Patents

Literature

44results about How to "Reduce the amount of lead used" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic electricity-getting mechanism and automatic electricity-getting method for gantry crane

ActiveCN102229405ARealize free plug and take powerImprove mobilityLoad-engaging elementsElectricityLocking mechanism

The invention discloses an automatic electricity-getting mechanism which is accurately and automatically connected with and reliably fixed to a socket frame through a plug frame and used for a gantry crane and an automatic electricity-getting method. The automatic electricity-getting mechanism for the gantry crane comprises a connecting mechanism, wherein the connecting mechanism is connected with the plug frame through a coupling mechanism which can be separated; the plug frame is mated with the socket frame; and the plug frame and the socket frame can be fixed together through a locking mechanism. According to the invention, the automatic insertion and extraction of a power socket is realized during the field transfer of the gantry crane with a cable reel for power supply, the field transfer efficiency is improved, the safety hazards in the prior art are eliminated during the insertion and extraction of the power plug, the mechanism has the advantages of simple operation and control, and is safe, convenient and rapid, the maneuverability of the gantry crane can be improved greatly, thus under the premises of finishing the same operation amount, the quantity of used gantry cranes can be reduced.

Owner:凯伏特(上海)动力技术有限公司

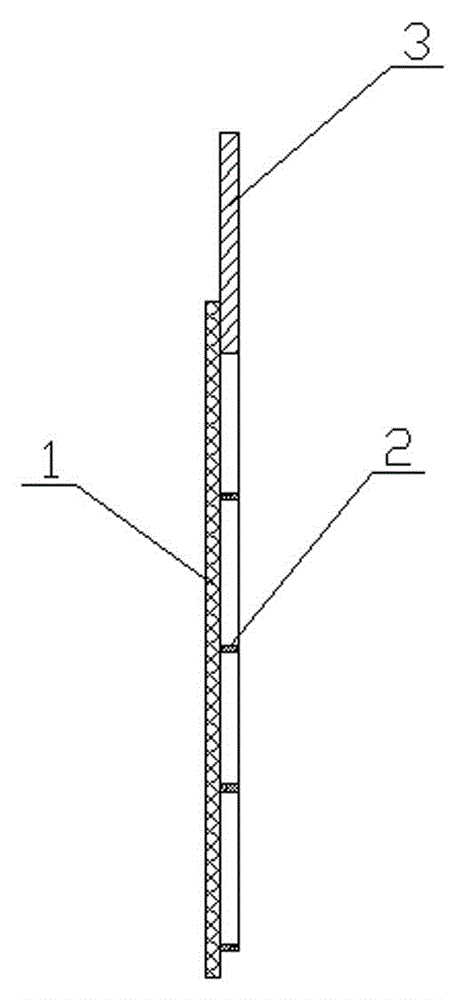

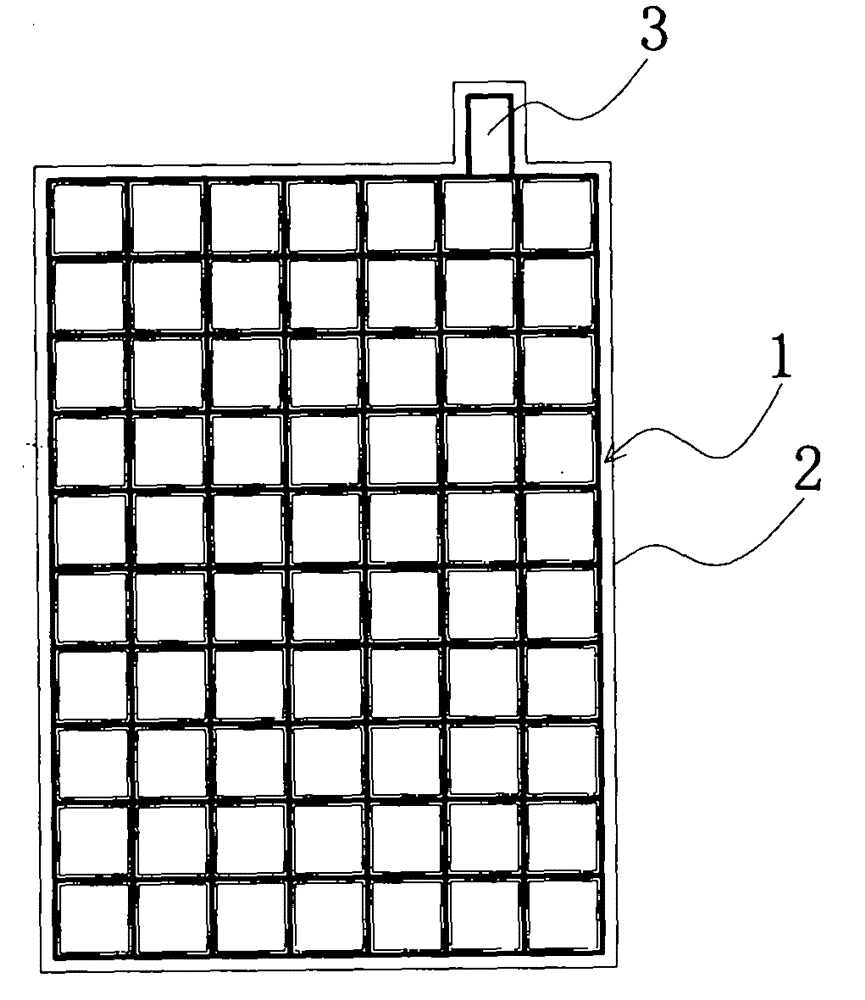

Plate grid of negative plate for lead-acid storage battery

InactiveCN105280924AReduce weightReduce thicknessElectrode carriers/collectorsElectrical resistance and conductanceCarbon fibers

The invention provides a plate grid of a negative plate for a lead-acid storage battery. The plate grid comprises a tab and a frame, the improvement is that the frame is formed by welding aluminum alloy ribs and a conductive carbon fiber felt, the tab is exposed, the conductive carbon fiber felt is a polyacrylonitrile-based carbon felt, and the gram weight of the conductive carbon fiber felt is 100 to 1520 g / m<2>.mm. The plate grid is few in lead dosage, and is beneficial for weight reduction and environmental protection; particularly during the fabrication of the negative plate, carbon fiber in the conductive carbon fiber felt is in close contact with an active substance, large contact area, low resistance, high utilization rate of the active substance and favorable charging reception are achieved, sulfation is overcome, and the service lifetime of the battery is effectively prolonged.

Owner:SHUANGDENG GRP

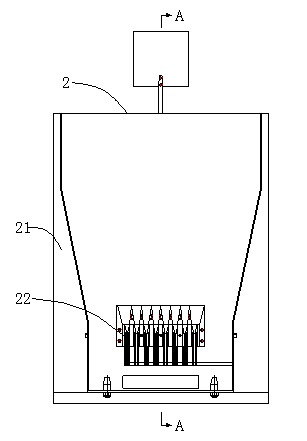

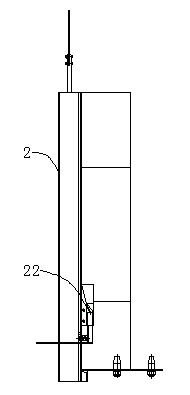

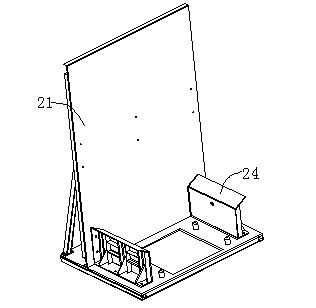

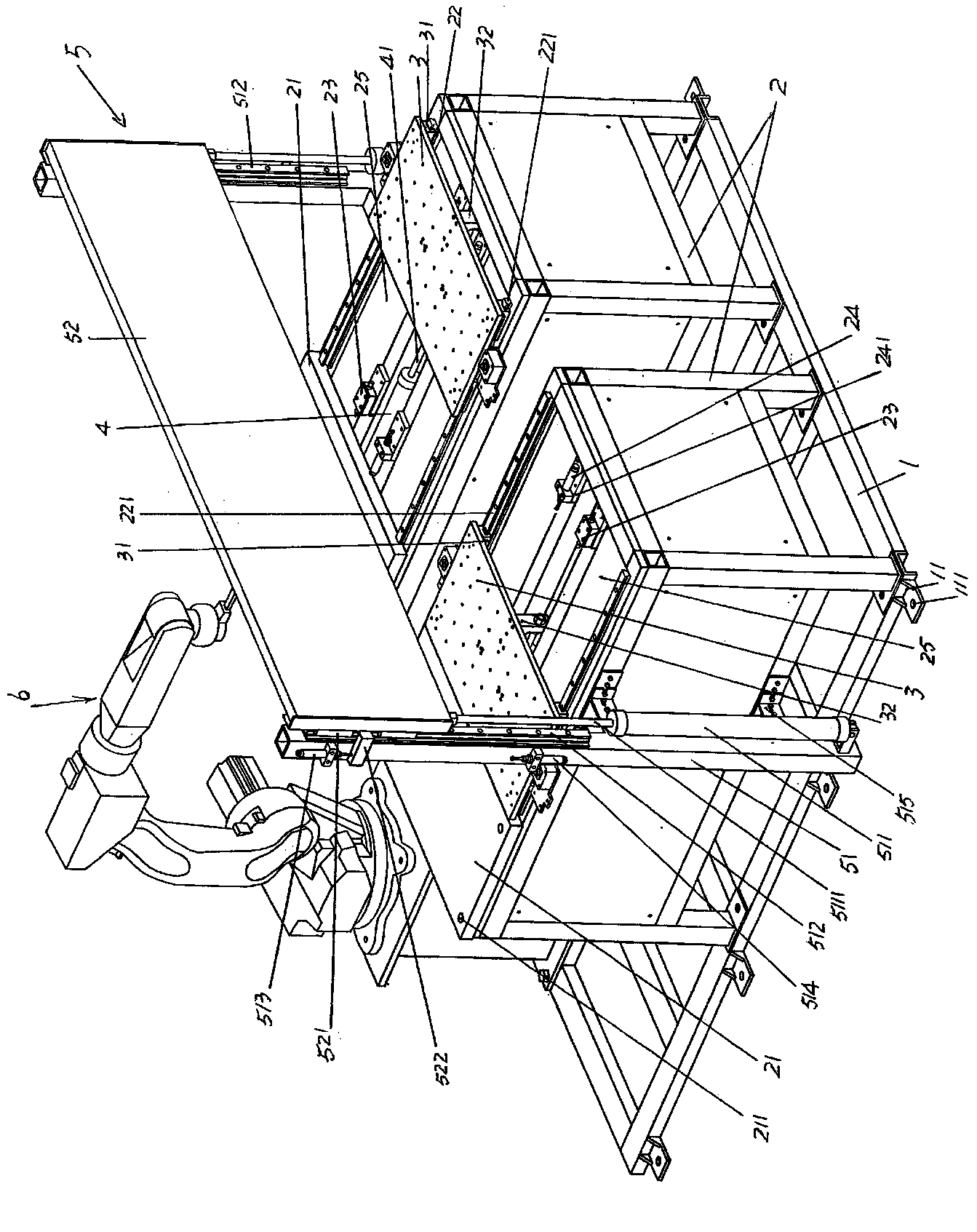

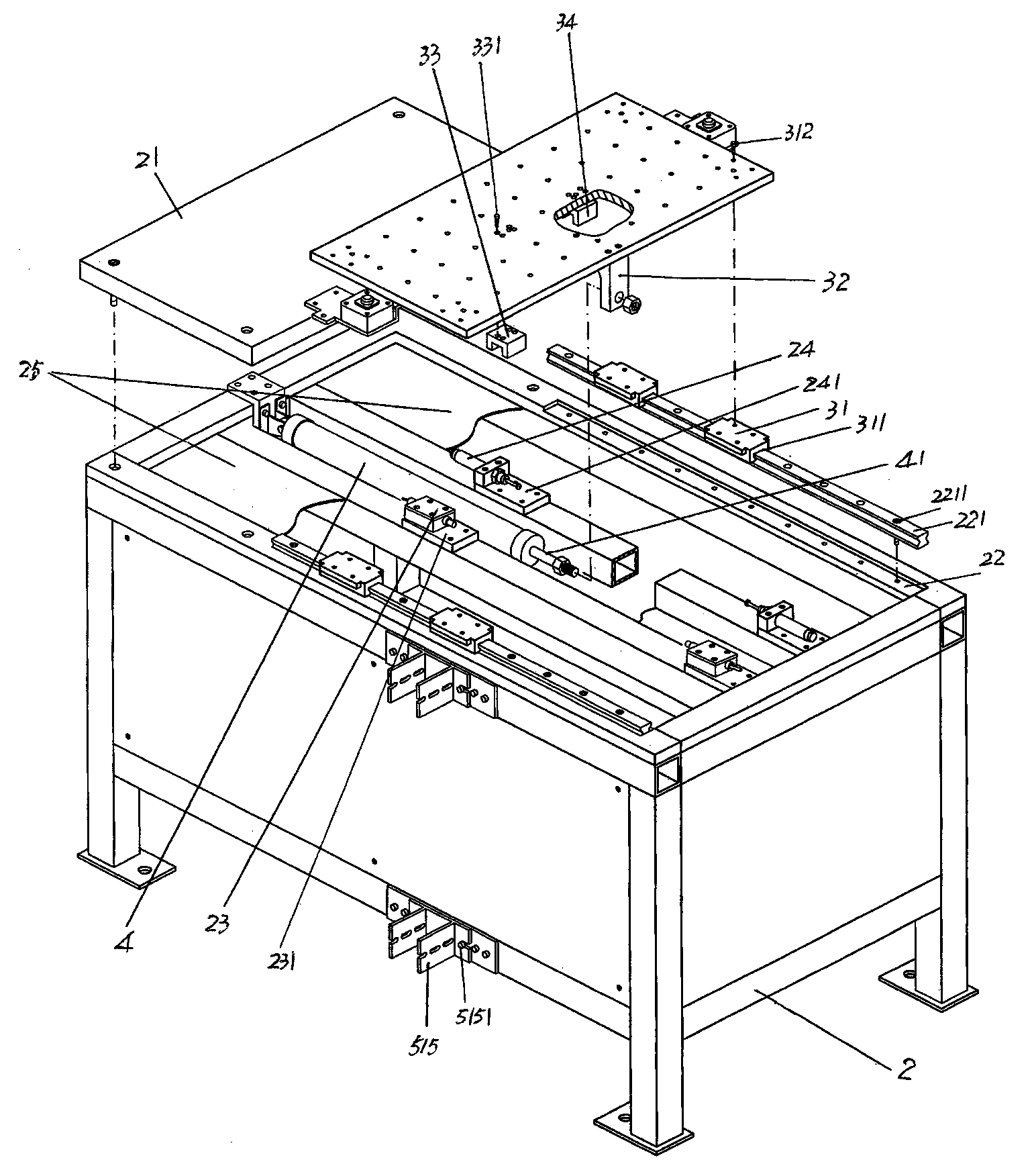

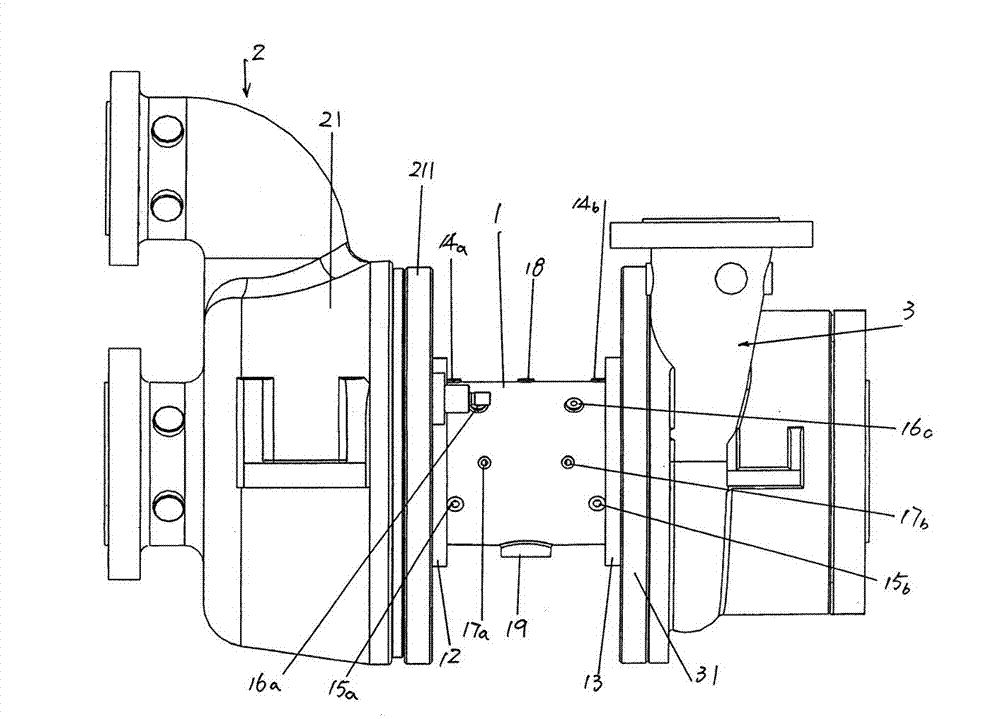

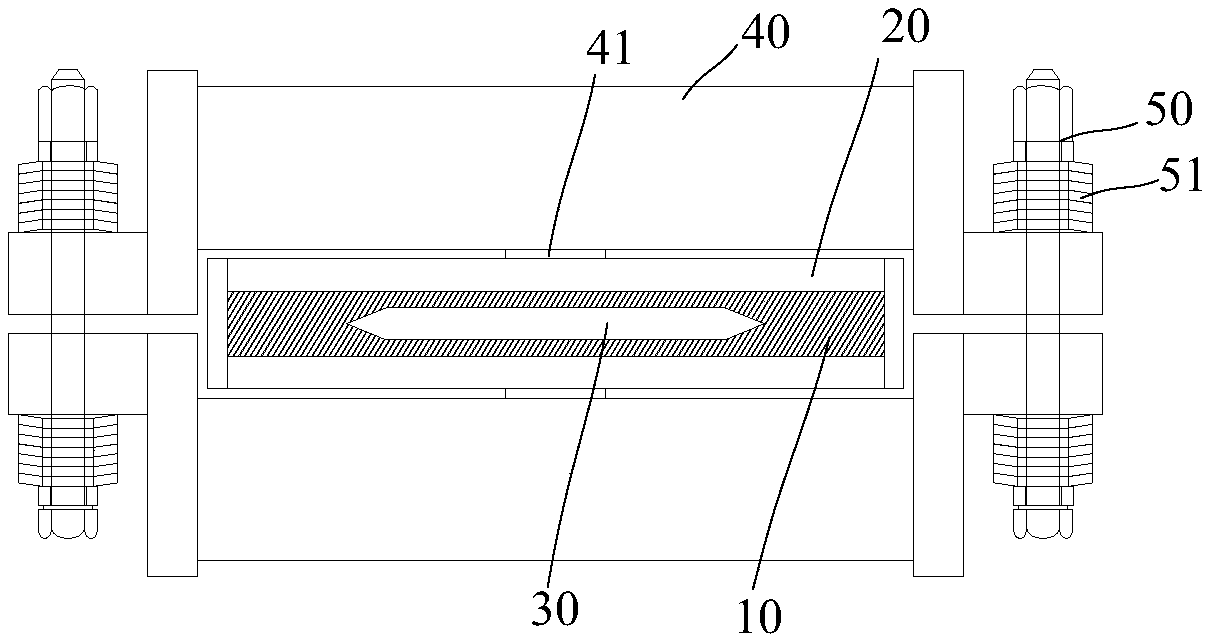

Workpiece clamping worktable structure matched with welding robot

ActiveCN103878472AReduce the amount of lead usedImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a workpiece clamping worktable structure matched with a welding robot, and belongs to the technical field of auxiliary facilities for automated welding. The structure comprises a base and a pair of worktables. The worktables are fixed to the base in a parallel moving state, the upper portion of each worktable is provided with a workpiece clamping platen in a sliding and matched mode, the lower portion, corresponding to the corresponding workpiece clamping platen, of each worktable is provided with a workpiece clamping platen drive action cylinder, and the workpiece clamping platen drive action cylinders are connected with the workpiece clamping platens and used for driving the workpiece clamping platens to slide in a reciprocating mode. The workpiece clamping platens on the worktables slide alternatively in opposite directions. Welding efficiency can be effectively improved, the use number of welding robots is reduced, labor resources are saved, and labor cost is lowered.

Owner:SOHBI CRAFT CHANGSHU

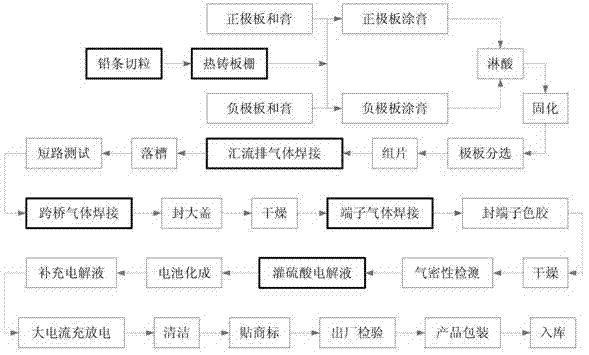

Lead-acid battery grid, polar plate and manufacturing method of grid

ActiveCN101740781AReduce the amount of lead usedImprove charge acceptanceElectrode carriers/collectorsLead-acid accumulator electrodesPunchingEngineering

The invention provides a lead-acid battery grid, comprising a grid main body, bulges which are arranged in arrays are formed on one side of the grid main body, and side-open type through holes are formed between the bulges and the grid main body. The invention also provides a lead-acid battery polar plate which comprises a grid and lead plaster coated on the surface of the grid. The invention also provides a method for preparing the above polar plate grid, comprising the steps of manufacturing a lead belt, rolling belt on the lead belt, punching and deep drawing. The invention can greatly save the use amount of lead, improve the charging receptivity, discharging platform, specific energy and specific power of the polar plate; the method provided in the invention is simple, and the manufactured polar plate grid has high quality, thus being capable of realizing continuous and high-yield production of the polar plate grid, reducing bit material remelting consumption of lead, and loweringproduction energy consumption and material oxidation.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

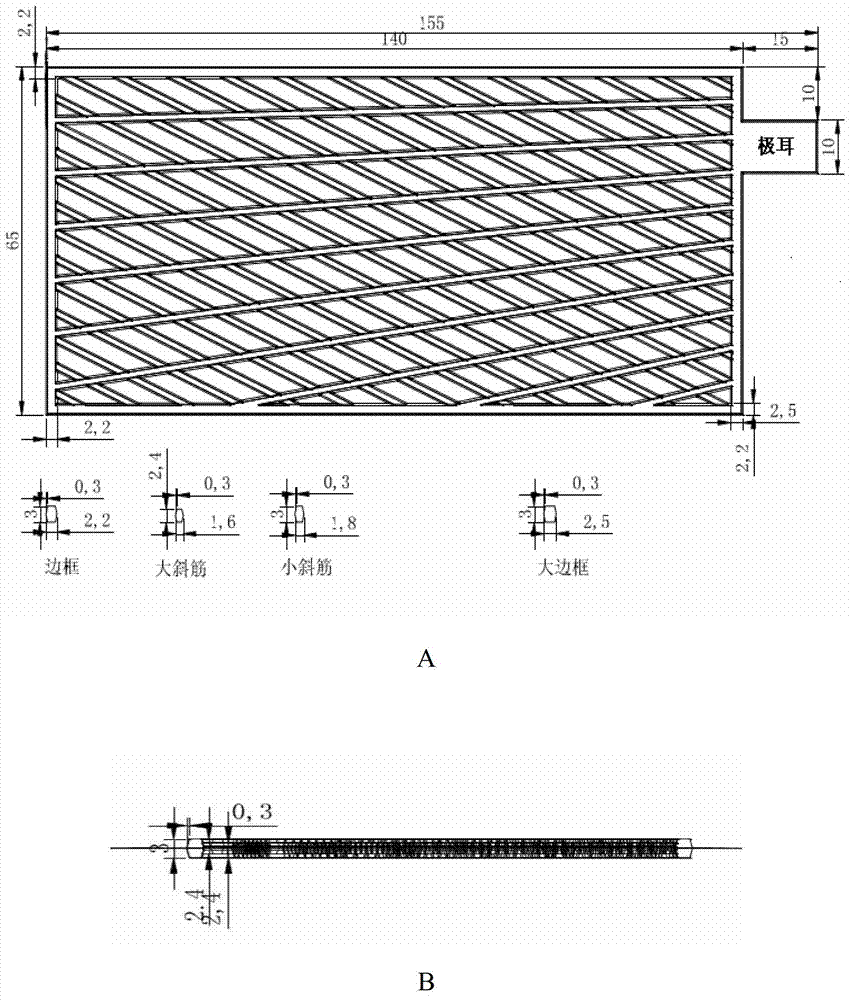

Carbon fiber composite board grid and preparation method thereof

InactiveCN102969511AReduce the amount of lead usedReduce pollutionElectrode carriers/collectorsActive polymerFiber

The invention discloses a carbon fiber composite board grid and a preparation method thereof; the carbon fiber composite board grid is molded by pouring carbon fiber composite basic material, wherein the composite basic material is prepared by mixing plastic polypropylene (PP), active polymer polyaniline and carbon fiber according to the weight percent ratio of 45-55wt%: 15-25wt%: 25-35wt%. The carbon fiber composite basic material is adopted to manufacture the board grid instead of alloy lead board grid, so that the weight of a battery is effectively reduced, and the mass ratio energy performance of the battery can be improved; the lead usage quantity is greatly reduced, so that the environmental pollution is reduced; and the invention plays an important role in preventing and governing heavy metal pollution of battery industrial, protecting labor of workers and protecting the environment.

