Method for preparing high-performance spherical lithium ion secondary battery cathode material

A cathode material and secondary battery technology, applied in the direction of battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as poor safety performance and cycle life, deterioration of electrolyte reaction, and poor battery performance, and achieve easy manufacturing methods , avoid low-valence ions, and reduce the effect of Co content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

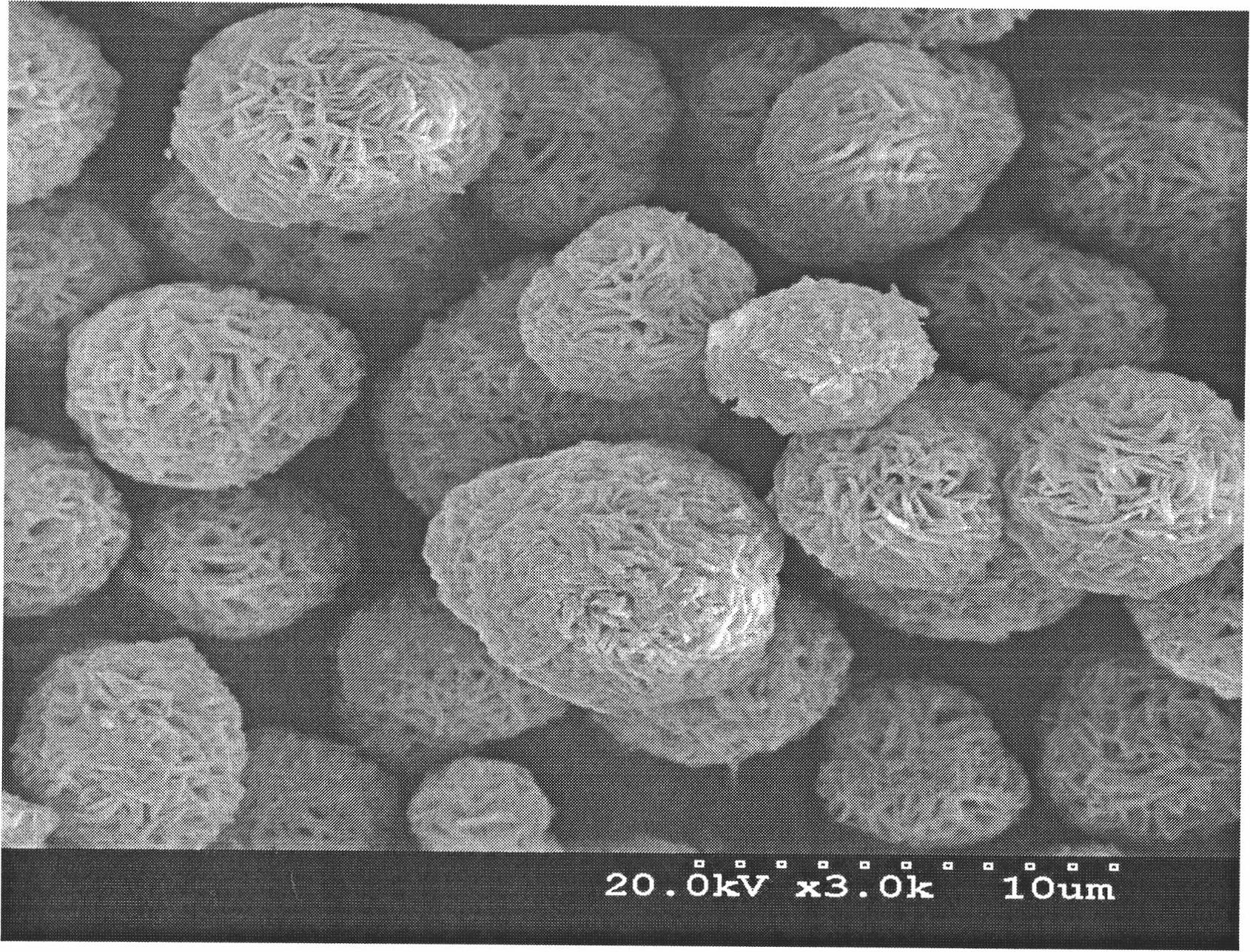

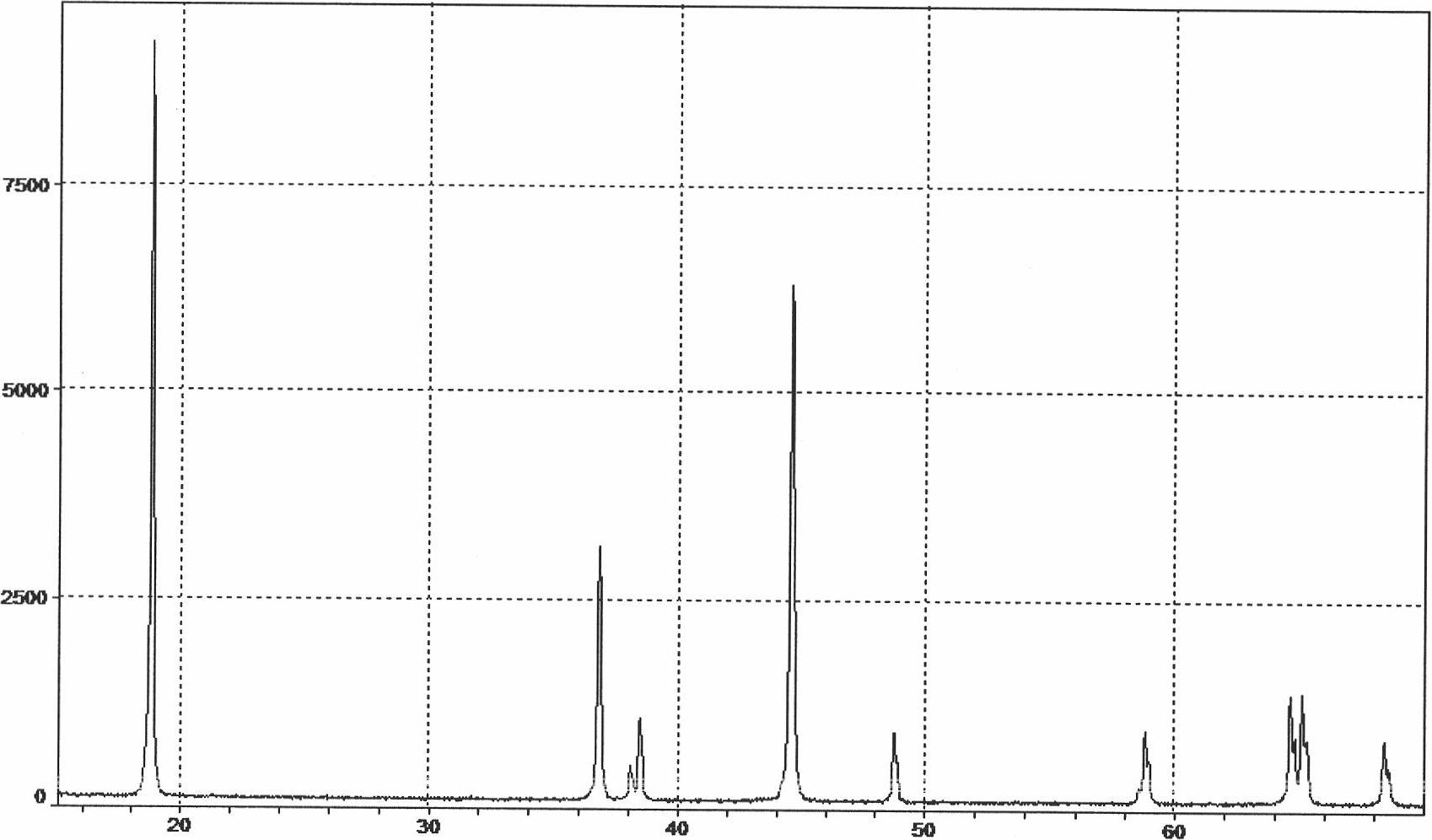

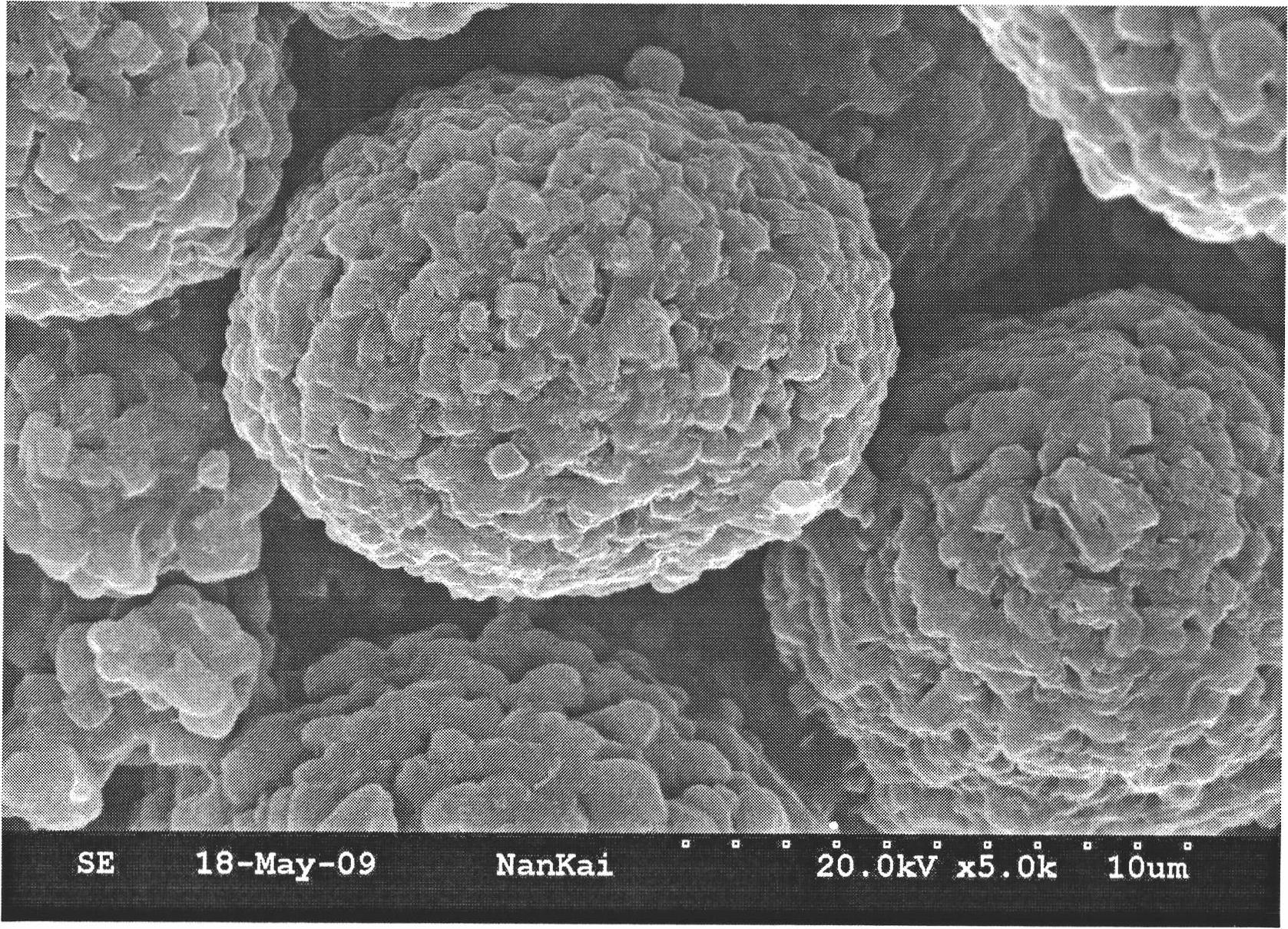

[0024] Synthetic formula LiNi 0.6 co 0.2 mn 0.2 o 2 (LiNi 0.5 co 0.25 mn 0.25 o 2 ·LiNi 0.4 co 0.3 mn 0.3 o 2 ) as an example, by Ni: Co: Mn=0.6: 0.2: 0.2 molar ratio preparation 2mol / L transition element nickel, cobalt and manganese sulfate mixed solution, and 6mol / L ammonia solution and 