Patents

Literature

90results about How to "Improve manufacturing process efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

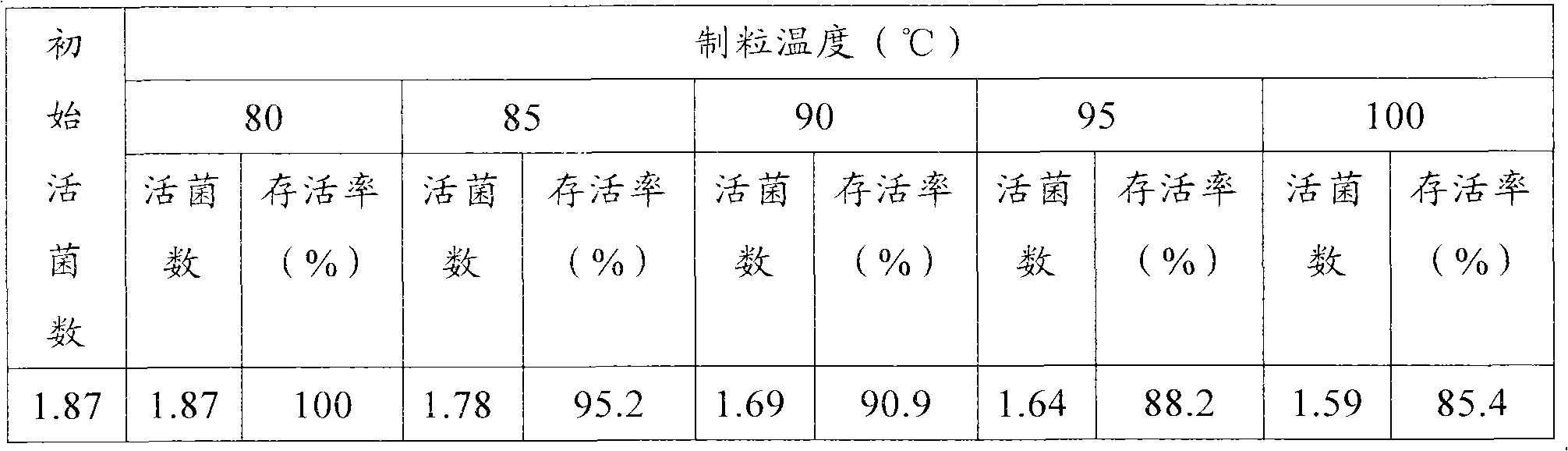

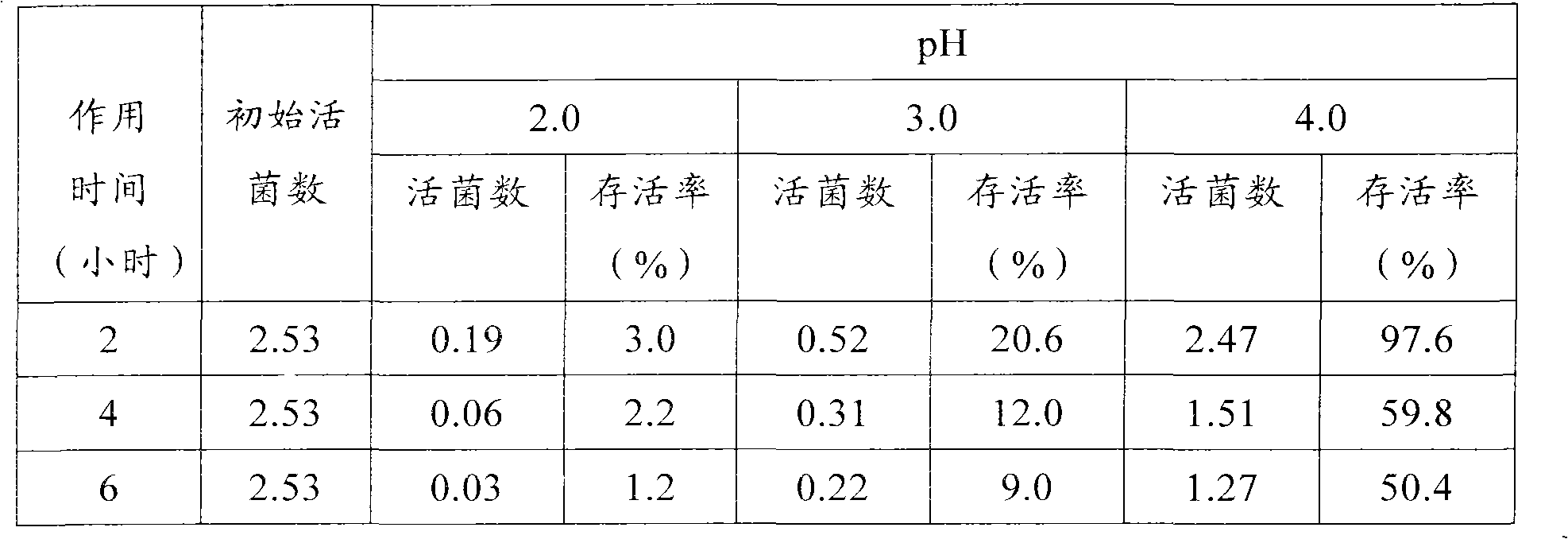

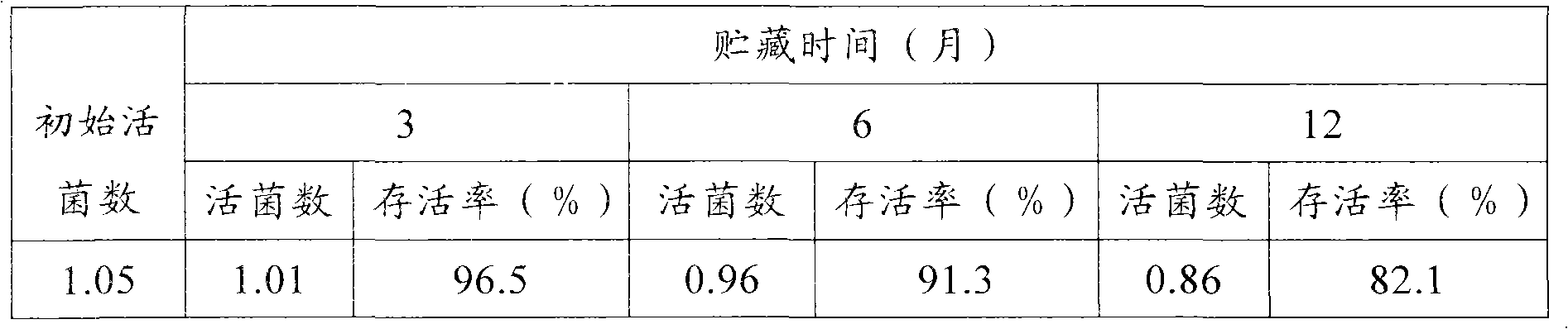

Bacillus subtilis preparation and preparation method thereof

ActiveCN102168045AHigh content of live bacteriaGuaranteed validityBacteriaAnimal feeding stuffBacillus subtilisFermentation broth

The invention discloses a bacillus subtilis preparation and preparation method thereof. The bacillus subtilis preparation is prepared by bacillus subtilis fermentation broth prepared by the following steps: accessing bacillus subtilis seed liquid into fermentation medium with 0.5 to 5% (weight ratio) of inoculation amount, and conducting fermentation for 20 to 40 hours, with pressure being 0.02 to 0.15 MPa, agitation speed being 100 to 300 r / m, and ventilation ratio being 1:0.3-1.5(volume ratio). The advantages of the invention: the invention adopts liquid deep fermentation method instead of solid fermentation method to improve efficiency of preparation technology, and further optimizes composition of the mediums used in various steps and fermentation technological conditions to substantially increase live bacteria content of the bacillus subtilis in final product; the bacillus subtilis preparation is acid resistant and cholate resistant, and keeps high efficiency and stability in intestinal tract environment; and gemma formation rate is high, the bacillus subtilis is more high-temperature resistant and convenient for processing and preservation.

Owner:北京科为博生物科技有限公司

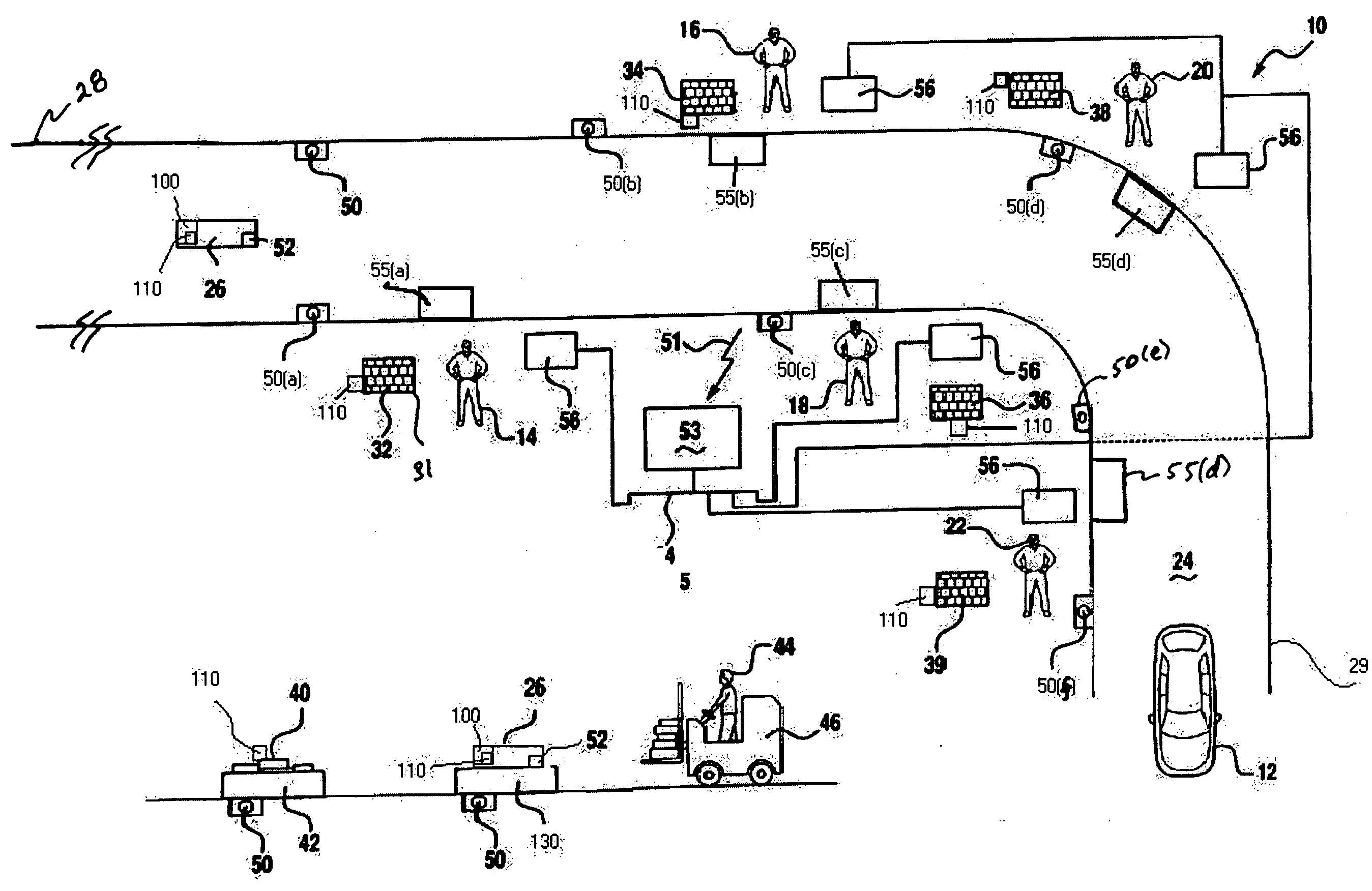

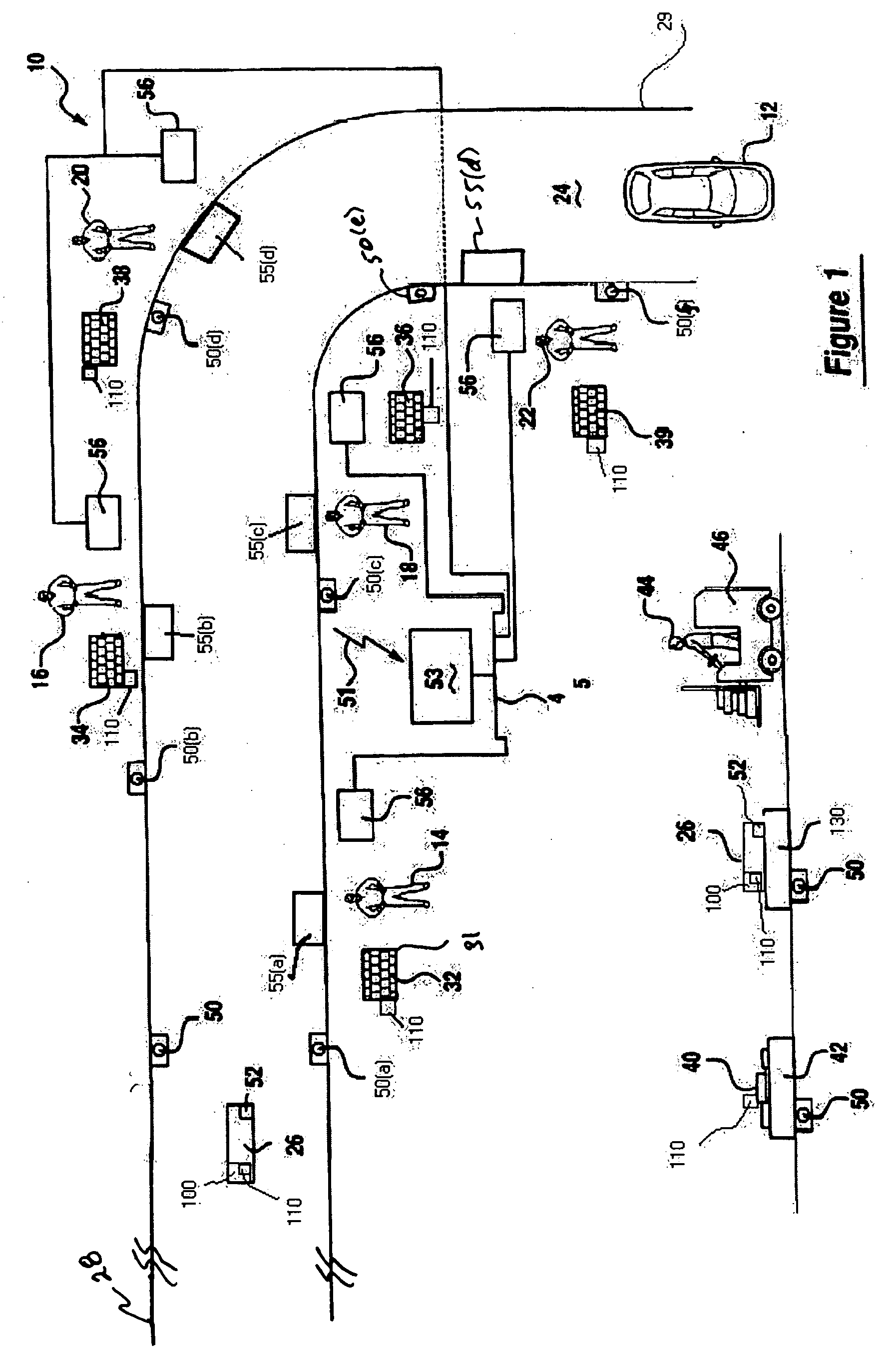

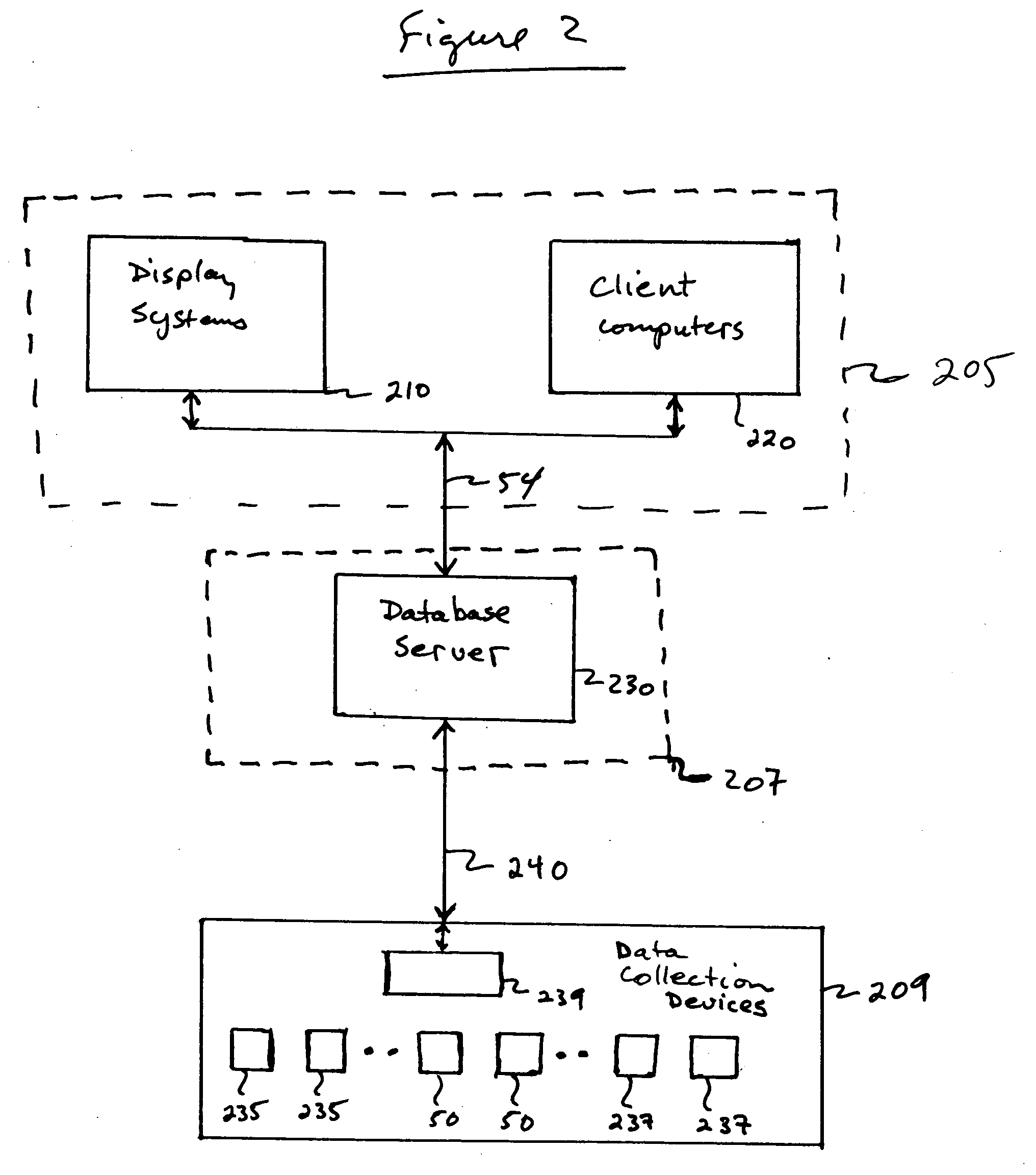

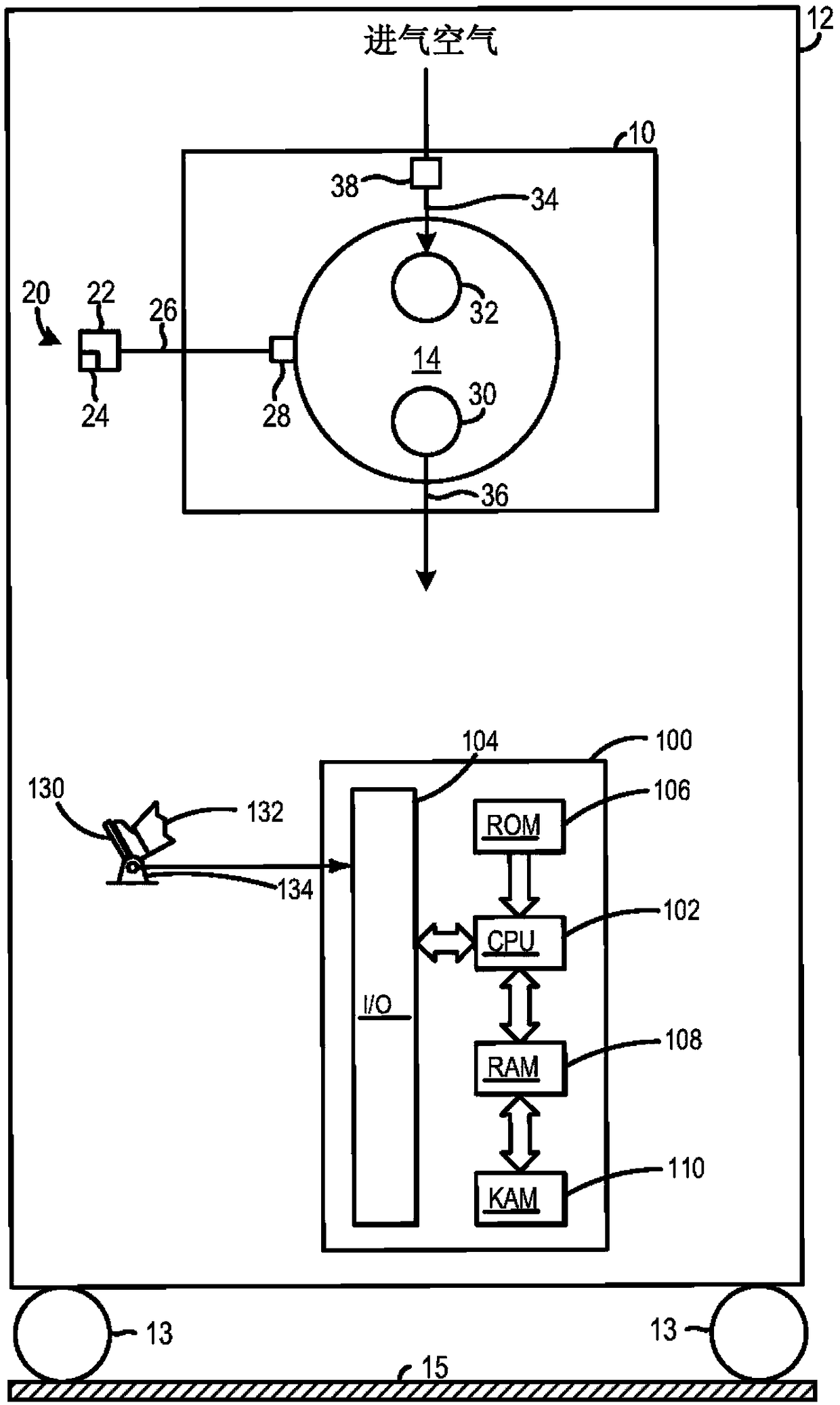

Method for manufacturing an item

InactiveUS20050149216A1Improve manufacturing process efficiencyImprove efficiencyAutomatic control devicesAssembly machinesAssembly lineProximate

According to a first aspect of the present invention, a method is provided for manufacturing an item. The method comprises the steps of creating a build schedule; creating a first portion of the item for manufacture; causing the first portion of the item to pass in close proximity to a first individual; which said individual assembles at least one of the several components on the first portion; notifying a second individual of the existence and location of the first portion of the item proximate to the first individual; causing the first portion of the item to pass in close proximity to the second individual whereby said second individual assembles at least one of the several components onto the first portion of the item. The method further includes applying dataforms or other such markings on individual components to uniquely identify them and, through such markings, tracking the application of those components to the item being manufactured at each manufacture step. Moreover, the information associated with the components as they are tracked through the manufacture process is used to maintain and enhance the efficient operation of the assembly line. These and other aspects, features, and advantages of the present invention will become apparent from a reading of the following detailed description of the preferred embodiment of the invention and by reference to the following drawings.