Owner:广州神力信息科技有限公司

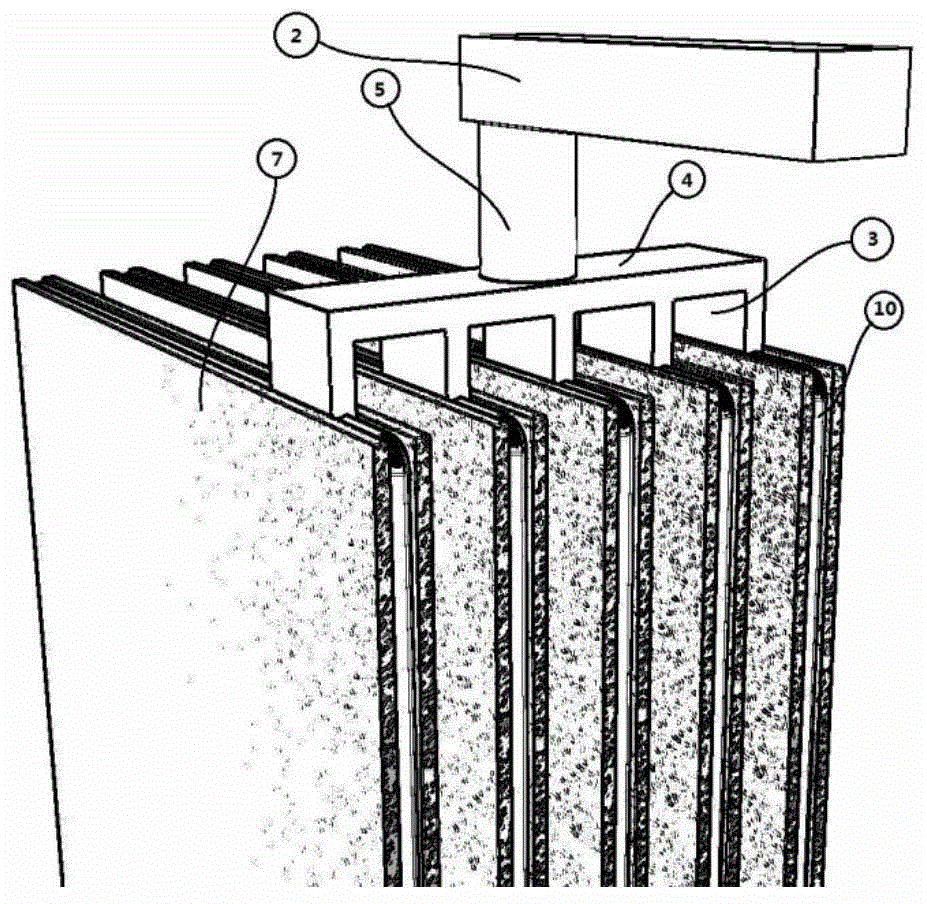

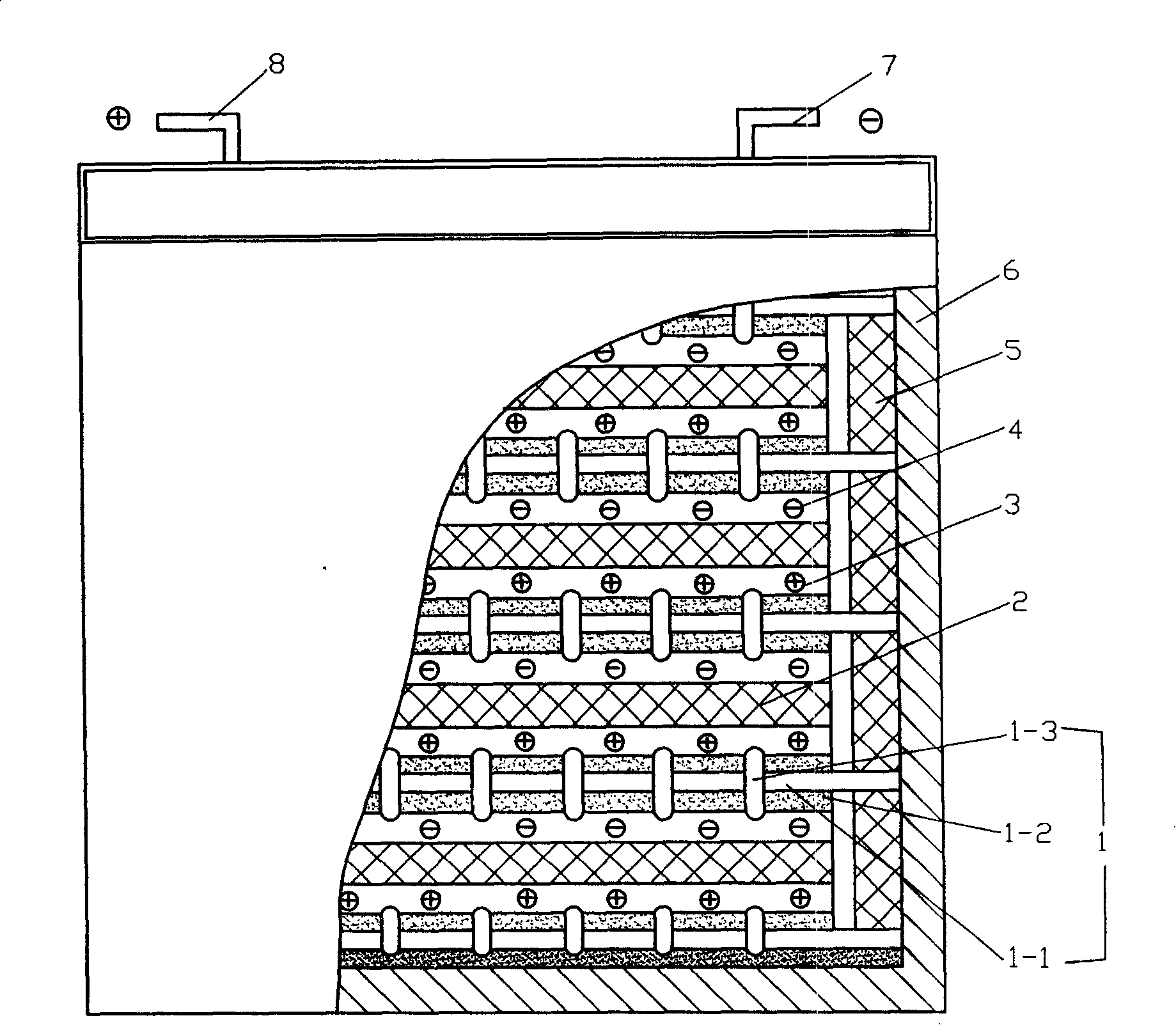

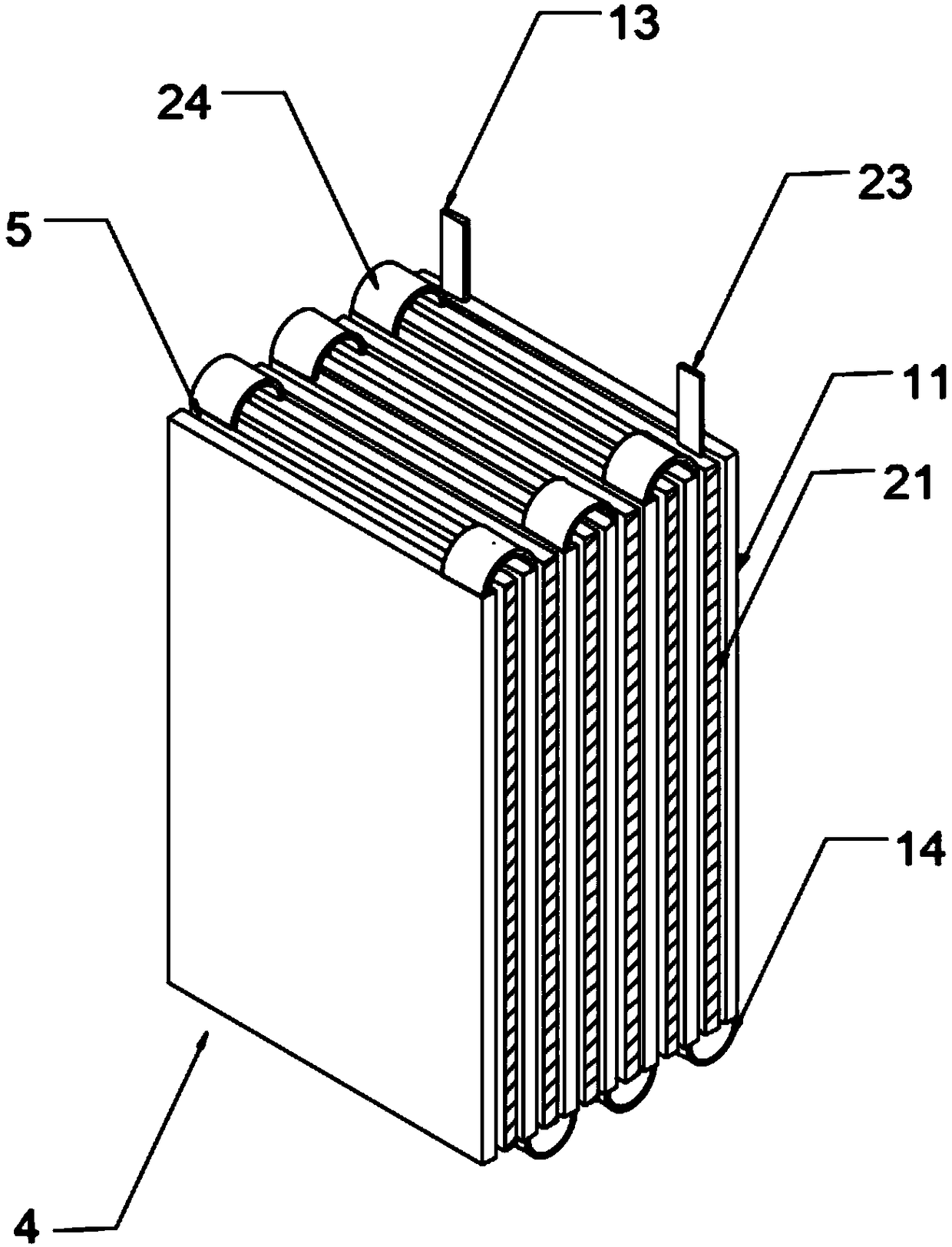

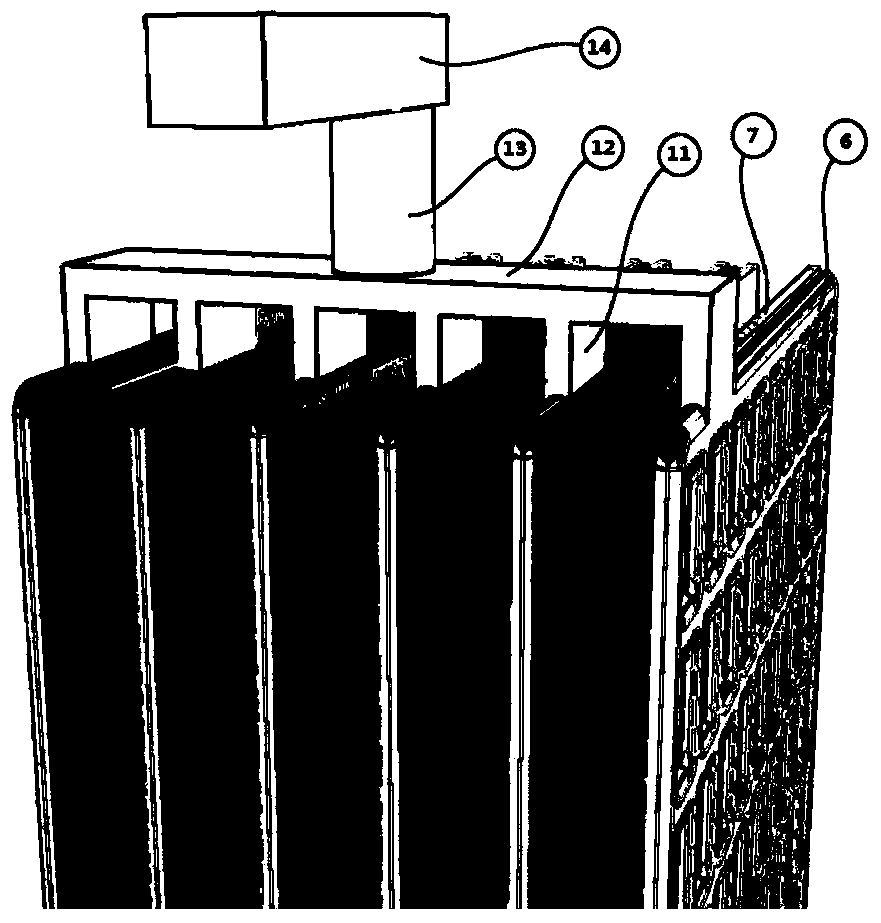

Bipolar-plate type unit high-energy lead-acid battery, high-voltage battery pack formed from same and package method of high-voltage battery pack

ActiveCN106207193AImprove resource utilizationSimple processFinal product manufactureElectrode carriers/collectorsElectrical conductorHigh energy

The invention relates to a lead-acid storage battery, in particular to a bipolar-plate type unit high-energy lead-acid battery, a high-voltage battery pack formed from the same and a package method of the high-voltage battery pack. The unit high-energy lead-acid battery comprises an electronic conductor bipolar plate, wherein a positive active material layer and a negative active material layer are respectively coated on two surfaces of the electronic conductor bipolar plate and are the same active material prepared by taking lead sulfate as main, and a batter partition plate is laid on the active material layer on one surface. After the unit battery disclosed by the invention is adopted to package batteries stacked in series, the battery with high voltage, low internal resistance and long cycle lifetime is easy to achieve, meanwhile, the production process of the battery is simplified, and the production cost is reduced.

Owner:曾碚凯

Novel lead acid accumulator with plastic-lead compound polar plate

InactiveCN101197441ASolution volumeAvoid weightLead-acid accumulatorsElectrode carriers/collectorsComposite electrodeInternal resistance

The invention discloses a novel lead-acid storage battery with a plastic composite electrode plate, and is mainly characterized in that: a plastic lead composite plate is used as a substitute for lead grids and lead connecting pieces of the prior lead-acid storage battery; the plastic composite electrode plate is composed by a composite electrode plate, a cotton layer on the surface of the electrode plate and lead particles embedded in the composite plate. The invention has the advantages that: 1. improving the specific energy form the original 30 wh / kg to 50 wh / kg; 2. reducing the weight of the storage battery by 40 percent compared with the storage batteries with the same capacity; 3. reducing the consumption of lead with 6g for per square meter of the composite electrode plate, thereby greatly reducing the cost; 4. small inner resistance, heavy output currency, long service life; 5. connecting a dozen or more than hundreds of the same batteries to form a storage battery of dozens of volts or hundreds of volts.

Owner:罗建阳 +1

Lead-acid storage battery polar plate grid

InactiveCN102751505AReduced lead melting processReduce emissionsElectrode carriers/collectorsCopper wireFiber

The invention discloses a lead-acid storage battery polar plate grid, which comprises a grid body, wherein the grid body is formed by a carbon fiber material, positive lead paste is coated on the grid body to form a positive plate; and negative lead paste is coated on the grid body to form a negative plate. The polar plates and polar clusters are connected in a tightening way without use of lead, copper wires are lead out to form a positive electrode and a negative electrode, so that the lead consumption for the storage battery is less, the lead can be saved about 40 to 60 percent compared with that of the traditional lead-acid storage battery; and moreover, in the entire production process, the lead melting steps are reduced, the lead emission is greatly reduced, and the environmental pollution caused by the lead in the production process can be further reduced.

Owner:杨成清

Fabrication method for negative plate of lead-acid storage battery

ActiveCN105226240AReduce weightThe strength does not decrease or even increaseLead-acid accumulator electrodesFiberCarbon fibers

A fabrication method for a negative plate of a lead-acid storage battery comprises grid fabrication and active substance filling and is characterized by comprising the following steps of: substituting the traditional framework of a negative plate grid by a conductive carbon fiber felt part; embedding a tab and conductive ribs onto the carbon fiber felt to form a novel grid; filling the interior and the surface of the novel grid with an active substance; and fabricating the negative plate. In the negative plate, lead dosage is reduced, the weight is favorably reduced, and an environment is protected; and particularly, the carbon fiber and the active substance are tightly combined, the contact area is large, the resistance is small, the utilization rate of the active substance is improved, the charging reception of the active substance is high, the sulphation is overcome, and the service life of the batter is prolonged.

Owner:SHUANGDENG GRP

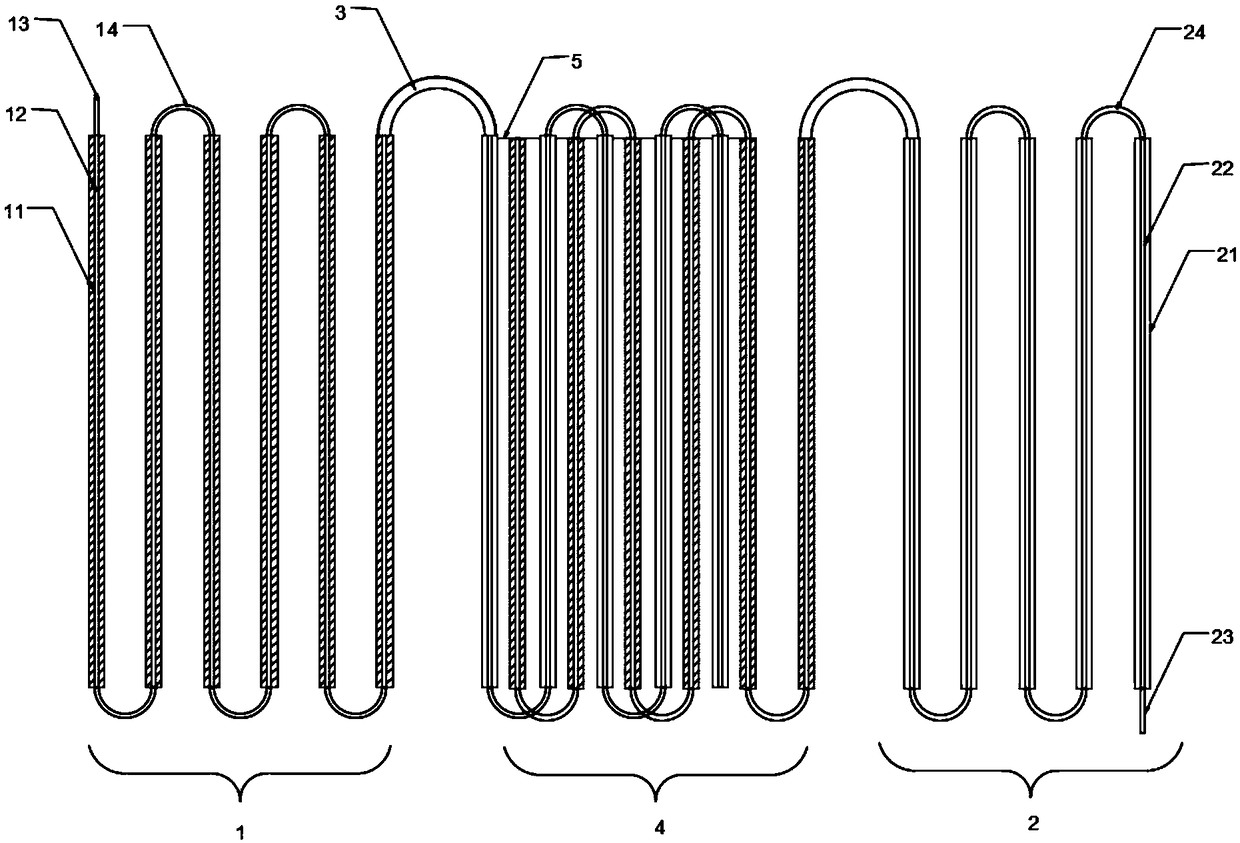

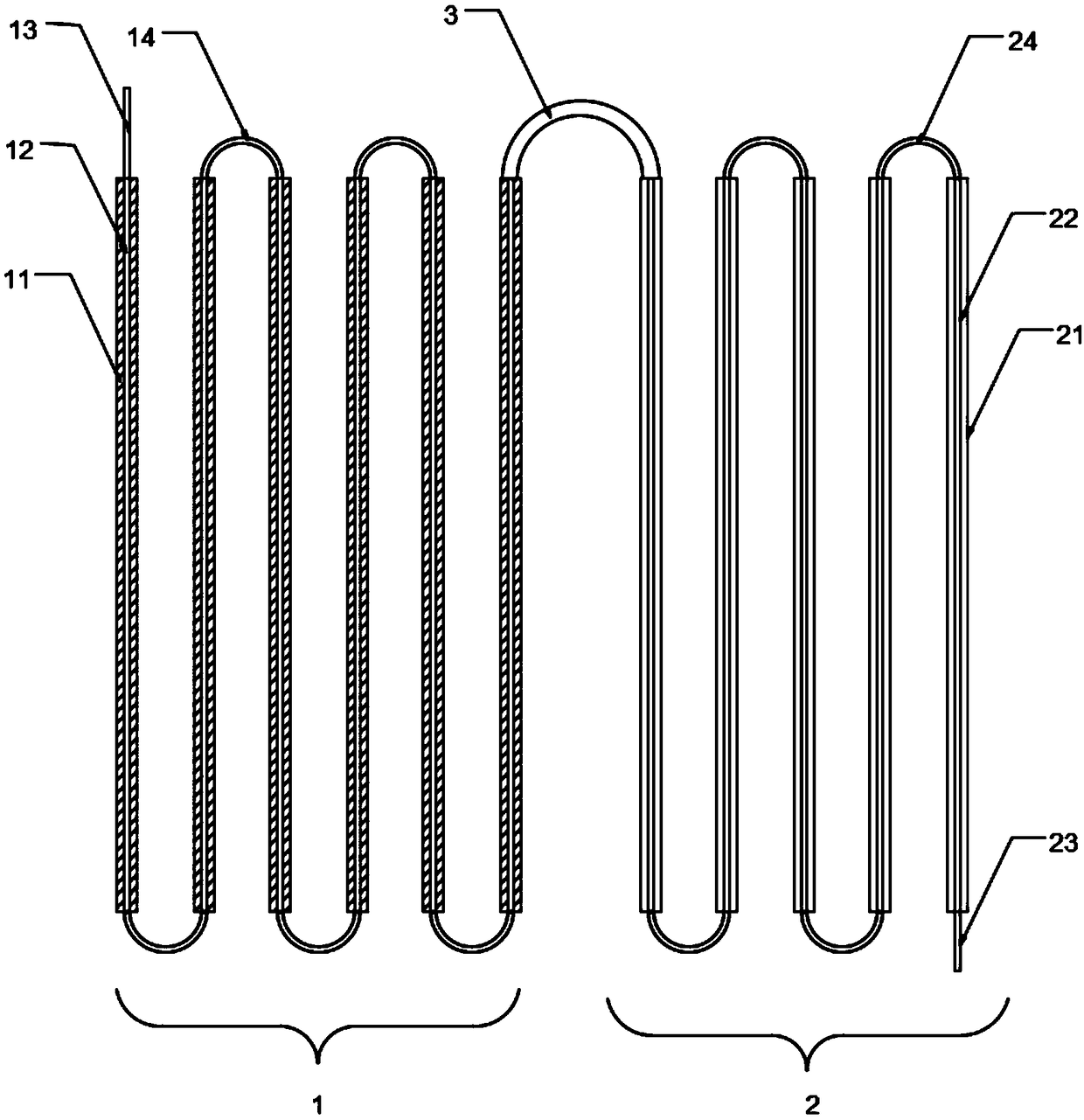

Welding-free storage battery and production method thereof

PendingCN108666636AReduce the amount of lead usedQuality improvementFinal product manufactureLead-acid accumulator electrodesContinuous designEngineering

The invention relates to the technical field of chemical power supply materials and in particular relates to a welding-free storage battery and a production method thereof. A continuous type welding-free lead storage battery pole group comprises continuous type positive electrode plates, continuous type negative electrode plates, a single-body-spanning connection sheet, a continuous type bipolar pole plate and a separation plate, wherein the continuous type bipolar pole plate is composed of the continuous type positive electrode plates, the continuous type negative electrode plates and the separation plate, which are inserted and matched. According to the welding-free storage battery provided by the invention, an integrated continuous design is carried out on the lead storage battery polegroup and a welding procedure of a plurality of pieces of the positive electrode plates or negative electrode plates in a pole plate group during a storage battery production process is eliminated; aserial and parallel connection welding procedure of bridge-spanning welding, wall-penetrating welding and the like of a plurality of single bodies of the storage battery is also eliminated. Therefore,the use amount of lead of the storage battery is reduced and sheet falling and missing welding phenomena do not happen between the pole plate group of the storage battery and the single bodies; the product quality and reliability of the storage battery are effectively improved.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

