Workpiece clamping worktable structure matched with welding robot

A technology for welding robots and work clamps, applied in welding accessories, welding equipment, auxiliary welding equipment, etc., can solve problems such as unheard of success in the industry, unseen technical inspiration, and affecting welding efficiency, so as to save labor resources , reduce the number of inputs, improve the effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] In the following descriptions, all the concepts involving up, down, left, right, front and back are for the position state of the figure being described, and thus should not be understood as a special limitation to the present invention.

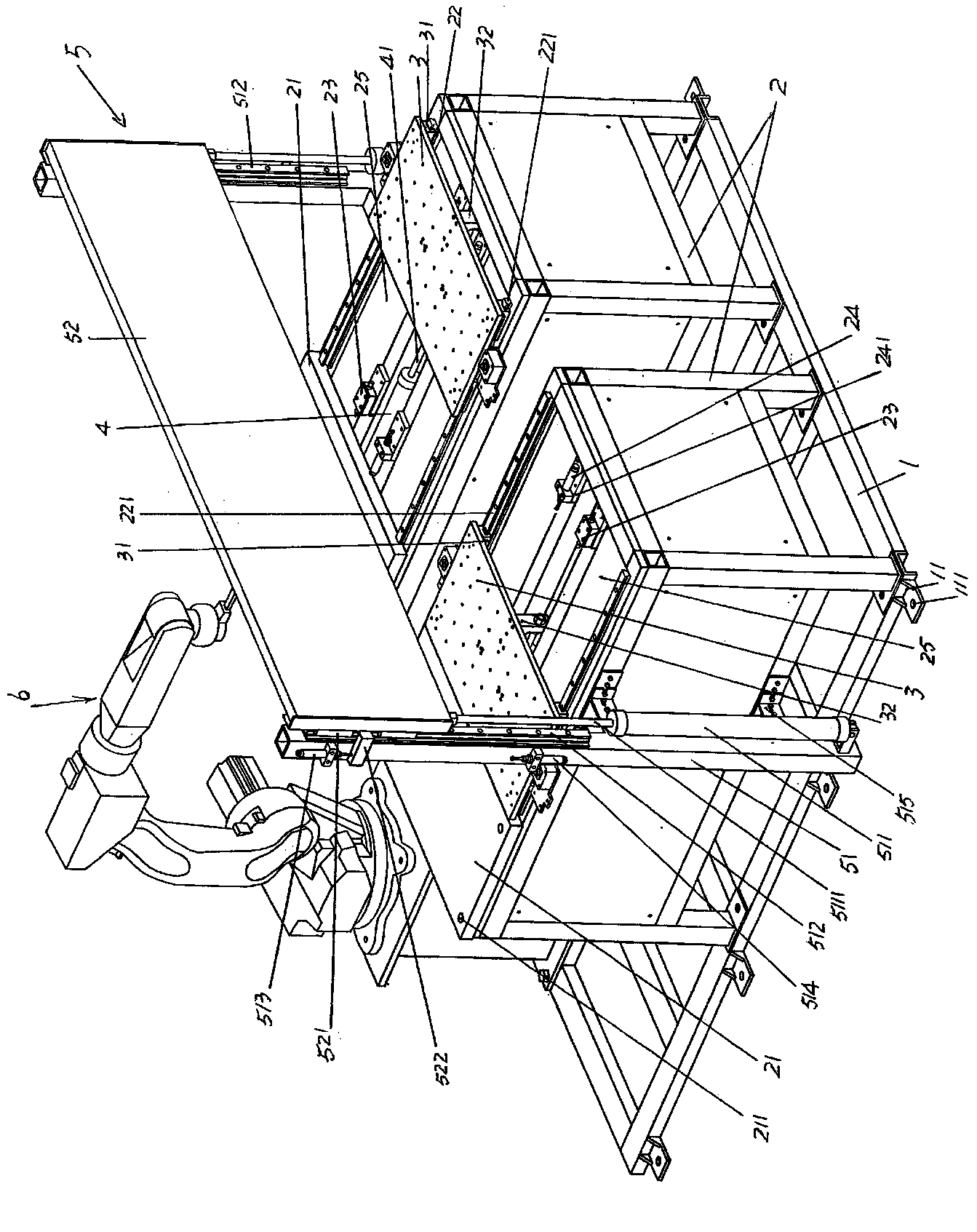

[0024] See figure 1 , a pedestal 1 is given, and the pedestal 1 is fixed on the floor of the place of use in a state of use. In order to facilitate the good fixing of the base 1 and the floor, a set of base fixing ears 11 are respectively welded on the front side and the rear side of the base 1, and a bolt fixing hole 111 is opened on the base fixing ears 11, by The bolts are located at positions corresponding to the bolt fixing holes 111 to fix the base 1 to the floor of the place of use.