Owner:AGENTWARE SYST

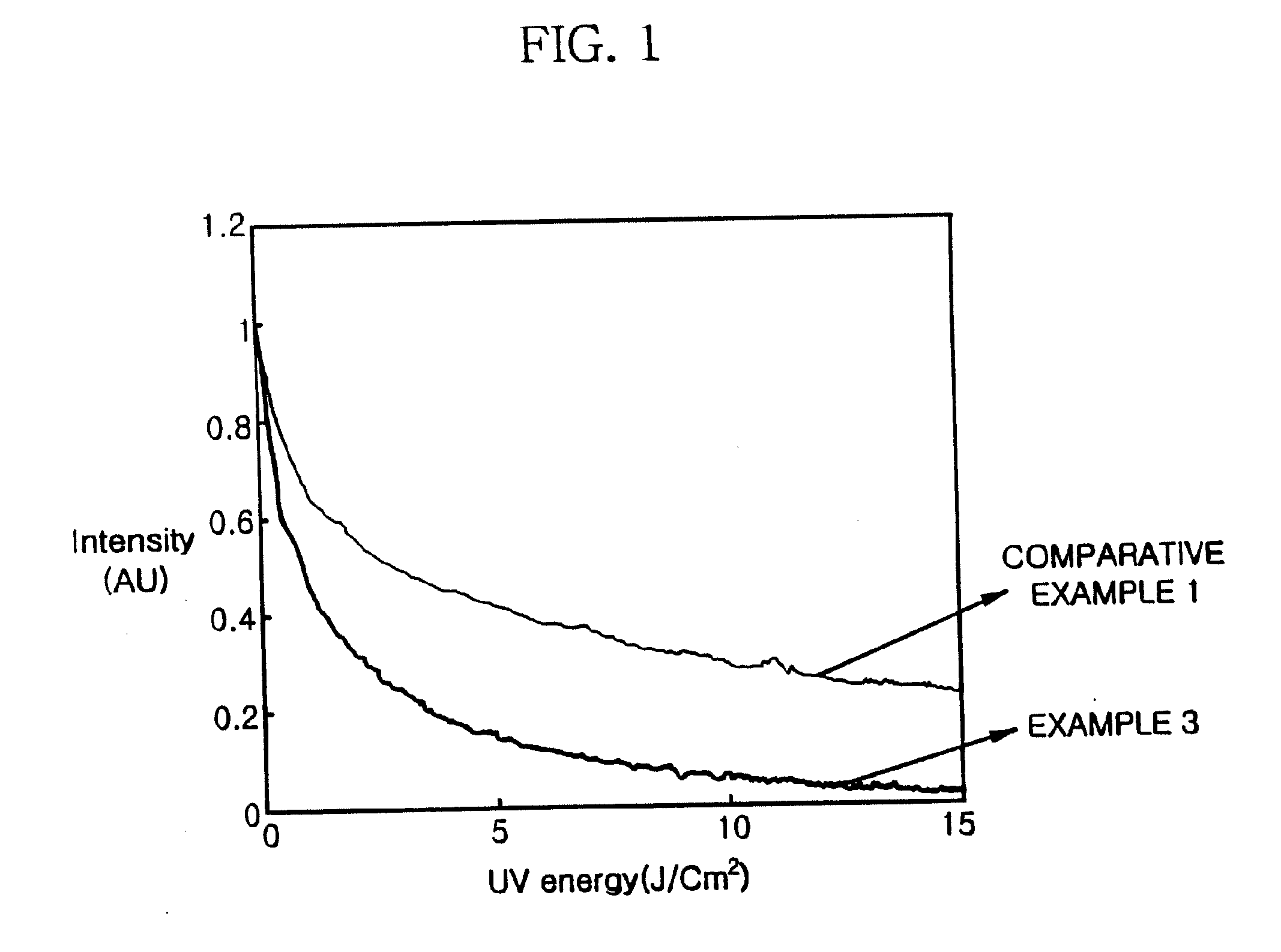

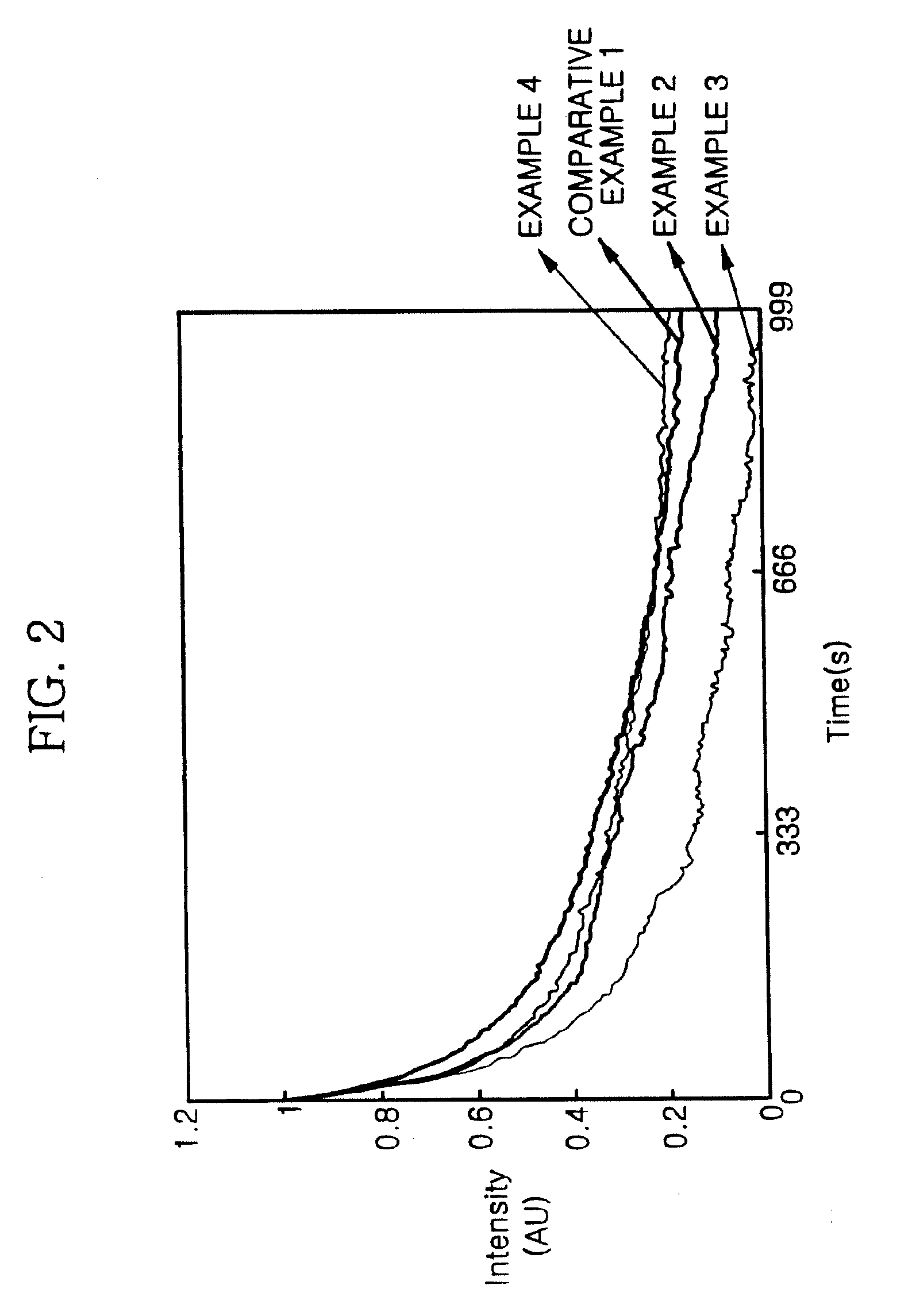

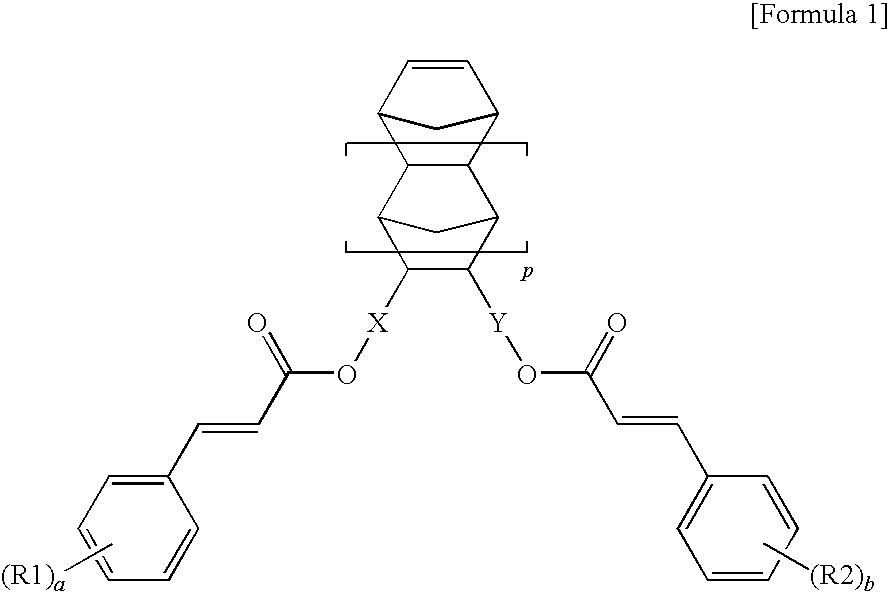

Norbornene monomer, polynorbornene derivative, liquid crystal photoalignment film containing the same and liquid crystal display containing the same

ActiveUS20100047481A1Improve photoresponse performanceImprove thermal stabilityLiquid crystal compositionsOrganic compound preparationPolynorbornenCrystallography

The present invention relates to a norbornene monomer, a polynorbornene derivative, a liquid crystal alignment film including the same, and a liquid crystal display device including the same. More particularly, the present invention relates to a norbornene monomer, a polynorbornene derivative, a liquid crystal alignment film including the same, and a liquid crystal display device including the same, which have an alignment property by photoreaction, excellent thermal stability and photoreactivity, the increased photo-reaction rate and reliability of the alignment film, thereby showing high manufacturing process efficiency.