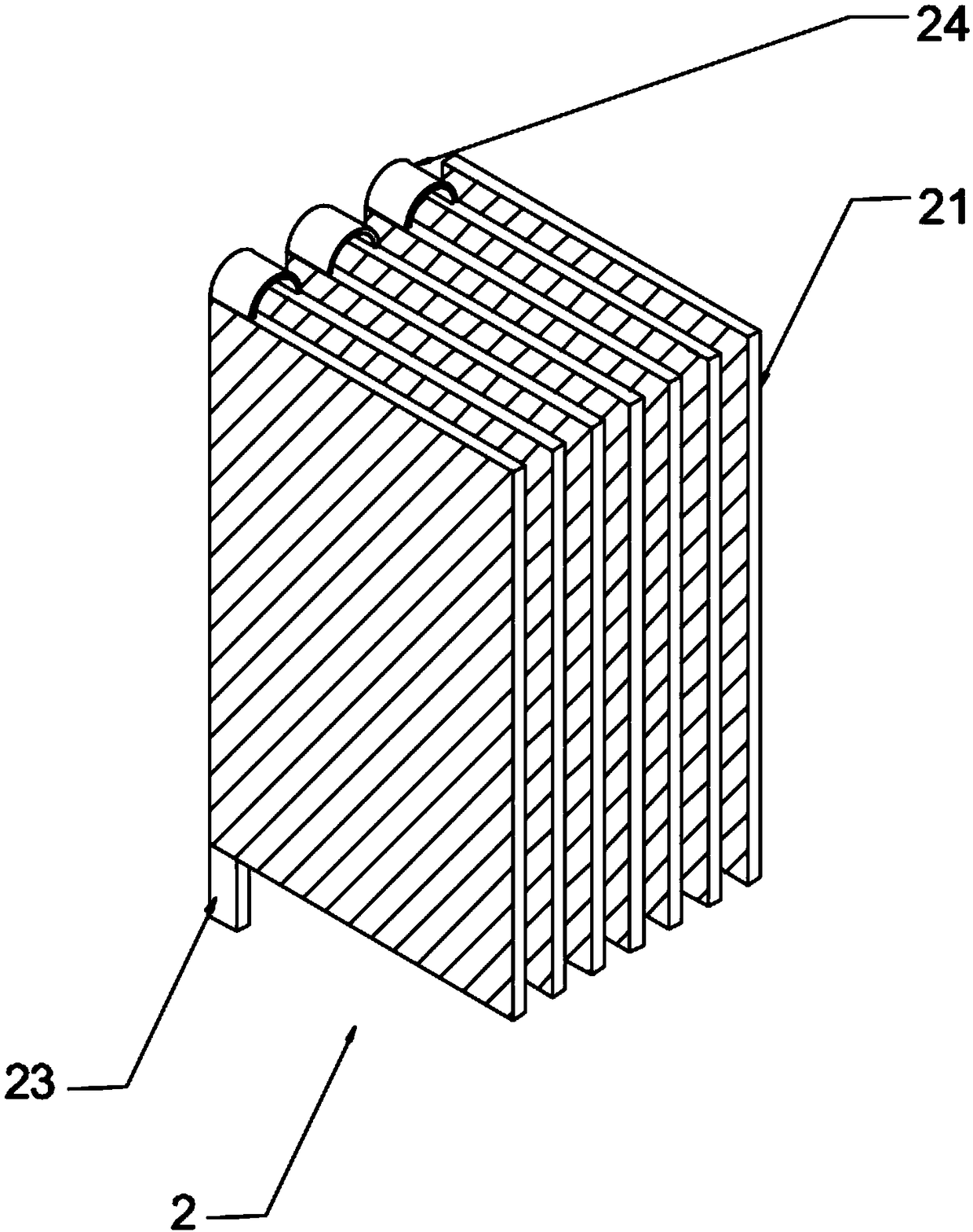

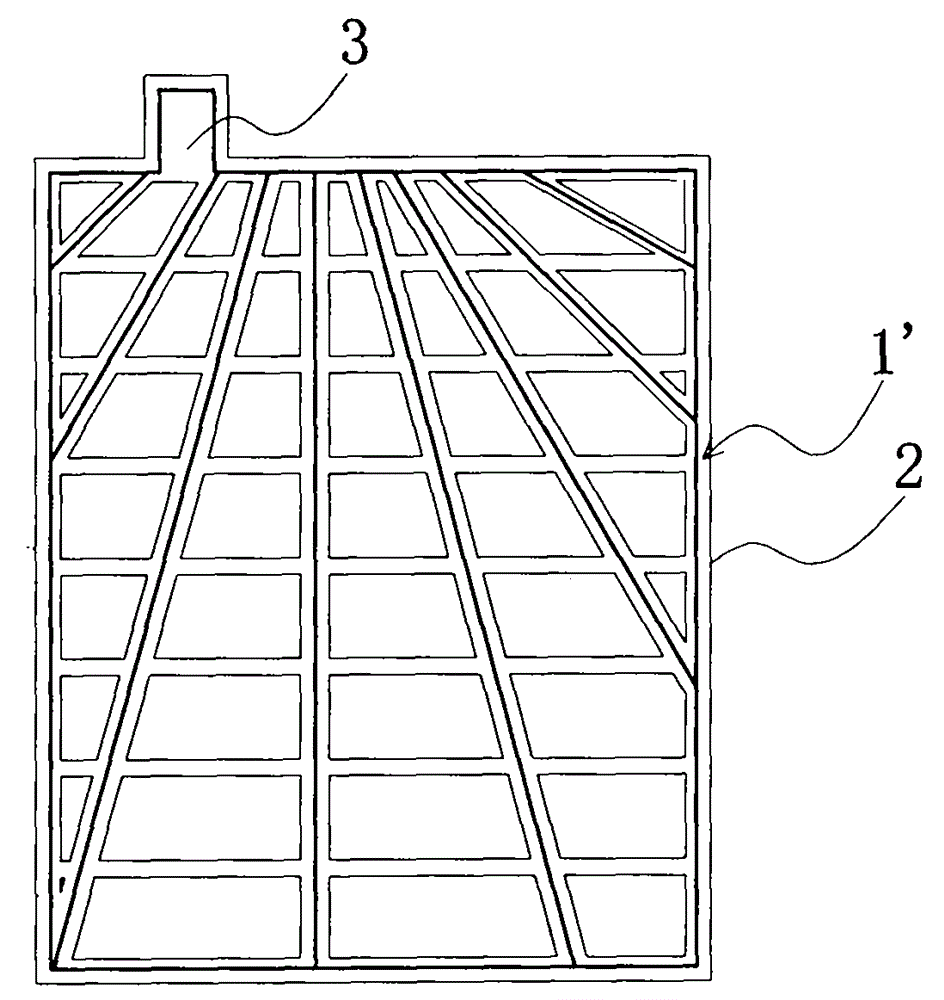

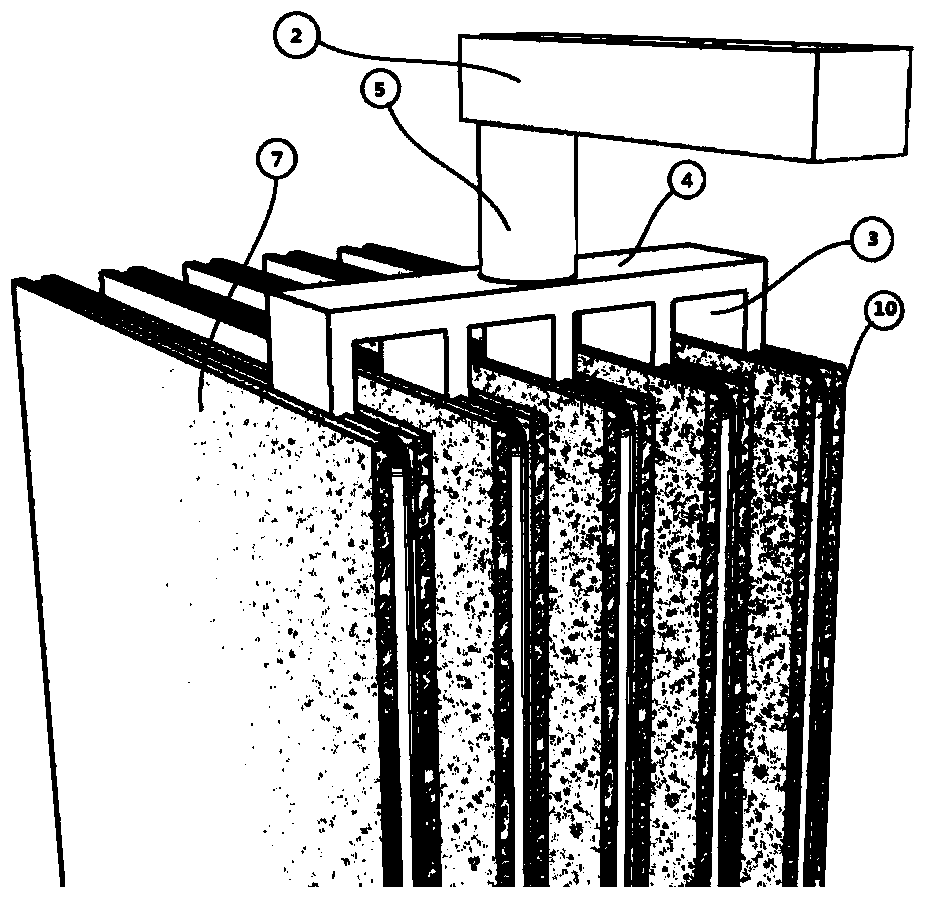

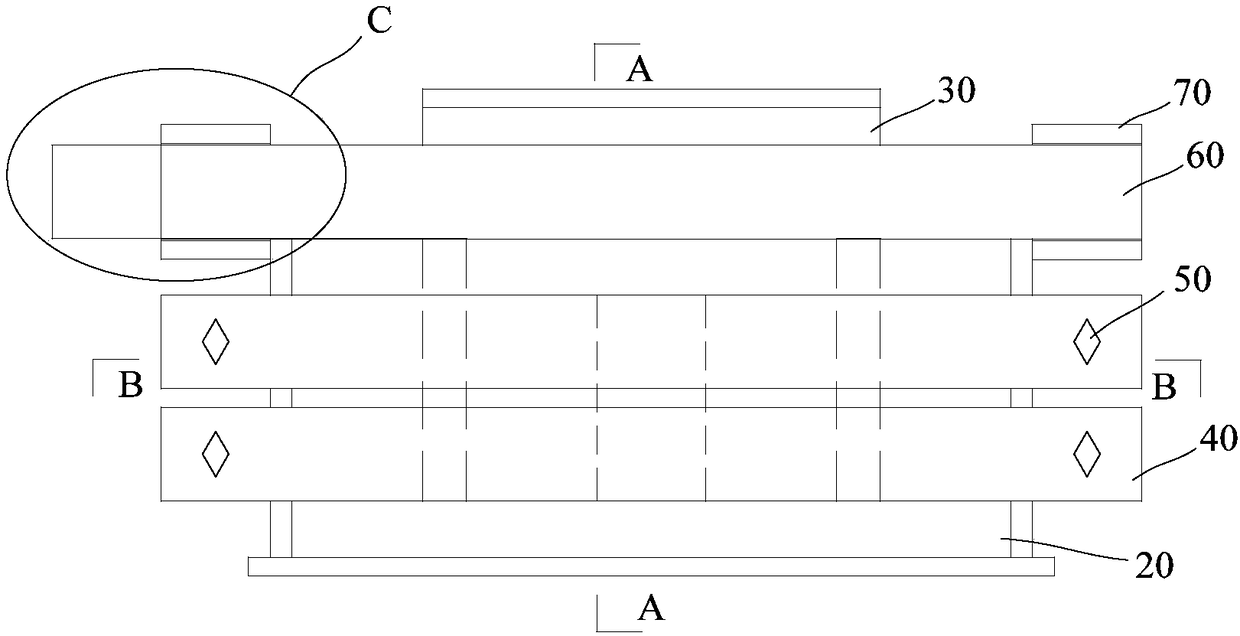

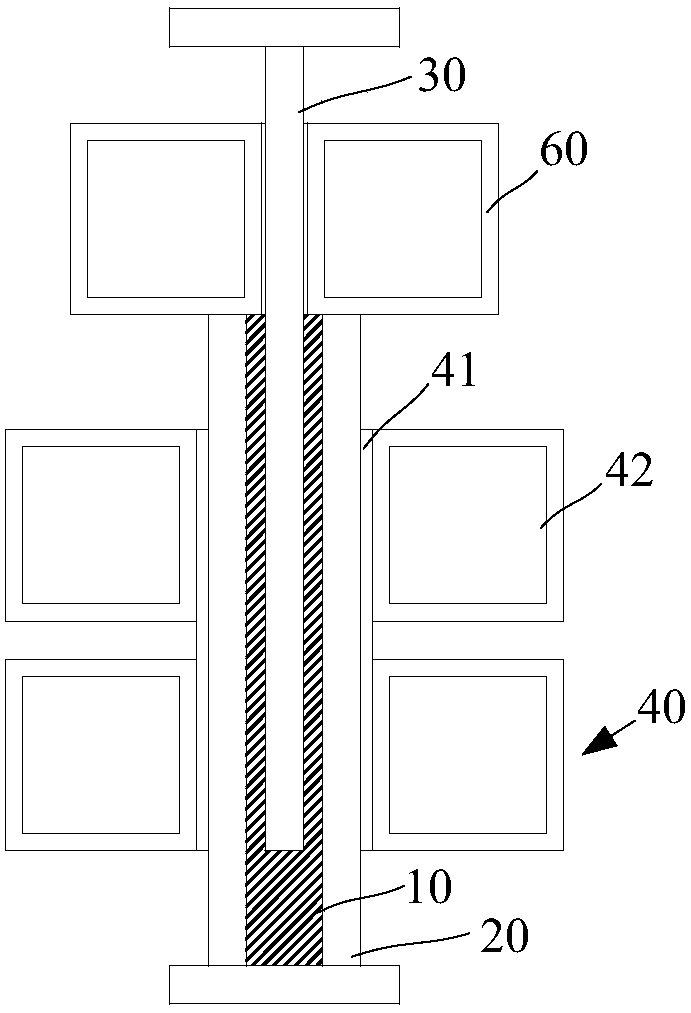

A continuous solder-free lead-acid battery electrode group and a manufacturing method thereof

PendingCN109004291AReduce the amount of lead usedQuality improvementFinal product manufactureCell component detailsBiochemical engineeringMonomer

The invention relates to the technical field of chemical power supply materials, in particular to a continuous solderless lead-acid battery electrode group and a manufacturing method thereof. The continuous solder-free lead-acid battery electrode group comprises a continuous positive electrode plate, a continuous negative electrode plate, a cross-unit connecting piece, a continuous bipolar electrode plate and a separator, wherein the continuous bipolar electrode plate is composed of a continuous positive electrode plate, a continuous negative electrode plate and a separator which are insertedand matched. A lead storage battery electrode group is integrally and continuously design, and that welding procedure of a plurality of positive plate or negative plates in the electrode plate group in the production process of the storage battery is eliminated, and the series and parallel welding procedures such as cross-bridge welding and through-wall welding between a plurality of monomers of the storage battery are also eliminated. This not only reduces the lead consumption of the battery, but also does not appear the phenomenon of chips falling off and missing welding between the electrode plate group and the monomer of the battery, which effectively improves the product quality and reliability of the battery. In addition, the electrode group of the invention has high manufacturing process efficiency and is convenient for production and processing.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

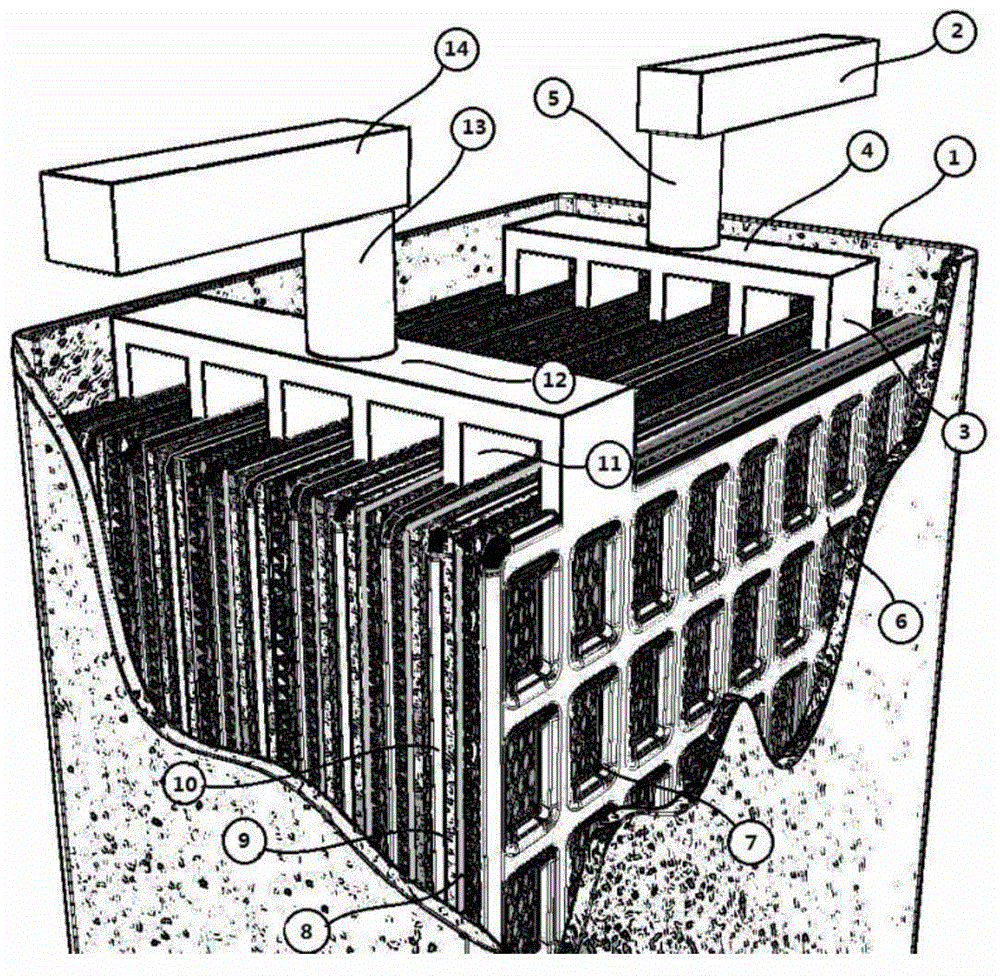

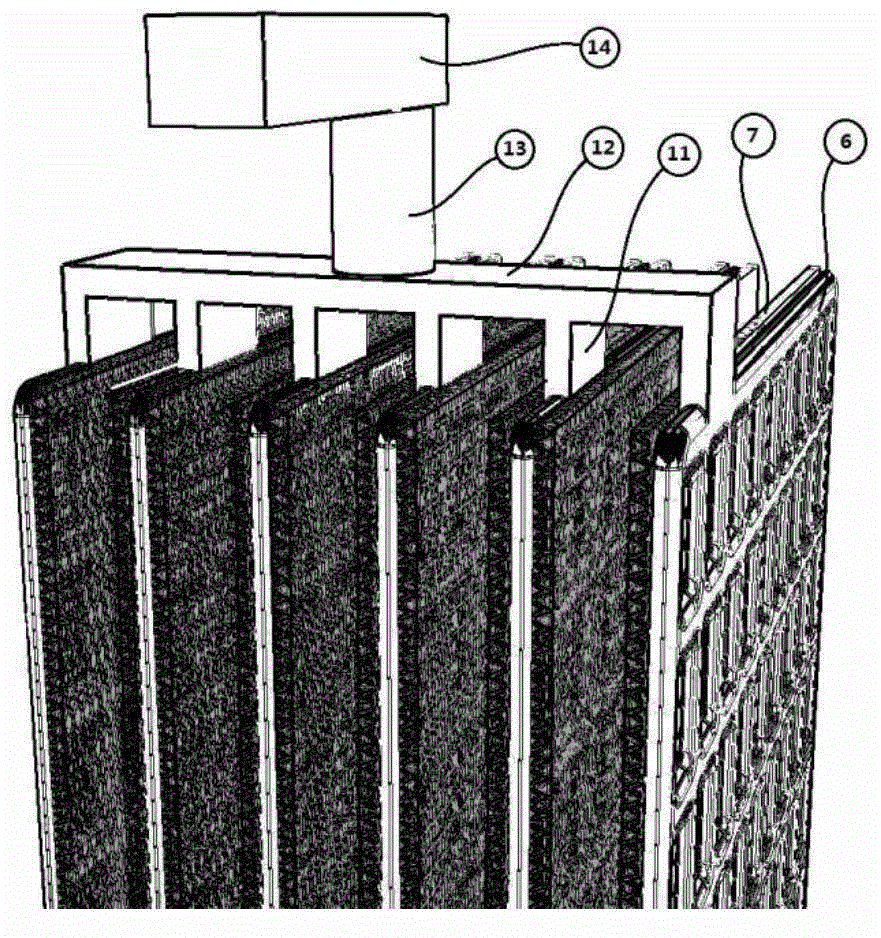

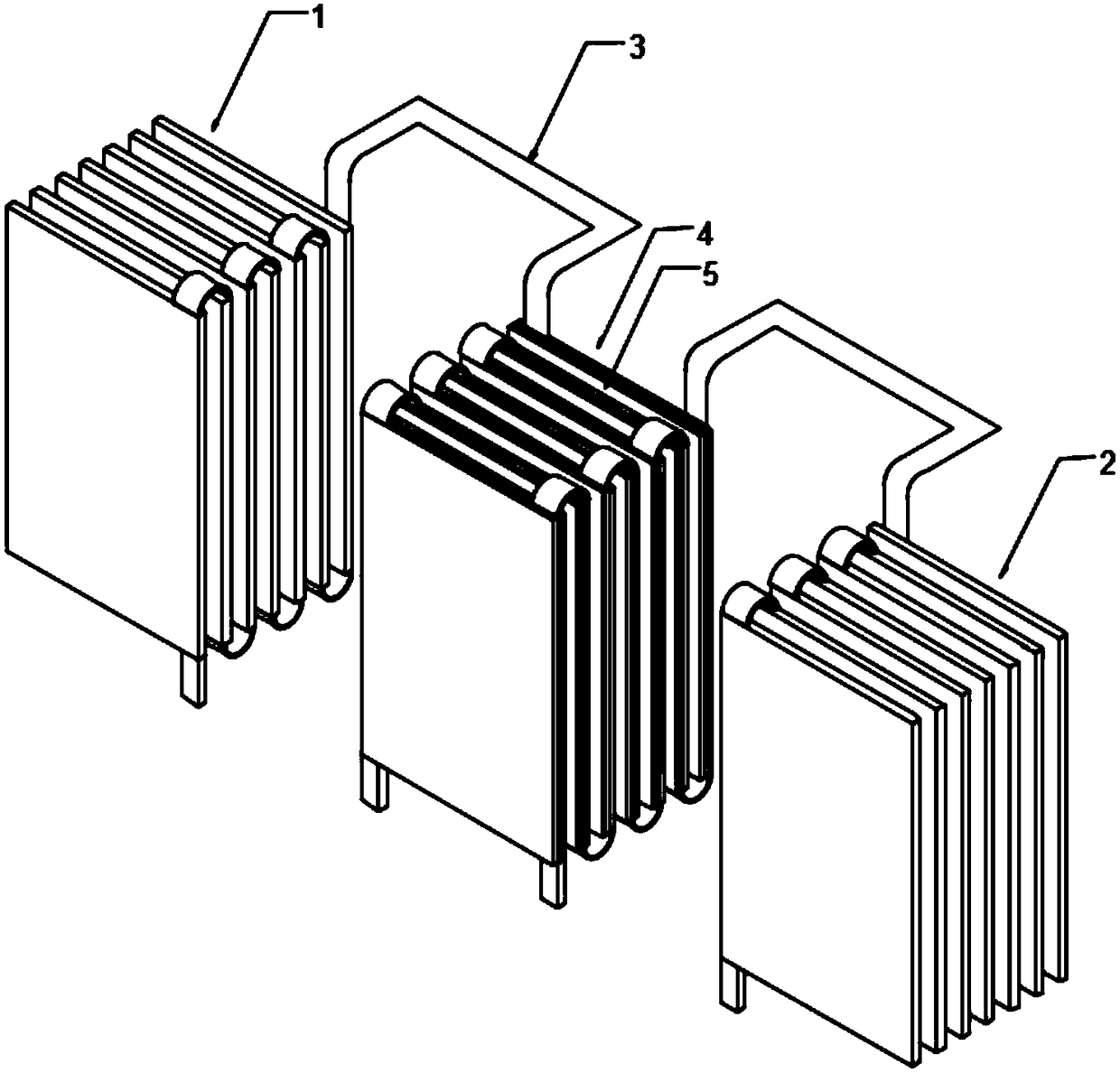

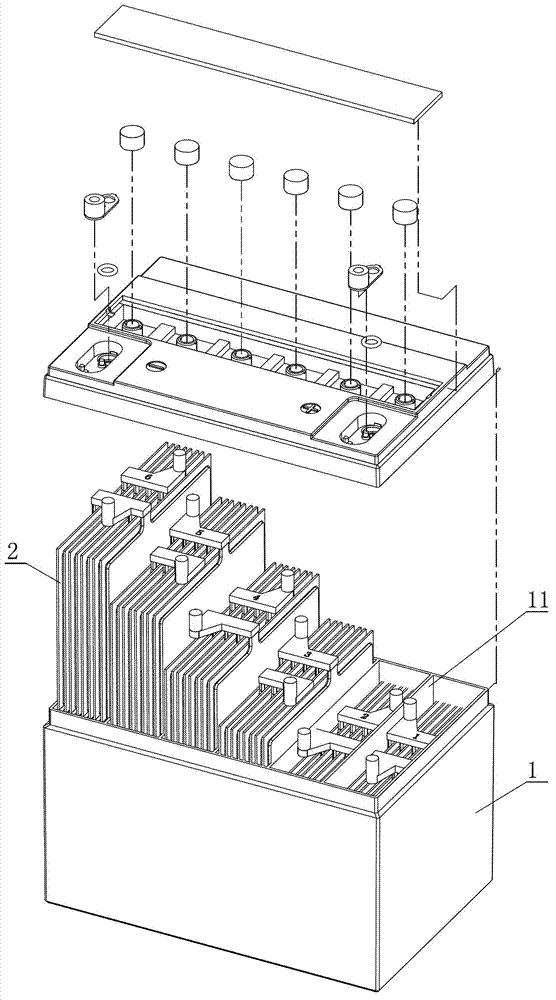

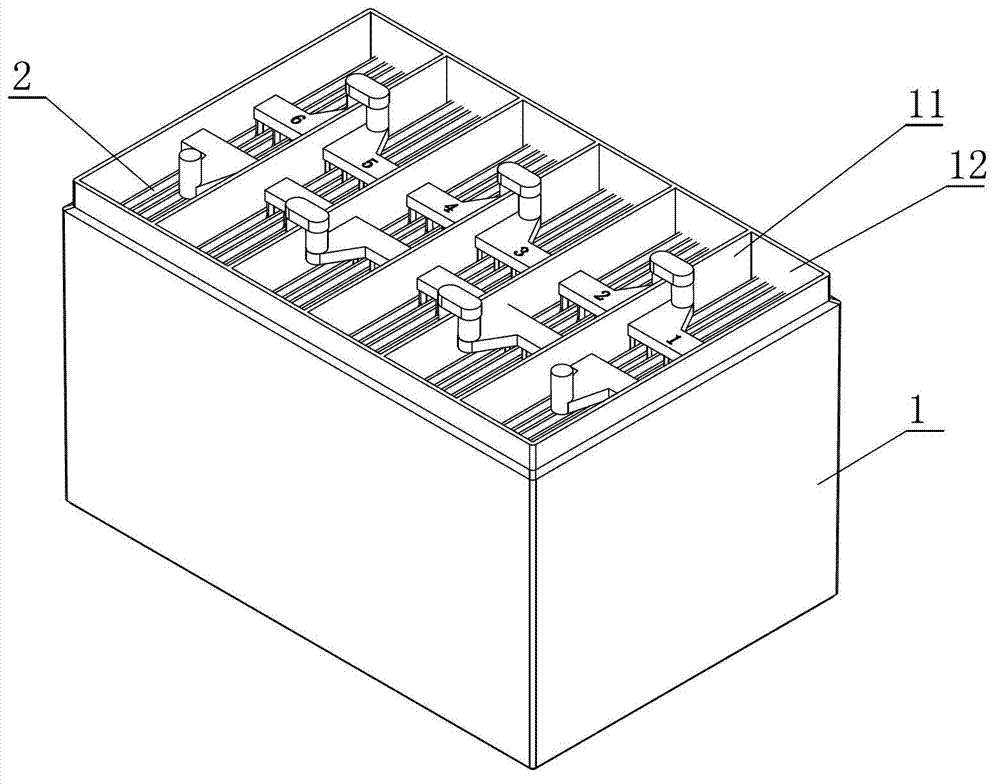

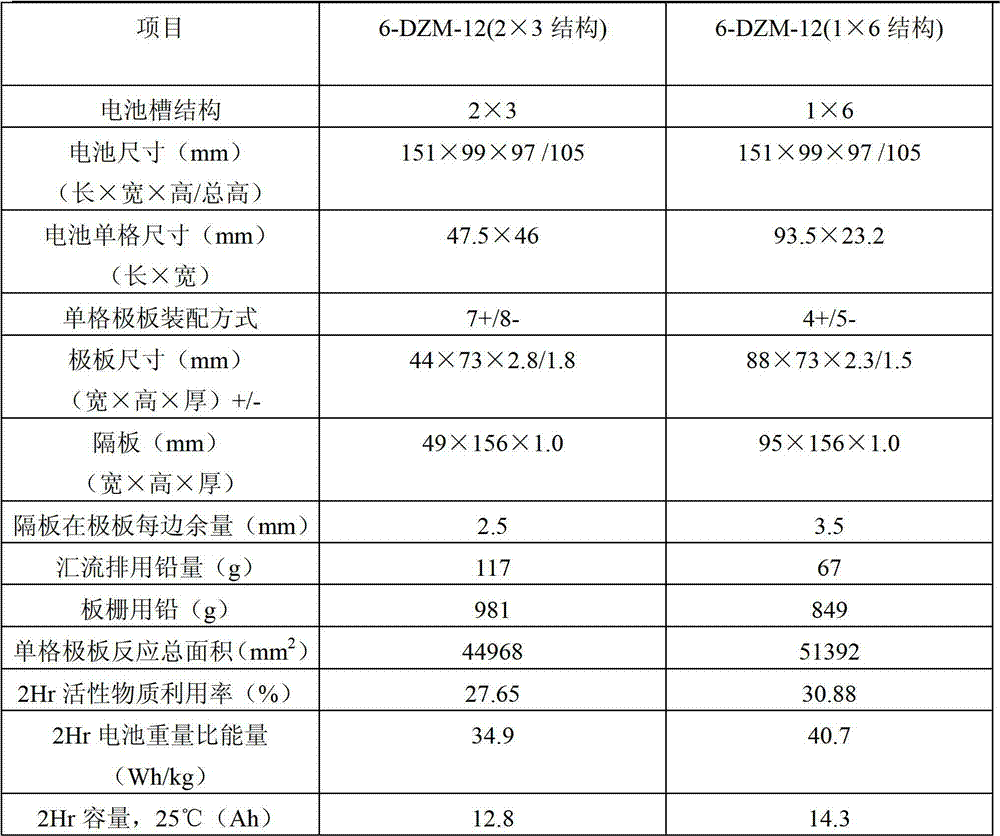

Lead-acid battery for electric moped

InactiveCN102856592AReduce the amount of lead usedLow costFinal product manufactureCell component detailsElectrical and Electronics engineeringLead–acid battery

The invention discloses a lead-acid battery for an electric moped. The lead-acid battery comprises a battery case and multiple pole units. Baffle plates are arranged in the battery case and divide the battery case into multiple side-by-side battery single cells. Each one of the multiple pole units is arranged in corresponding one of the multiple side-by-side battery single cells. The lead-acid battery can effectively reduce a lead use amount of a grid and a lead use amount of a bus-bar and also greatly reduce a product cost.