4mol / L NaOH solution, According to the flow rate of 1L / min, 0.5L / min, and 1.25L / min, inject it into a 25L reactor, keep the reaction temperature at 65°C, and the pH value at 10.0, and react in the reactor at a speed of 400r / min. for 6h, Uniform spherical Ni can be obtained after washing, filtering and drying 0.6 co 0.2 mn 0.2 (OH) 2 Precursor. Then add it in the 50L reactor, add 4 times the quality of deionized water; press the molar ratio of Ni:Co:Mn=0.5:0.25:0.25 to prepare the sulfuric acid of transition elements nickel, cobalt and manganese of 0.5mol / L Salt mixed solution, the total amount of solute in sulfate solution is Ni 0.6 co 0.2 mn 0.2 (OH) 2 40% of the 1L / min f...

Embodiment 2

[0028] Synthetic formula LiNi 0.6 co 0.2 mn 0.2 o 2 (LiNi 0.4 co 0.3 mn 0.3 o 2 ·LiNi 0.33 co 0.33 mn 0.33 o 2 ) as an example, according to the molar ratio of Ni:Co:Mn=0.6:0.2:0.2, prepare 1.5mol / L transition element nickel, cobalt and manganese sulfate mixed solution, and 5mol / L ammonia solution and 4mol / L NaOH solution , according to the flow rate of 1L / min, 0.5L / min, 1.25L / min respectively into the 25L reactor, keep the reaction temperature at 65 ℃, pH value 10.0, react in the reactor at 400r / min. speed for 6h , uniform spherical Ni can be obtained after washing, filtering and drying 0.6 co 0.2 mn 0.2 (OH) 2 Precursor. Then add it in the 50L reactor, add 4 times the quality of deionized water; press the molar ratio of Ni: Co: Mn=0.4: 0.3: 0.3 to prepare the sulfuric acid of transition elements nickel, cobalt and manganese of 0.75mol / L Salt mixed solution, the total amount of solute in sulfate solution is Ni 0.6 co 0.2 mn 0.2 (OH) 2 40% of the 1L / min flo...

Embodiment 3

[0032] Synthetic formula LiNi 0.7 co 0.15 mn 0.15 o 2 (LiNi 0.5 co 0.25 mn 0.25 o 2 ·LiNi 0.4 co 0.4 mn 0.4 o 2 ) as an example, according to the molar ratio of Ni:Co:Mn=0.7:0.15:0.15, prepare 2.5mol / L transition element nickel, cobalt and manganese sulfate mixed solution, and 7mol / L ammonia solution and 5mol / L NaOH solution , according to the flow rate of 1L / min, 0.5L / min, 1.25L / min respectively into the 50L reactor, keep the reaction temperature at 70 ℃, pH value of 10.5, react in the reactor at 350r / min. speed for 6h , uniform spherical Ni can be obtained after washing, filtering and drying 0.7 co 0.15 mn 0.15 (OH) 2 Precursor. Then add it into a 100L reactor and add 6 times the mass of deionized water; prepare 1mol / L of transition element nickel, cobalt and manganese sulfate at a molar ratio of Ni:Co:Mn=0.5:0.25:0.25 Mixed solution, the amount of the total substance of the sulfate solution solute is Ni 0.6 co 0.2 mn 0.2 (OH) 2 40% of the 1L / min flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com