Owner:LG CHEM LTD

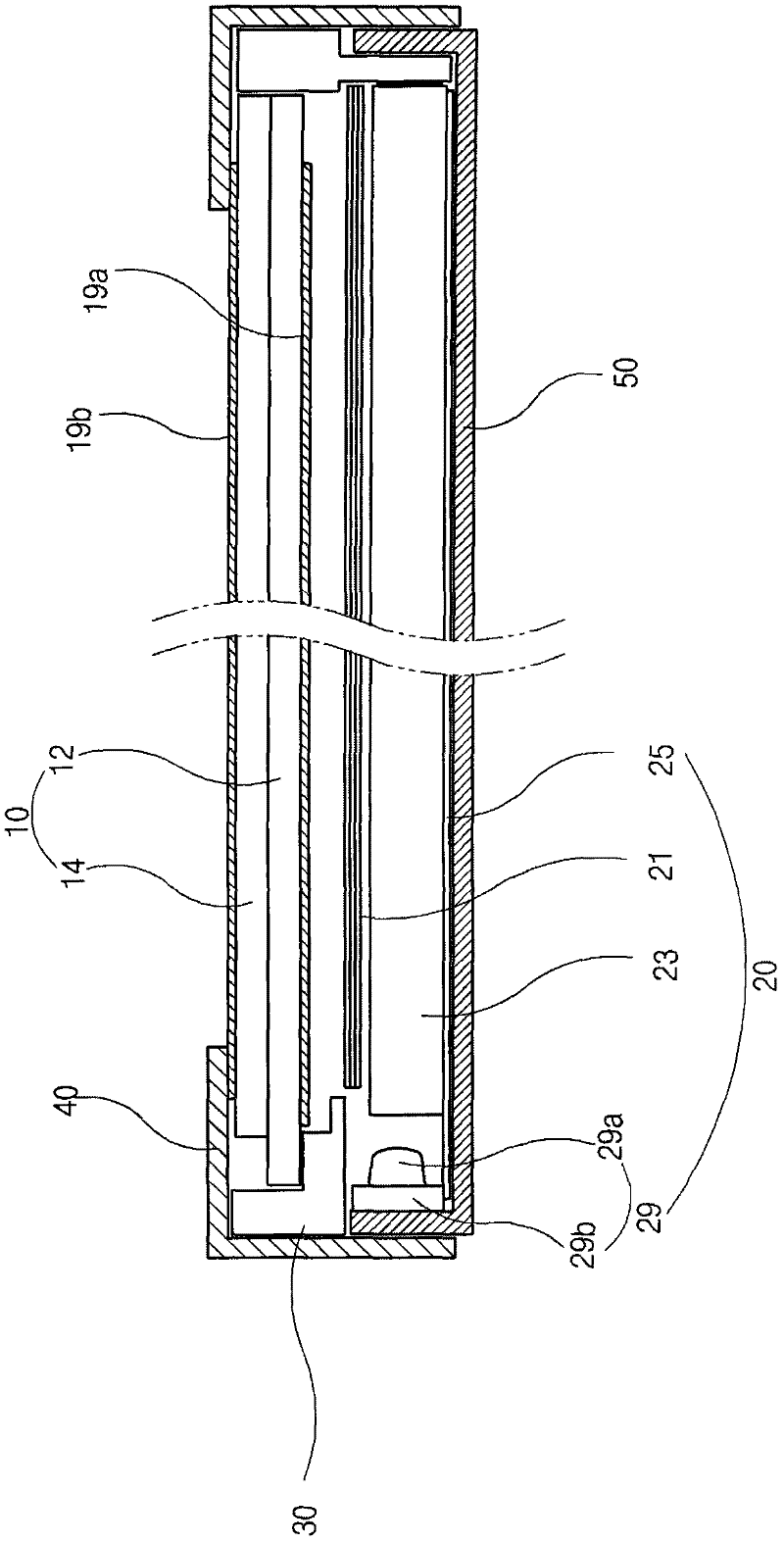

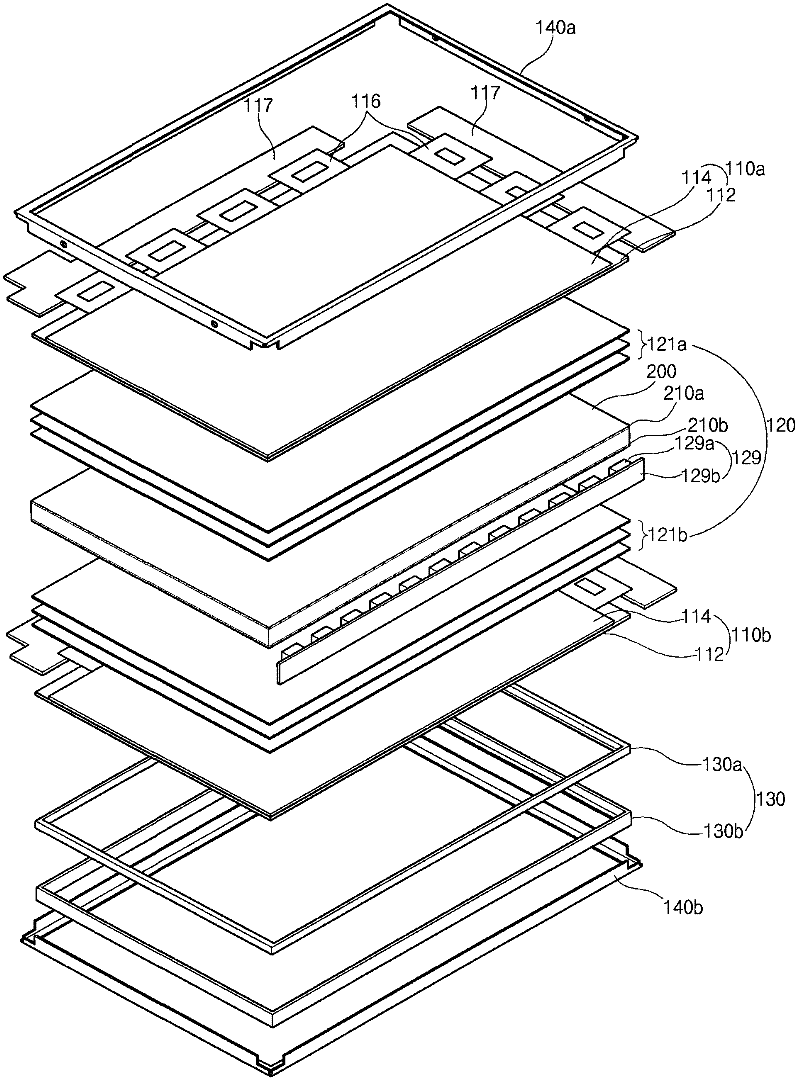

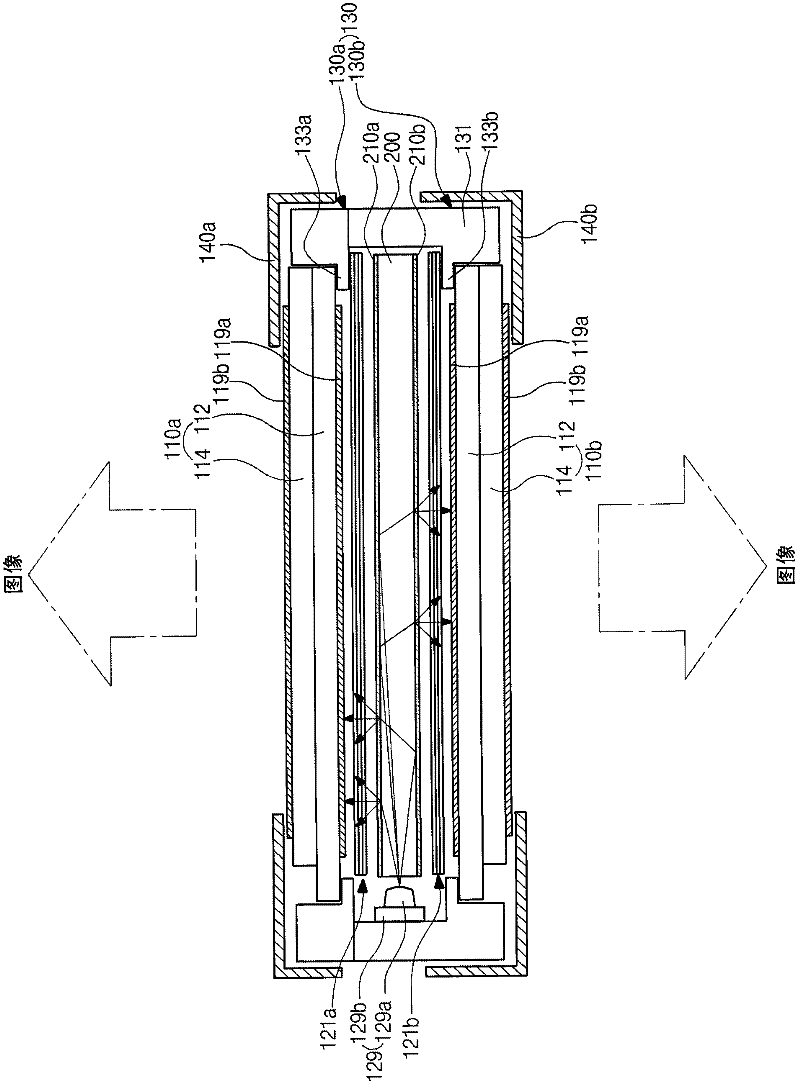

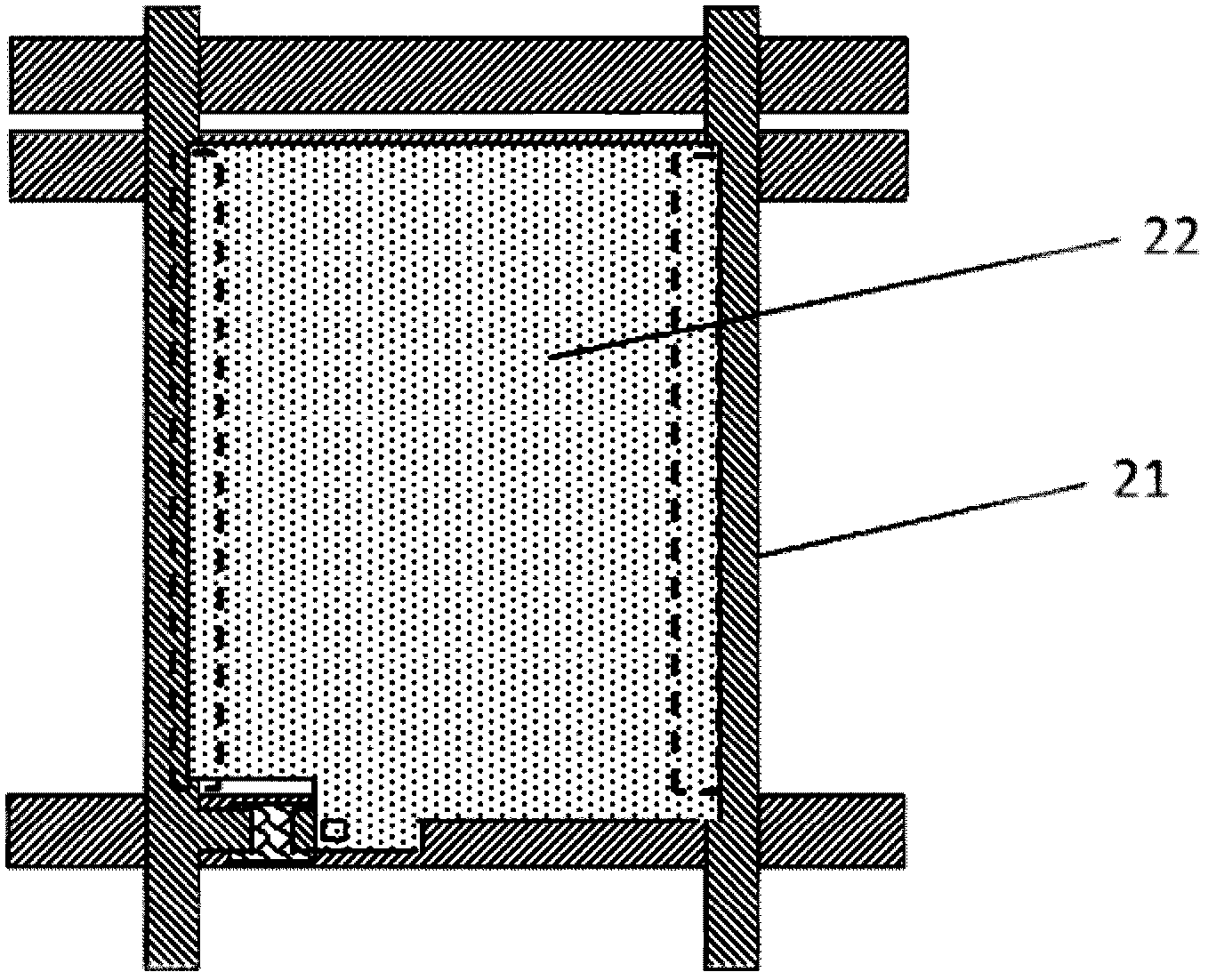

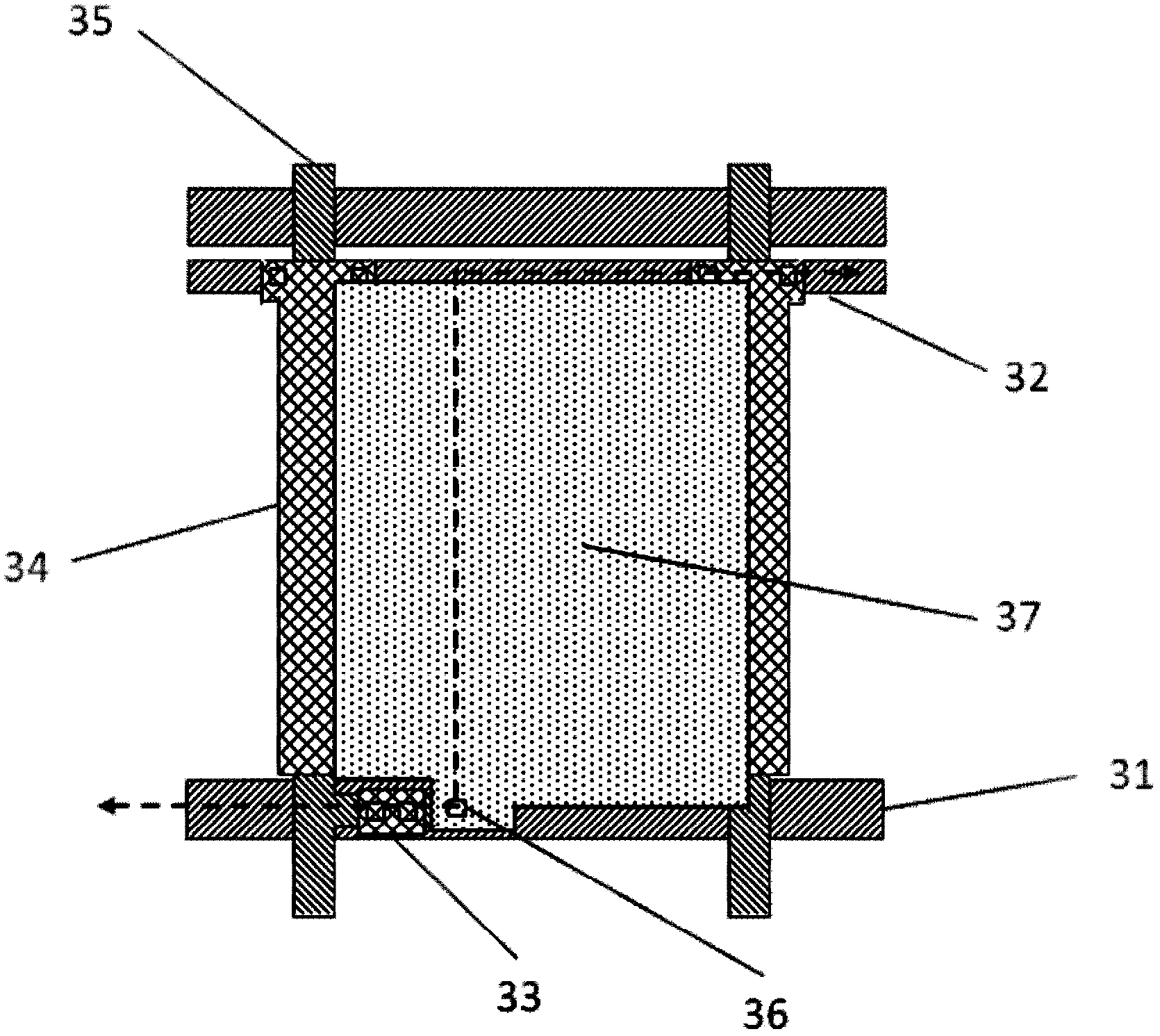

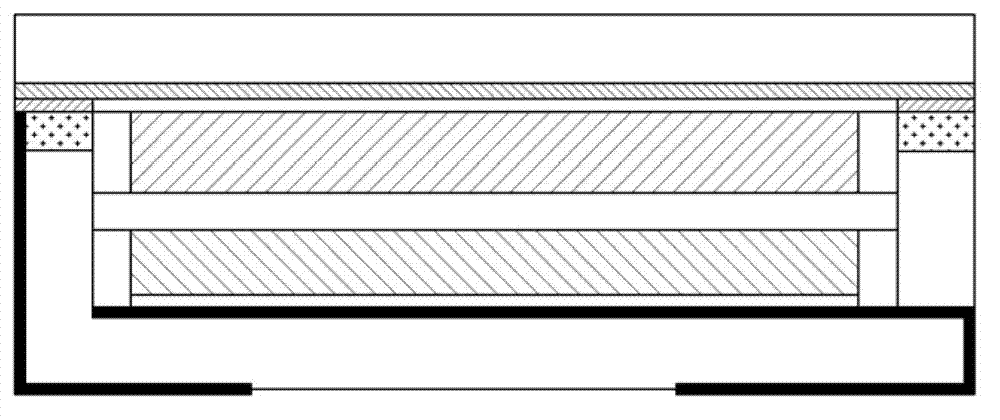

Two-way liquid crystal display device

InactiveCN102540568AReduce manufacturing costImprove manufacturing process efficiencyMechanical apparatusPoint-like light sourceLiquid-crystal displayLight guide

A two-way liquid crystal display device includes first and second liquid crystal panels; a backlight unit disposed between the first and second liquid crystal panels and including an LED assembly and a light guide plate, wherein the LED assembly is disposed at a side surface of the light guide plate and the light guide plate includes predetermined patterns at first and second surfaces thereof facing the first and second liquid crystal panels, respectively; and a support main including a first part guiding the first liquid crystal panel and a second part guiding the second liquid crystal panel and the back light unit, wherein light emitted from the LED assembly is guided by the light guide plate and is provided to the first and second liquid crystal panels.

Owner:LG DISPLAY CO LTD

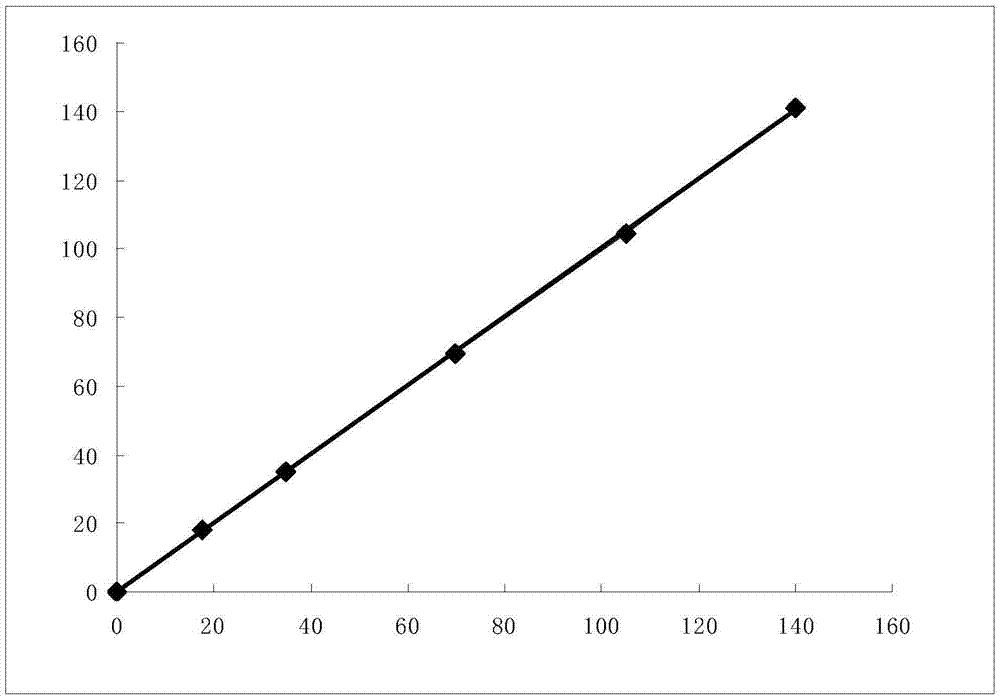

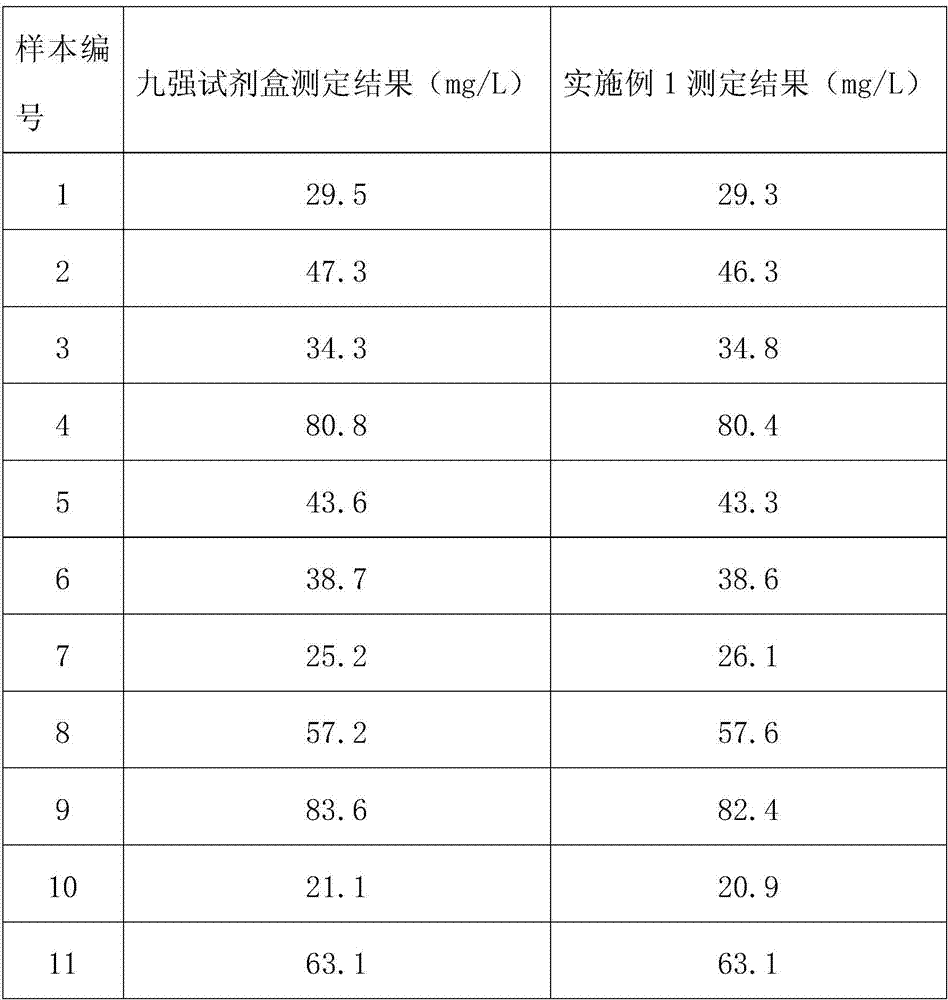

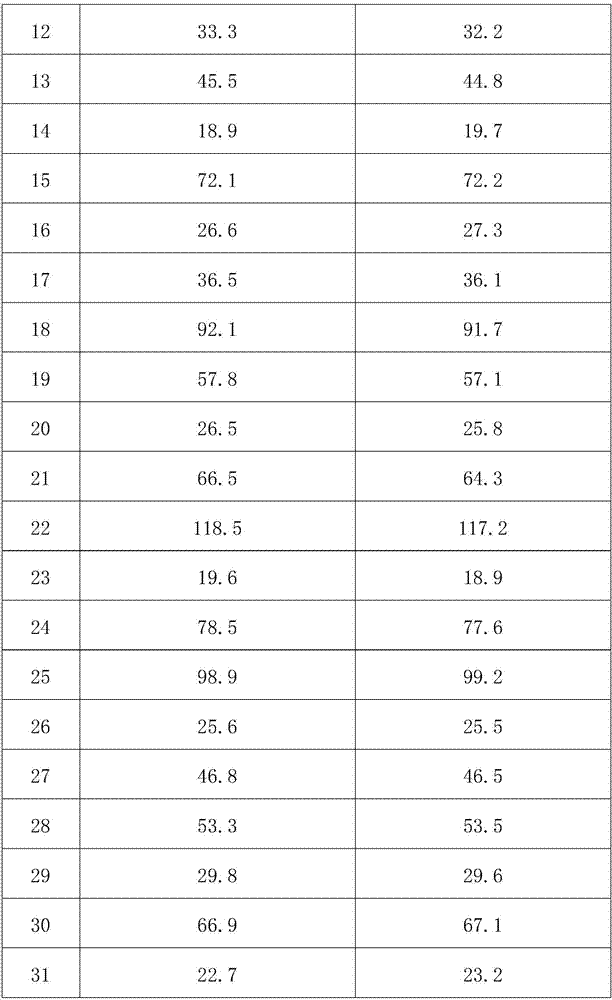

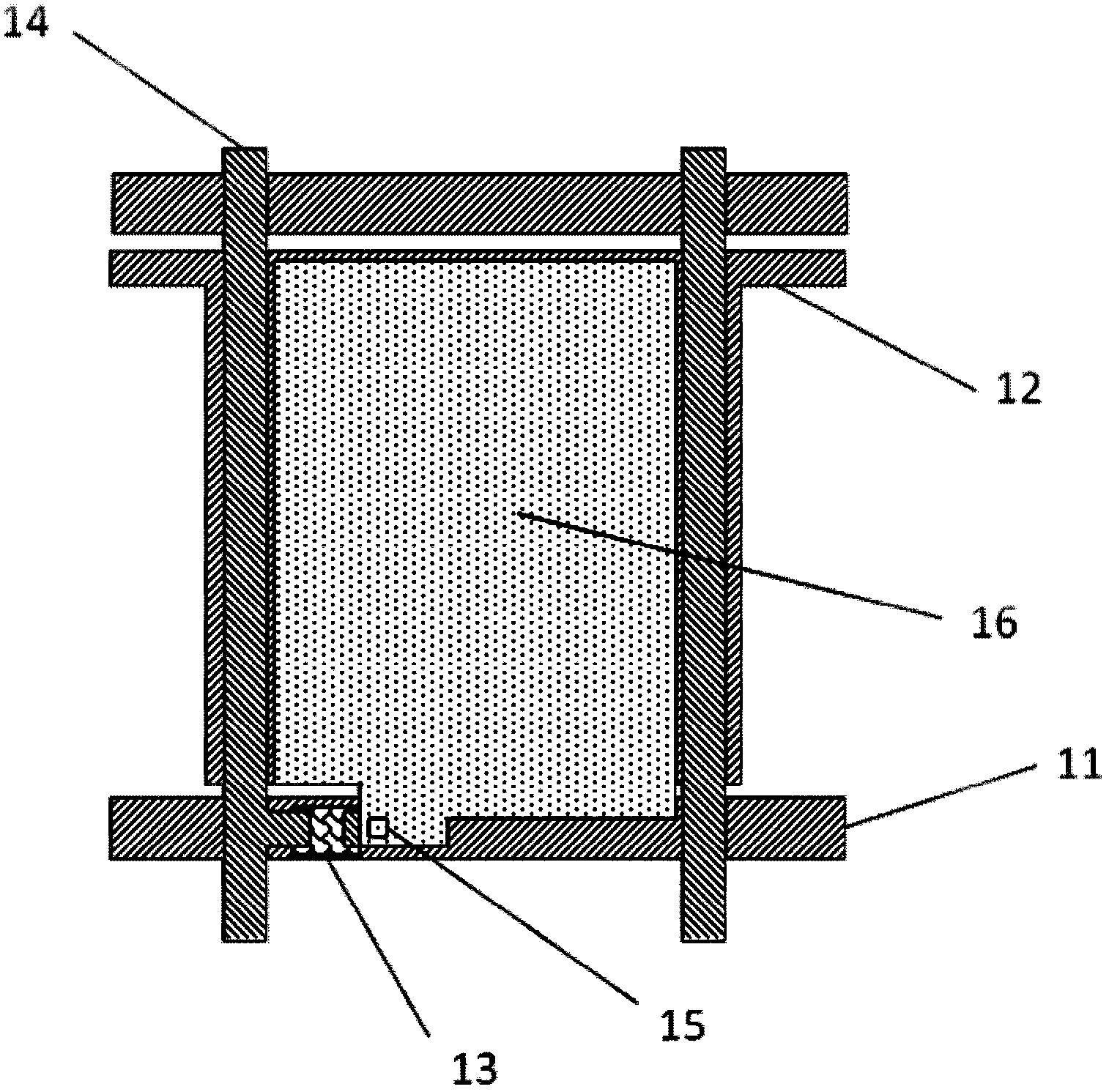

Test kit for measuring content of retinol conjugated protein in serum of human body and preparation method of test kit

InactiveCN106932589AImprove stabilityStrong specificityBiological testingVitamin A RetinolLatex particle

The invention provides a test kit for measuring the content of retinol conjugated protein in serum of a human body and a preparation method of the test kit. The volume ratio of a reagent R1 and a reagent R2 is 3:1. The R1 comprises 0.01-4%w / w of emulsifiers, 0.1-2%w / w of sodium chloride, 0.05-2%w / w of sensitizers, 0.02%w / w of preservative and 30-100mmol / L of buffer solutions. The R2 comprises 0.1-0.5%w / w of latex particle combined with a retinol conjugated protein antibody, 0.1-1.0%w / w of bovine serum albumin, 0.02-2%w / w of Tween 20, 0.02-2%w / w of stabilizers 2, 0.02-2%w / w of protein protective agents, 0.02%w / w of preservative and 20-50mmol / L of buffer solutions. The test kit has wide linearity range, high sensitivity and stability and good clinical application prospect.

Owner:SHANGHAI FOSUN LONG MARCH MEDICAL SCI CO LTD

Pixel structure, manufacturing method thereof and display panel

ActiveCN104345511AEliminate the effects ofImprove manufacturing process efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorHydrogen

The invention discloses a pixel structure, a manufacturing method thereof and a display panel. Insulating layers made of different materials are used, so that the semiconductor characteristics of metallic oxides used in a semiconductor device are represented, and the conductor characteristics of metallic oxides above the data line of an array substrate are represented. The insulating layers on the two sides of an oxide semiconductor layer are made of oxide insulating materials, and at least one side of the two sides of an oxide conductor layer is made of an insulating material containing hydrogen (H) or other strong reduction elements. The oxide conductor layer serves as the shielding layer of the data line, the influence of the signals of the data line to a pixel electrode is eliminated, and the aperture ratio of pixels can be improved. In the manufacturing process, the manufacturing working procedures of existing devices are fully utilized in the working procedure of preparing the shielding layer, the manufacturing method is simple and easy to realize, and the processing cost does not need to be increased.