Owner:江苏永达电源股份有限公司

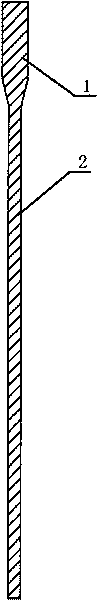

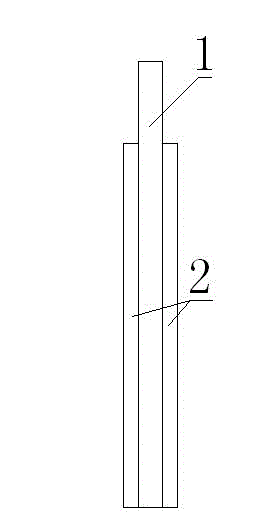

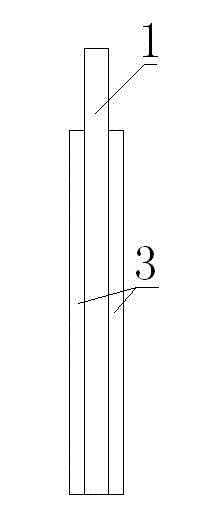

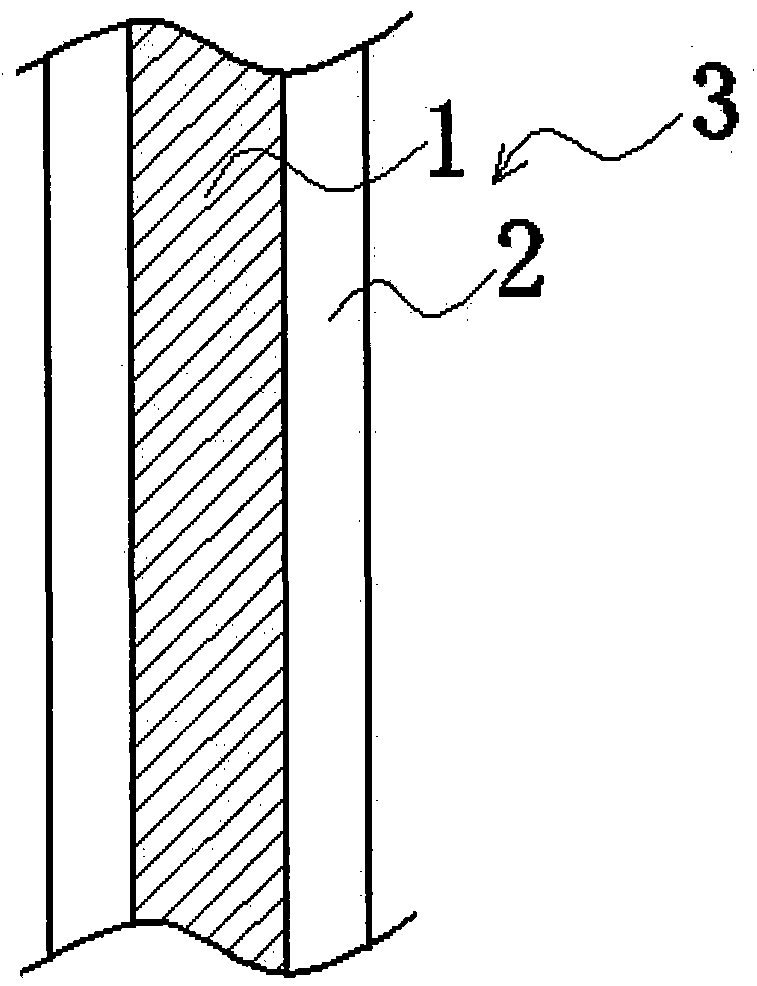

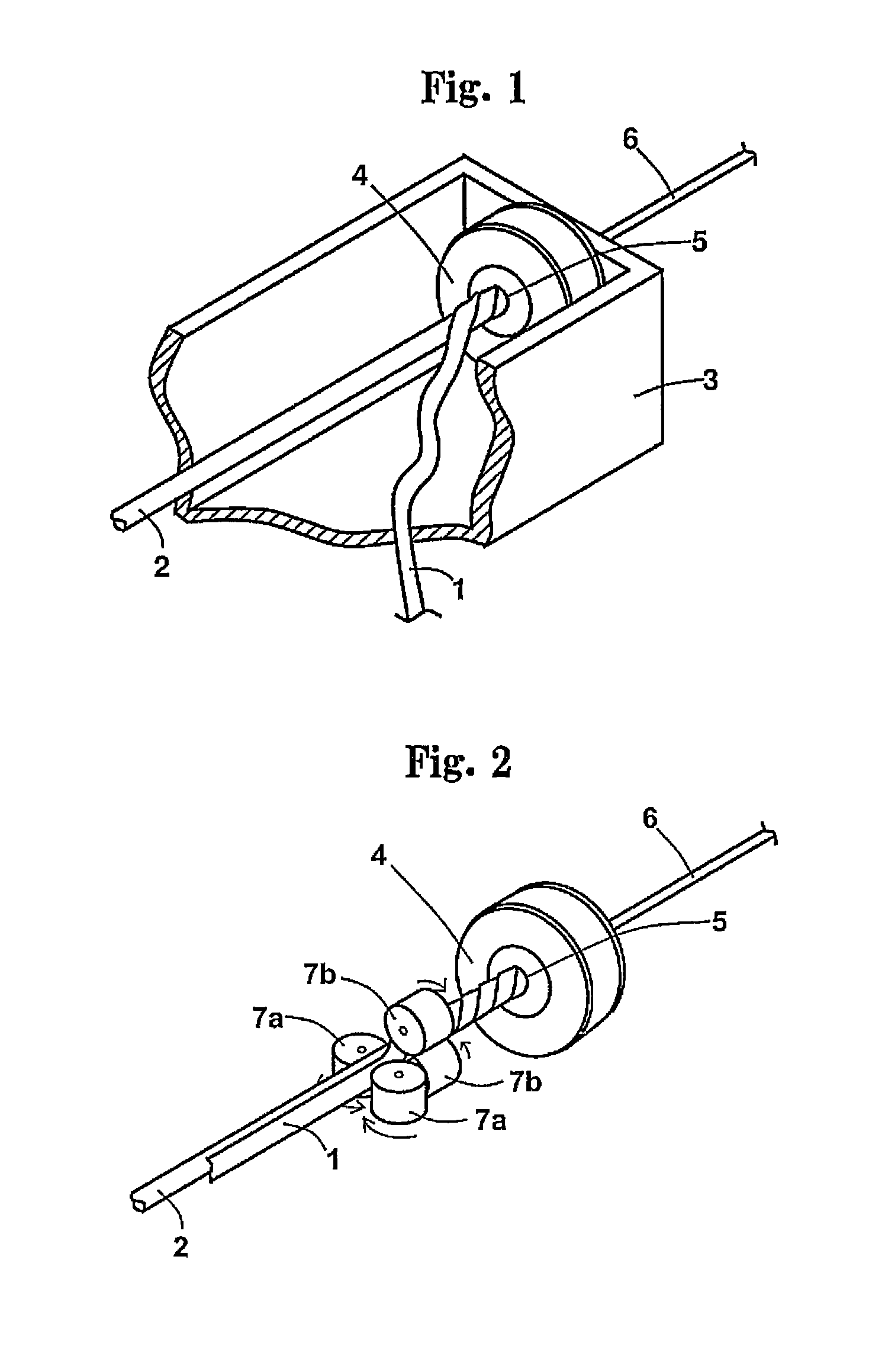

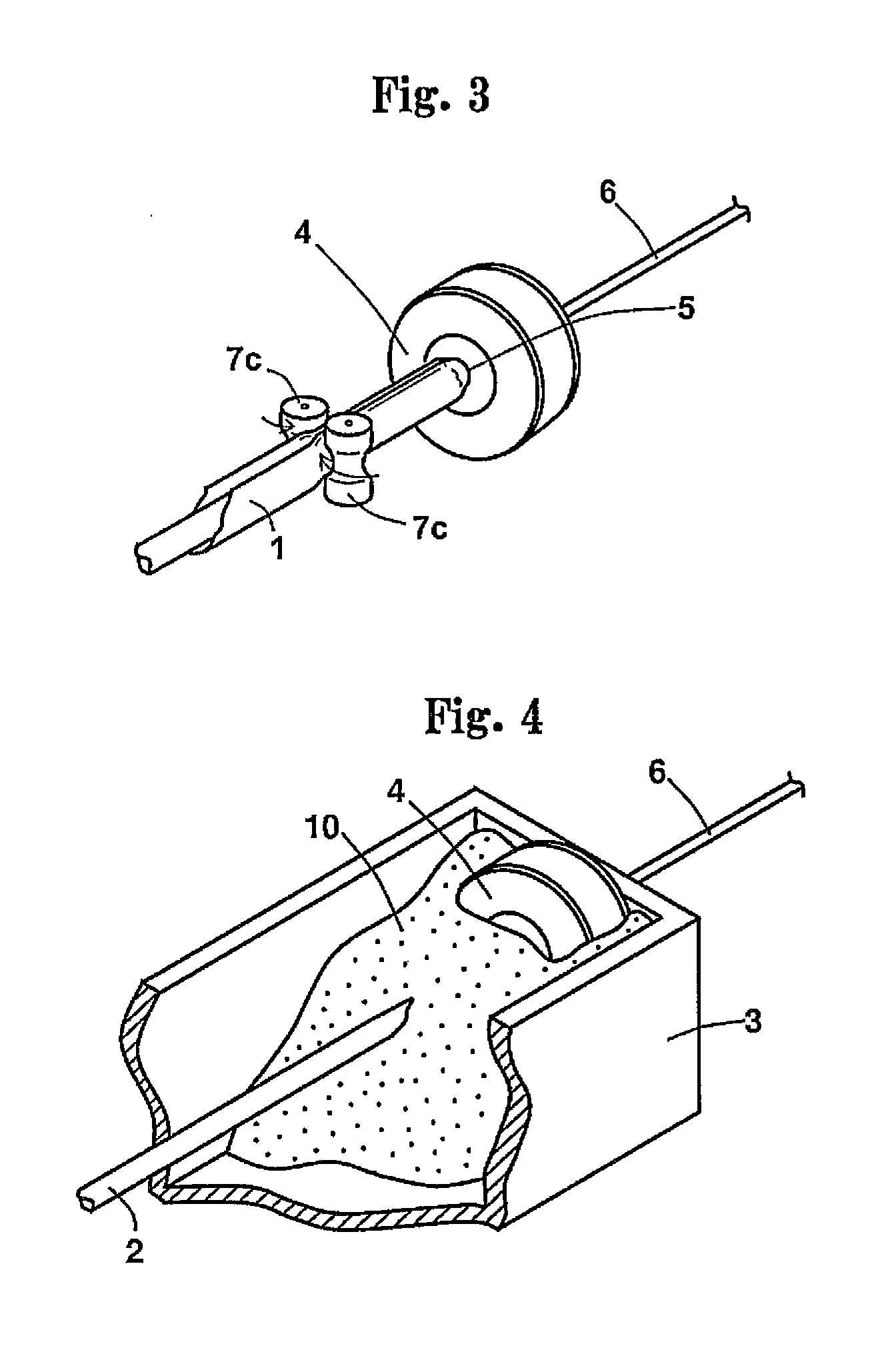

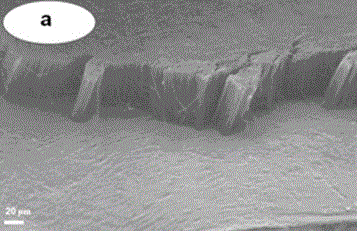

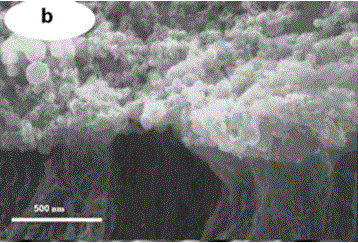

Lead-coated carbon composite material and application thereof

InactiveCN104377362AReduce quality problemsReduce pollutionElectrode carriers/collectorsCarbon compositesElectrochemistry

The invention relates to a lead-coated carbon composite material and an application thereof. The lead-coated carbon composite material is characterized in that lead (2) is used for coating the surrounding of a powder-form or rod-form carbon-based material (1) for extrusion moulding, or the powder-form carbon-based material (1) is compressed to a carbon-based grid or is wound to obtain the carbon-based grid after being made to a filament state, and then a lead sheath is used for coating on an outer layer of the carbon-based grid. The lead-coated carbon composite material can be used for making the grid for a storage battery electrode plate, volume ratio energy and discharge capacity of a storage battery can be effectively increased; the carbon-based material with light weight and strong conductivity can be taken as a conductive inner core, a lead layer with strong corrosion resistance and electrochemistry performance is used for coating outer part, so that lead amount is reduced, grid weight is greatly reduced, cell weight is greatly reduced, and environmental pollution can be mitigated.

Owner:JIANGSU JINDING AUTOMOBILE TECH

Production process of plate grid

InactiveCN104466121AImprove grid performanceReduce the amount of lead usedElectrode carriers/collectorsLead-acid accumulator electrodesLead plateAluminium

The invention relates to a production process of a plate grid. Carbon, aluminum or conducting alloy is adopted for manufacturing the plate grid, lead or lead alloy with the thickness of 0.1-2mm is sprayed on the surface layer of the plate grid after the plate grid is formed, the lead layer on the surface and the plate grid are bonded through strong extrusion, or a thin lead plate with the thickness of 0.1-0.8mm is strongly extruded to be clad on the surface layer of the plate grid, so that the lead density on the surface layer can be increased by more than 5 times. The plate grid produced by the production process can be applied to manufacturing of the electrode plate of the storage battery, the traditional thinking that the plate grid is made of pure lead or lead alloy is abandoned, the light conducting inner core is added to improve the performance of the grid plate, the using amount of the lead is reduced, the environment pollution is reduced, the weight of the storage battery can be reduced, and the volumetric specific energy and the discharge capacity of the storage battery can be increased.

Owner:JIANGSU JINDING AUTOMOBILE TECH

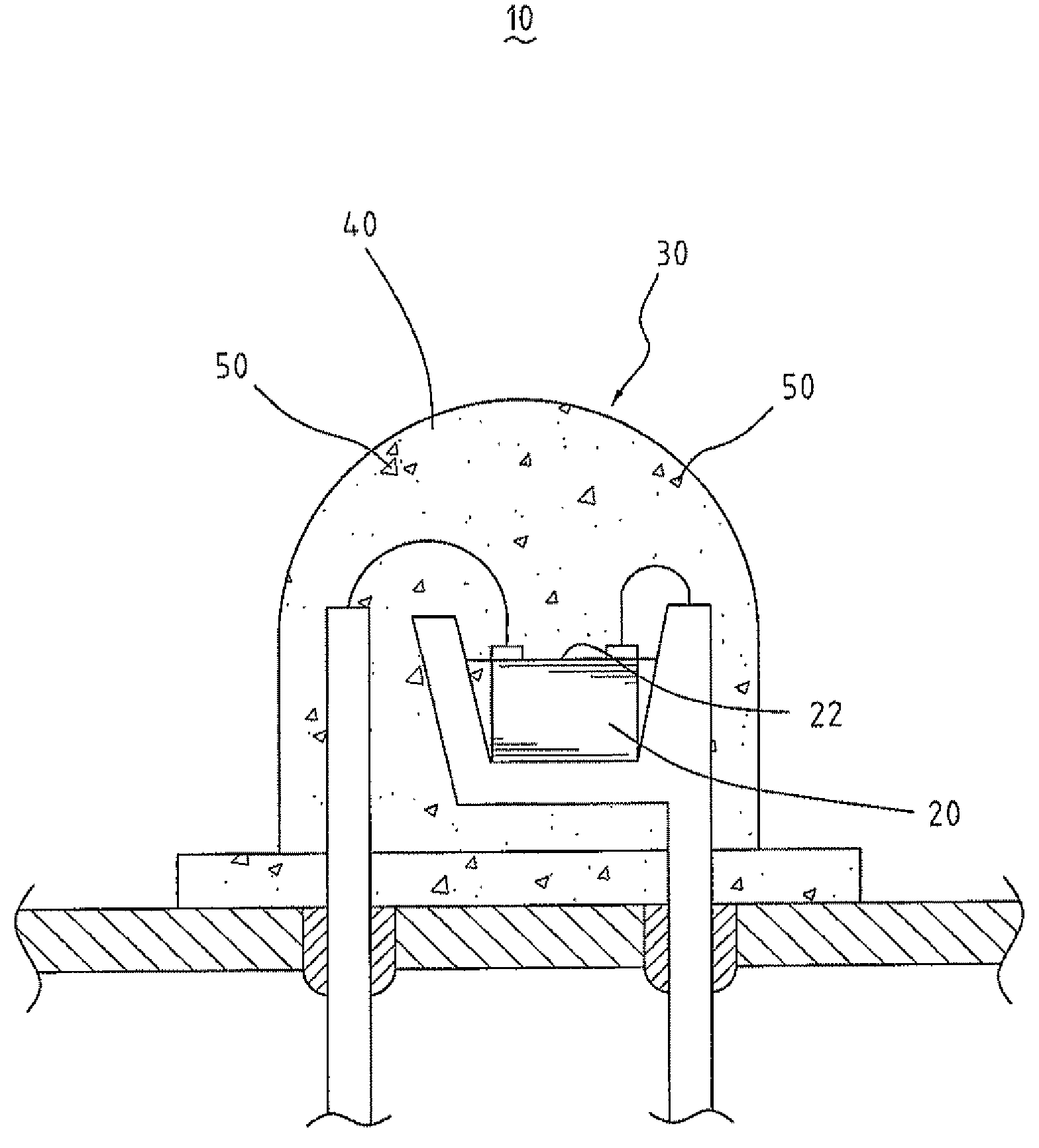

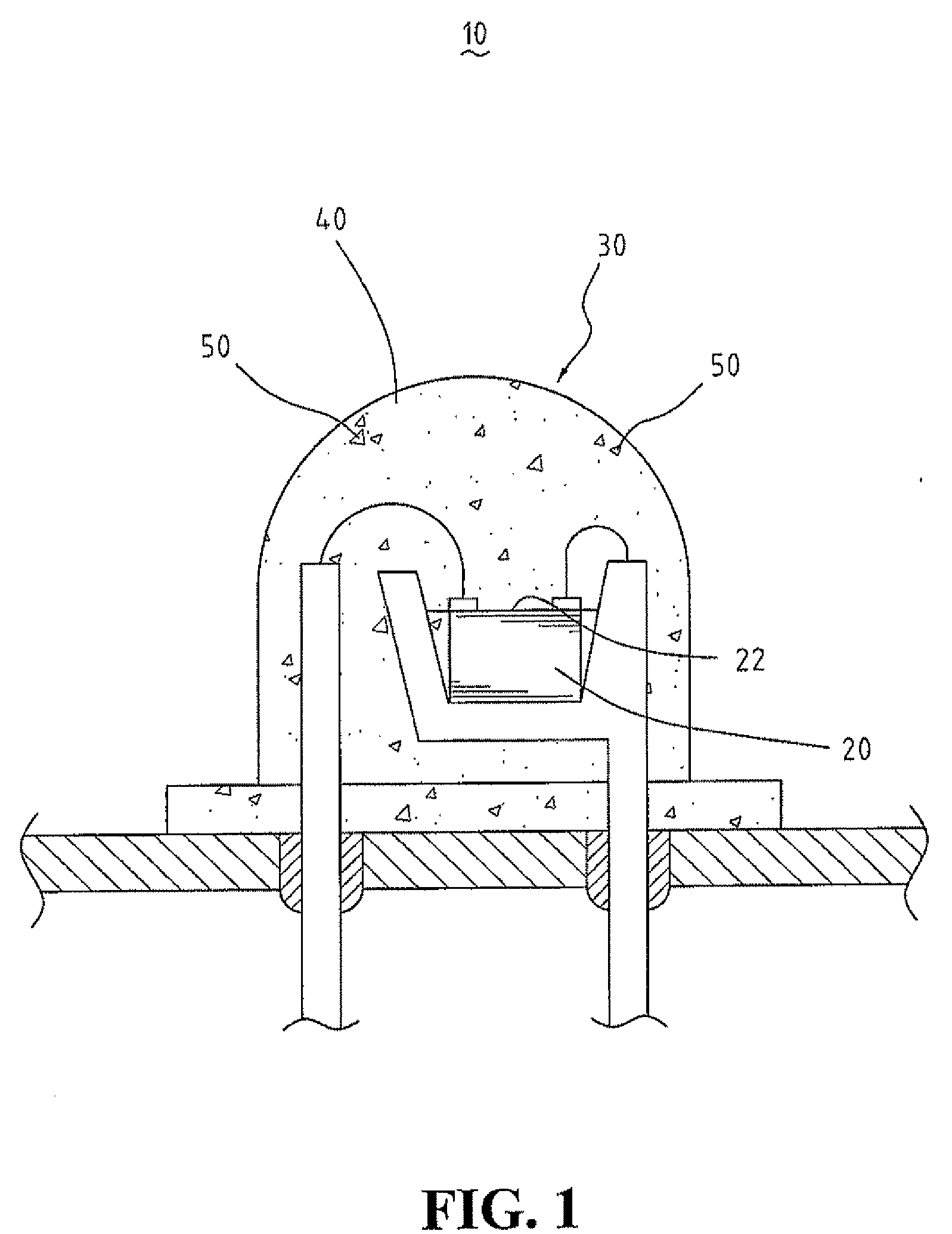

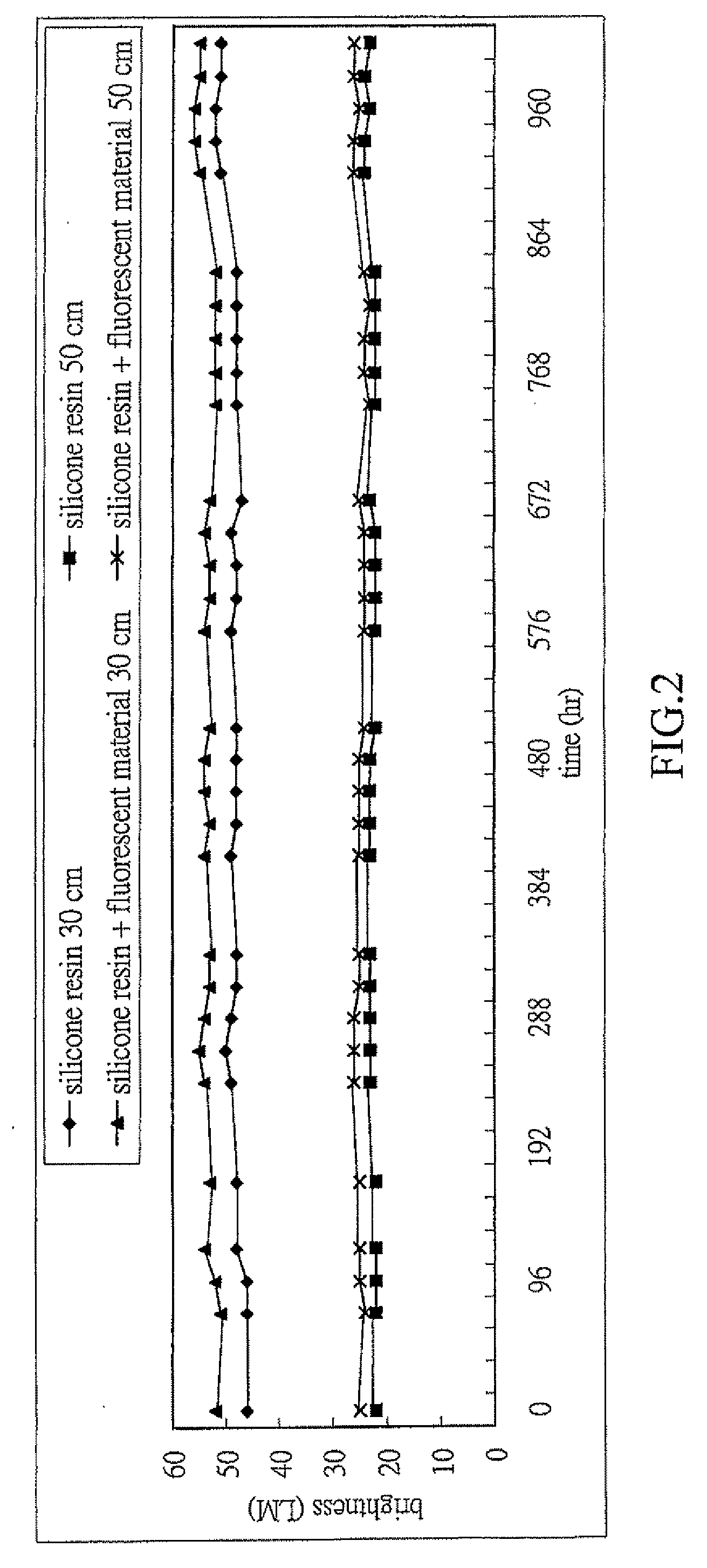

Enhanced Brightness Light Emitting Device

InactiveUS20090230859A1Solve low luminous efficiencyIncrease brightnessDischarge tube luminescnet screensLamp detailsLight emitting deviceSilicon

There is provided an enhanced brightness light emitting device, comprising a light emitting element, and a transparent encapsulation layer which encloses the light emitting element. The transparent encapsulation layer includes a resin and a fluorescent material selected from a non-aromatic fluorescent material, an aromatic fluorescent material, and a non-aromatic fluorescent material containing silicon.

