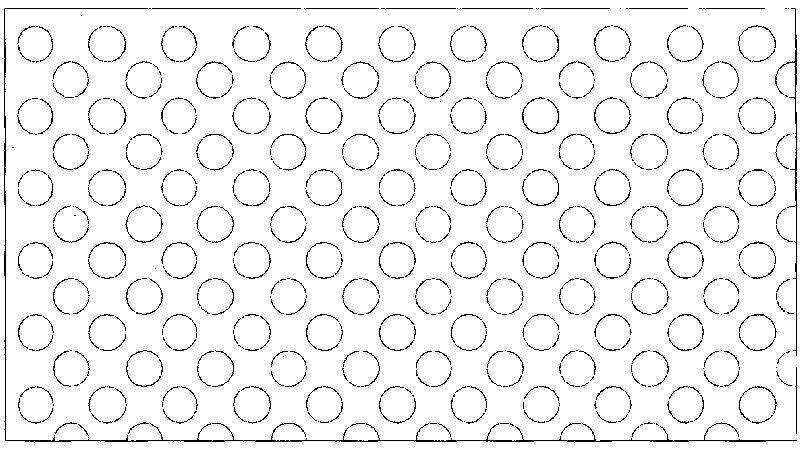

[0046] Use 0.08mm thick aluminum strip to punch to make aluminum mesh, rough surface, make the mesh into a circle with a diameter of 1mm, in a staggered and regular arrangement, the distance between the center of each adjacent circular mesh in the horizontal or vertical row It is 2mm, and the mesh area accounts for about 50% of the area of the stainless steel belt.

[0047] The aluminum mesh was washed with deionized water and dried by circulating air.

[0048] Preparation of semi-dry slurry: Mix 92% iron disulfide, 2% graphite, 1% acetylene black, 1% carbon black and 4% CMC by mass, and then add 9.5 times the mass of CMC. Ionized water to make a viscous semi-dry slurry.

[0049] The coated aluminum mesh is dried, and the thickness of the coating after drying is controlled at 0.35mm. Then, cut the aluminum mesh into a rectangle of 330mm×42mm, and then roll and weld the tabs to make the positive electrode sheet of the AA type battery.

Embodiment 3

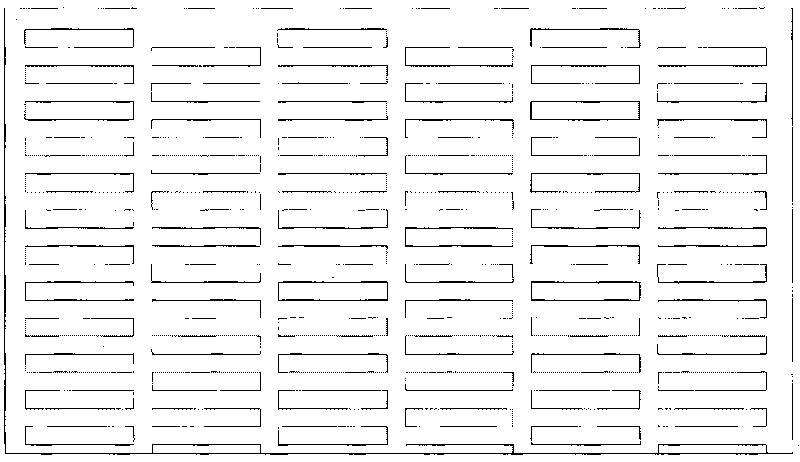

[0051] Use 0.10mm thick nickel tape to punch to make aluminum mesh, the surface is roughened, the mesh is made into a rectangle, the length x width is 2mm x 1mm, it is arranged in a staggered order, and the long sides of the adjacent rectangular mesh in the vertical row are vertical. The distance is 0.5mm, the distance between two adjacent vertical rows is 0.5mm, and the mesh area accounts for about 60% of the area of the stainless steel strip.

[0052] The nickel mesh was washed with deionized water and dried by circulating air.

[0053] Preparation of semi-dry slurry: Mix 94% iron disulfide, 1.5% graphite, 2% acetylene black and 4.5% PVDF by mass, and then add NMP whose mass is 9 times that of PVDF to make a viscous paste Semi-dry slurry.

[0054] The coated nickel mesh was dried, and the thickness of the coating after drying was controlled at 0.3 mm. Then, the nickel mesh was cut into a rectangle of 330mm×42mm, and then rolled and tab welded to form an AA-type battery p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com