Owner:NANJING CEC PANDA LCD TECH

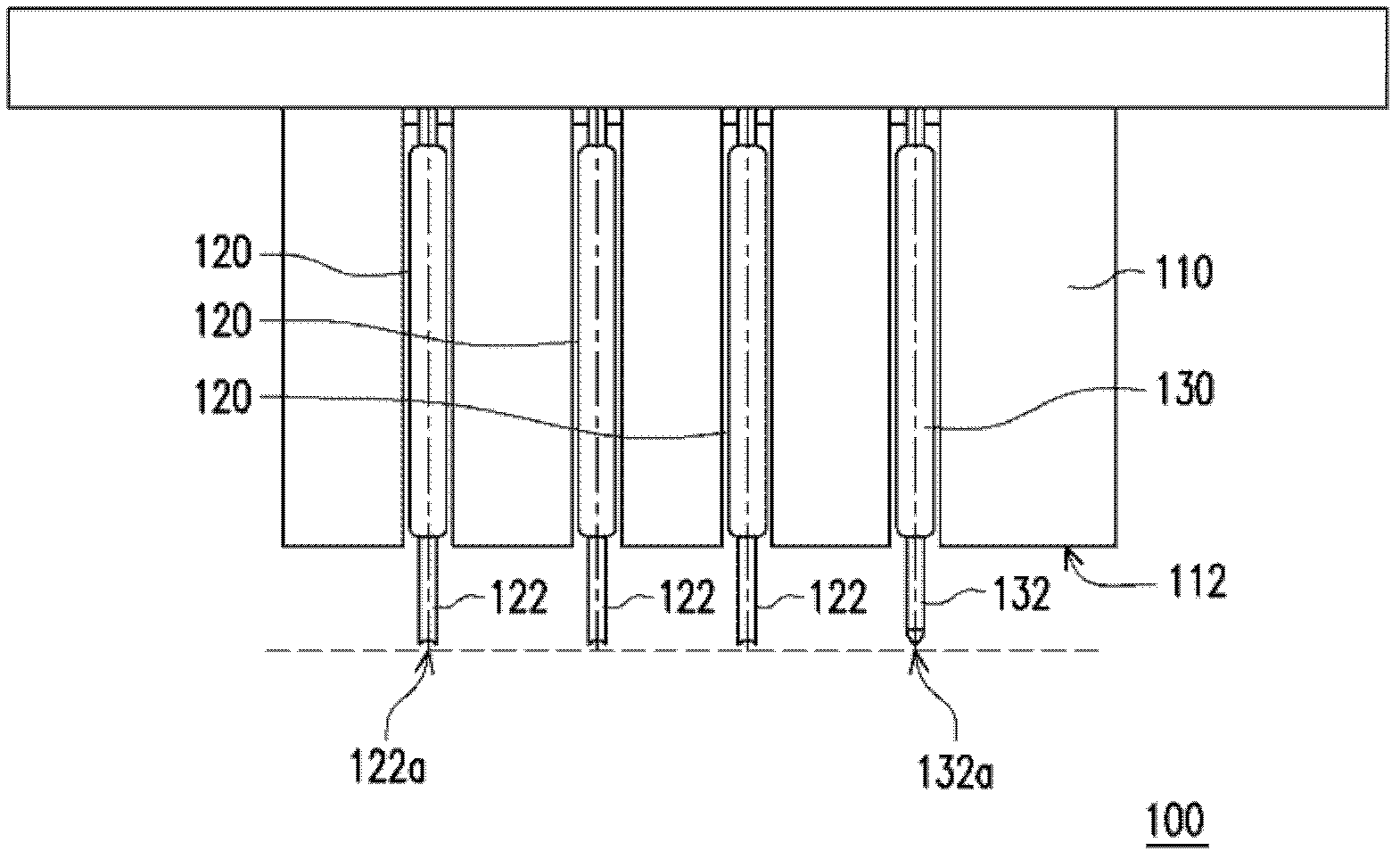

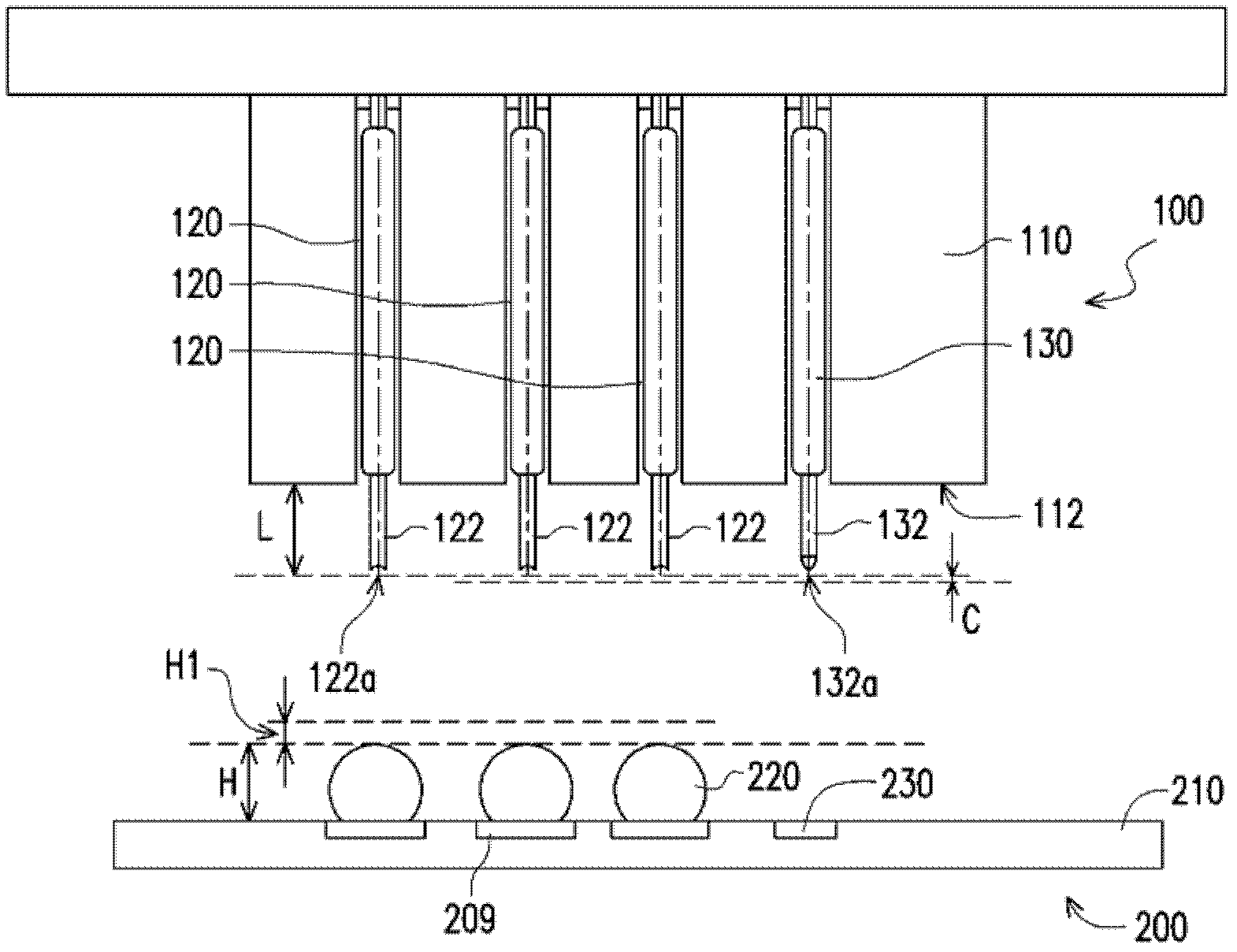

Probe card and test method

ActiveCN102435798AReduce testing processImprove manufacturing process efficiencyElectrical measurement instrument detailsElectrical testingComputer hardwareProbe card

The invention discloses a probe card and a test method. The probe card integrates multiple probes with different strokes. The multiple probes with the different strokes can contact connecting points at different heights when facing to the connecting points at the different heights on an object to be tested, so that the object to be tested can be tested. In addition, the test method employing the probe card is also disclosed.