Owner:LUMINOSO PHOTOELECTRIC TECH

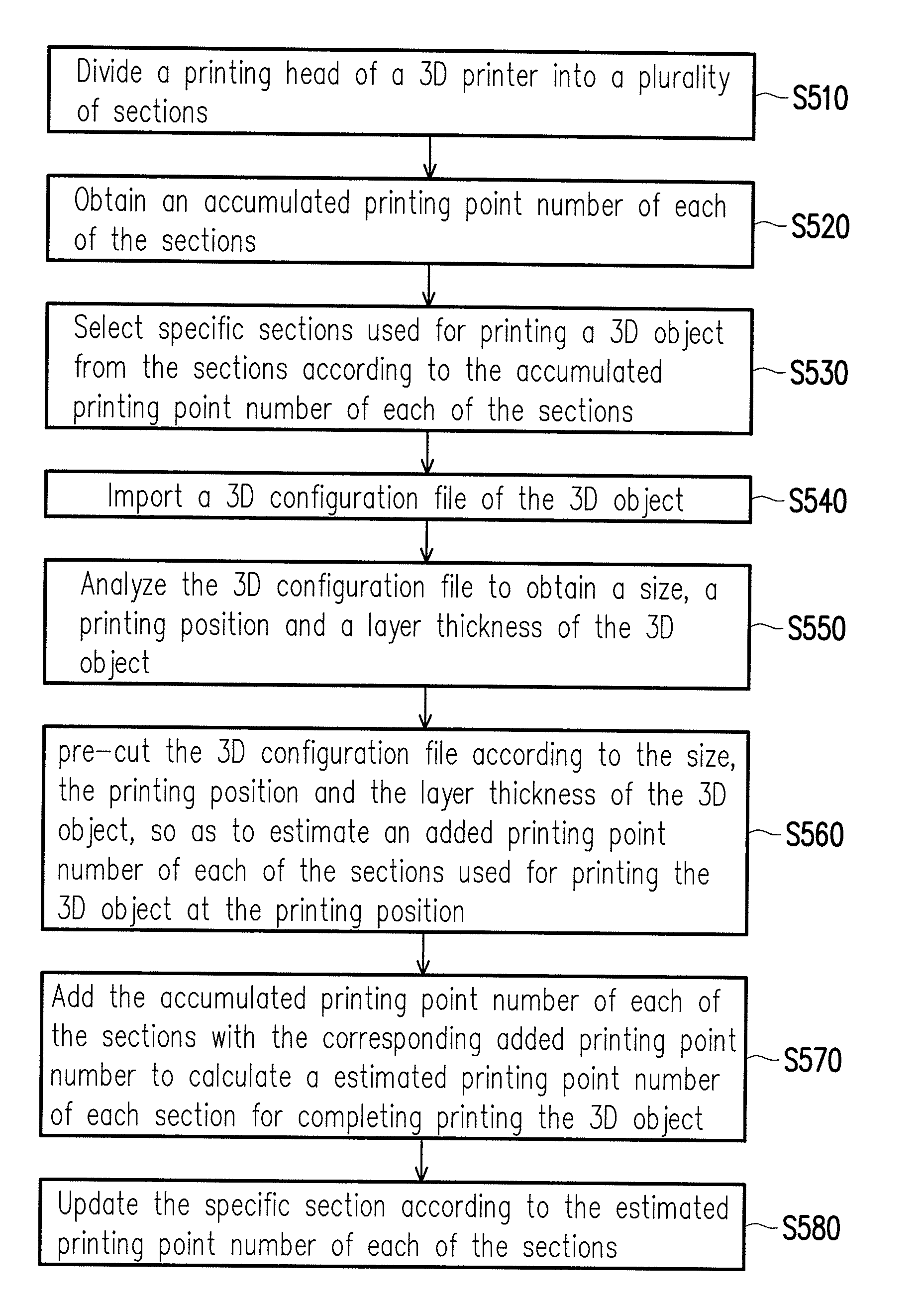

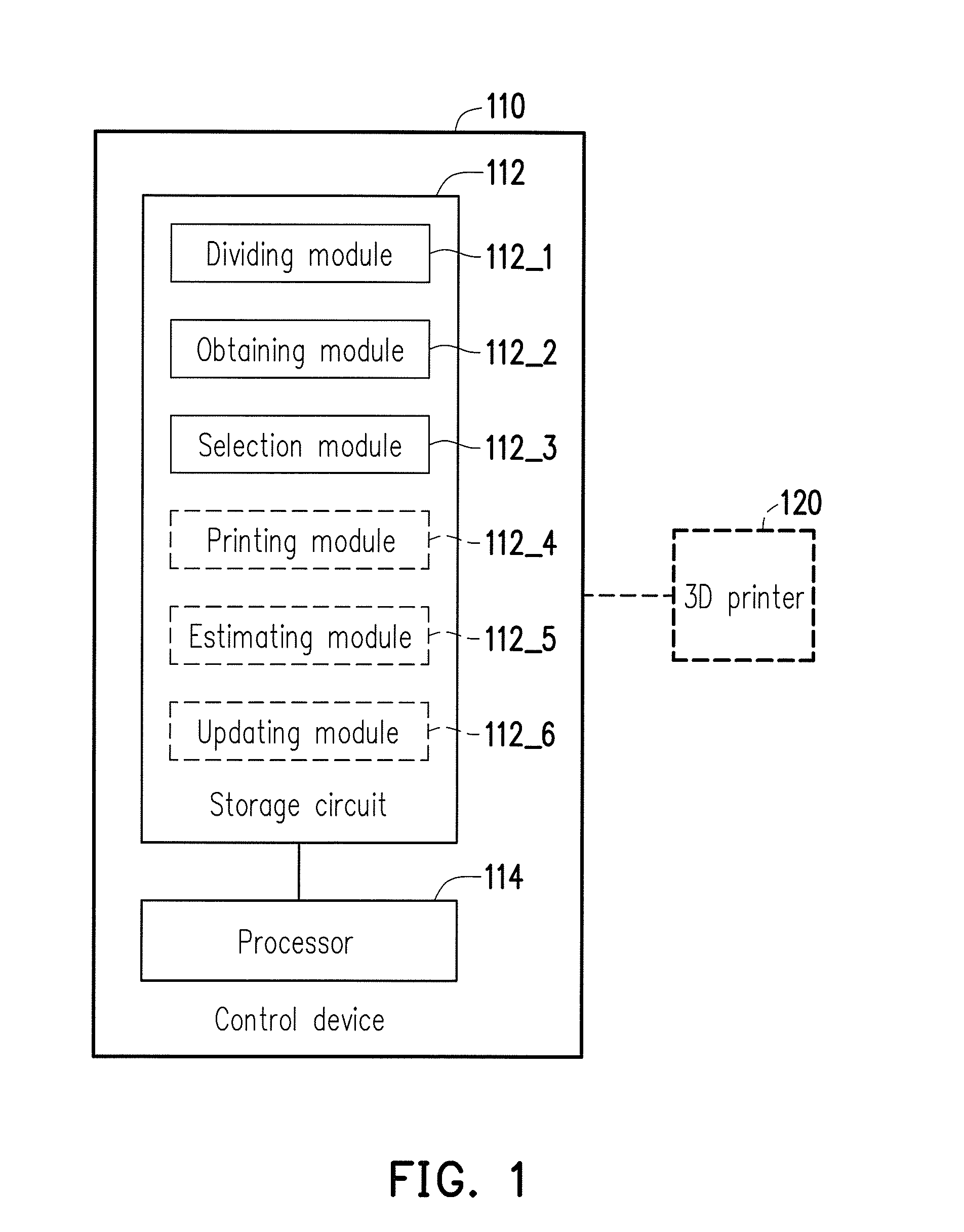

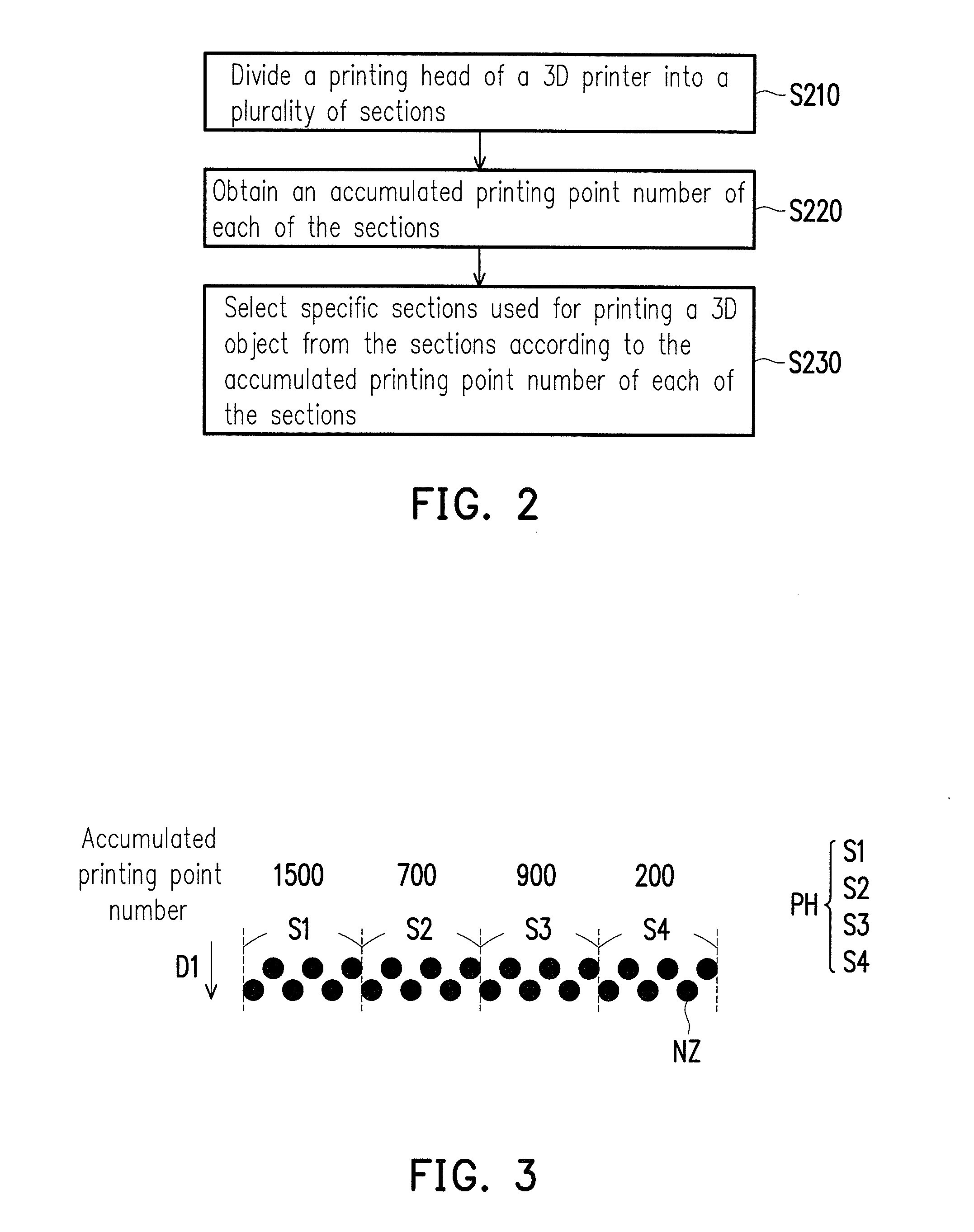

Method for adjusting printing head usage amount of 3D printer and control device

InactiveUS20170028645A1Reduce the amount of lead usedSolve low usageProgramme controlAdditive manufacturing apparatus3d printerControl equipment

Owner:XYZPRINTING +2

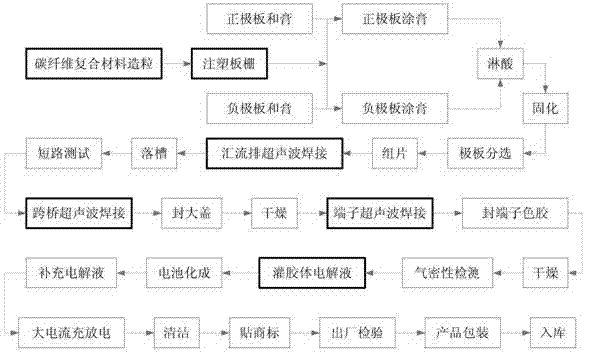

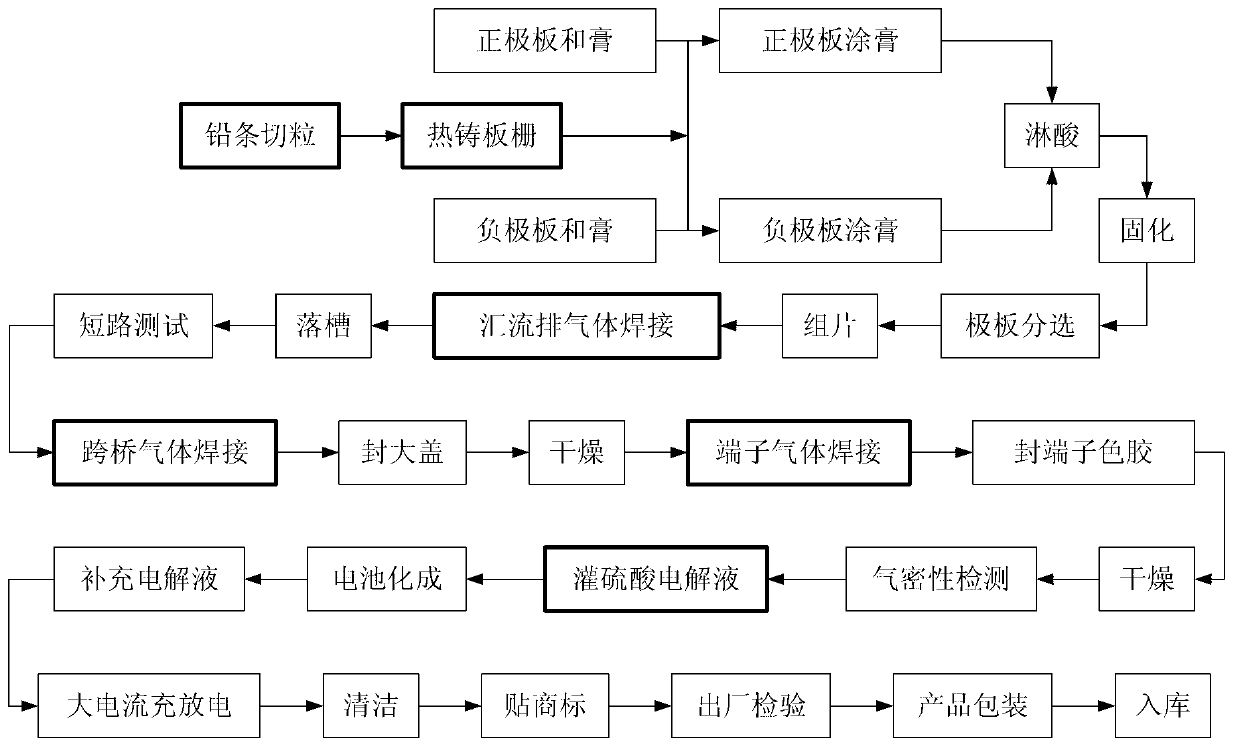

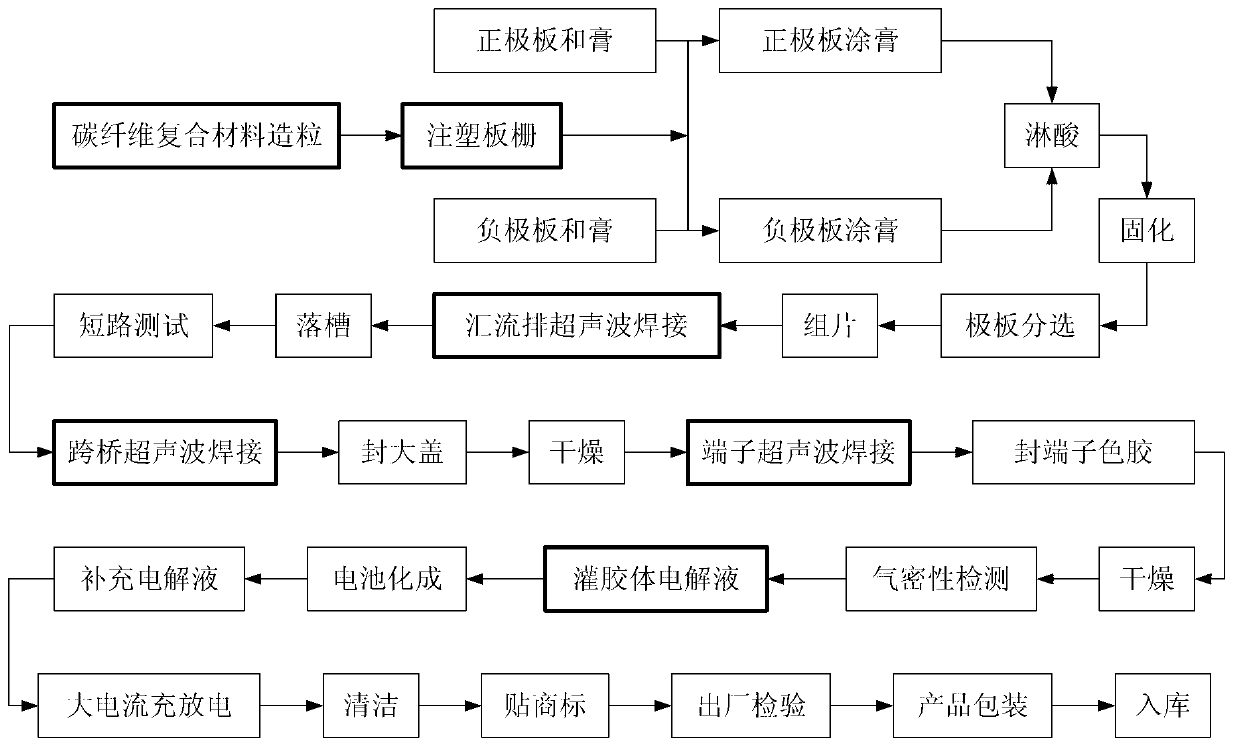

Assembly method of carbon fiber composite storage battery

InactiveCN103000855AAvoid defectsEliminate pollutionFinal product manufactureCell component detailsPhysical healthWorking environment

The invention discloses an assembly method of a carbon fiber composite storage battery. The assembly method comprises the following steps of: preparing a connecting piece, and connecting the connecting piece, wherein the connecting piece is prepared from a carbon fiber composite and the connection of the connecting piece is formed by adopting ultrasonic waves to weld. According to the assembly method disclosed by the invention, the defects of the traditional lead-acid battery can be overcome, and the carbon fiber composite is adopted for replacing lead to manufacture a tab, a binding post and a busbar / span bridge, so that the using quantity of the lead is reduced; and the connection of the connecting piece adopts an ultrasonic wave welding process to replace a gas soldering process of acetylene and oxygen, so that the environmental pollution in a welding process is reduced, the working environment is improved and the physical health of workers can be protected.

Owner:广州神力信息科技有限公司

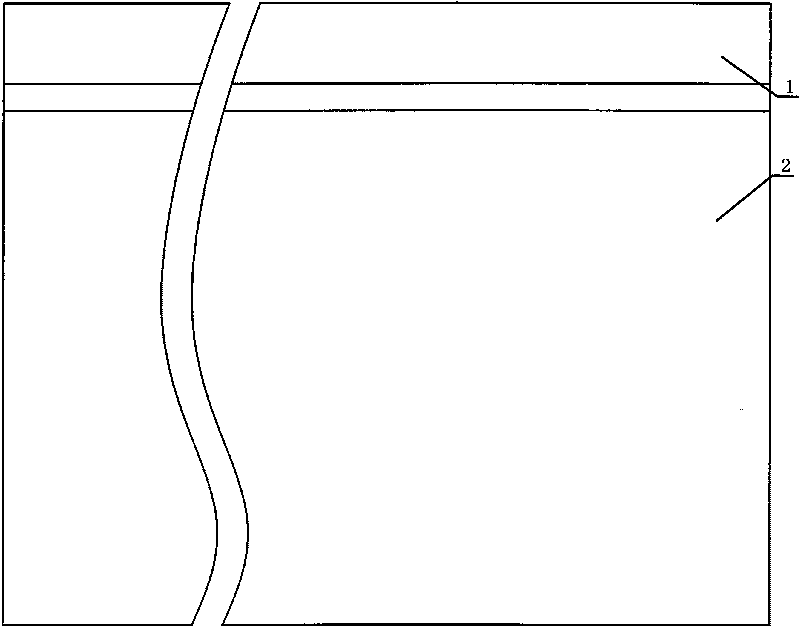

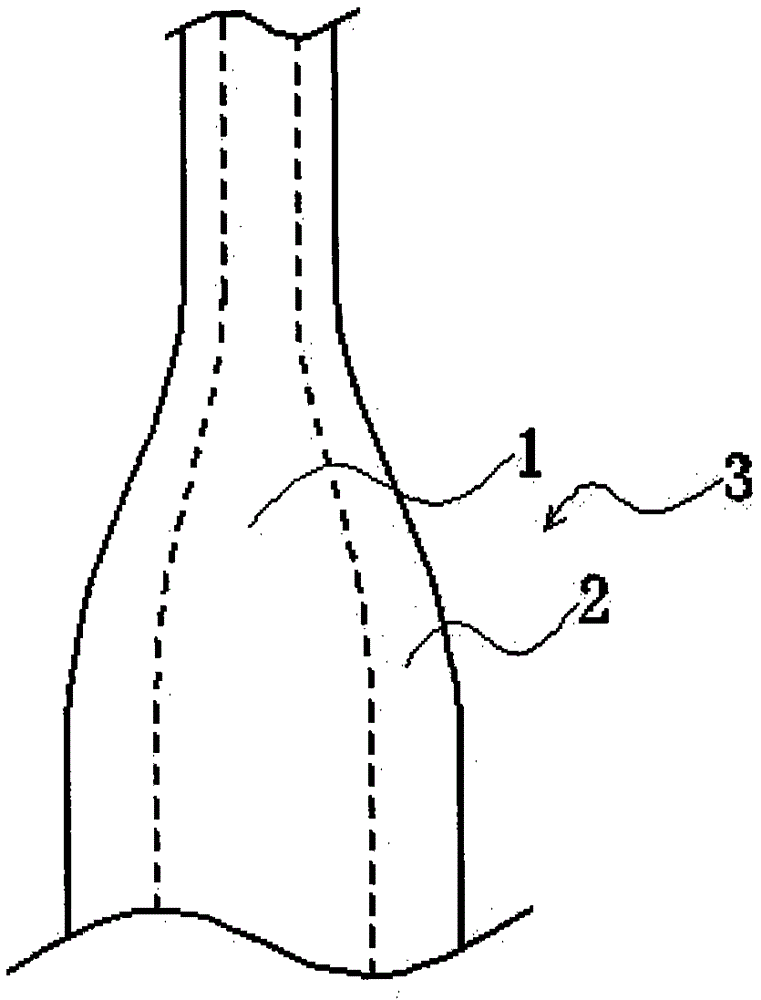

Lead-acid storage battery curved plate gate structure

PendingCN109860622AIncrease specific energySimple structureElectrode carriers/collectorsAgricultural engineeringSpecific energy

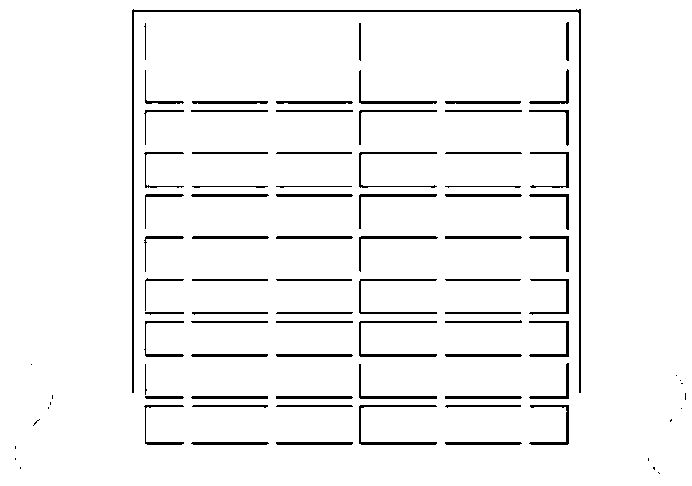

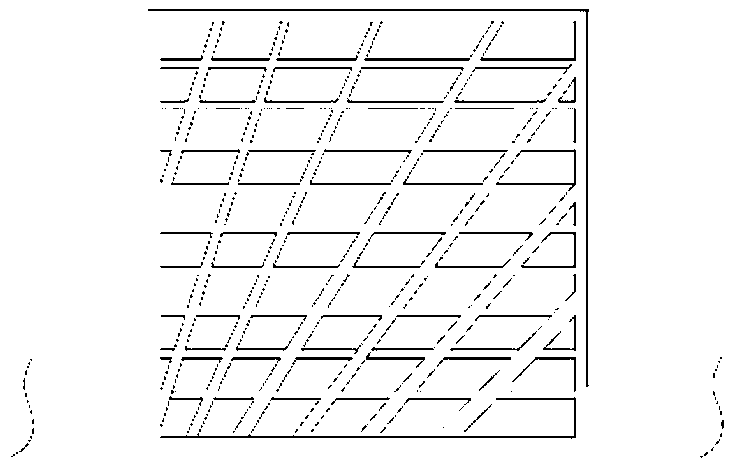

A lead-acid storage battery curved plate gate structure relates to the technical field of batteries. The lead-acid storage battery curved plate gate structure comprises a frame, vertical ribs, horizontal ribs and a tab. The frame comprises a first horizontal frame, a second horizontal frame, a first vertical frame and a second vertical frame. The plurality of vertical ribs are arranged between thefirst horizontal frame and the second horizontal frame, the plurality of horizontal ribs are arranged between the first vertical frame and the second vertical frame, the tab is arranged on the firstvertical frame, the vertical ribs are arranged on the horizontal ribs in a staggered mode and in a wavy shape, the cross sectional areas of the horizontal ribs are gradually reduced from the first vertical frame to the second vertical frame, the cross sectional area of the first vertical frame is larger than the cross sectional area of the second vertical frame, the closer the horizontal rib getsto the tab, the bigger the cross sectional area of the horizontal rib is, so that it is convenient for current conduction, two of horizontal ribs at the upper and lower portions of the first verticalframe and the second vertical frame are reinforcing horizontal ribs, and the cross sectional areas of the reinforcing horizontal ribs are larger than these of the horizontal ribs. The lead-acid storage battery curved plate gate structure can facilitate production, can effectively reduce the lead usage amount and pole plate resistance, can save cost, can improve the specific energy of the battery,is not easy to deform and fall off, and can prolonging the service life.

