Carbon fiber composite board grid and preparation method thereof

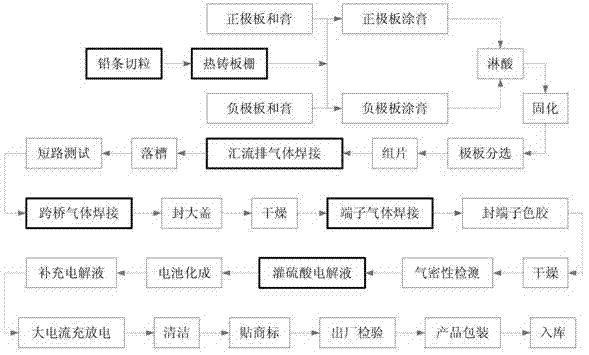

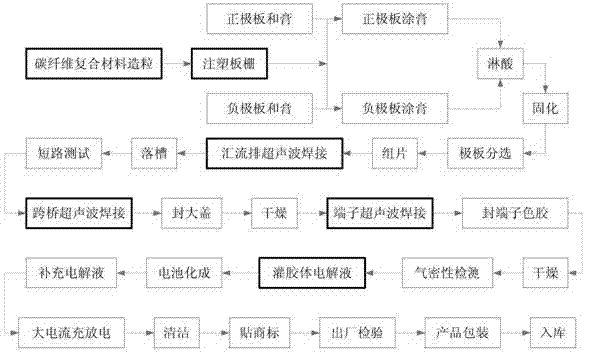

A carbon fiber and composite board technology, applied in the direction of electrode carrier/collector, can solve the problems of restricting the development of batteries, low battery profits, and inability to promote, and achieve excellent chemical stability, prevent heavy metal pollution, and remediate heavy metal pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Carbon fiber composite grid

[0039] Carbon Fiber Composite Grid

[0040] The carbon fiber composite grid of this embodiment is formed by injection molding the carbon fiber composite basic material; the carbon fiber composite basic material is obtained by mixing plastic PP:active polymer polyaniline:carbon fiber=45wt%:22wt%:33wt%.

[0041] Preparation

[0042] The preparation method of the carbon fiber composite grid of this embodiment comprises the following steps:

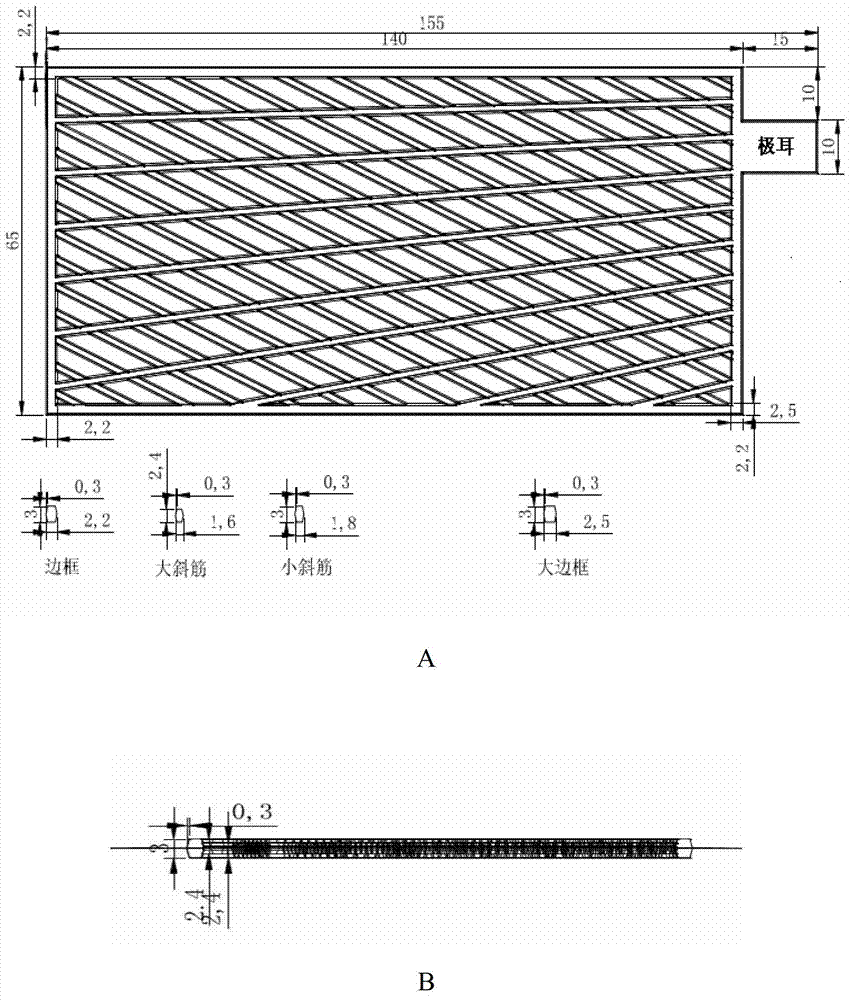

[0043] (1) Design grid

[0044] Grid design such as image 3 As shown, the main features of its shape are: the vertical grid branches are arranged radially downward with the pole lug as the center; the horizontal grid branches of adjacent rows are arranged in a mirror image based on the center line of the transverse section; each grid is independently set There are tabs; the thickness of the positive grid of each grid is 3mm, and 75g of active material can be applied (8.5g of active ma...

Embodiment 2

[0070] The carbon fiber composite grid in this embodiment is formed by injection molding the carbon fiber composite basic material; the carbon fiber composite basic material is obtained by mixing plastic PP:active polymer polyaniline:carbon fiber=50wt%:20wt%:30wt%. The conductivity is 4×10 3 / Ω·m

[0071] The preparation method of the carbon fiber composite grid and the preparation method of the colloidal battery containing the carbon fiber composite grid in this embodiment are the same as those in Embodiment 1.

[0072] The battery weight of the obtained gel battery was 5.04kg, and the measured capacity was 12V24.5Ah.

Embodiment 3

[0074] The carbon fiber composite grid of this embodiment is formed by injection molding the carbon fiber composite basic material; the carbon fiber composite basic material is obtained by mixing plastic PP:active polymer polyaniline:carbon fiber=55wt%:18wt%:27wt%. The conductivity is 3×10 3 / Ω·m.

[0075] The preparation method of the carbon fiber composite grid and the preparation method of the colloidal battery containing the carbon fiber composite grid in this embodiment are the same as those in Embodiment 1.

[0076] The battery weight of the obtained gel battery was 5.03kg, and the measured capacity was 12V24Ah.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com