Owner:ADVANCED SEMICON ENG INC

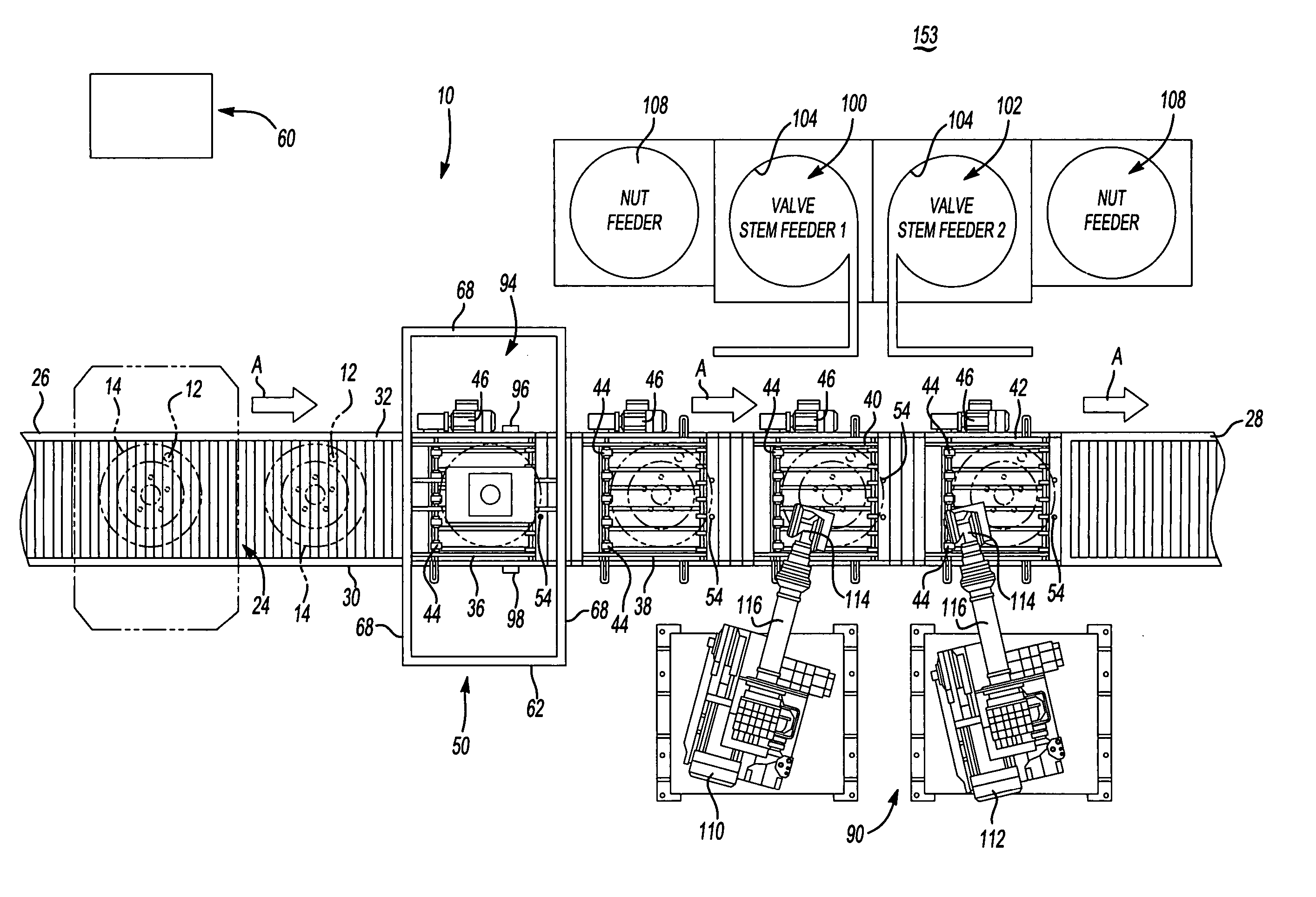

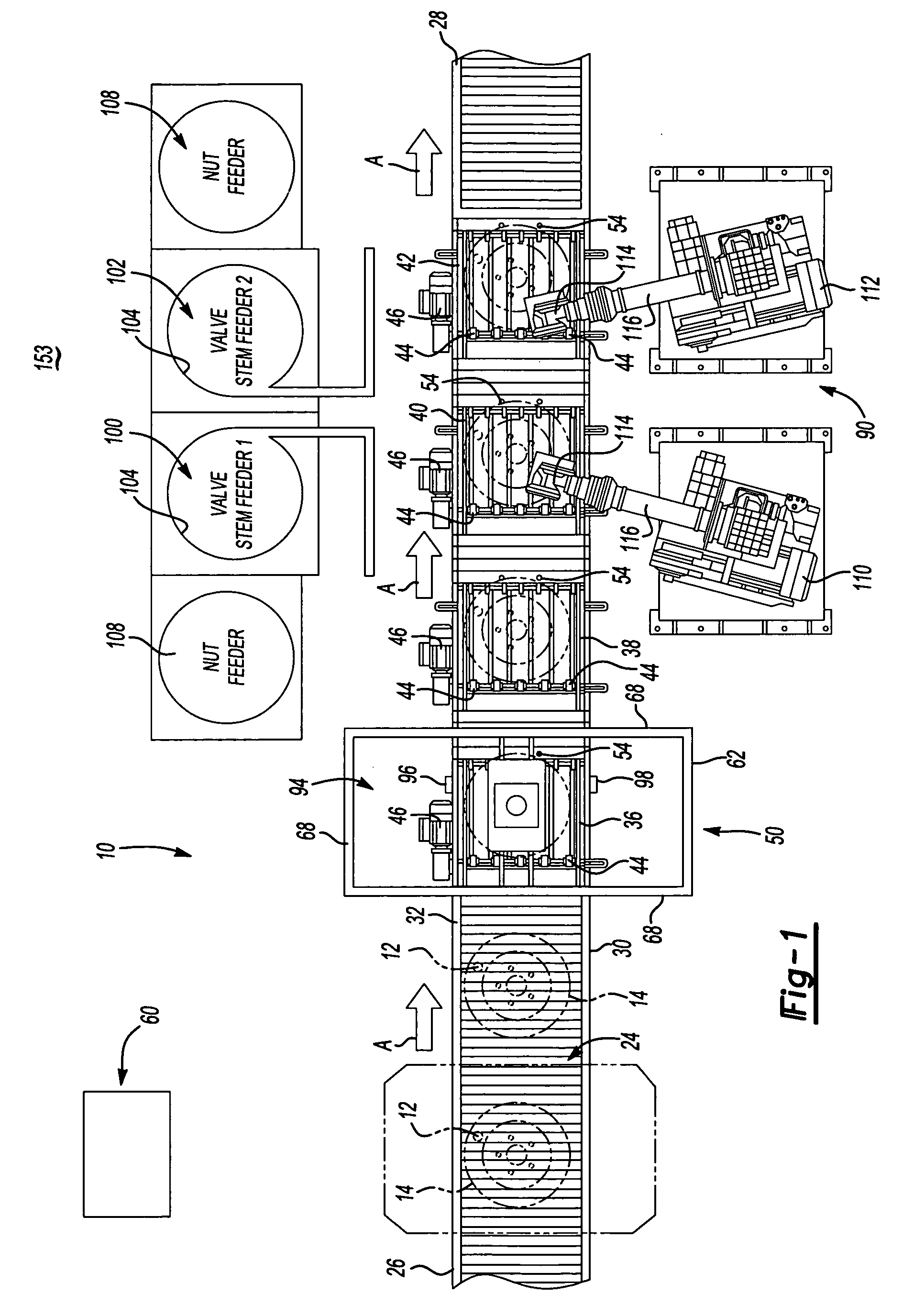

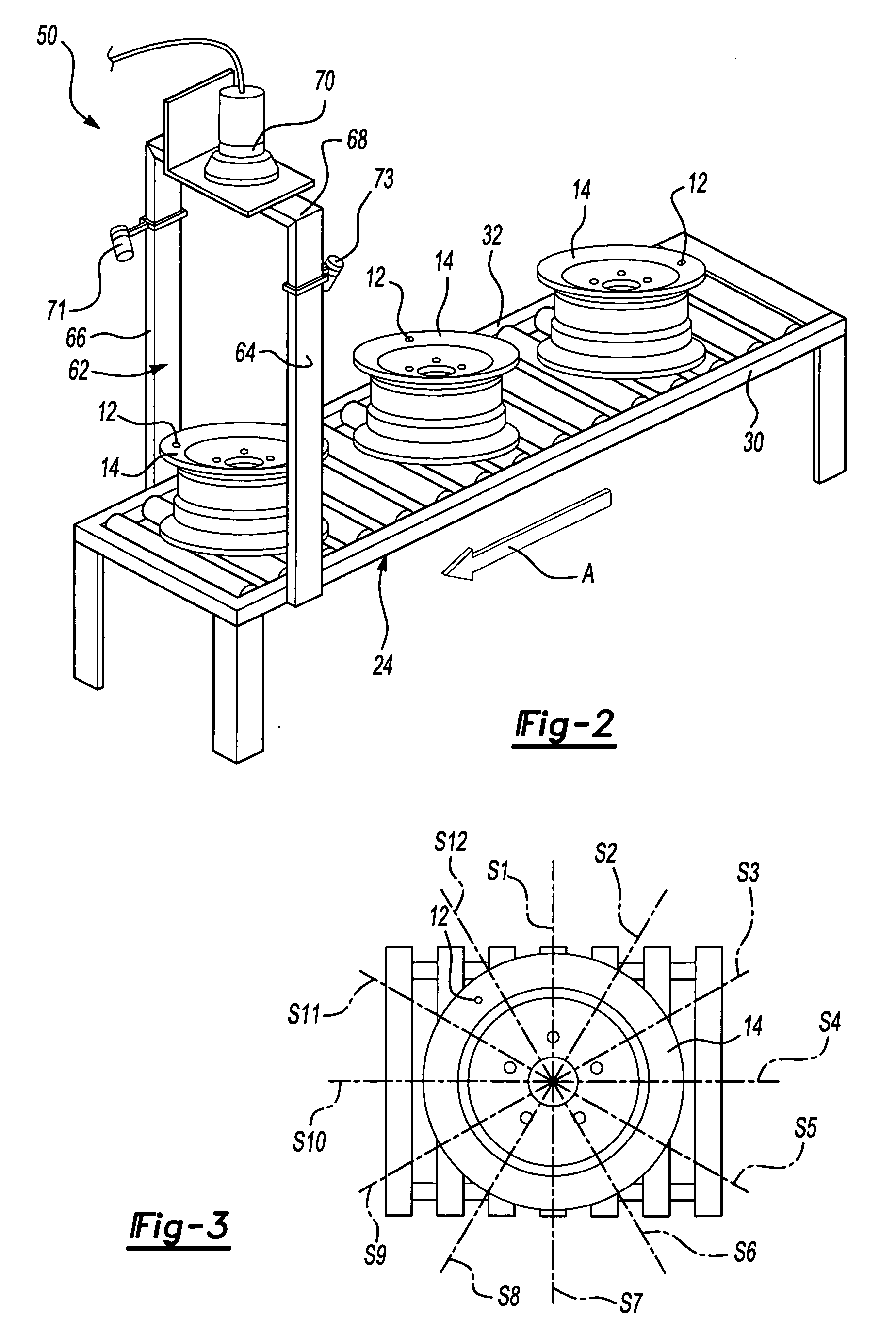

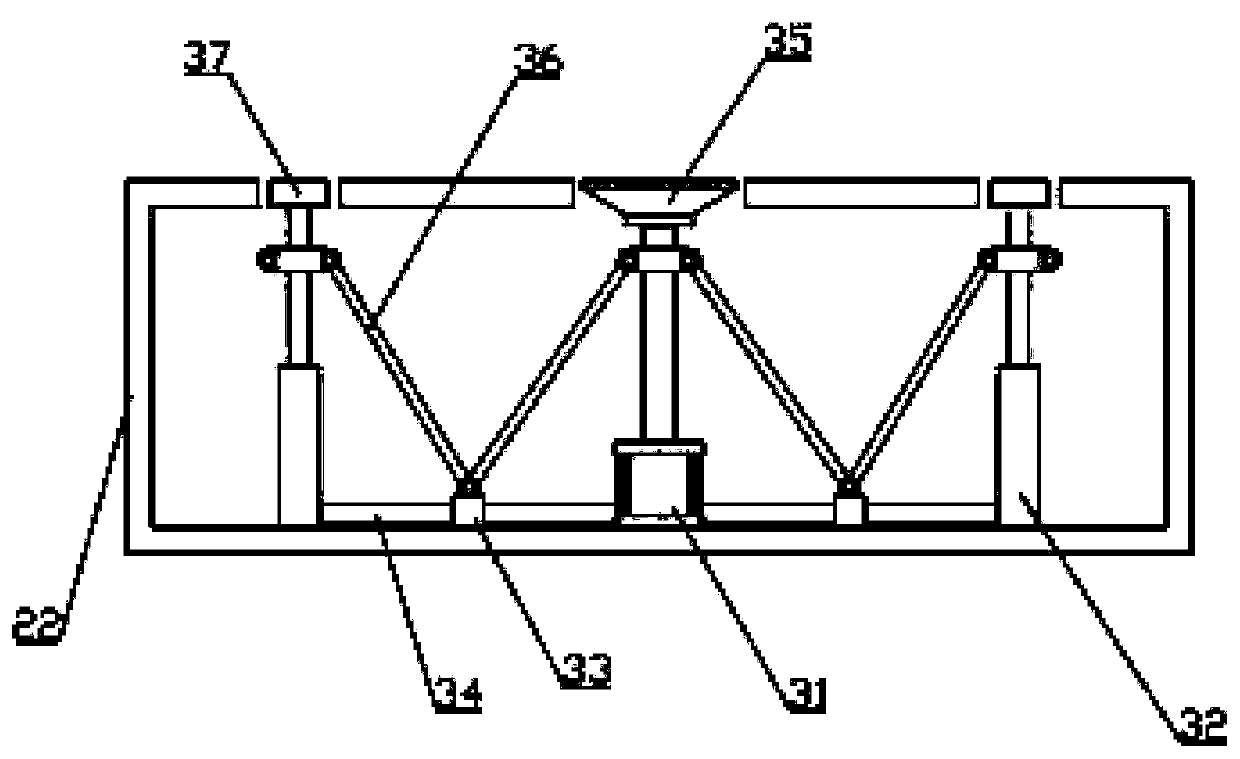

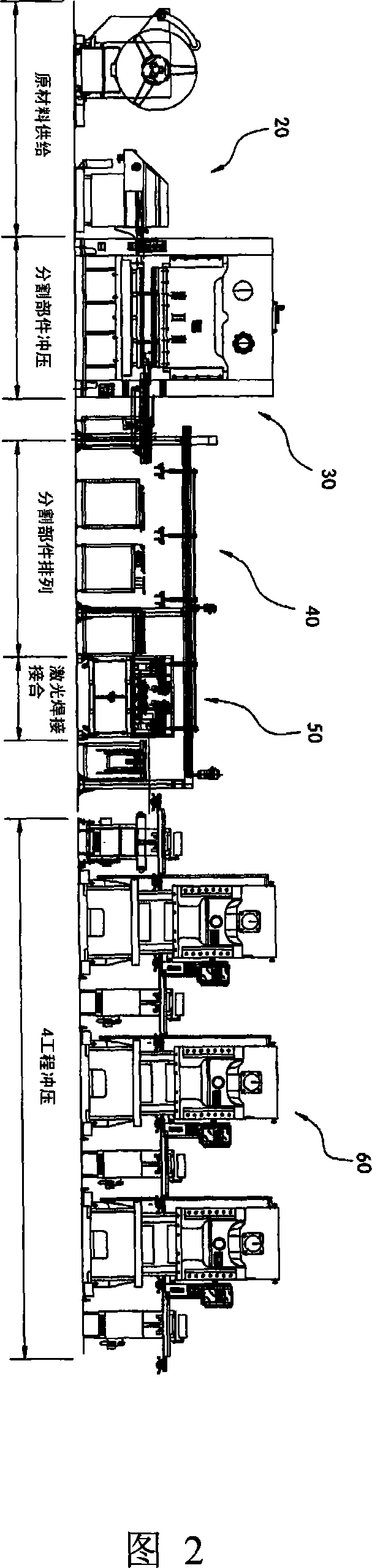

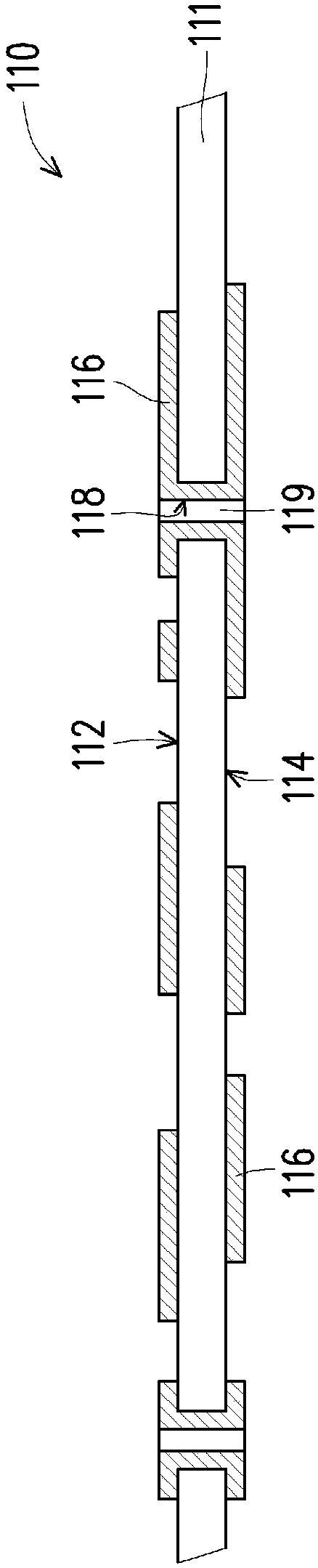

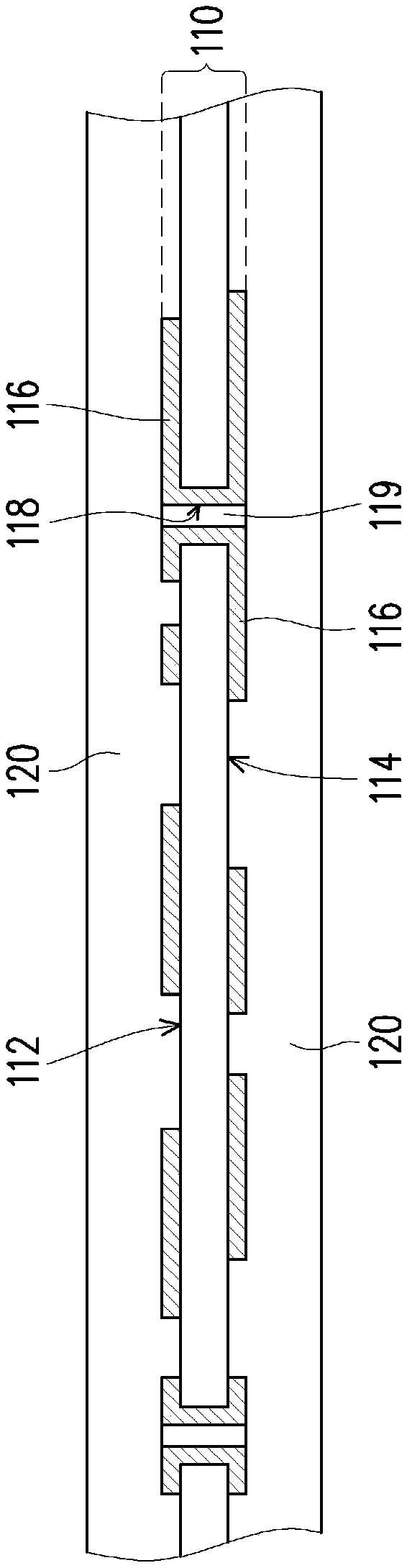

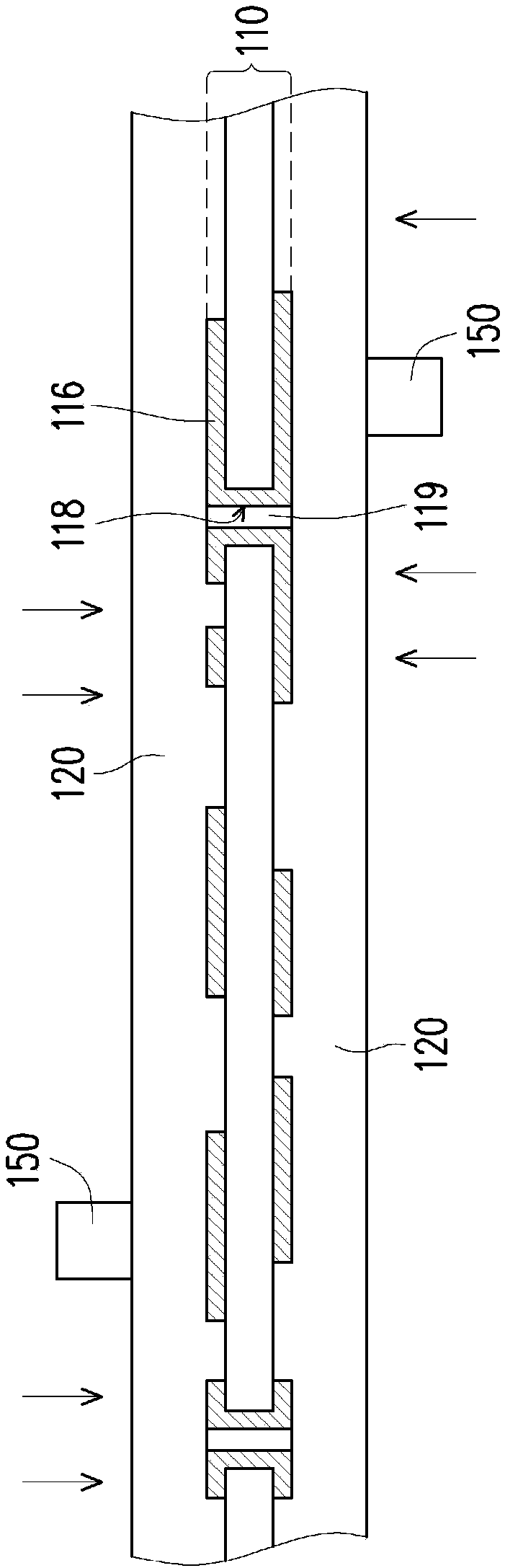

Valve stem installation system and method of installing the valve stem

ActiveUS20060107510A1Improve mating accuracyIncrease speedAutomatic control devicesValve arrangementsTarget signalControl theory

A valve stem installation system (10) includes a conveyor (24) for moving wheel (14). A controller (60) is adaptable for segmenting the wheel (14) into a plurality of sections (S1-S11). A detector (70) identifies and signals a general location of the aperture (12) to the controller (60) to identify a target section (S11) transmitted to the controller (60) by a first signal. A robotic manipulator (110, 112) is operably connected to the controller (60) and adaptable for inserting the valve stem into the aperture (12). A sensor (153) is connected to the robotic manipulator (110, 112) and is adaptable for visually identifying the target section (S11) and transmitting the general location of the aperture (12) within the target section by a second signal. The controller (60) generates a target signal transmitted to the robotic manipulator (110, 112) to increase the speed and accuracy of mating the valve stem into the aperture (12) in response to the target signal.

Owner:DURR SYST INC

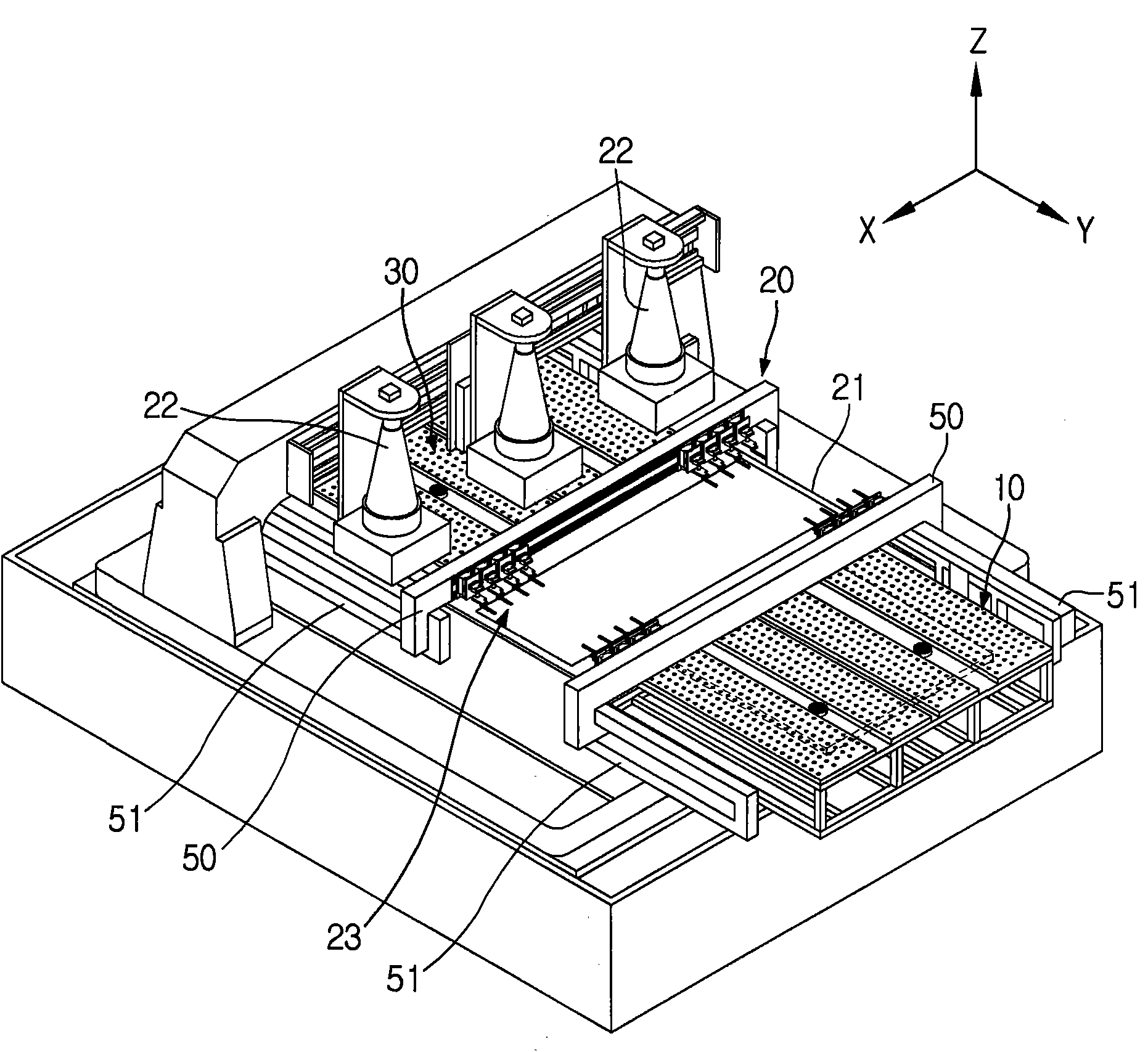

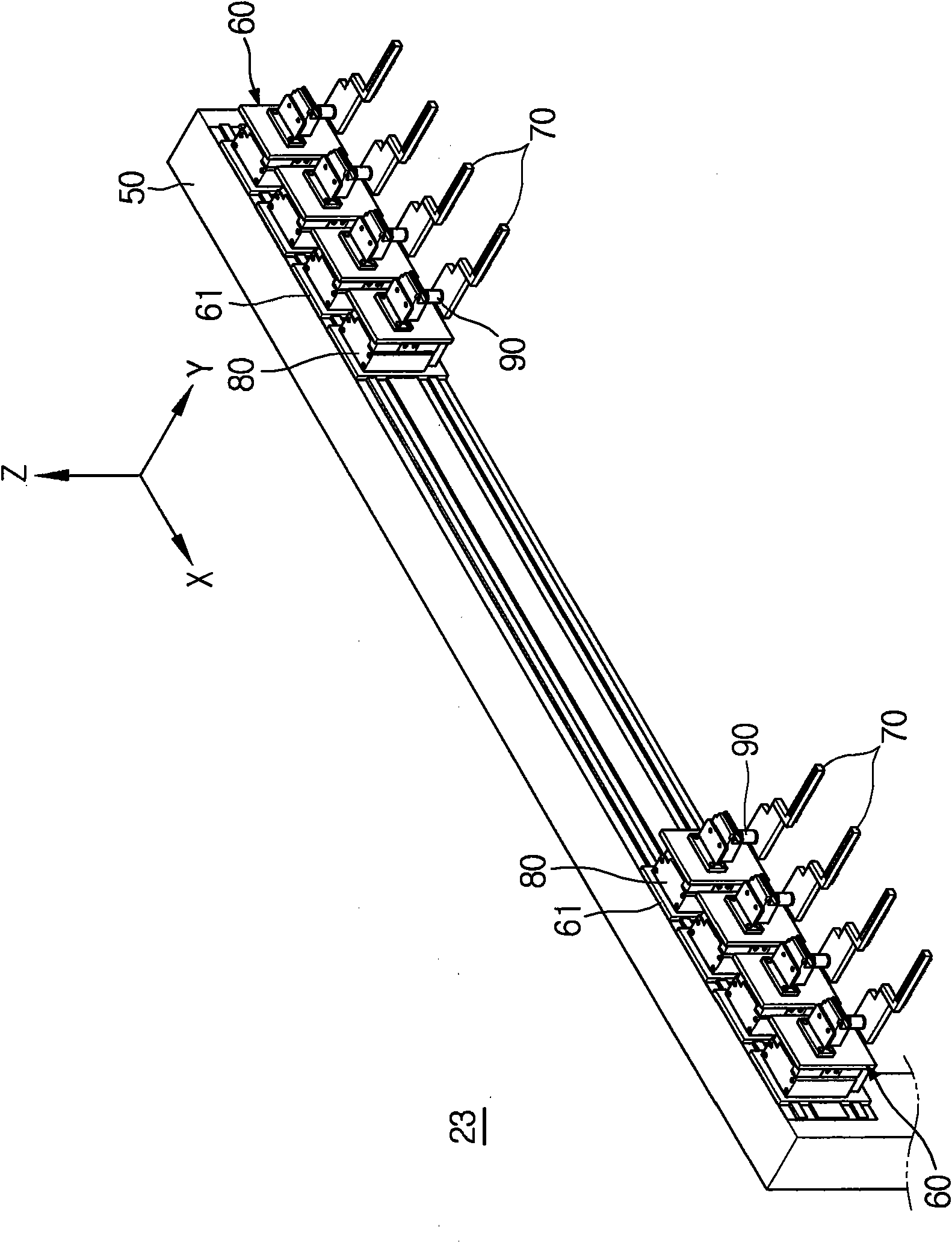

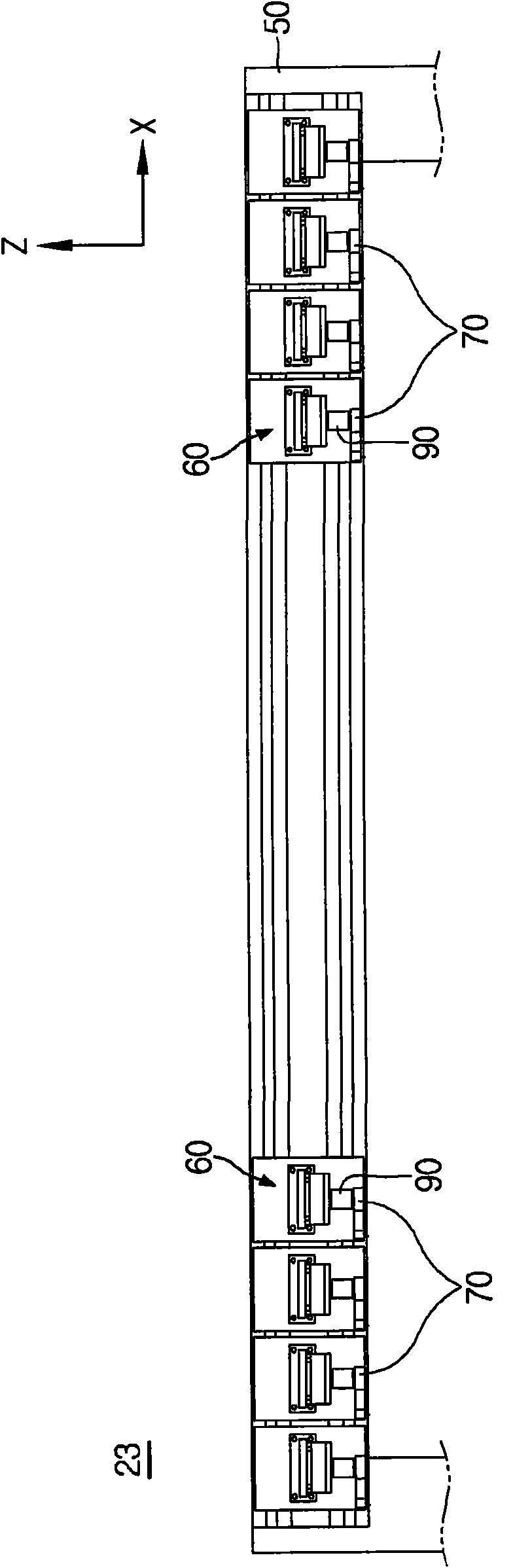

Array substrate detecting device and method thereof

InactiveCN102053400AImprove manufacturing process efficiencyElectrical measurement instrument detailsElectrical testingPhysicsElectrode

