Lead-acid battery for electric moped

A technology of lead-acid batteries and electric mopeds, applied in the direction of lead-acid batteries, lead-acid battery construction, battery pack components, etc., can solve the problems of plate thickness, battery capacity attenuation, and pole group pressure reduction, etc., to reduce product cost and the effect of reducing the amount of lead used in the grid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

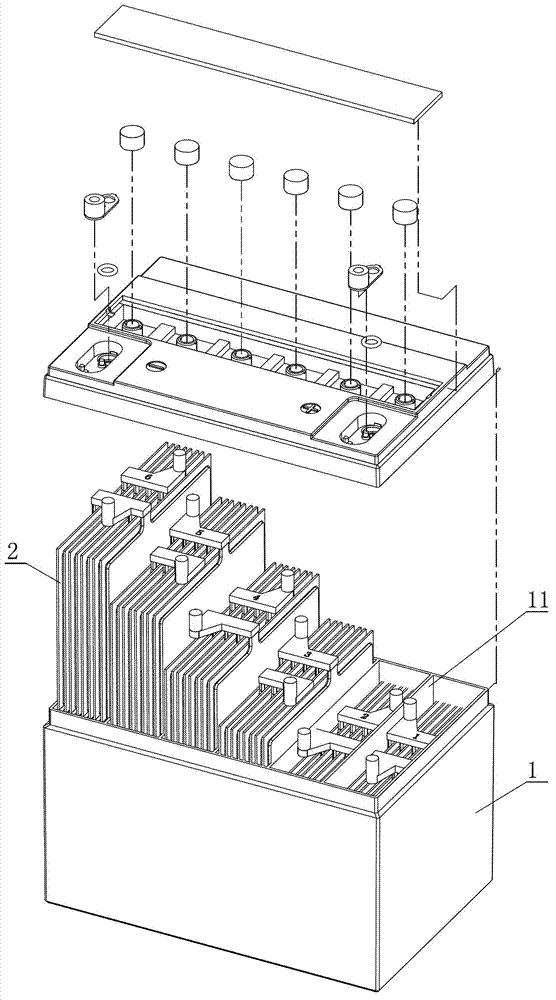

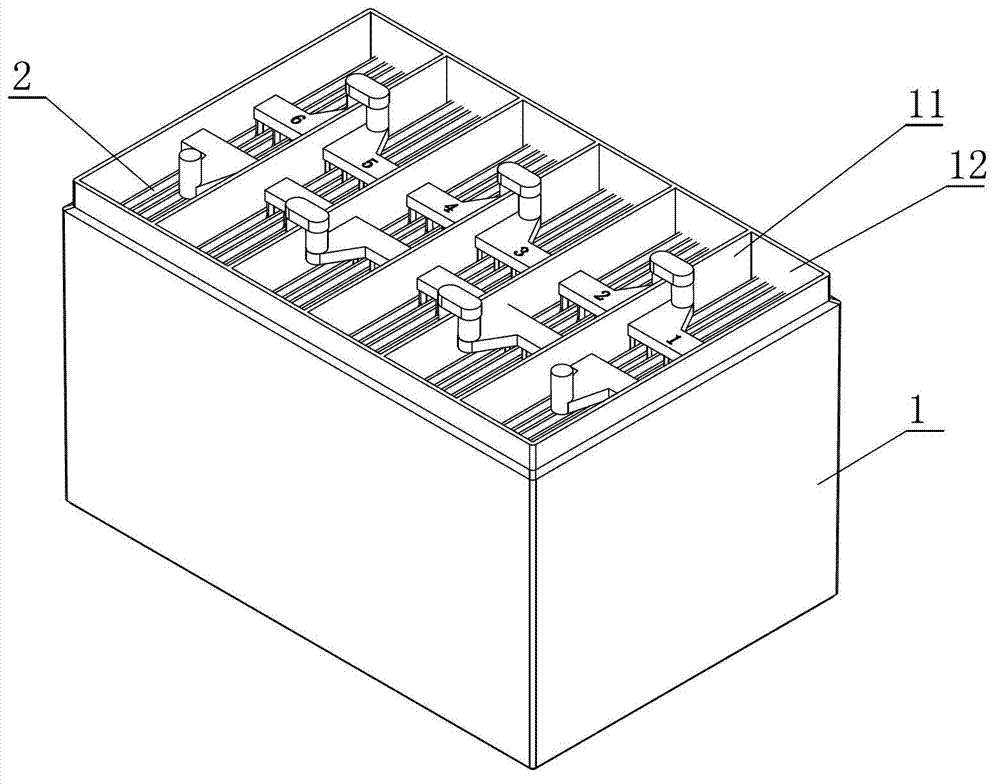

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

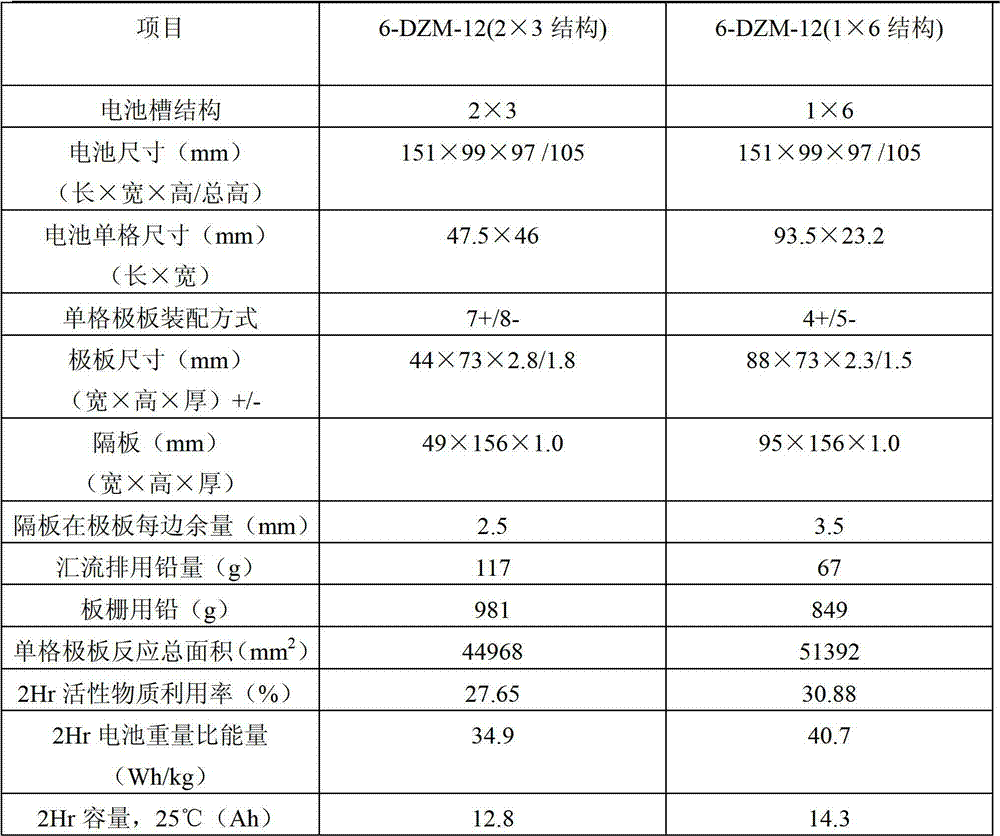

[0015] figure 1 Shown is the lead-acid battery for the electric bicycle of the present invention, including a battery tank 1 and several pole groups 2, the battery tank 1 is provided with a baffle plate 11 to divide the battery tank into six side-by-side battery cells 12, as figure 2 As shown, each electrode group is placed in a battery cell. A single pole group includes 4 positive plates and 5 negative plates stacked alternately. The aspect ratios of the positive and negative plates are both 1.2. The thickness of the positive and negative plates is 1.5-2.3 mm, which is beneficial to increase the surface area of the electrochemical reaction of the plates, enhance the high-current discharge capacity of the battery, effectively improve the charge acceptance performance, and increase the utilization rate of positive and negative active mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com