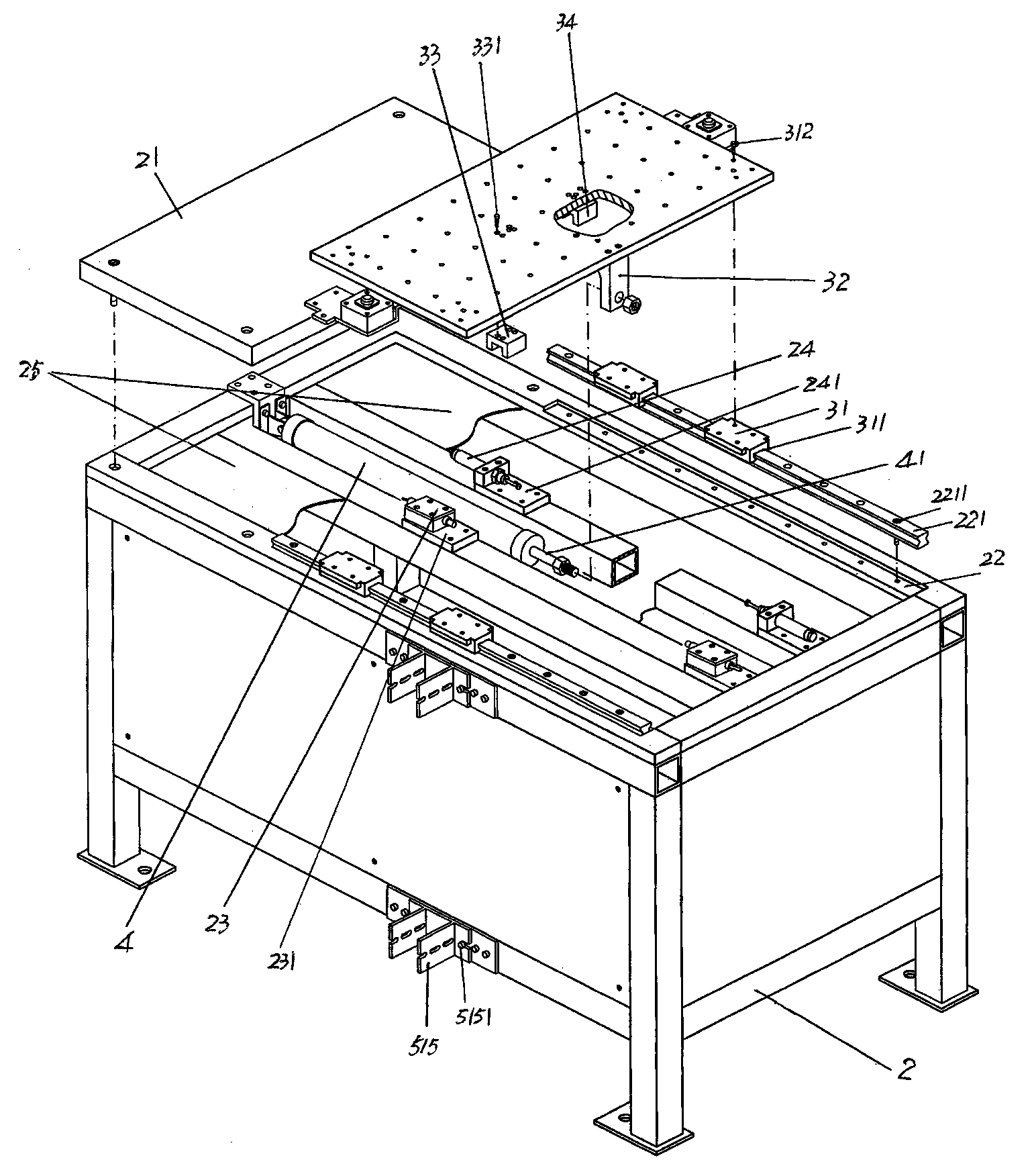

[0025] See figure 2 and continue to combine figure 1 , given a pair of bench 2 ( figure 2 One is shown in ), the pair of workbenches 2 are fixed on the base 1 in a state parallel to each other, and a workpiece clamping platen 3 is slidably p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com