Owner:TOP ENG CO LTD

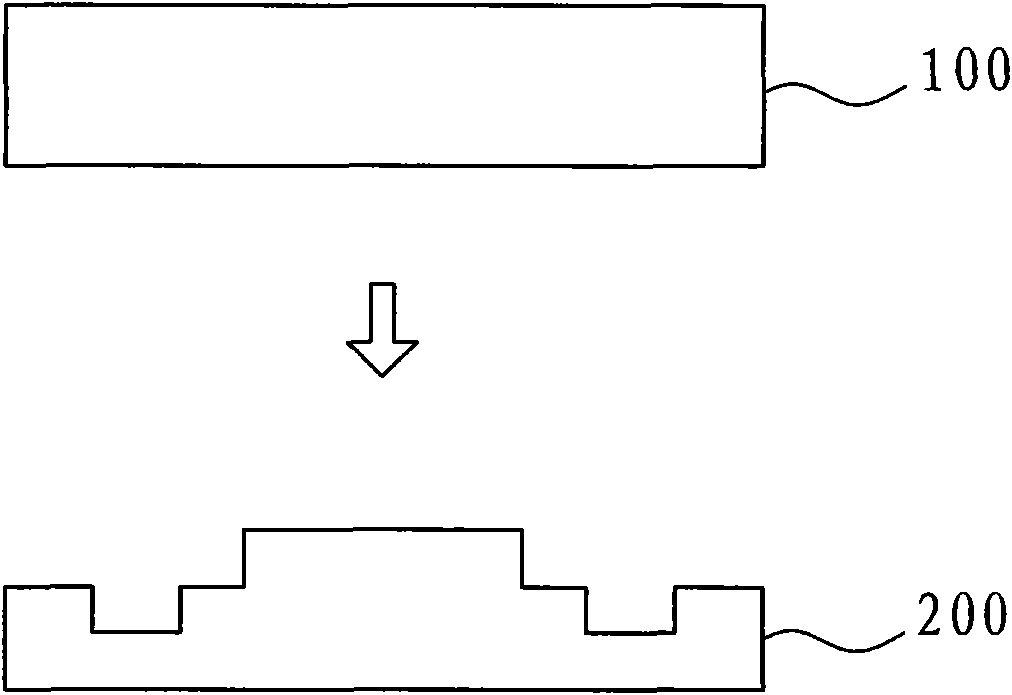

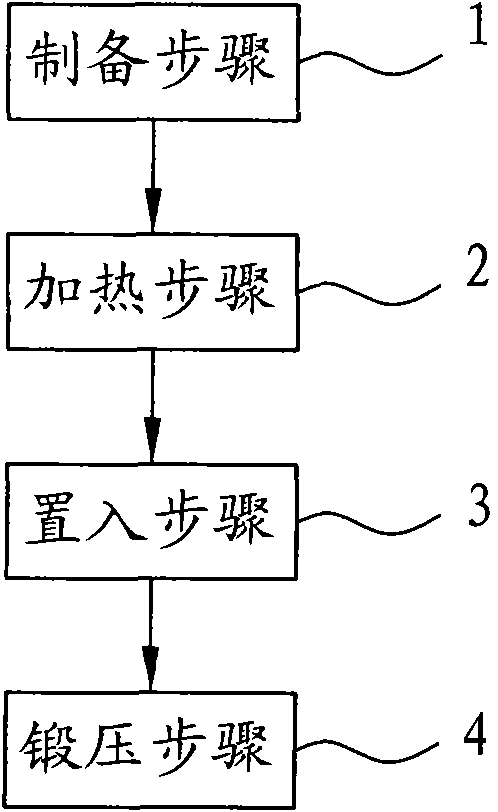

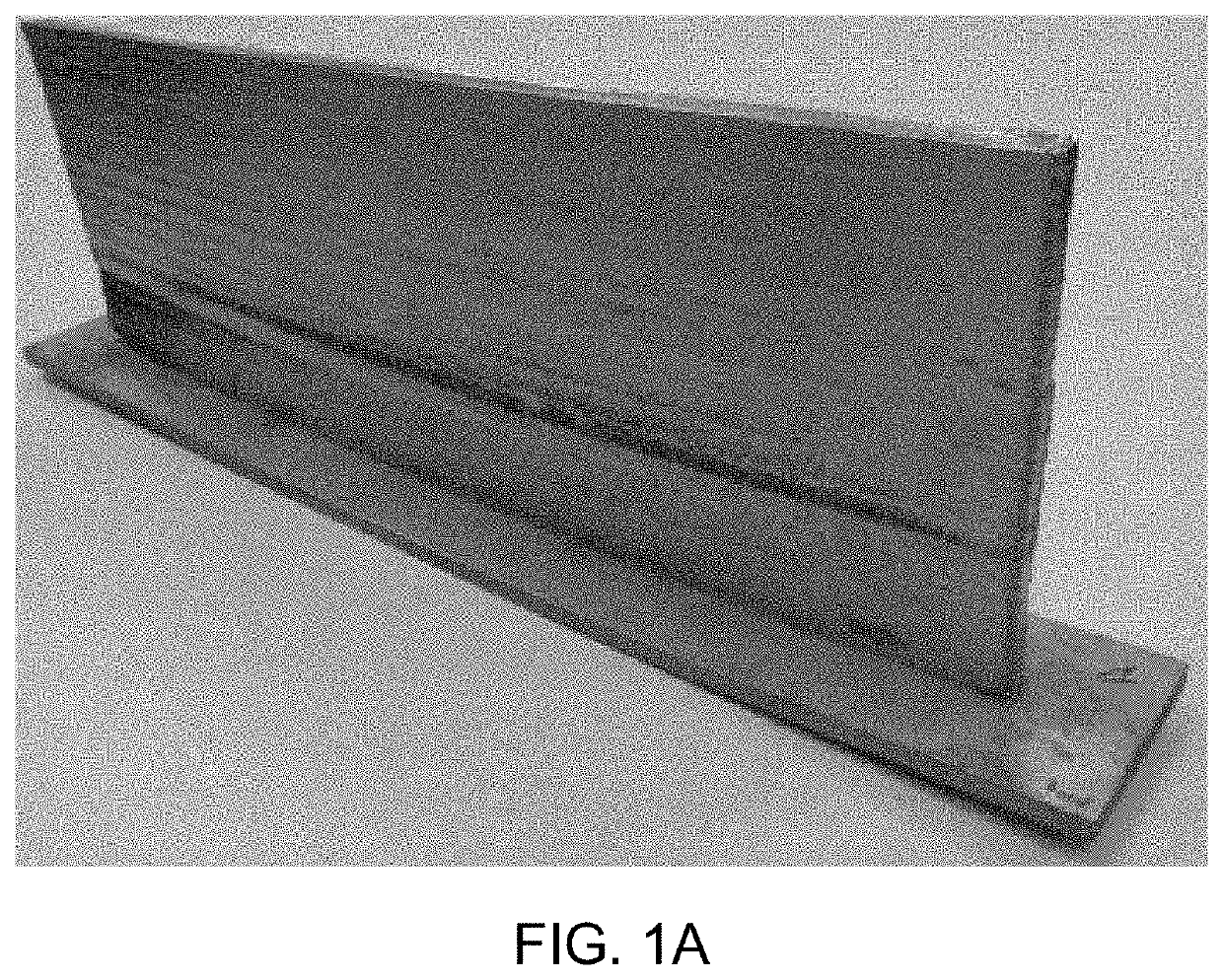

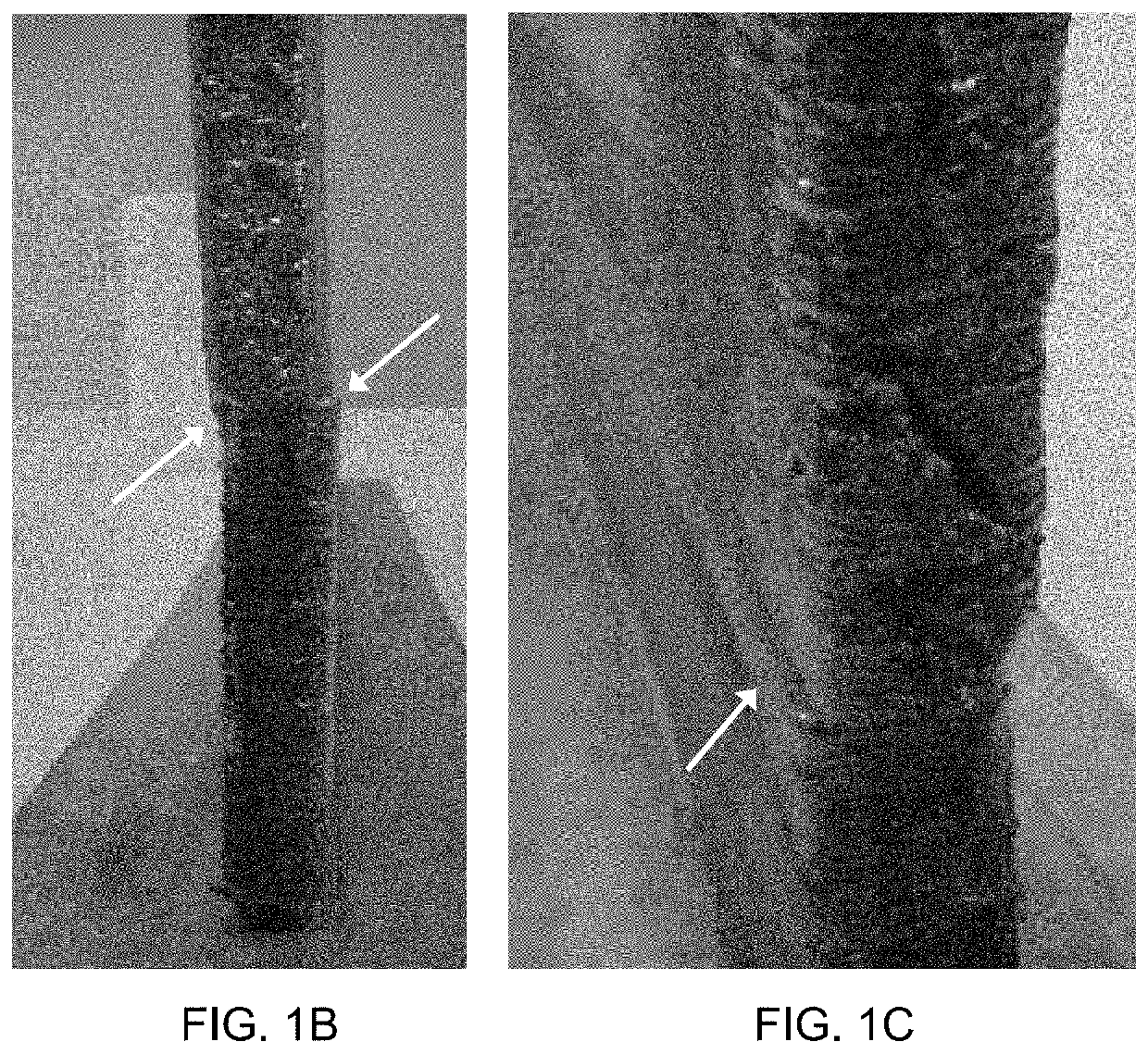

Forging method of golf club head

InactiveCN101875088AReduce generationIncrease profitMetal-working apparatusGolf BallMaterials science

The invention relates to a forging method of a golf club head, which comprises a preparing step, a heating step, a putting step and a forging step. In the preparing step, a platy main body with a side peripheral surface is manufactured; in the heating step, the main body is heated to 700 DEG C to 1000 DEG C; in the putting step, the heated main body is put into a die cavity of a mould which has at least one opening used for communicating the die cavity with the outside; in the fording step, the mould is heated to 350 DEG C to 500 DEG C; the side peripheral surface of the main body put into the die cavity is forged through the opening of the mould so that the main body is deformed towards the thickness direction and tightly clings to the die cavity; scrap produced in the manufacturing process is less by means of the forming mode; the spent time of heating the main body to proper temperature is less; and accordingly, the manufacturing technological efficiency in forging is effectively enhanced.

Owner:O TA PRECISION IND

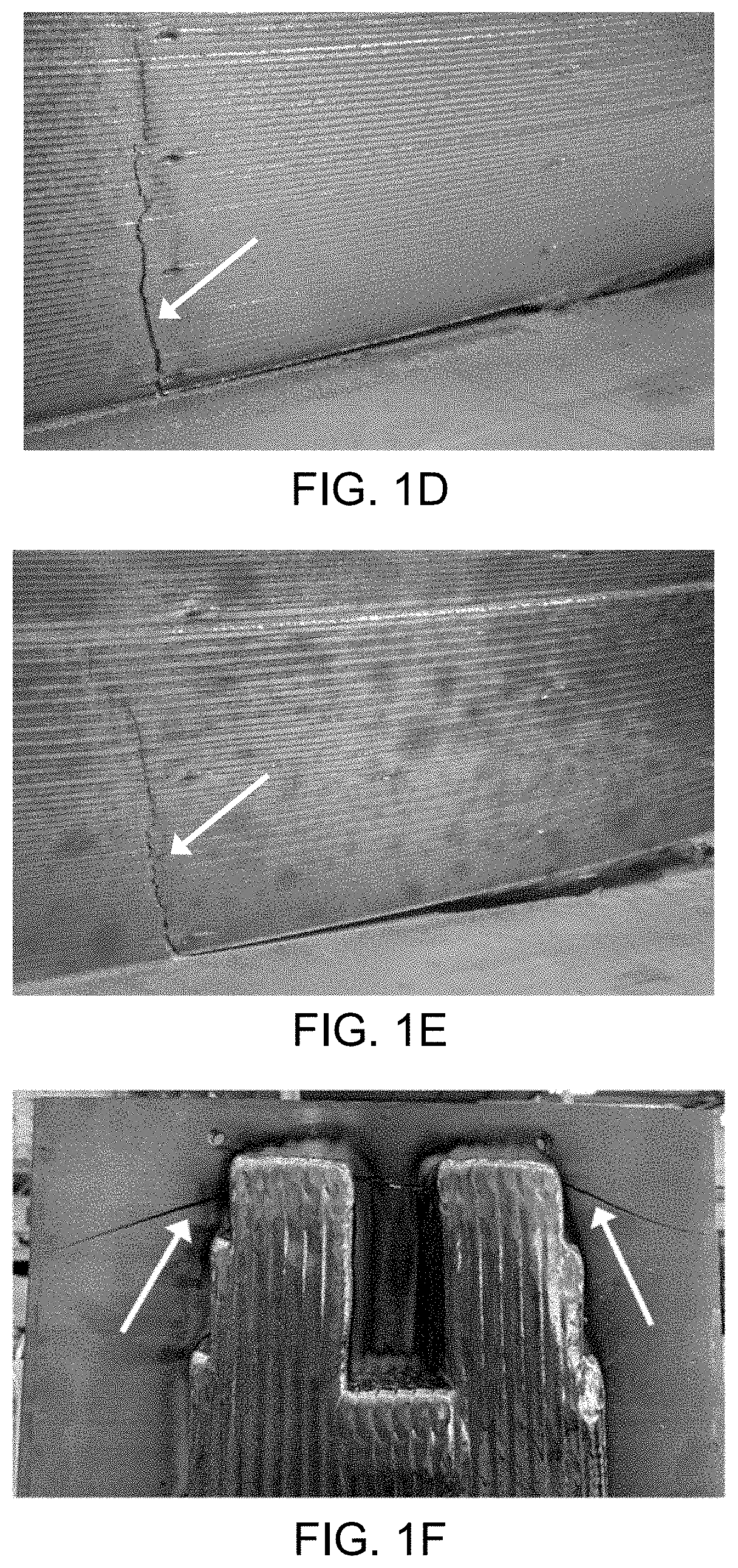

Distortion mitigation in directed energy deposition

PendingUS20210154732A1Reduced and minimized residual stressReduced and minimized and distortionAdditive manufacturing apparatusWelding/cutting auxillary devicesEngineeringTitanium

Provided are a curved clamping mold and systems and methods using the curved clamping mold for manufacturing objects, especially titanium and titanium alloy objects, by directed energy deposition. The methods include thermally pre-bending the substrate onto which the object is to be manufactured to form a pre-bent substrate, attaching the pre-bent substrate to a jig using the curved clamping mold as an underlying support, pre-heating the substrate, and forming the object on the pre-heated, pre-bent substrate using a directed energy deposition technique.

Owner:NORSK TITANIUM

High-strength square chain and manufacturing method thereof

ActiveCN108559920AHigh tensile strengthLow costLoad-engaging elementsMetal chainsFriction weldingSulfur

The invention relates to a high-strength square chain and a manufacturing method thereof, and belongs to the technical field of chain manufacturing. The high-strength square chain is sequentially formed by chain links with notches in a chaining manner, and a closed chain ring is formed by friction welding; and each chain link is formed by arc sections at the two ends and a straight line section between the arc sections at the two ends, the notches are located in the straight line sections, and cross sections of the straight line sections are rectangular. The chain links are formed by low alloysteel bars through drawing, and low alloy steel comprises, by weight, 0.021%-0.025% of carbon, 0-0.025% of silicon, 1.10%-1.40% of manganese, 0.40%-0.60% of chromium, 0.90%-1.10% of nickel, 0.50%-0.60% of molybdenum, 0.025%-0.050% of aluminum, not larger than 0.020% of sulfur, not larger than 0.020% of phosphorus and the balance iron and inevitable impurities.

Owner:山东华源索具有限公司

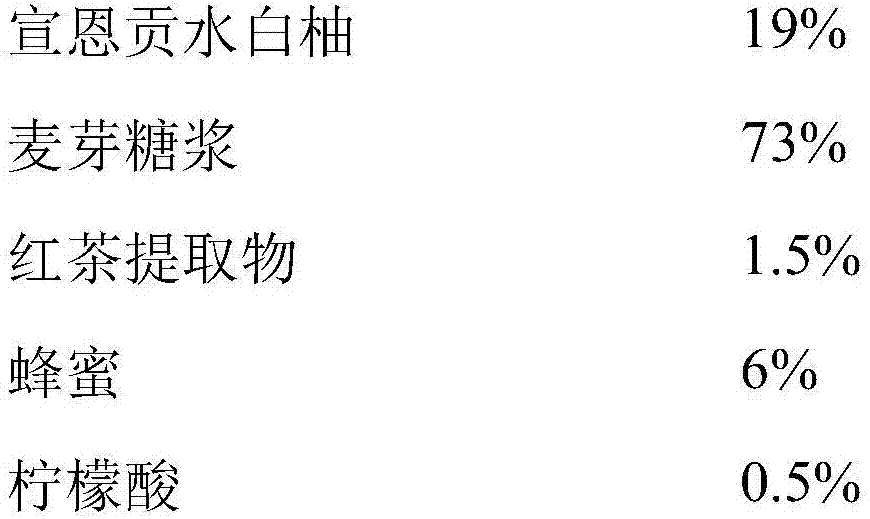

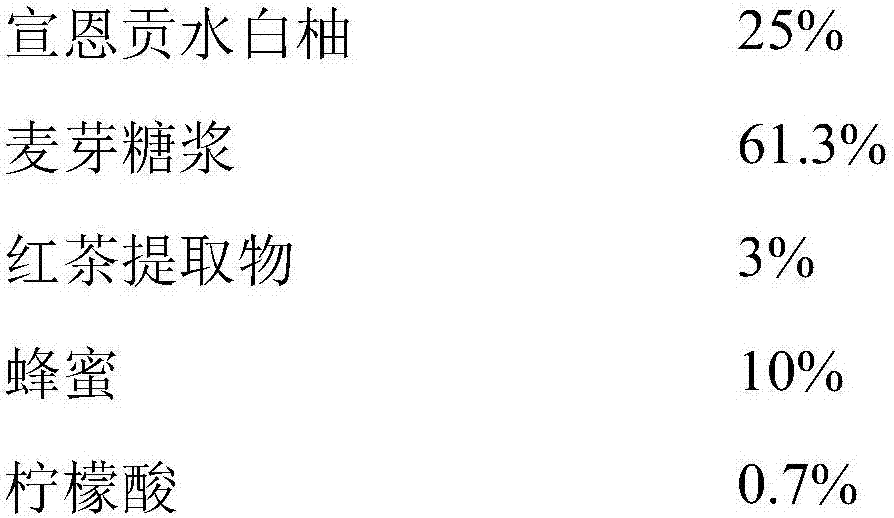

Pomelo tea as well as preparation method and application thereof

InactiveCN107094933AImprove high added valueImprove manufacturing process efficiencyTea extractionNutritive valuesAdditive ingredient

The invention belongs to the technical field of beverage processing, and specifically relates to pomelo tea and a preparation method thereof. Specifically, the invention provides pomelo tea comprising the following components, a pomelo raw material, malt syrup, a black tea extract, honey and citric acid. In order to overcome the defects that in the prior art, a product is abnormal in flavor, bitter, and poor in mouthfeel, and damage to nutritional ingredients and natural flavor is serious, a cell wall breaking technology and a fermentation engineering technology are utilized to achieve 100% utilization of whole fruits of the raw material, and especially, vitamins, mineral nutrients, bioflavonoids, polysaccharides, dietary fibers, bacterial proteins and the like rich in pomelo are retained and / or added to the utmost extent. The nutritive value and the health-care function value of a product are maximized, so as to greatly improve the high added-value of comprehensive processing of the pomelo, comply with huge market demands on safe, nutritional and health foods, and promote transformation and upgrading of traditional low-value processing of the pomelo. Moreover, the efficiency of preparation process of the pomelo tea is also improved obviously.

Owner:王鸿彪

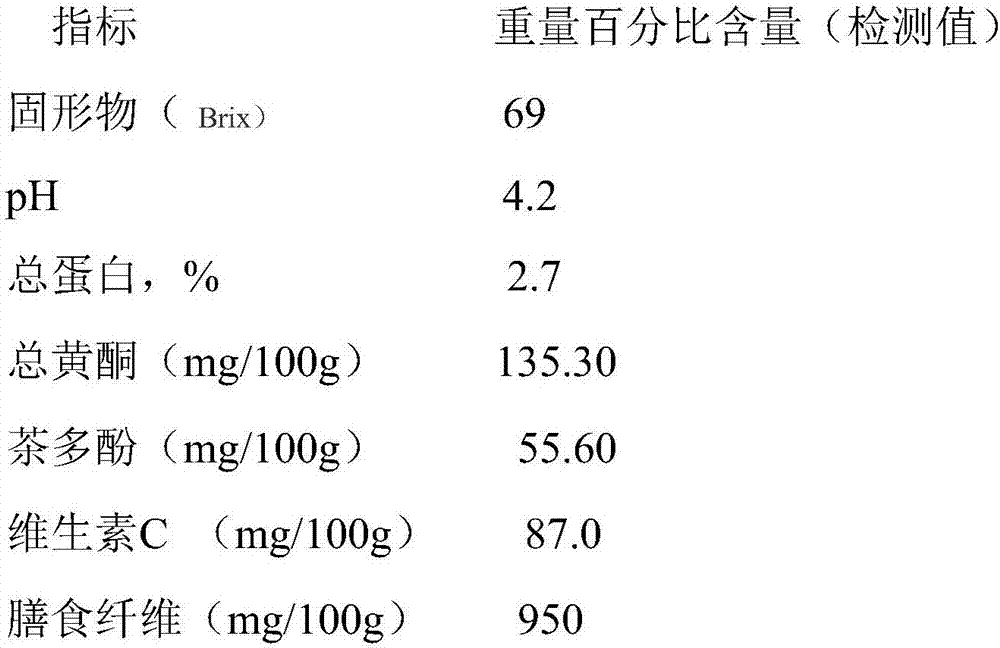

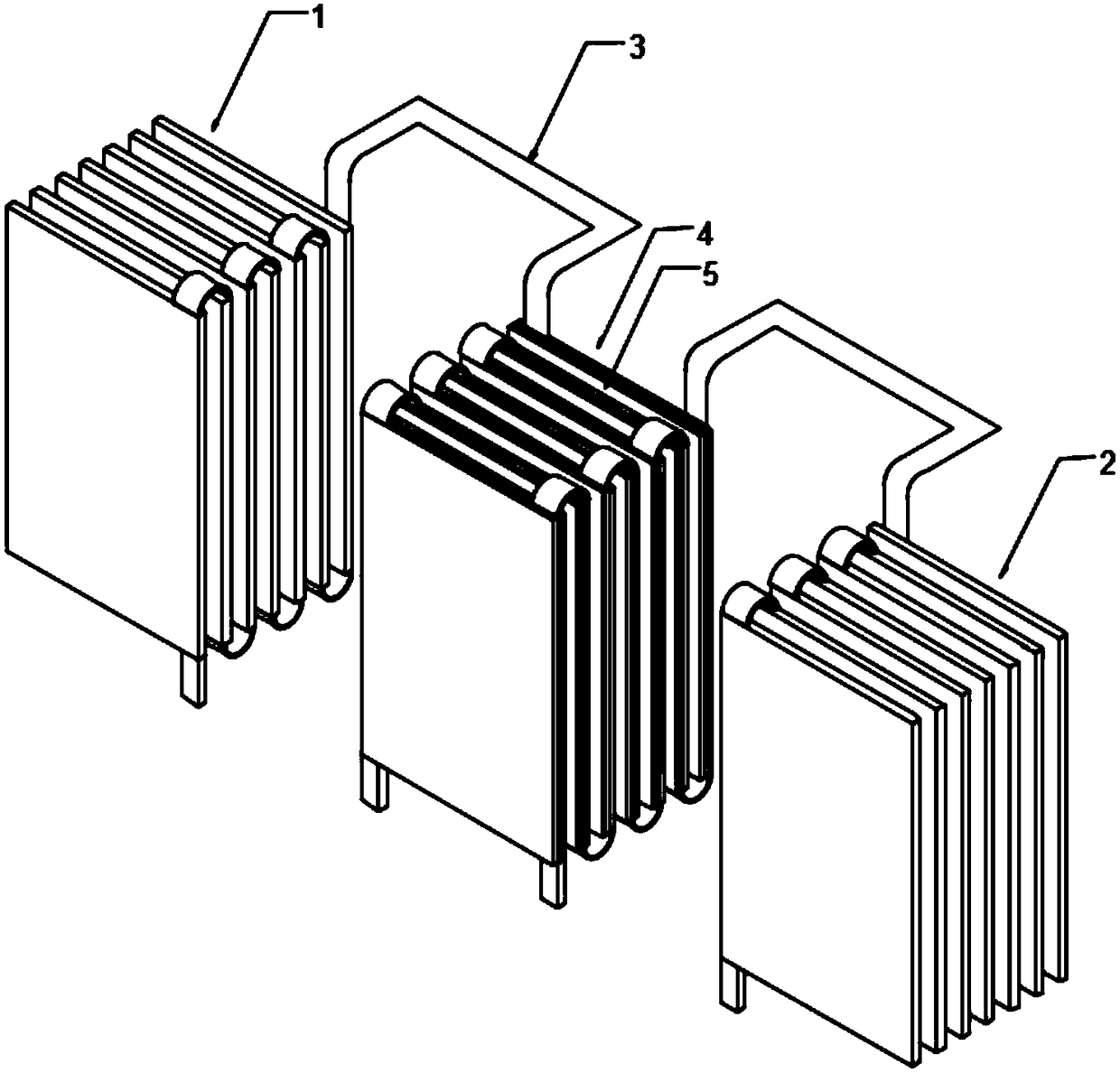

Welding-free storage battery and production method thereof

PendingCN108666636AReduce the amount of lead usedQuality improvementFinal product manufactureLead-acid accumulator electrodesContinuous designEngineering