Owner:JIANGSU AOXIN TECH DEV

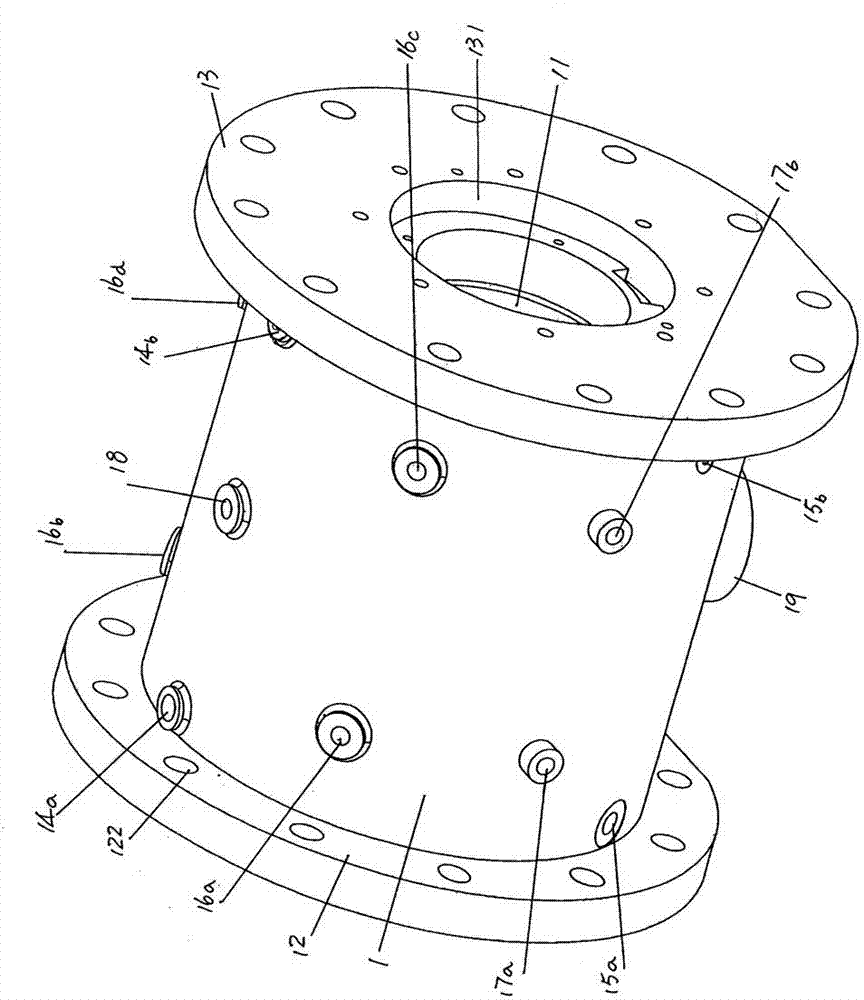

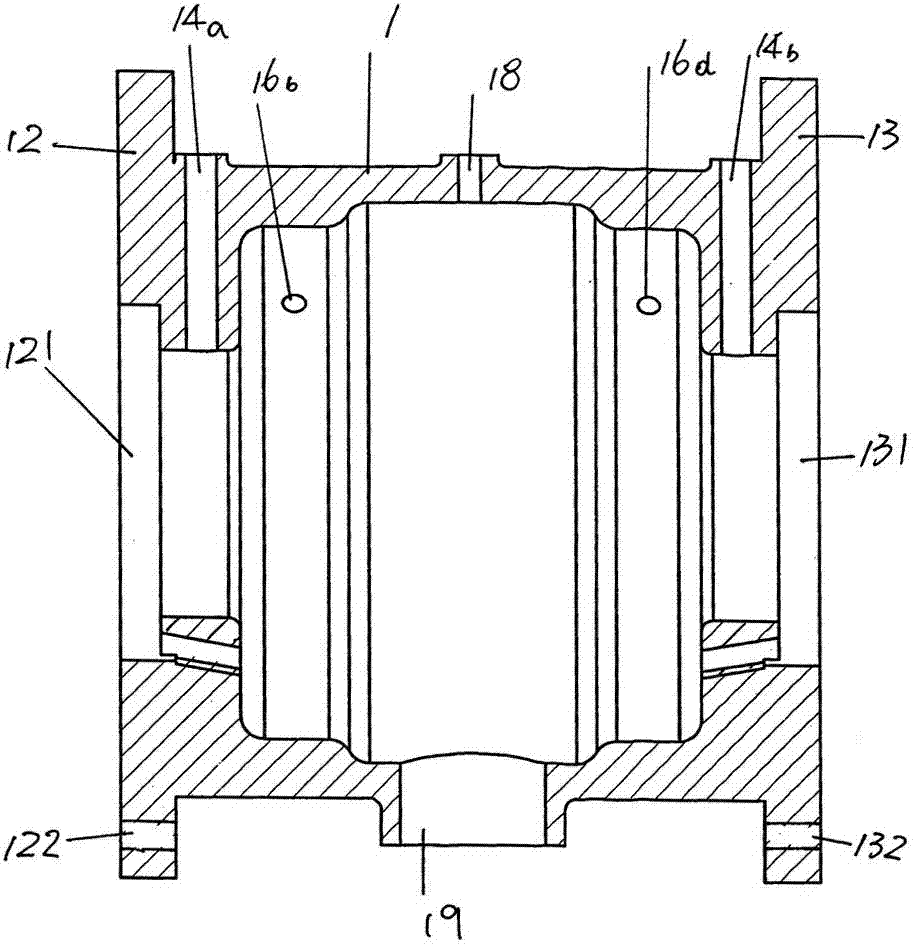

H-shaped cylinder structure for external work output connection of turbo expander

InactiveCN102865111ASimple structureReduce weightMachines/enginesEngine componentsVibration measurementEngineering

An H-shaped cylinder structure for external work output connection of a turbo expander belongs to low temperature equipment. The H-shaped cylinder structure comprises a cylinder, wherein a first matched connection flange and a second matched connection flange are respectively formed at two ends of the cylinder; a first bearing fit cavity and a second bearing fit cavity are formed in the middle of the first matched connection flange and the second matched connection flange; a first oil inlet connector and a second oil inlet connector are arranged on the cylinder and face to one end of the first matched connection flange and one end of the second matched connection flange; a first air inlet connector and a second air inlet connector are arranged on the cylinder and face to one end of the first matched connection flange and one end of the second matched connection flange; a first vibration measurement probe, a second vibration measurement probe, a third vibration measurement probe and a fourth vibration measurement probe are arranged on the cylinder and face to one end of the first matched connection flange and one end of the second matched connection flange; a first temperature measurement connector and a second temperature measurement connector are arranged on the cylinder and face to one end of the first matched connection flange and one end of the second matched connection flange; and a rotating speed measurement connector and an oil outlet connector communicated with a cylinder cavity are arranged on the cylinder. The H-shaped cylinder structure has the advantages of being convenient to assemble and maintain and high in universalization degree, saving materials, reducing difficulties of mold design and reducing using quantity of molds.

Owner:联优机械(常熟)有限公司

Band-shaped lubricating material for dry wiredrawing and process for producing same

InactiveUS20140290320A1Processing state is stableAvoid seizuresWork treatment devicesCeramic shaping apparatusLow speedBand shape

Provided is an innovative belt-shaped lubricating material for dry wiredrawing which not only can be used under severe wiredrawing processing conditions such as those of high temperature / high pressure / high speed as well as conventional powdered or granular lubricants for dry wiredrawing but also can cope with diameter reduction to a wide range of wire diameters ranging from a small diameter to a large diameter and a wide range of linear speeds ranging from a low speed to a high speed, has excellent functionalities such as lubricity, followability, spreadability, adhesiveness, heat resistance, processability, workability, safety, durability and productivity irrespective of a processed shape, is effective in improving work environments and is friendly to the global environment.The belt-shaped lubricating material for dry wiredrawing includes a film containing 10 to 90% by weight of a metal salt of a saturated fatty acid and 10 to 90% by weight of a thermoplastic resin.

Owner:KYOEISHA CHEM CO LTD

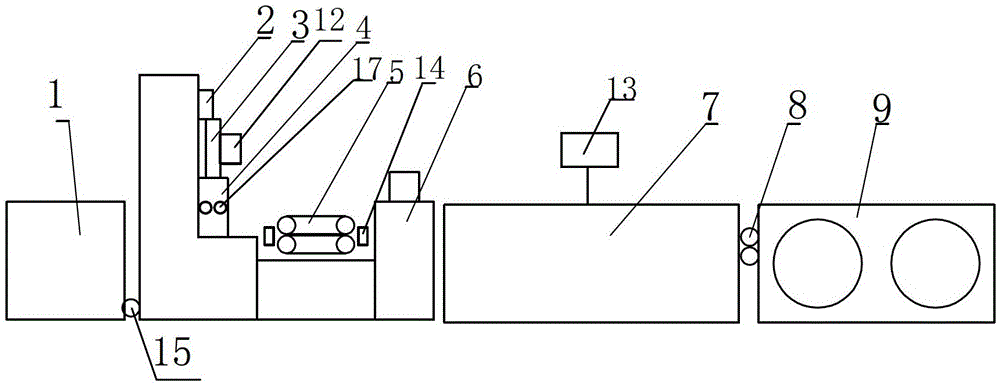

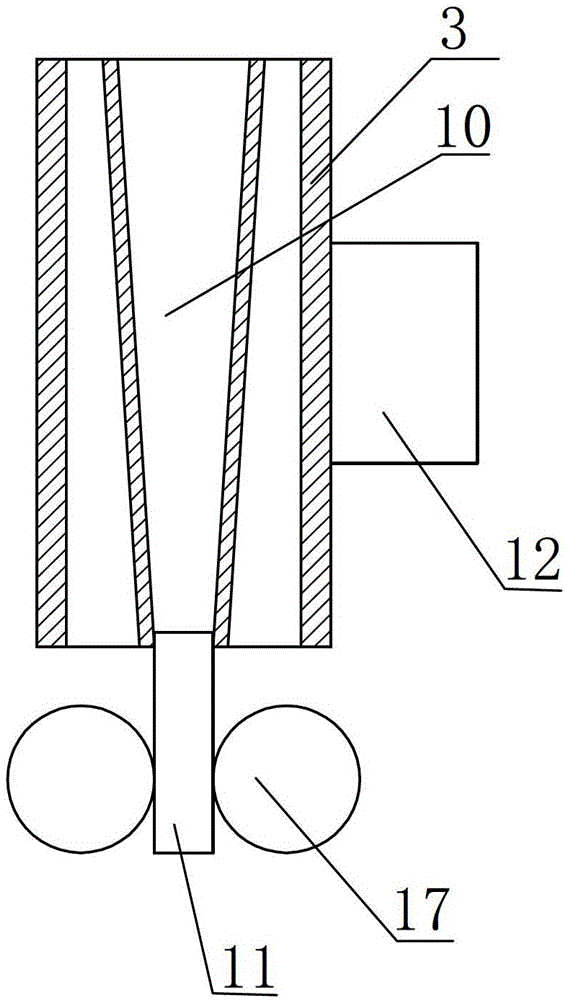

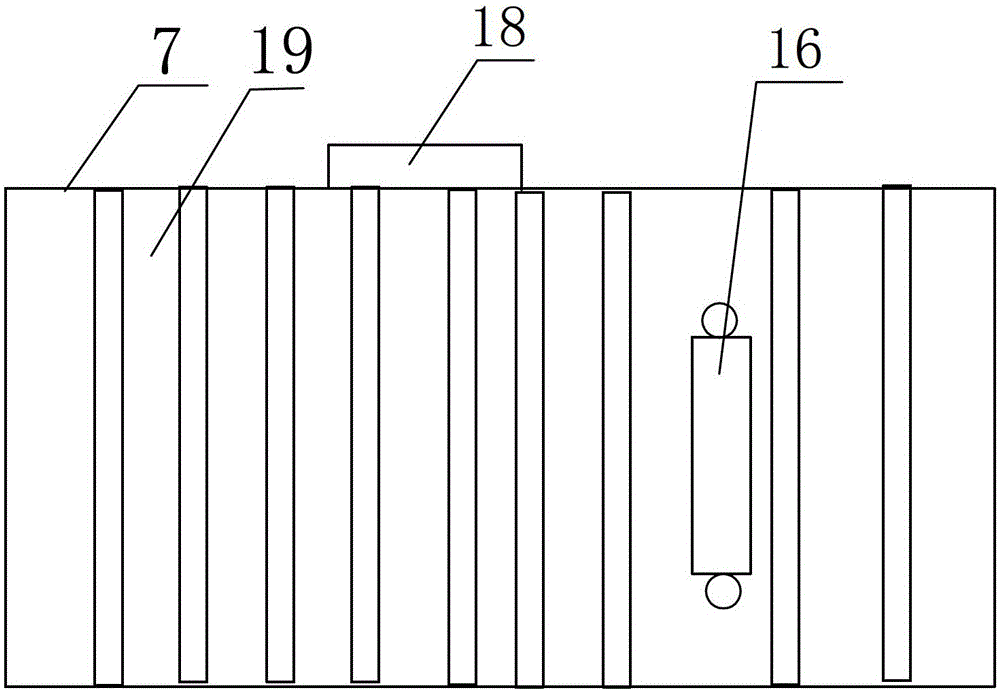

Lead and lead alloy strip continuous casting and rolling production equipment and production process

InactiveCN103240272BReduce consumptionEasy to manageMetal rolling stand detailsMetal rolling arrangementsControl systemAcid corrosion

The present invention relates to the technical field of continuous casting and continuous rolling of lead and lead alloy strips, in particular to a continuous casting and rolling production device for lead and lead alloy strips and a production process. The continuous casting and rolling production device for lead and lead alloy strips includes Furnace, ladle, continuous casting water jacket, traction device, front hydraulic cutting device, continuous rolling unit, feeding device, trimming device, automatic winding device, and PLC control system; there is a crystallization cavity in the continuous casting water jacket A dummy plate is provided, and a vibrator is provided on the continuous casting water jacket to vibrate the continuous casting water jacket. The traction device has at least one pair of traction wheels with opposite rotation directions, and the traction device is connected with the dummy plate. The invention adopts continuous casting and rolling to produce lead or lead alloy strips, which saves energy consumption, has less discharge of lead fumes, is clean and environmentally friendly, and is convenient for management; saves production sites, reduces labor costs, and reduces labor intensity; the produced lead or lead The alloy strip has good physical properties and good acid corrosion resistance.

Owner:吴铭荣

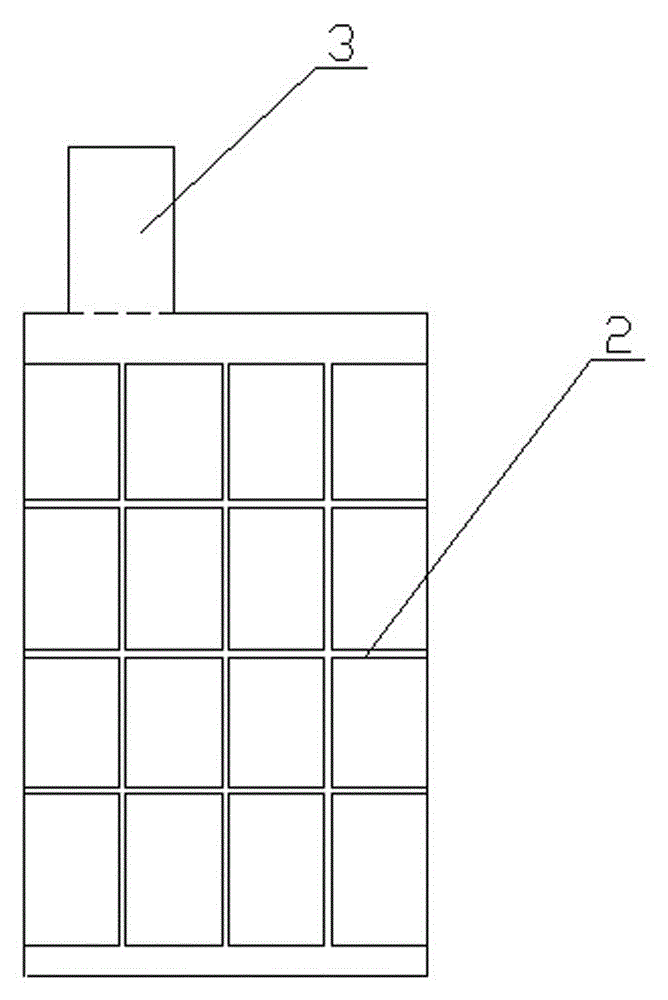

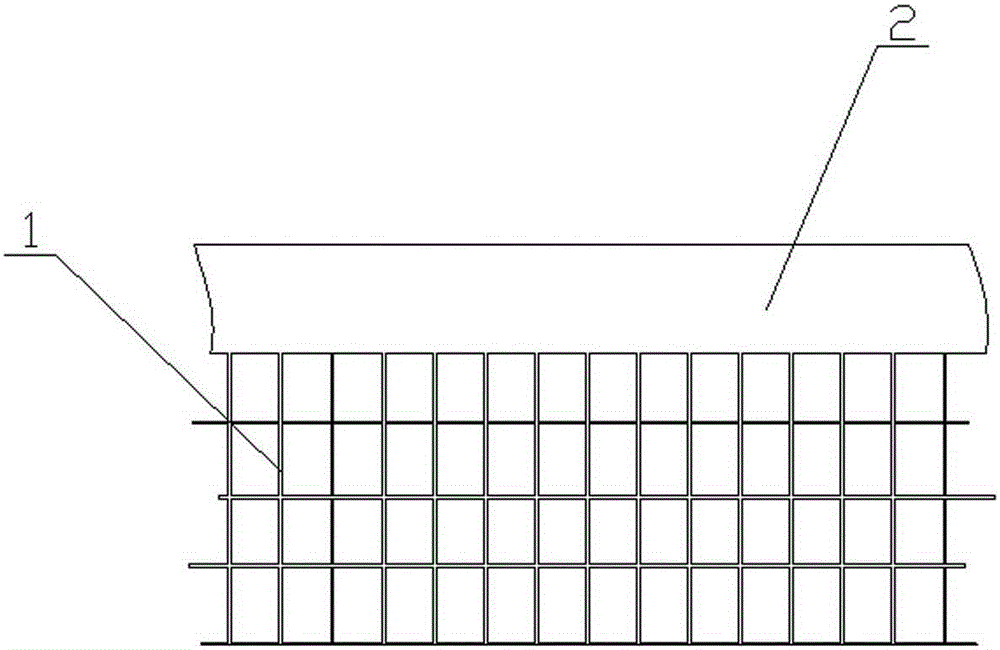

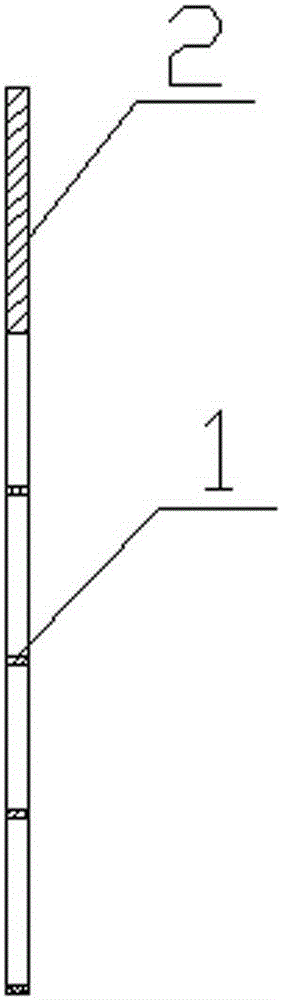

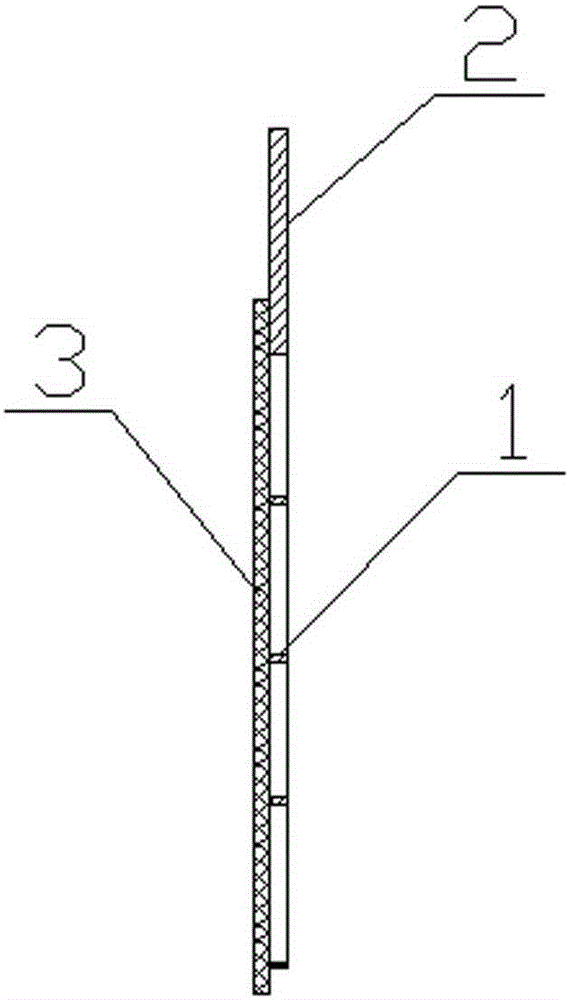

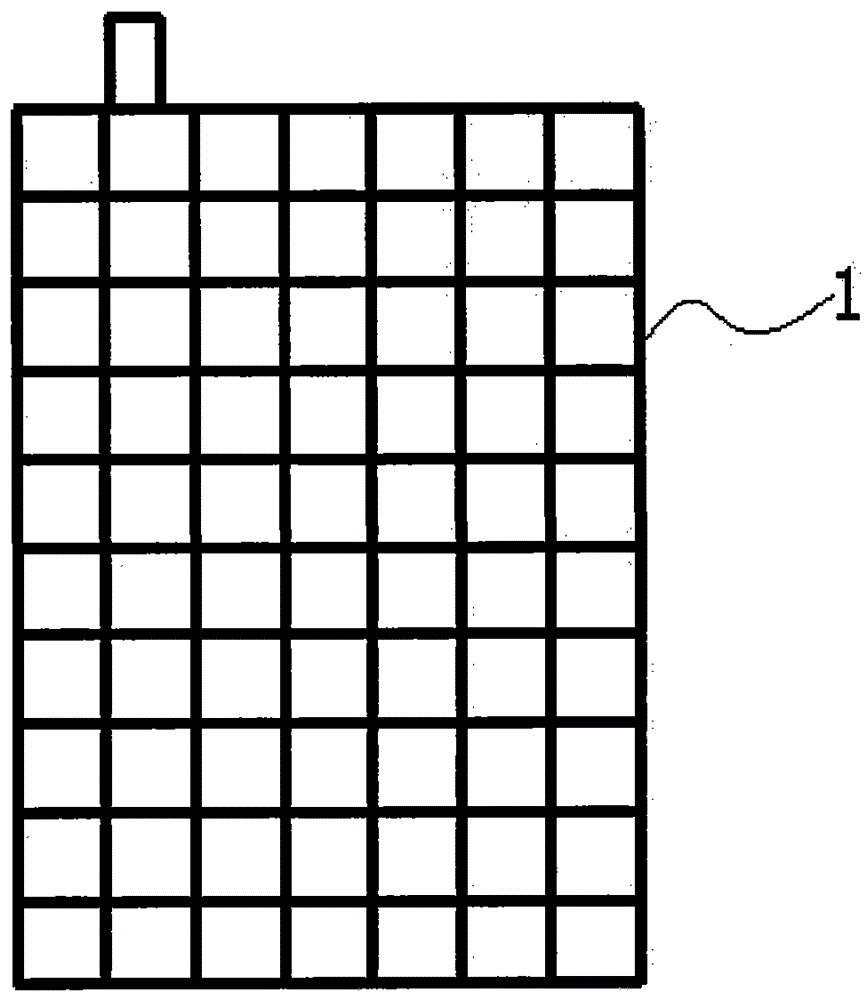

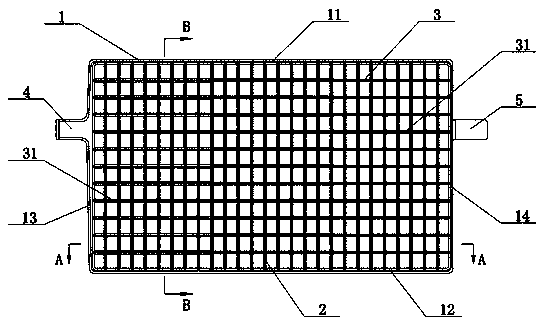

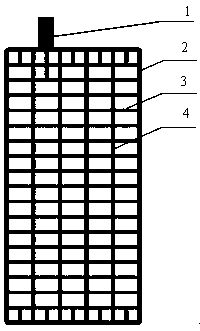

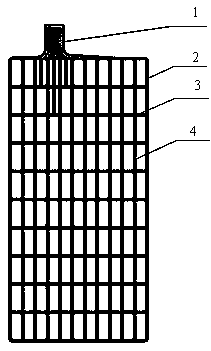

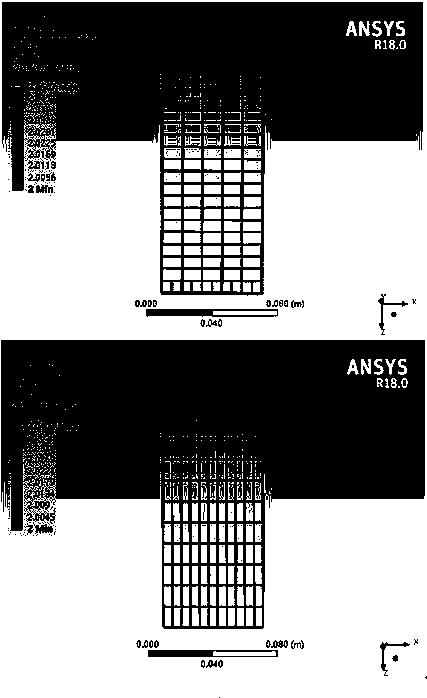

Novel light-weight lead-acid power battery grid

InactiveCN110061241AIncreased energy-to-weight ratioReduce weightElectrode carriers/collectorsPower batteryHigh rate

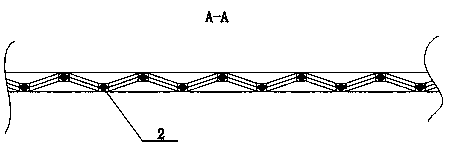

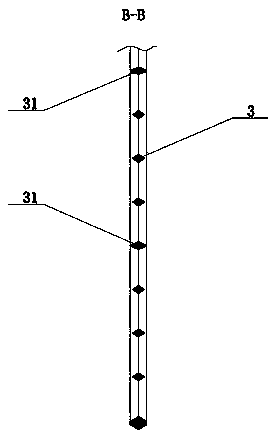

The invention relates to a novel light-weight lead-acid power battery grid; the novel light-weight lead-acid power battery grid is characterized in that the grid is composed of tab 1, a frame 2, transverse ribs 3 and vertical ribs 4, wherein the tab 1 is positioned at the edge of one side of the frame 2; and the vertical ribs 4 and the transverse ribs 3 are vertically interlaced and combined to form a longitudinal rectangular mesh, wherein the distance between the transverse ribs 3 is 1.5-2.0 times of the distance between the vertical ribs 4, and the number of the vertical ribs 4 is 2-3 timesthat of a traditional grid. The grid can be used for preparing a power lead-acid battery, a lead-carbon battery and the like with high rate, high energy density and long cycle life and capability of improving current convergence, so that the current transmission distance is shorter, the ohmic voltage drop on a polar plate is reduced, the grid is safer, and the grid is suitable for popularization and application.