The invention relates to the technical field of chemical power supply materials and in particular relates to a welding-free storage battery and a production method thereof. A continuous type welding-free lead storage battery pole group comprises continuous type positive electrode plates, continuous type negative electrode plates, a single-body-spanning connection sheet, a continuous type bipolar pole plate and a separation plate, wherein the continuous type bipolar pole plate is composed of the continuous type positive electrode plates, the continuous type negative electrode plates and the separation plate, which are inserted and matched. According to the welding-free storage battery provided by the invention, an integrated continuous design is carried out on the lead storage battery polegroup and a welding procedure of a plurality of pieces of the positive electrode plates or negative electrode plates in a pole plate group during a storage battery production process is eliminated; aserial and parallel connection welding procedure of bridge-spanning welding, wall-penetrating welding and the like of a plurality of single bodies of the storage battery is also eliminated. Therefore,the use amount of lead of the storage battery is reduced and sheet falling and missing welding phenomena do not happen between the pole plate group of the storage battery and the single bodies; the product quality and reliability of the storage battery are effectively improved.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

Electrochemical polymerization process for forming solid electrolyte layer on solid electrolytic capacitor

InactiveCN101866750AThe method of pH control and adjustment is simplePerformance is easy to controlCapacitor electrolytes/absorbentsCapacitanceElectrolysis

The invention provides an electrochemical polymerization process for forming a solid electrolyte layer on a solid electrolytic capacitor, which comprises the following step of: carrying out constant current polymerization in an electrochemical polymerization solution to prepare a second solid electrolyte layer by connecting the surface of an anode body on which a solid electrolyte layer is formed by a chemical polymerization process with an external electrode as an anode and using a conductive electrode as a cathode, wherein the pH value of the electrochemical polymerization solution is controlled to range from 3.0-6.0. The electrochemical polymerization process for forming a solid electrolyte layer on a solid electrolytic capacitor enables the properties of the solid electrolytic capacitor produced by the electrochemical polymerization process to be more controllable, the electrolytic capacitor prepared in the range of the pH value is better in properties such as capacitance, loss, ESR and the like, and the polymerization process simplifies the process flow and improves the process efficiency.

Owner:FUJIAN GUOGUANG ELECTRONICS SCI & TECHCO

A continuous solder-free lead-acid battery electrode group and a manufacturing method thereof

PendingCN109004291AReduce the amount of lead usedQuality improvementFinal product manufactureCell component detailsBiochemical engineeringMonomer

The invention relates to the technical field of chemical power supply materials, in particular to a continuous solderless lead-acid battery electrode group and a manufacturing method thereof. The continuous solder-free lead-acid battery electrode group comprises a continuous positive electrode plate, a continuous negative electrode plate, a cross-unit connecting piece, a continuous bipolar electrode plate and a separator, wherein the continuous bipolar electrode plate is composed of a continuous positive electrode plate, a continuous negative electrode plate and a separator which are insertedand matched. A lead storage battery electrode group is integrally and continuously design, and that welding procedure of a plurality of positive plate or negative plates in the electrode plate group in the production process of the storage battery is eliminated, and the series and parallel welding procedures such as cross-bridge welding and through-wall welding between a plurality of monomers of the storage battery are also eliminated. This not only reduces the lead consumption of the battery, but also does not appear the phenomenon of chips falling off and missing welding between the electrode plate group and the monomer of the battery, which effectively improves the product quality and reliability of the battery. In addition, the electrode group of the invention has high manufacturing process efficiency and is convenient for production and processing.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

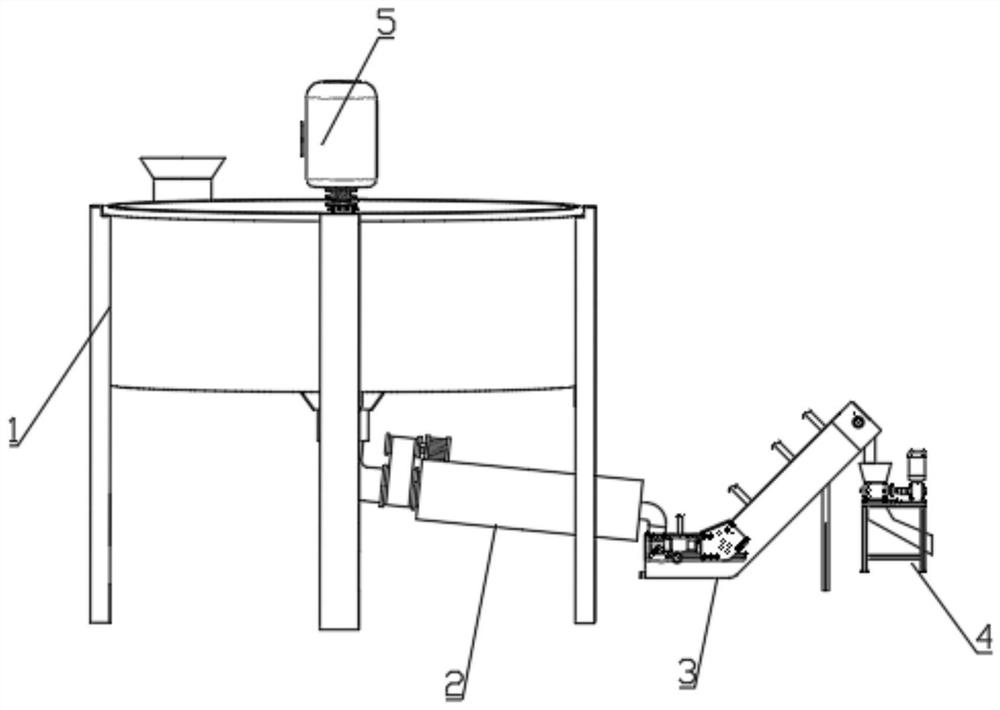

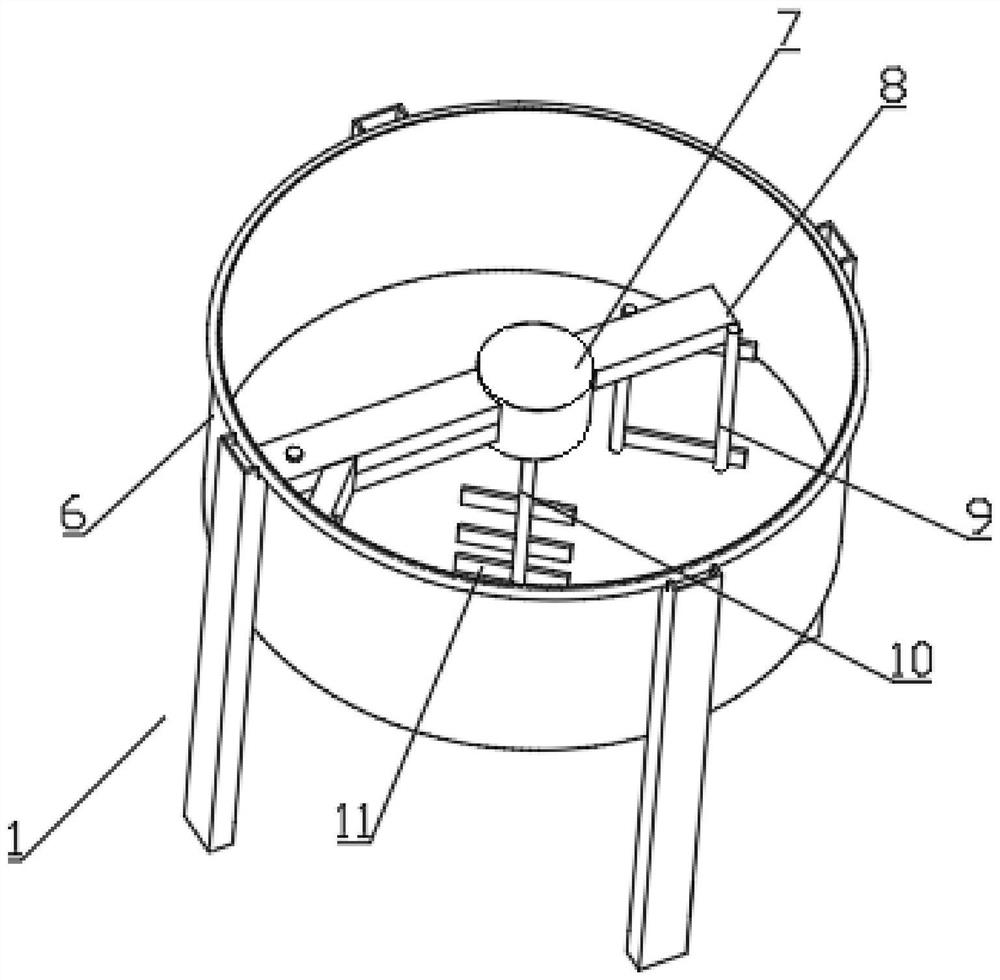

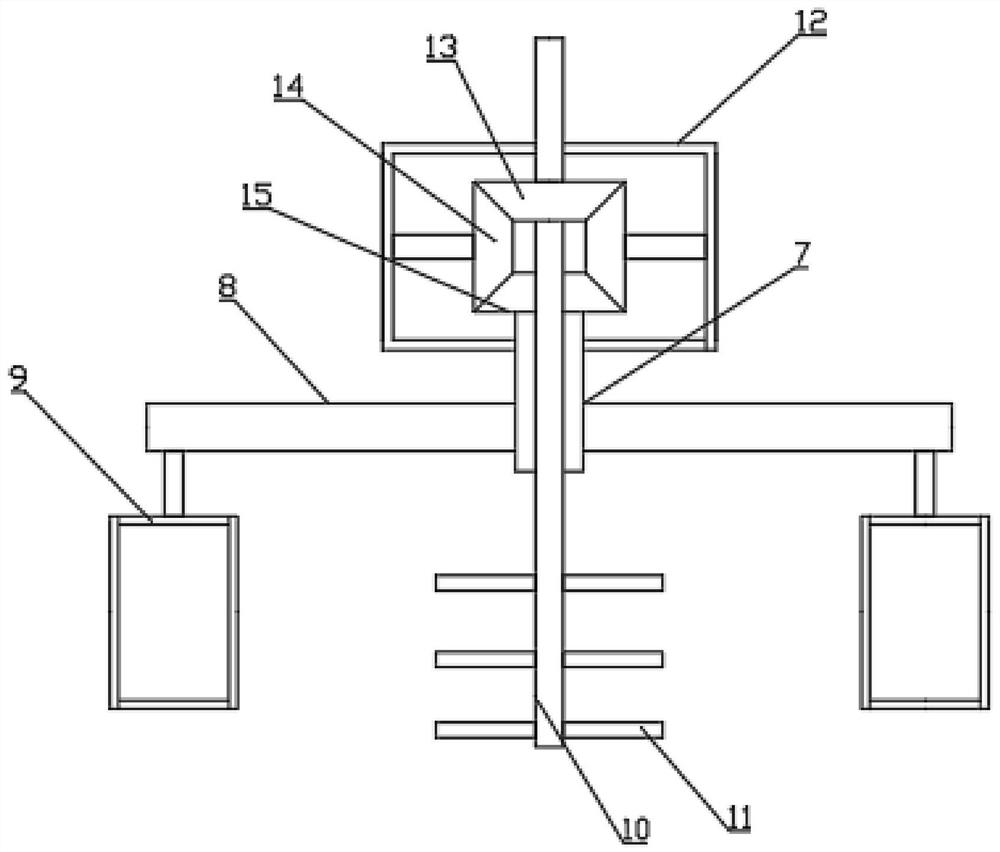

High-performance anti-deformation 3D printing material and preparation method thereof

InactiveCN111792873AHigh structural strength Anti-deformationGood flexibilityAdditive manufacturing apparatusRotary stirring mixersEmulsionOragene

The invention discloses a high-performance anti-deformation 3D printing material, which comprises the following raw materials in parts by weight: 1 part of acrylic emulsion and 20-200 parts of inorganic compound powder. The preparation method comprises following steps: mixing and stirring acrylic emulsion and inorganic compound powder by a mixing device; introducing uniformly mixed raw materials into a drying device; firstly, making the raw materials fall into a rotary drum through a first material guide pipe; introducing the centrifugally dried raw materials into a conveying device; making centrifugally dried raw materials fall onto a conveying belt conveying the raw materials through the conveying belt, heating the raw materials on the conveying belt during the conveying of the raw materials, introducing residual mother liquor into a condenser from a condenser connecting pipe, making the raw materials conveyed to the top of a conveying box fall into a crushing device; and grinding the raw materials by two sets of grinding rollers driven by a gear and a transmission shaft so as to obtain the 3D printing material. The 3D printing material has high structural strength and deformation resistance of the inorganic compound and high flexibility of an organic polymer, and the preparation process is high in efficiency.