Owner:卢云峰

A kind of nano-carbon lead supercapacitor battery

ActiveCN103219162BFast chargingExtend your lifeLead-acid accumulatorsHybrid capacitor electrodesCapacitanceHigh energy

The invention discloses a nanometer carbon-lead super capacitor battery, which comprises electrodes, wherein the electrodes are made of a carbon nanomaterial and a foam lead composite material; the carbon nanomaterial and the foam lead composite material are prepared by adopting an electrolytic deposition method; and the electrolytic deposition method comprises the following steps: preparing an electrolytic deposition solution; adding a carbon nanomaterial into the electrolytic deposition solution prepared in the step (1); and performing electrolytic deposition to obtain the carbon nanomaterial and the foam lead composite material. According to the nanometer carbon-lead super capacitor battery disclosed by the invention, a lead-acid battery is combined with a super capacitor, so that high energy storage density and high power density are realized simultaneously; high charging and discharging performances are achieved, and the charging speed of the battery is the same as the discharging speed in an unsaturated charging running mode; a carbon material can be used for preventing the phenomenon of sulfation on the cathode, so that a past failure factor of the battery is improved, and the service life of the battery is prolonged; and the nanometer carbon-lead super capacitor battery has very high safety performance, and is an environment-friendly safe battery.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

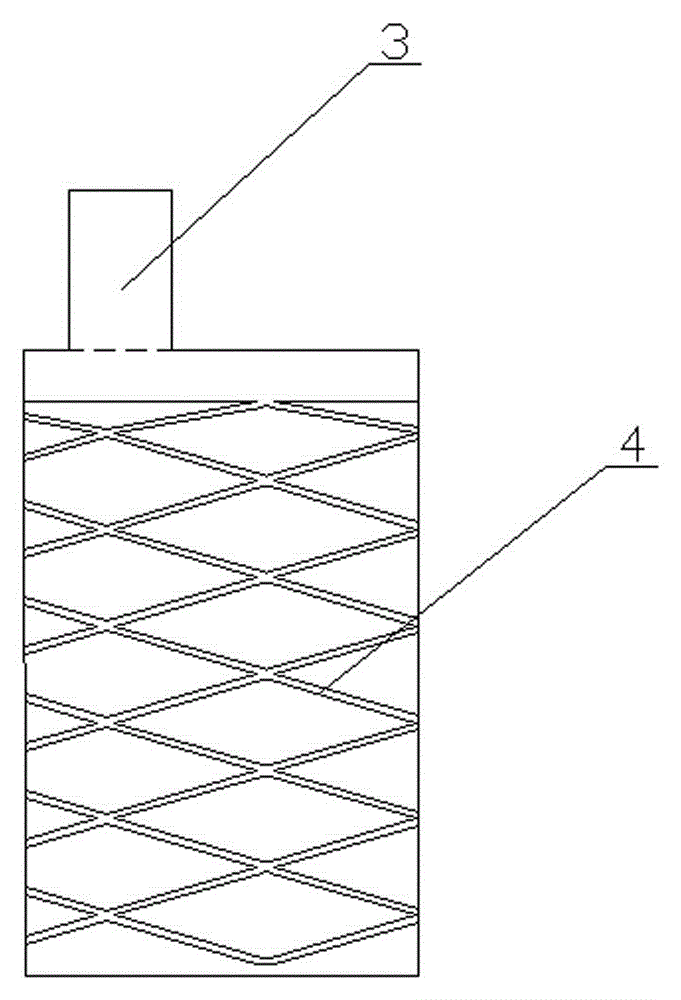

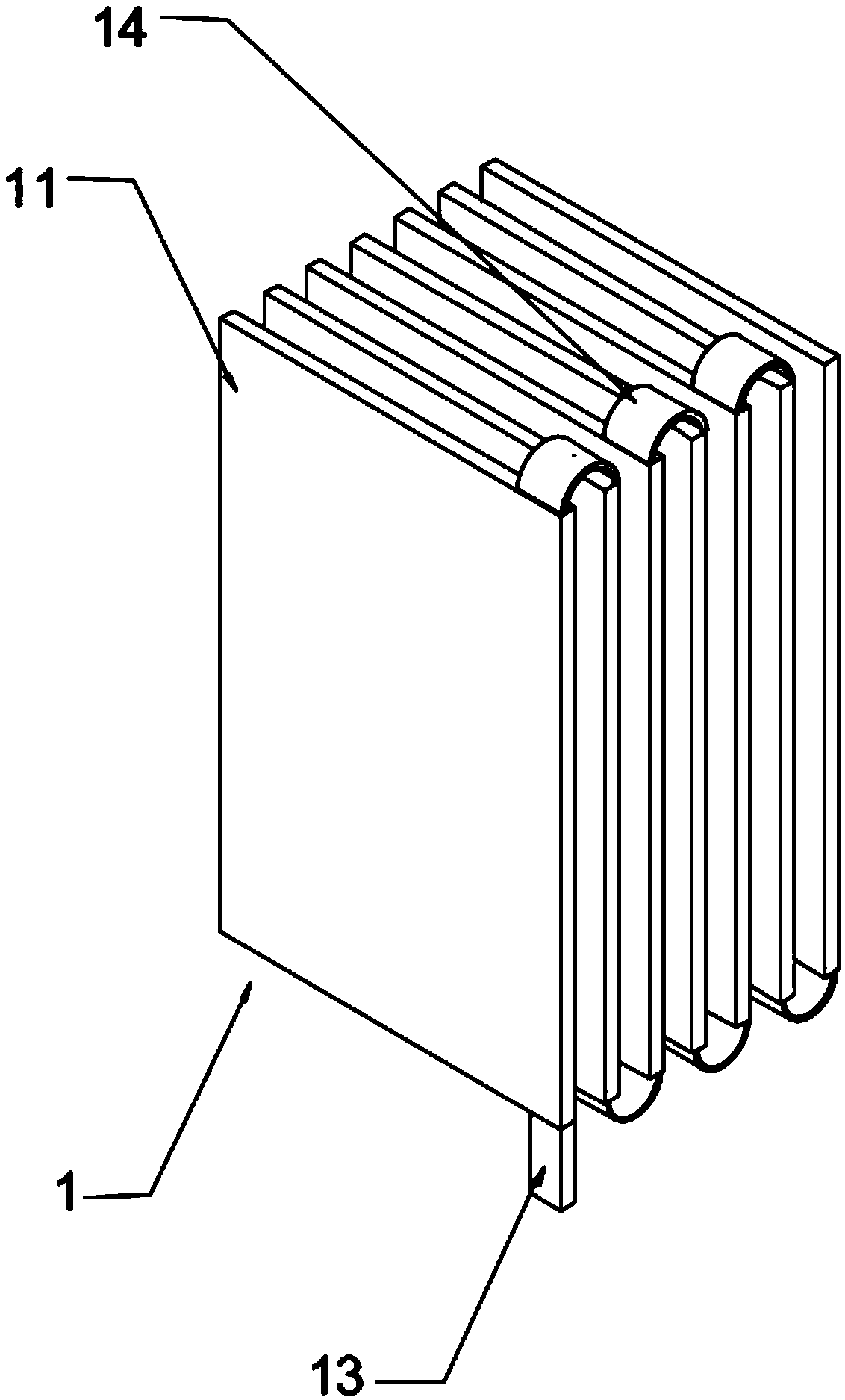

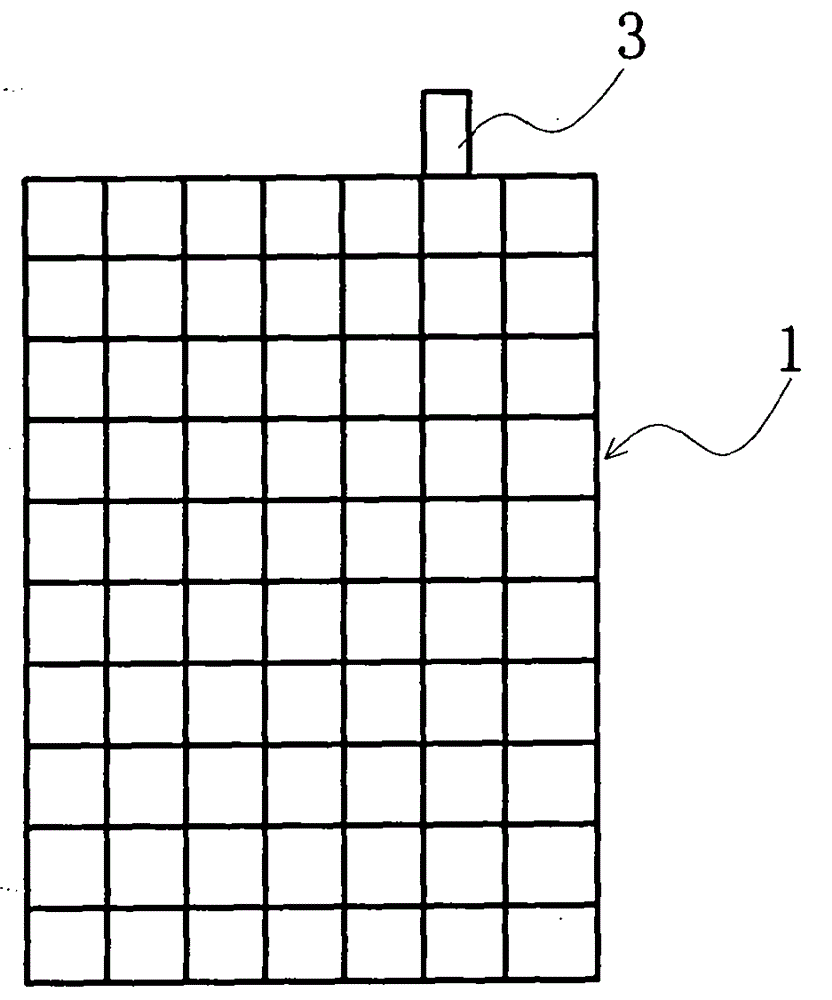

Continuous type welding-free lead storage battery pole plate and manufacturing method thereof

PendingCN108649187AImprove manufacturing process efficiencyEasy to processFinal product manufactureElectrode carriers/collectorsEngineeringMonomer

The invention discloses a continuous type welding-free lead storage battery pole plate and a manufacturing method thereof. The continuous type welding-free lead storage battery pole plate is characterized in that a continuous type lead storage battery grid is adopted and comprises a plurality of plate coating areas (2); the adjacent plate coating areas (2) are connected by a connecting area (3); one end or both ends of the continuous type lead storage battery grid are provided with terminal areas (1); the plate coating areas (2) and the connecting areas (3) are integrally formed; each plate coating area (2) of the continuous type lead storage battery grid is coated with an active matter layer, so as to obtain a pole plate area. The continuous type welding-free lead storage battery pole plate has the advantages that by adopting the integrated continuous type design, the procedure of welding multiple pole plates in a pole plate group of a single unit in the production process of the storage battery is eliminated, and the serial and parallel welding procedures of bridge-crossing welding, wall-penetrating welding and the like between multiple units of the storage battery are also eliminated; the lead usage amount of the storage battery is effectively reduced, the piece falling and welding missing in the pole plate group and between the units of the storage battery are avoided, andthe quality and reliability of the storage battery product are effectively improved.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

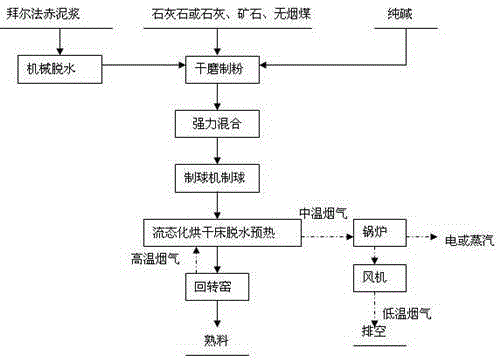

Production method for clinker used in alumina sintering method

InactiveCN105399117AReduce the number of large equipment usedImprove pass rateEnergy inputAluminium oxides/hydroxidesFlue gasRotary kiln

The invention relates to a production method for a clinker used in an alumina sintering method, and relates to the improvement on a sintering method by using Bayer process red mud to blend. The production method is characterized in that the production process comprises the following steps: (1) dehydrating Bayer process red mud to obtain dehydrated filter cake slurry; (2) performing dry grinding on limestone or lime, ore and anthracite coal to obtain a fine power material, and drying the fine power material; (3) uniformly mixing the red mud filter cake slurry, the fine power material obtained through dry grinding, and soda to obtain a raw material; (4) making the prepared raw material into raw material balls, drying and preheating; (5) adding the dried and preheated raw material balls into a rotary kiln to be sintered to produce the clinker. Through adoption of the production method, the number of used large-scale equipment in a wet method blending process can be greatly reduced, the qualification rate of ingredients of the raw material is increased, the heat utilization in the sintering process is improved, flue gas waste heat is fully utilized, physical and chemical quality and the like of the clinker are improved, the consumption of burning coal in the kiln is reduced by about 20% or above, and the productivity of the kiln can be increased by about 20% or above.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

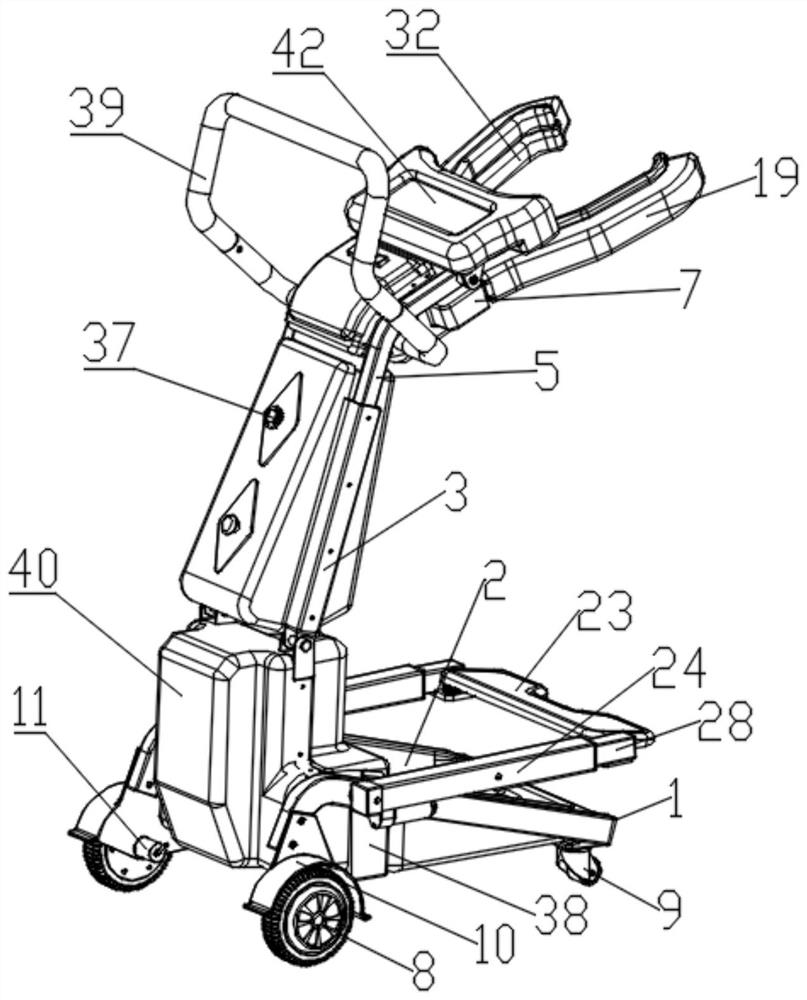

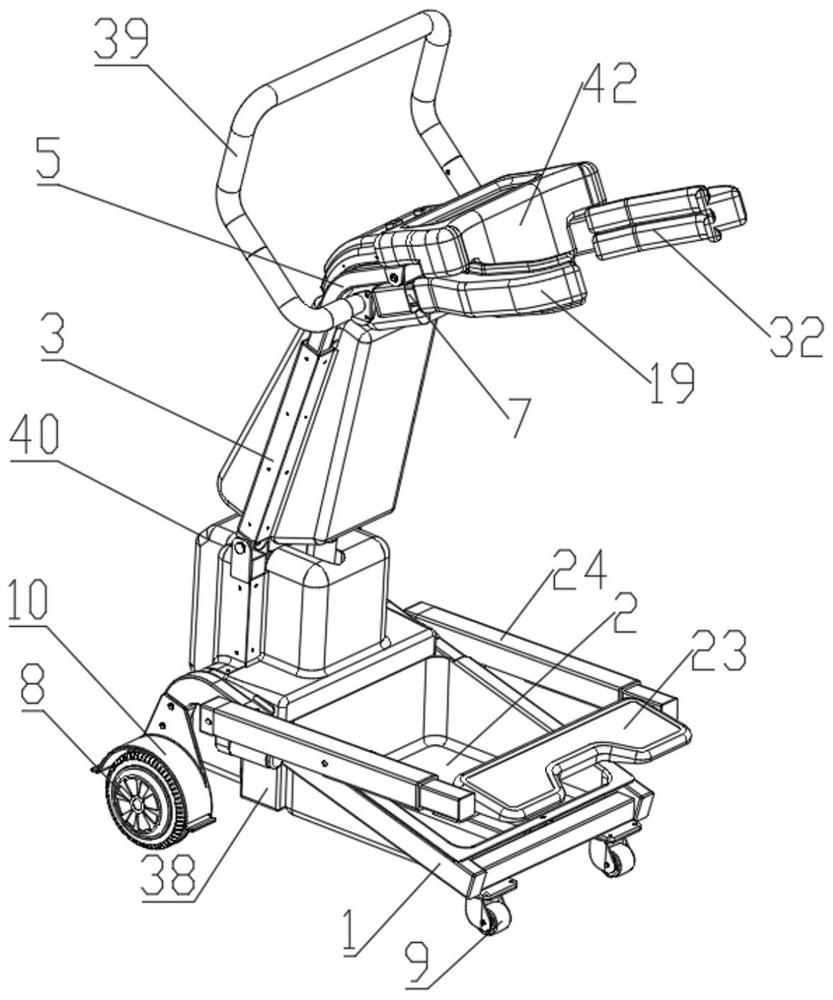

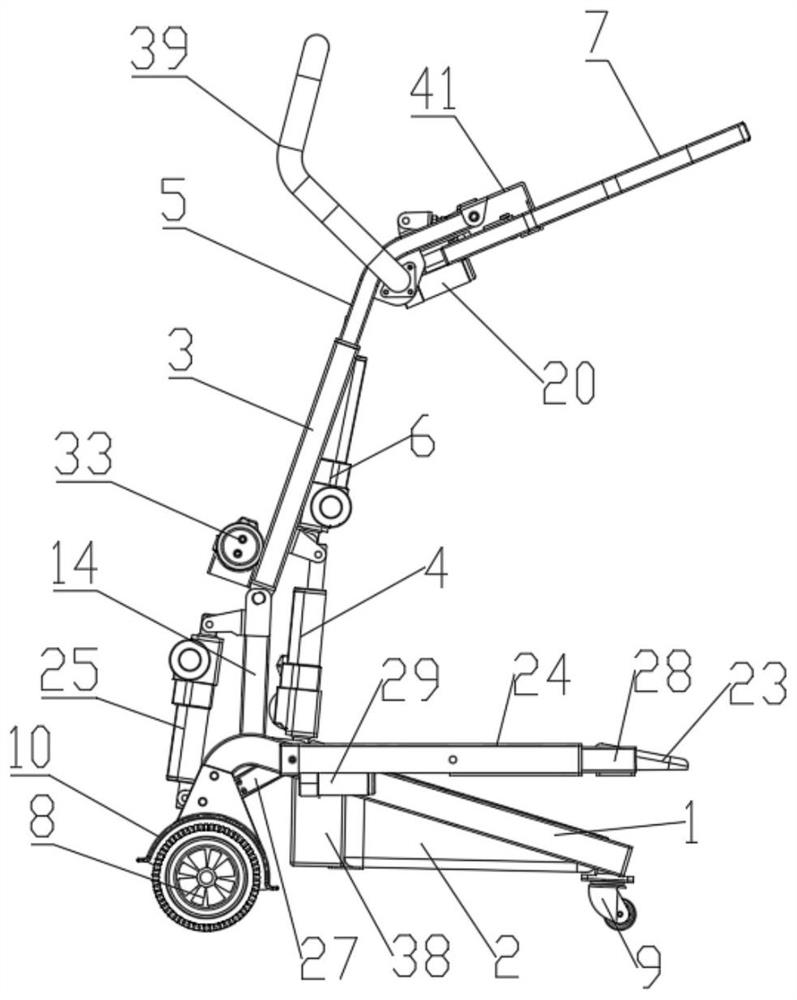

Nursing transfer car

The invention relates to the technical field of nursing equipment, in particular to a nursing moving trolley which comprises a rack at the bottom and a pedal located on the rack, and a walking mechanism is arranged at the bottom of the rack; an upper swing frame is hinged to the upper portion of the machine frame, a first thrust device is connected between the machine frame and the upper swing frame, the upper swing frame is provided with a telescopic supporting frame, and a second thrust device is arranged between the supporting frame and the upper swing frame. A thoracico-abdominal supporting frame is arranged at the top of the supporting frame, and a thoracico-abdominal pad is arranged on the thoracico-abdominal supporting frame; clamping arms capable of swinging are arranged on the two sides of the thoracoabdominal supporting frame; the medical nursing device has the beneficial technical effects that the holding is soft and stable, the clamping height is adjustable, the number of nursing personnel and the labor intensity of nursing workers are reduced, the operation links are improved, and the living quality of patients is also improved; the whole machine is compact in size and small in occupied space, is suitable for being used in common families and medical and maintenance units and can also be used in narrow space occasions.

Owner:宸瑞机器人(重庆)有限公司

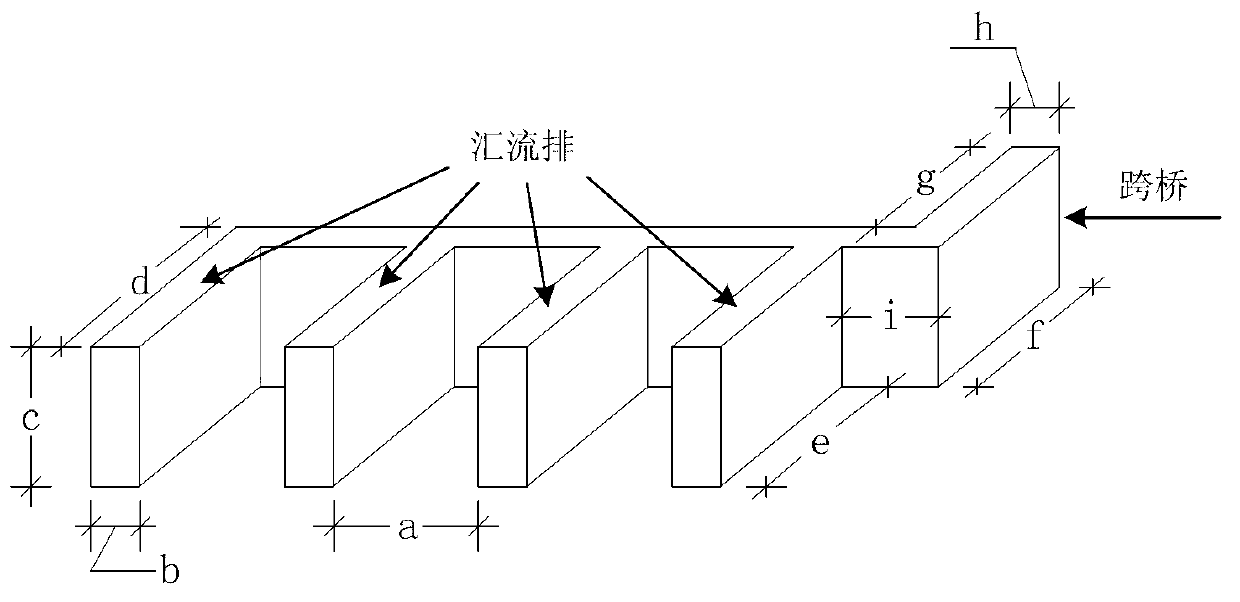

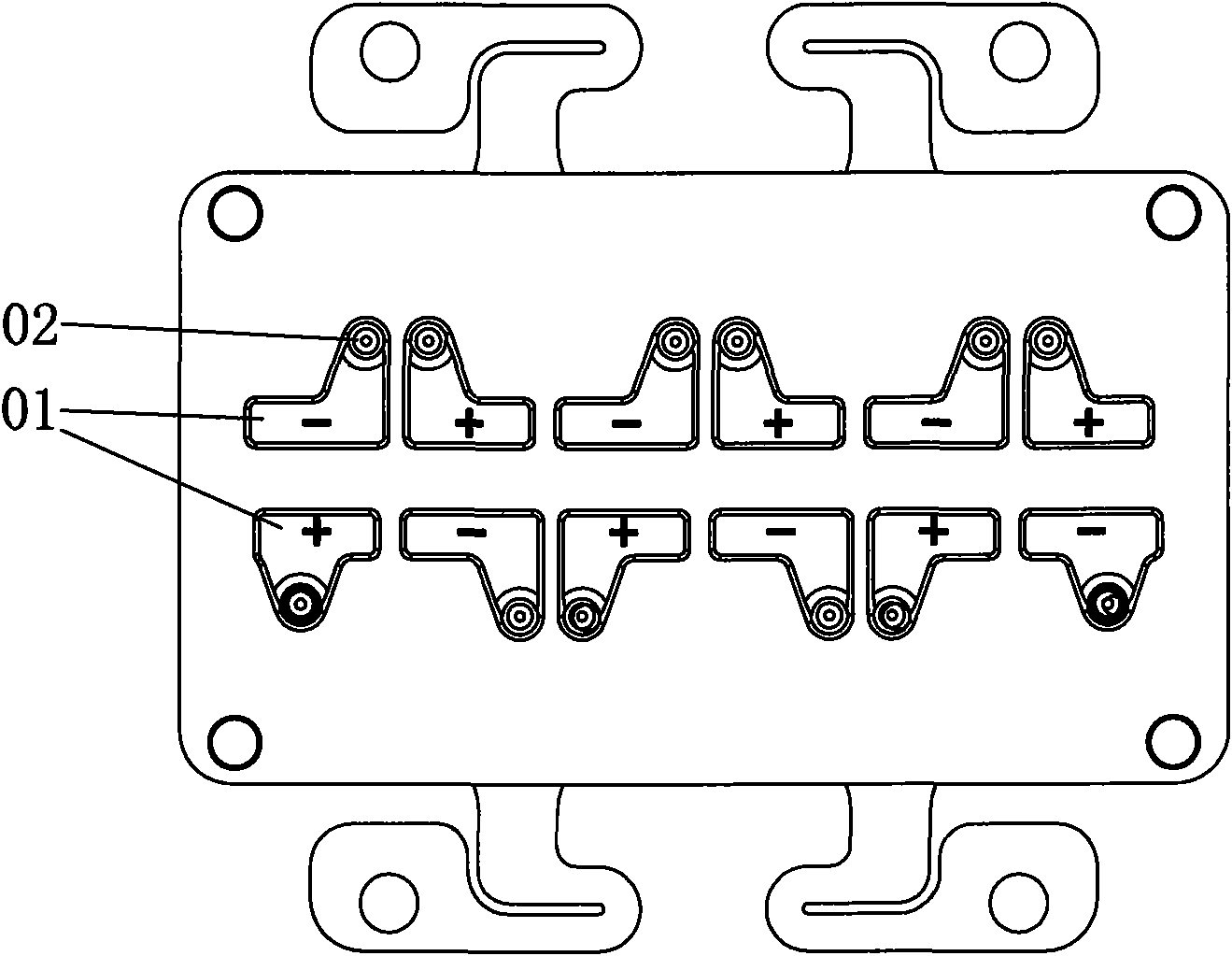

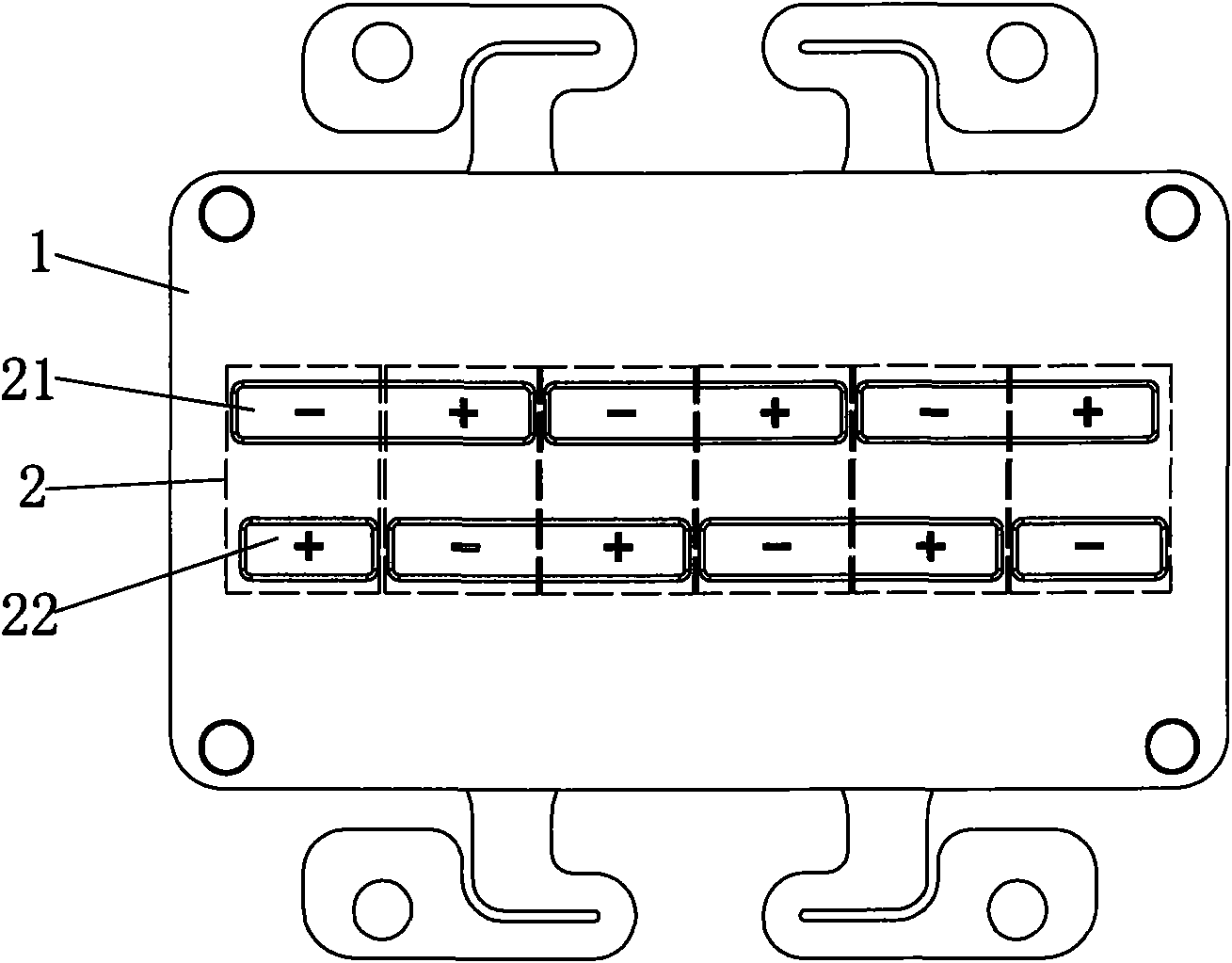

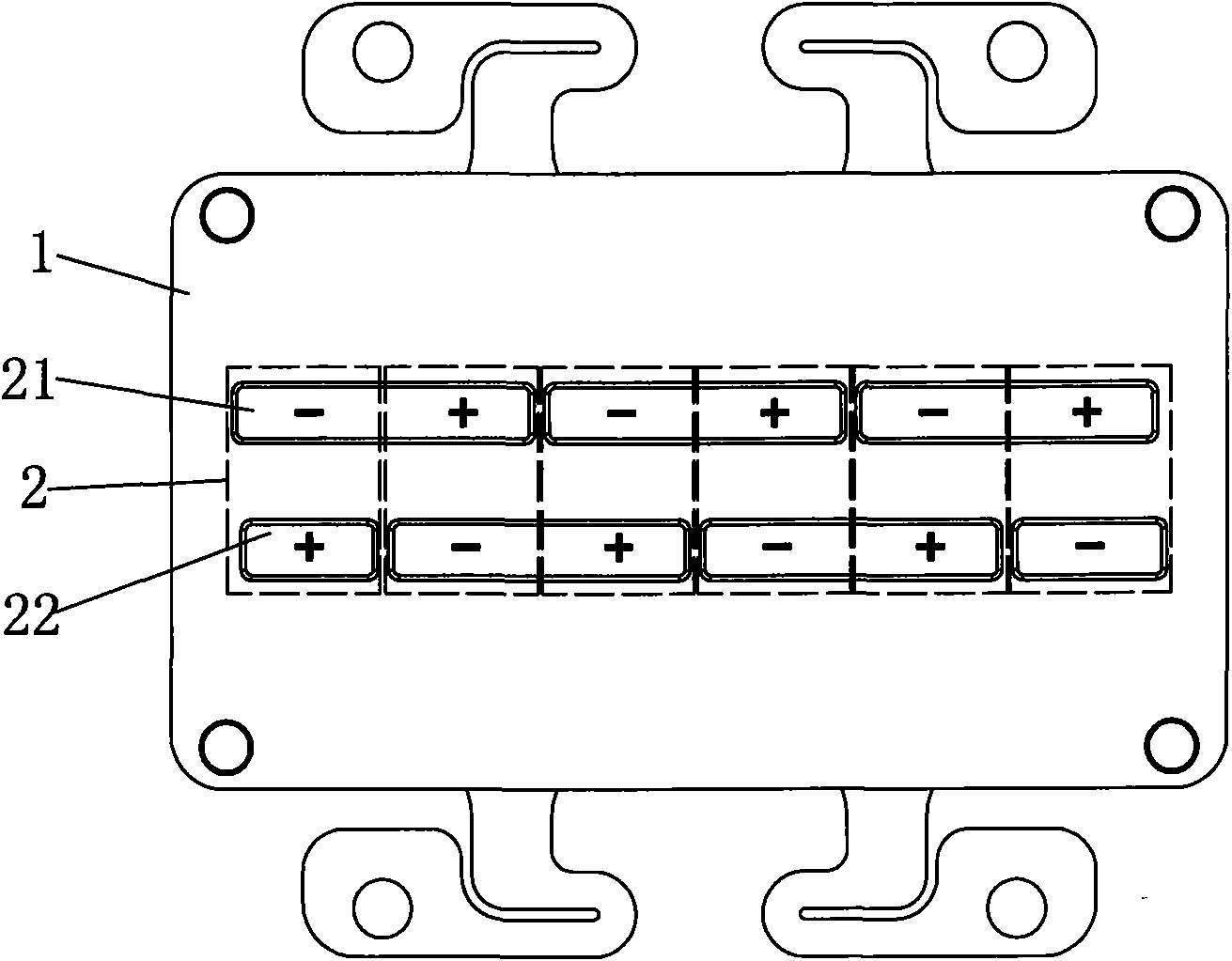

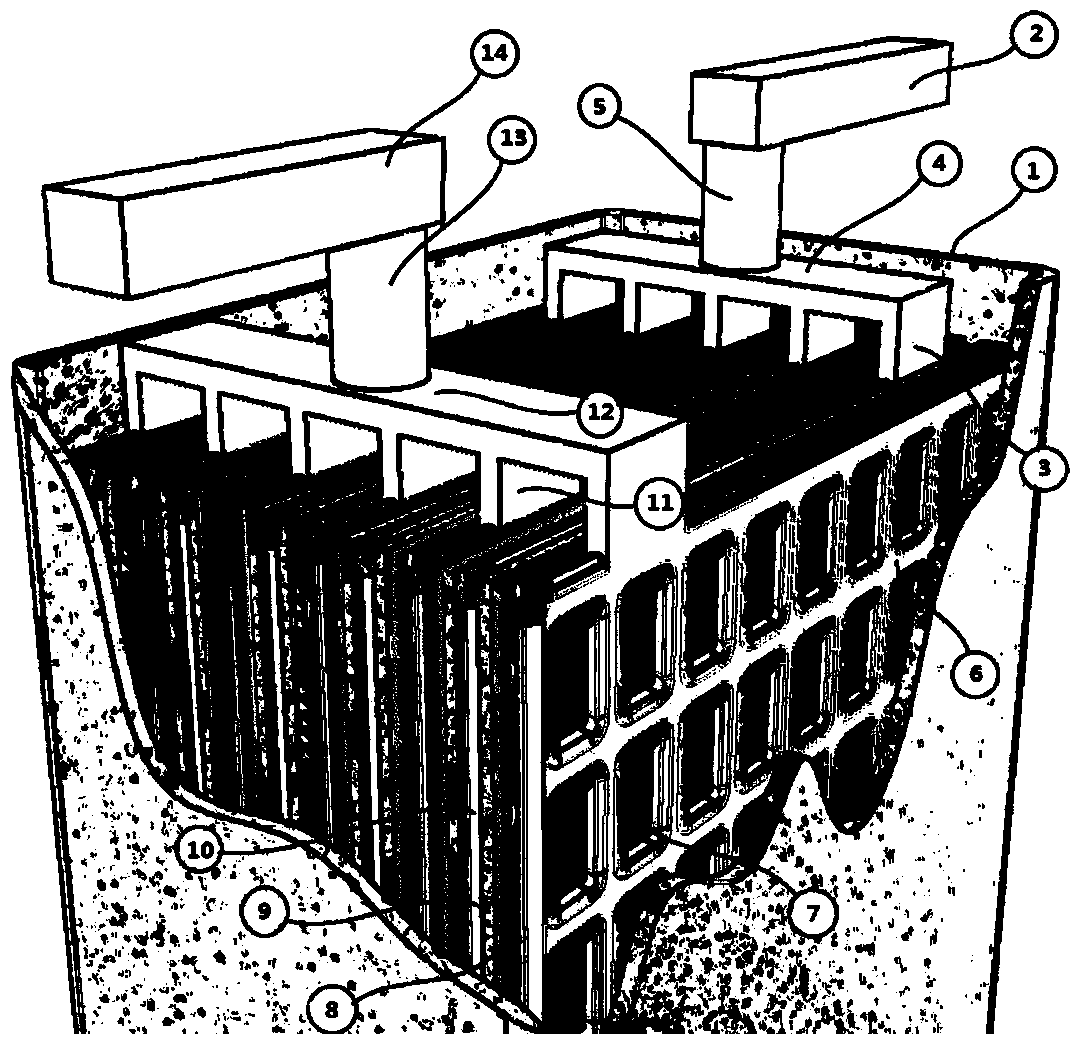

Improved structure of battery cast welded mold

The invention discloses an improved structure of a battery cast welded mold, comprising a cast welded mold body. A plurality of forming structures for casting a current-collecting bar are distributed on the surface of the cast welded mold body in sequence; each formed structure consists of a positive electrode groove and a negative electrode groove; positions of a positive electrode groove and a negative electrode groove which are arranged in an adjacent forming structure are arranged in a staggered way, wherein the negative electrode groove or the positive electrode groove in the forming structure is correspondingly connected with the positive electrode groove or the negative electrode groove in the adjacent forming structure into an integral structure, so that the structure of the surface of the cast welded mold can be greatly simplified, cast welding working procedures can be reduced, the welding efficiency can be improved and the production cost can be saved to the maximum extent while ensuring the welding quality.

Owner:陈义忠

A bipolar plate-type unit high-energy lead-acid battery and its high-voltage battery pack and packaging method

ActiveCN106207193BChange structureReduce the amount of lead usedFinal product manufactureElectrode carriers/collectorsElectrical conductorInternal resistance

The invention relates to a lead-acid storage battery, in particular to a bipolar-plate type unit high-energy lead-acid battery, a high-voltage battery pack formed from the same and a package method of the high-voltage battery pack. The unit high-energy lead-acid battery comprises an electronic conductor bipolar plate, wherein a positive active material layer and a negative active material layer are respectively coated on two surfaces of the electronic conductor bipolar plate and are the same active material prepared by taking lead sulfate as main, and a batter partition plate is laid on the active material layer on one surface. After the unit battery disclosed by the invention is adopted to package batteries stacked in series, the battery with high voltage, low internal resistance and long cycle lifetime is easy to achieve, meanwhile, the production process of the battery is simplified, and the production cost is reduced.

Owner:曾碚凯

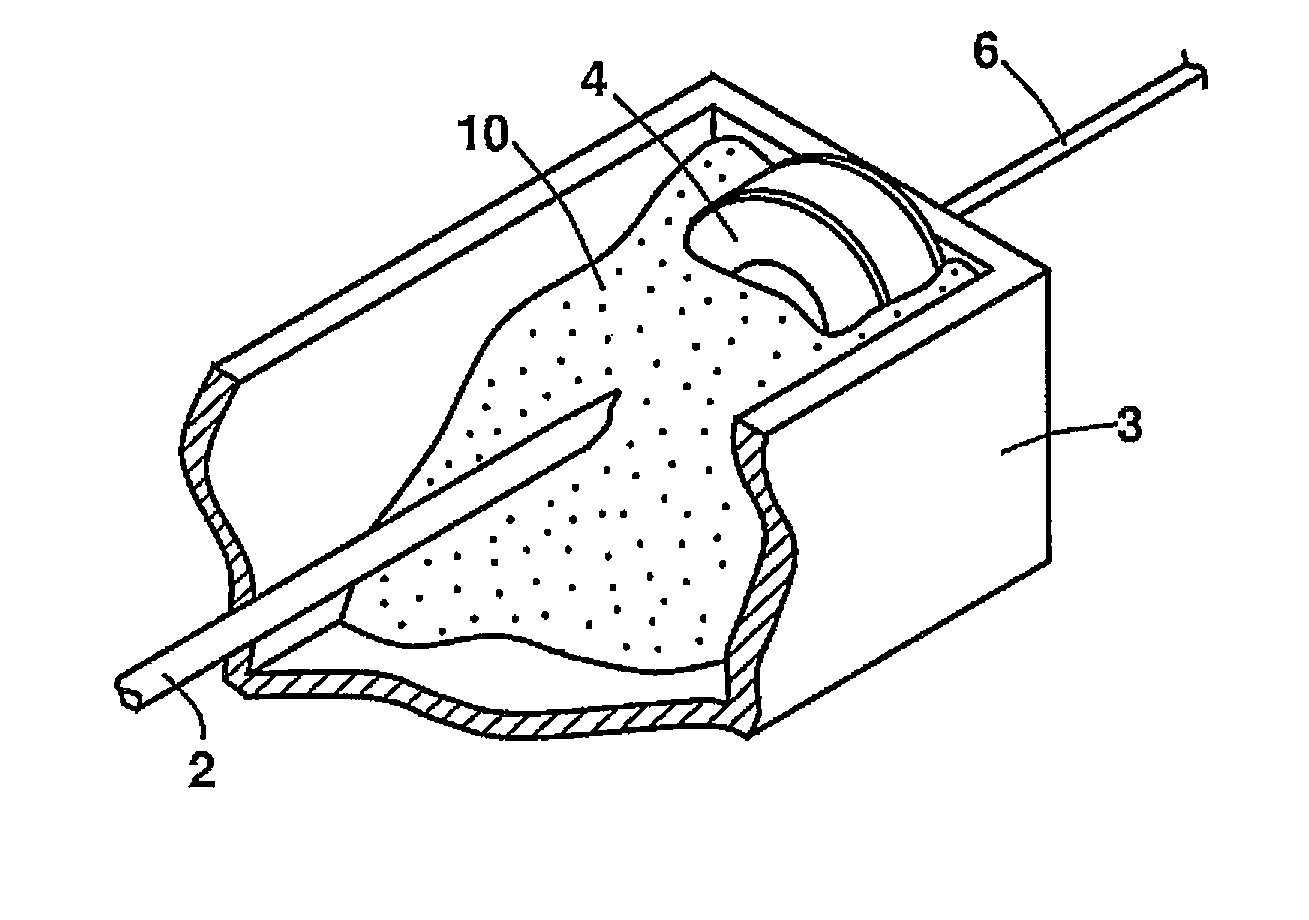

Driving pressurized extrusion friction composite lead damper.

PendingCN108204163AImprove work efficiencyReduce the amount of lead usedProtective buildings/sheltersShock proofingEngineeringEnergy consumption

The invention relates to a driving pressurized extrusion friction composite lead damper. The driving pressurized extrusion friction composite lead damper comprises a lead storage box, an inserting plate and extrusion structures, wherein lead is contained in the lead storage box, and an opening in communication with the inner portion of the lead storage box is formed in the lead storage box; the inserting plate is inserted into the lead storage box in a sealing mode by the opening, part of the inserting plate exposes outside the lead storage box, and the inserting plate can move in the lead storage box; and the extrusion structures are arranged on the opposite sides of the lead storage box, the extrusion structures exert clamping force on the side portion corresponding to the lead storage box, when the damper is stressed, the inserting plate moves in the lead storage box and produces extrusion and friction energy consumption with the lead in the lead storage box at the end portion of the inserting plate and the loading range of the extrusion structures. According to the driving pressurized extrusion friction composite lead damper, extrusion and friction area between the lead and steel is large, materials are saved, and the efficiency is high. The inserting plate and the lead storage box are simple in structure, so that the damper can adopt a lead plate and a steel plate to carryout cold-working assembly, and the process is convenient and lead-free. The sealing direction of a sealing layer is perpendicular to the movement direction of a moving part, and the width of a sealing surface on the extrusion area with large force is very narrow, so that the sealing difficulty is low and the sealing performance is good.

Owner:SHANGHAI KUNYI SEISMIC DAMPING ENG TECH CO LTD

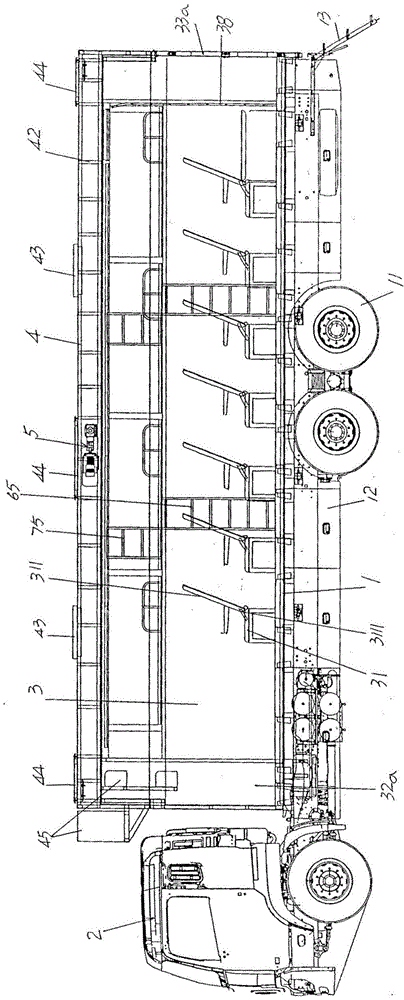

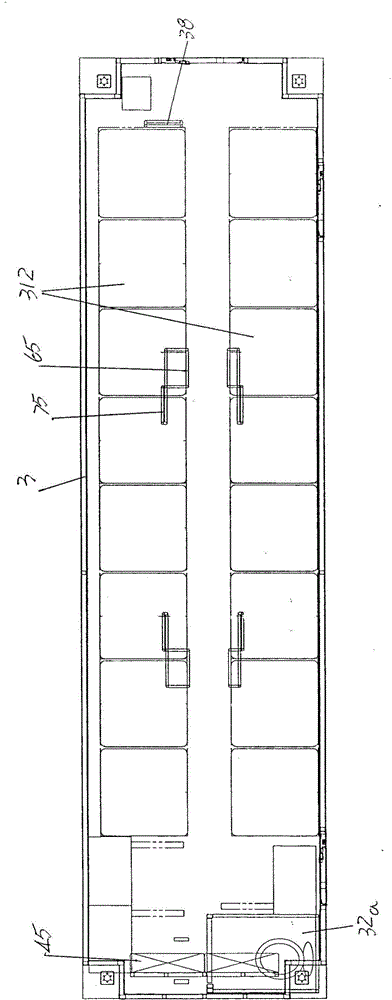

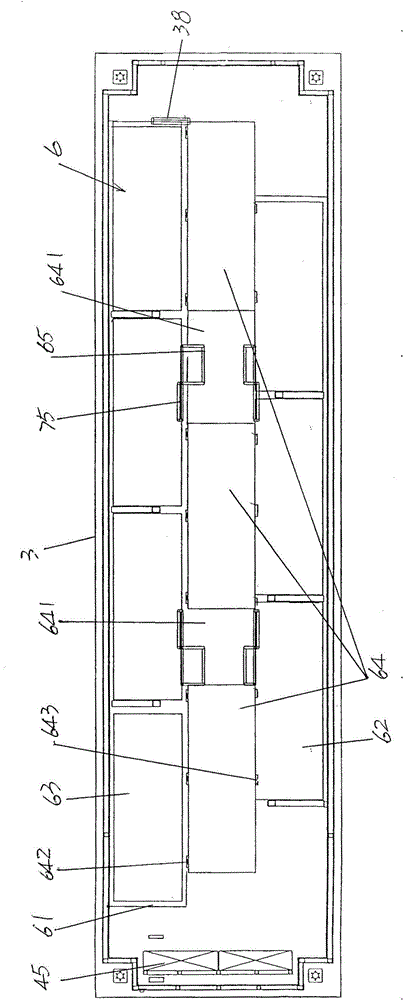

Peacetime and war time integral camping troop crawler

InactiveCN104802693AIncrease the number of campersReduce the amount of lead usedVehicle with living accommodationSitting PositionsEngineering

A peacetime and war time integral camping troop crawler belongs to the technical field of vehicles, and comprises a walking chassis, a vehicle head connected with the walking chassis and a compartment arranged on the walking chassis; the cavity of the compartment is internally provided with hinged seats, and the seats are converted to camping seat beds by match with seat backrests; the peacetime and war time integral camping troop crawler is characterized by also comprising a compartment floating ceiling and a floating ceiling drive mechanism; the compartment floating ceiling is matched with the compartment; the floating ceiling drive mechanism is arranged on the compartment floating ceiling; the cavity of the compartment is internally provided with a middle layer camping mechanism; a top layer camping mechanism is arranged above the middle layer camping mechanism; when the compartment floating ceiling moves down to a state of being closed with the compartment body of the compartment, the camping space formed between the top layer camping mechanism and the compartment floating ceiling disappears, and when the floating ceiling drive mechanism drives the compartment floating ceiling to move upwards, the clamping space between the top layer camping mechanism and the compartment floating ceiling is established. The peacetime and war time integral camping troop crawler can meet the double requirements of sitting and camping along with the vehicle, camping staff are increased, the airtightness and camping environment are good, and the use quantity of the vehicle is reduced.

Owner:常熟华东汽车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com