Owner:韶关市飞胜新材料有限公司 +1

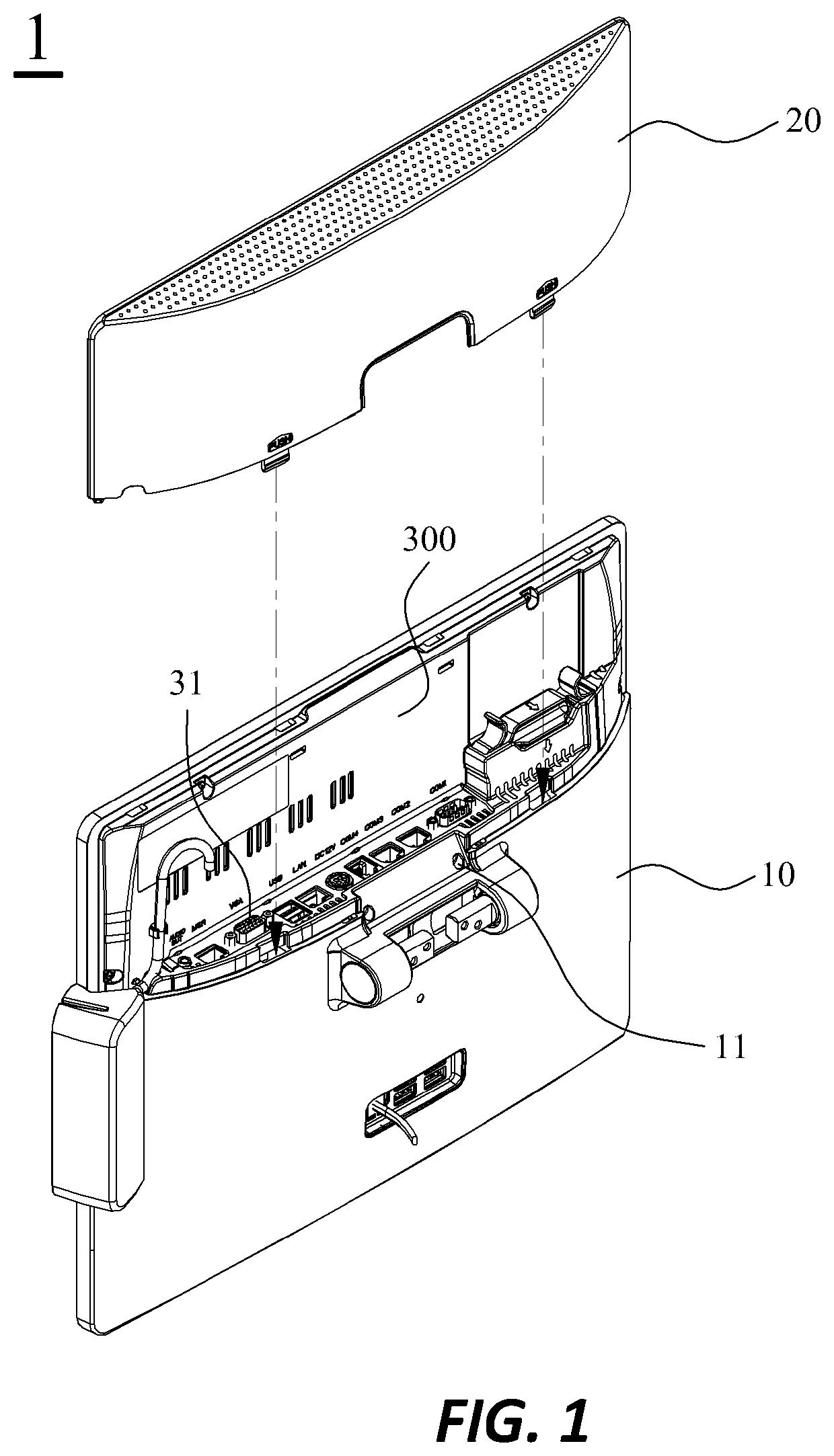

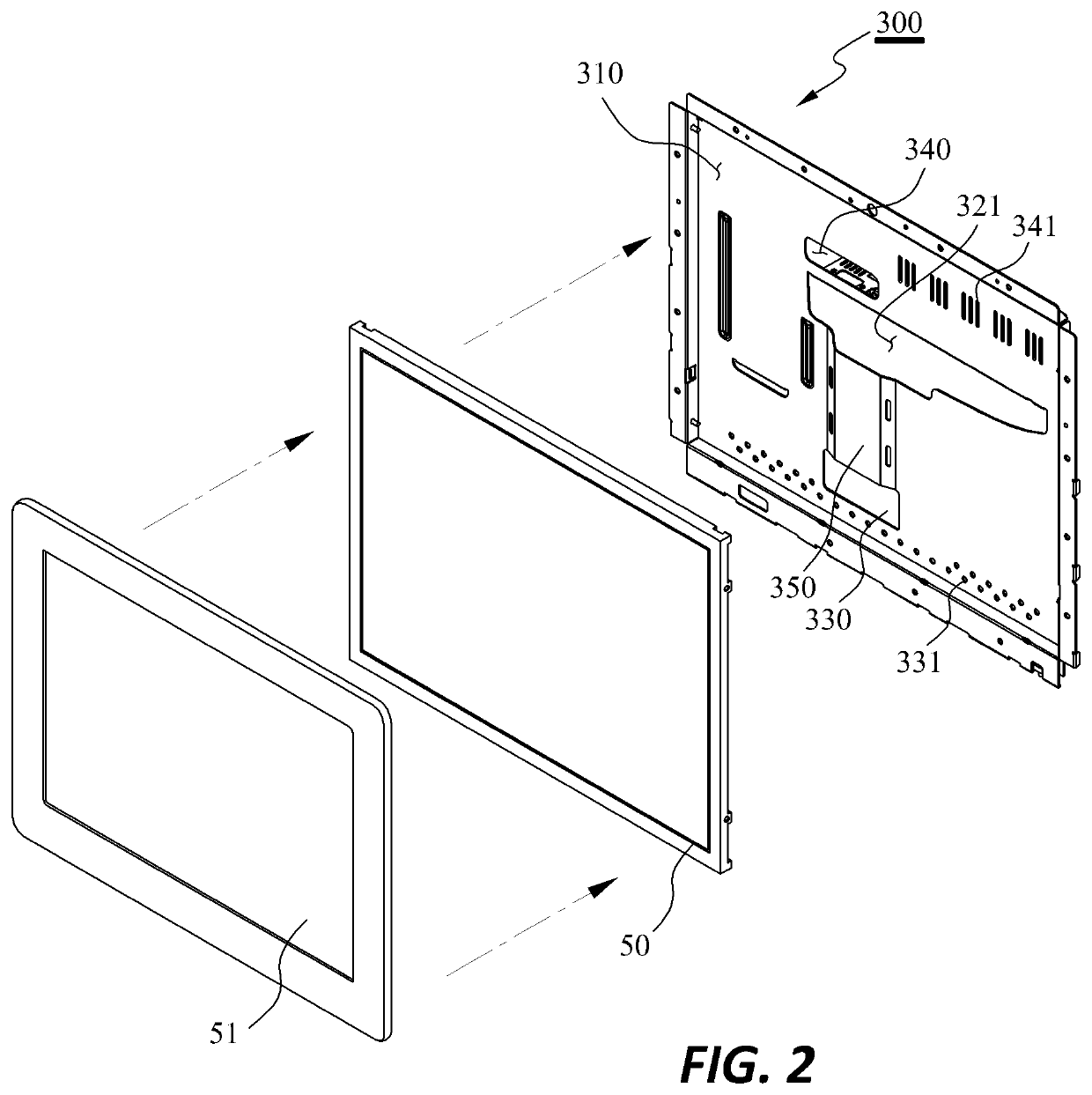

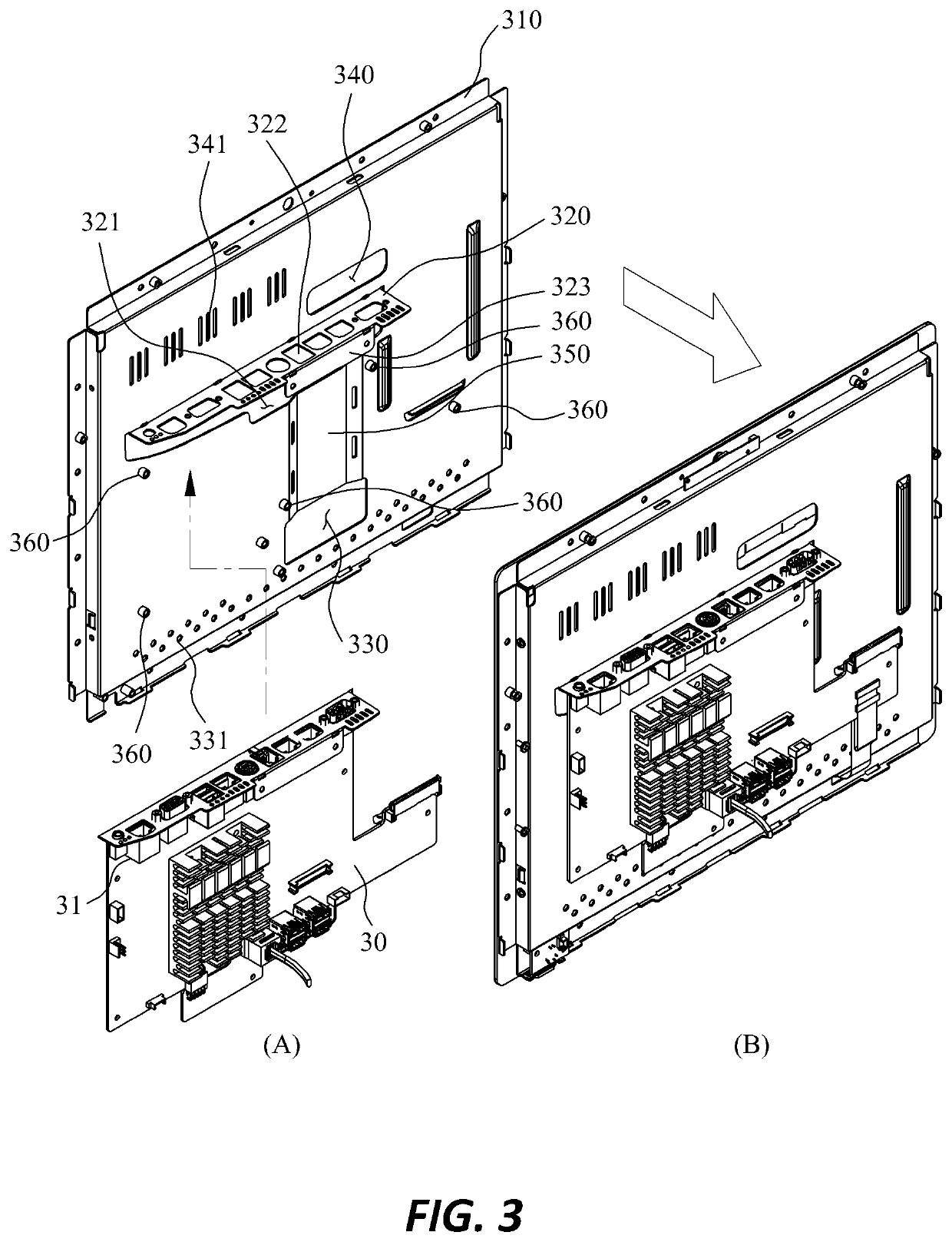

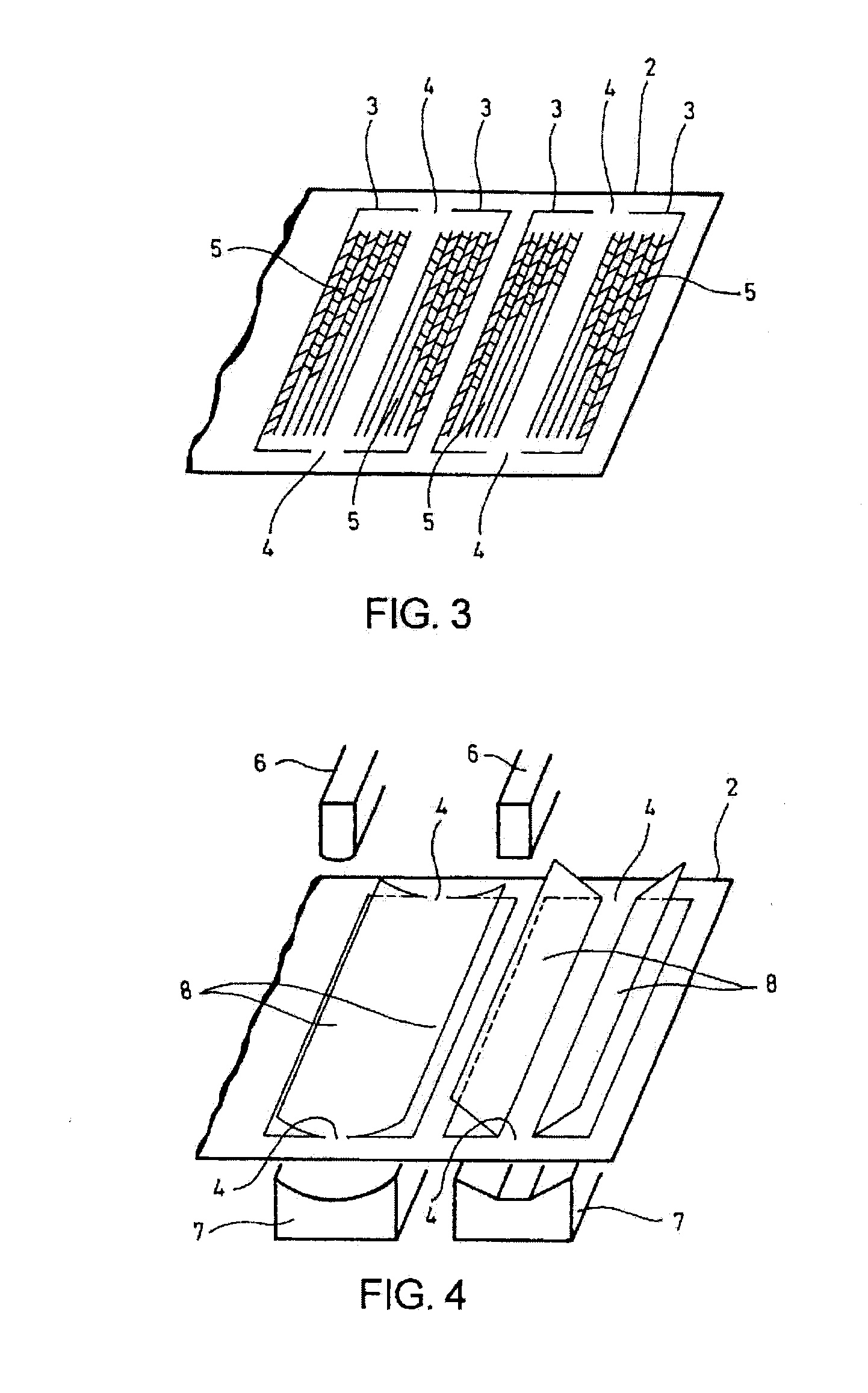

Input/output port mounting unit integrated type display frame for POS equipment

ActiveUS20200294371A1Increase manufacturing costImprove manufacturing process efficiencyCash registersStands/trestlesControl theoryMechanical engineering

The present invention relates to an input / output port mounting unit integrated type display frame for POS equipment, the input / output port mounting unit integrated type display frame (300) for POS equipment comprising: a display panel mounting unit (310), in which a display panel (50) is loaded, formed at a front surface thereof; an input / output port mounting unit (320) formed at a rear surface thereof and having an input / output port mounting hole (322), in which an input / output port (31) provided at a main substrate (30) is inserted and coupled, the input / output port mounting unit having a part cut from an input / output port mounting unit perforation (321) and being formed to be bent towards the rear direction so as to be protruded therefrom; and a lower main ventilation hole (330) formed at a lower side of the rear surface thereof.

Owner:POSBANK

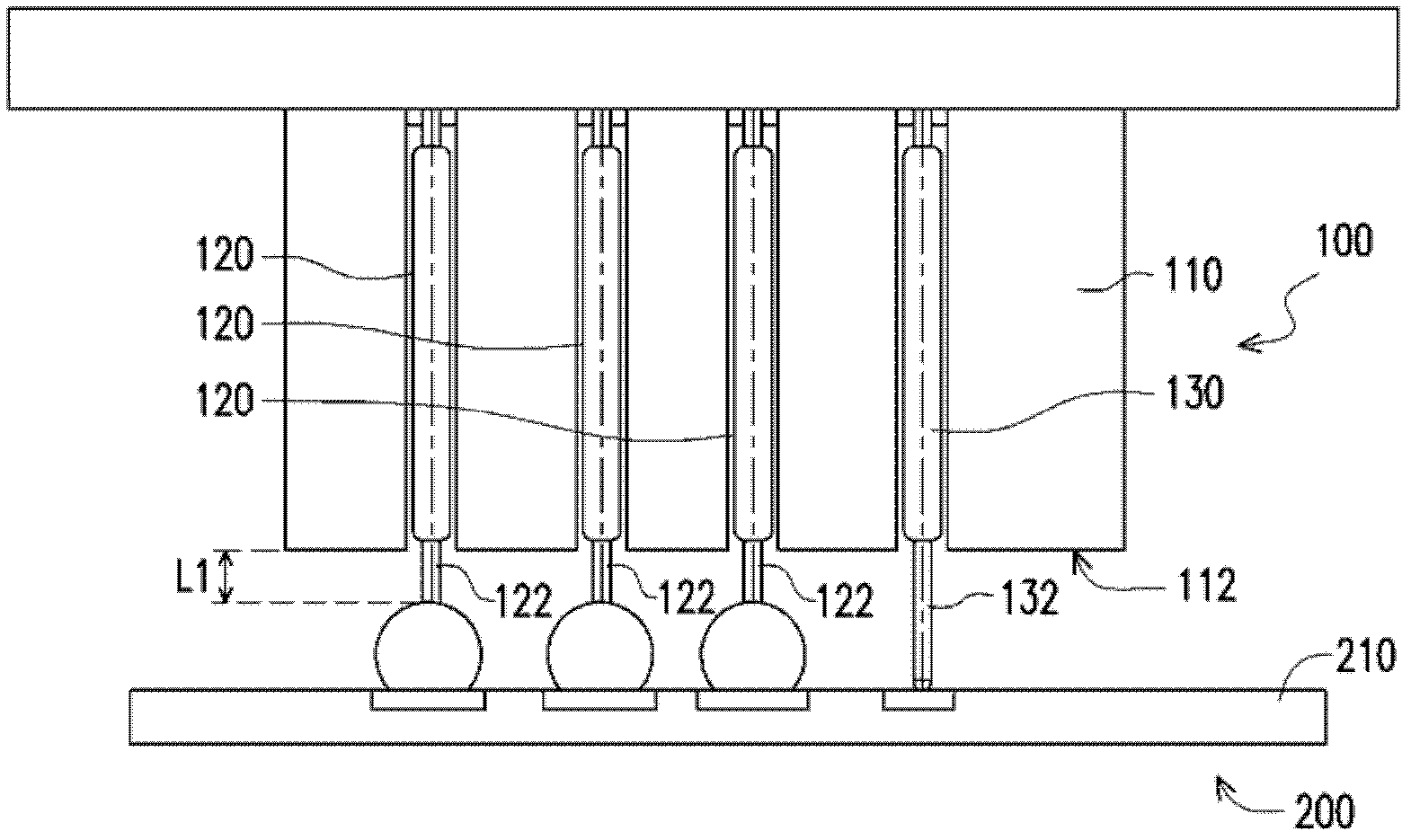

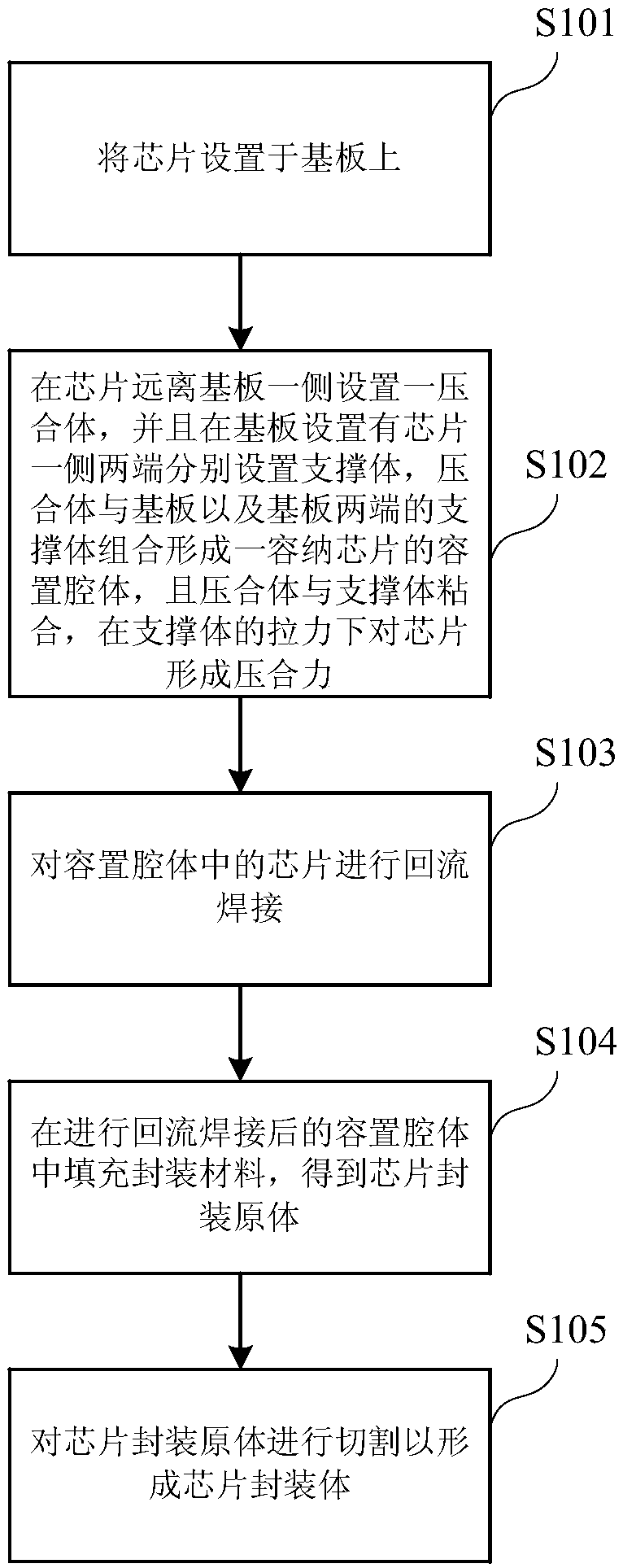

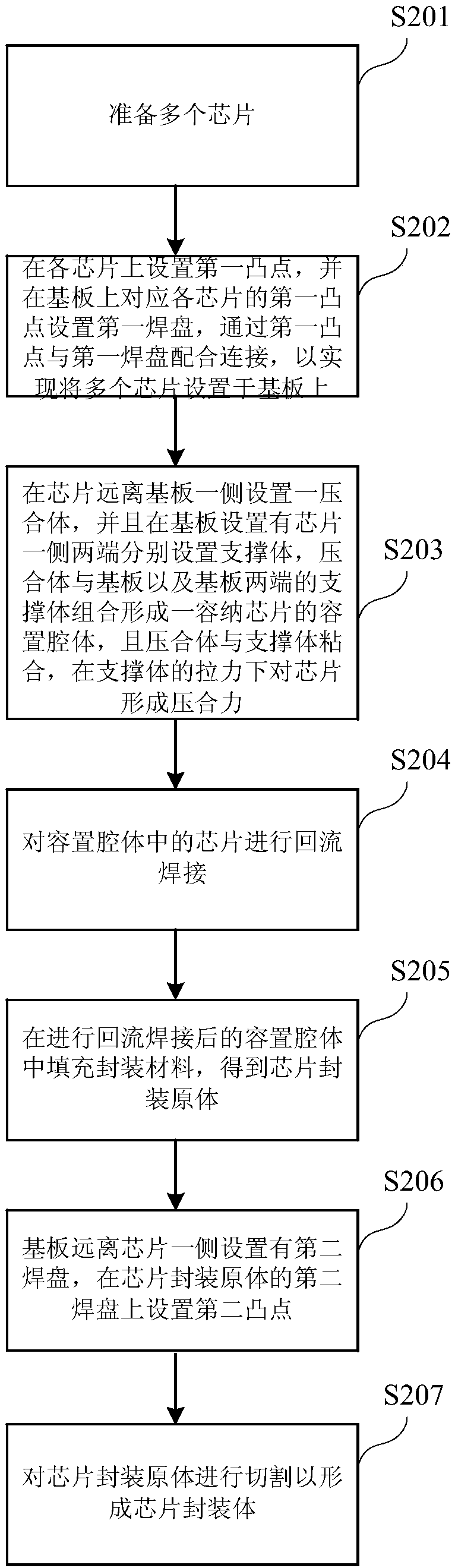

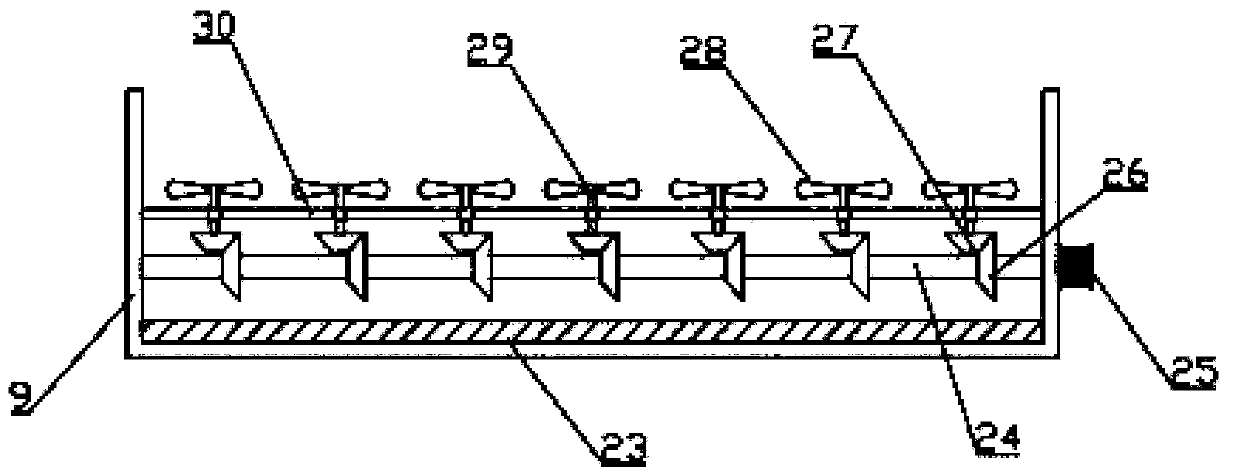

Preparation method of chip packaging body and chip packaging body

ActiveCN108231603AImprove interconnection efficiencyImprove manufacturing process efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringIntegrated circuit packaging

The invention relates to the technical field of integrated circuit chip packaging, and discloses a preparation method of a chip packaging body and the chip packaging body. The method comprises the following steps: arranging a chip on a base plate; arranging a press-fit body on one side, far away from the base plate, of the chip; respectively arranging supporting bodies on two ends of the side, provided with the chip, of the base plate; combining the press-fit body, the base plate and the supporting bodies at the two ends of the base plate to form an accommodating cavity for accommodating the chip; adhering the press-fit body with the supporting bodies; forming press-fit force to the chip under tensions of the supporting bodies; performing reflow soldering on the chip in the accommodating cavity; filling the accommodating cavity subjected to the reflow soldering with a packaging material to obtain a chip packaging original body; cutting the chip packaging original body to form the chippackaging body. According to the method, the efficiency of a chip packaging body preparation process can be improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

Manufacturing method of LCP material high-frequency plate

ActiveCN111565515AEffective combinationImprove manufacturing process efficiencyPrinted circuit dryingNon-metallic protective coating applicationThin membraneElectric machinery

The invention discloses a manufacturing method of an LCP material high-frequency plate. The manufacturing method of the LCP material high-frequency plate comprises the following steps that a base plate is adsorbed and fixed through a sucker, then an air cylinder is controlled to contract and is located on the top face of a fixing box, and then a driving motor is controlled to work clockwise intermittently, so that each set of installed base plates sequentially pass through a spraying plate connected with a first raw material barrel, and a liquid film is sprayed to the surface of the base plate; after the base plate is completely coated, the coated substrate is moved to the position above an opening of a drying oven through a conveying belt, and a thin film layer is formed on the substrate;a liquid LCP material is sprayed on the surface of the substrate; after the high-frequency base plate made of the LCP material is formed, the air cylinder is controlled to contract, then the limitingsliding block drives the other set of movable rods to move an ejector block on the telescopic rod upwards along the limiting sliding rod, and the manufactured high-frequency base plate is ejected out; spraying, drying and coating are effectively combined, and the efficiency of the preparation process is greatly improved.

Owner:江苏胜帆电子科技有限公司

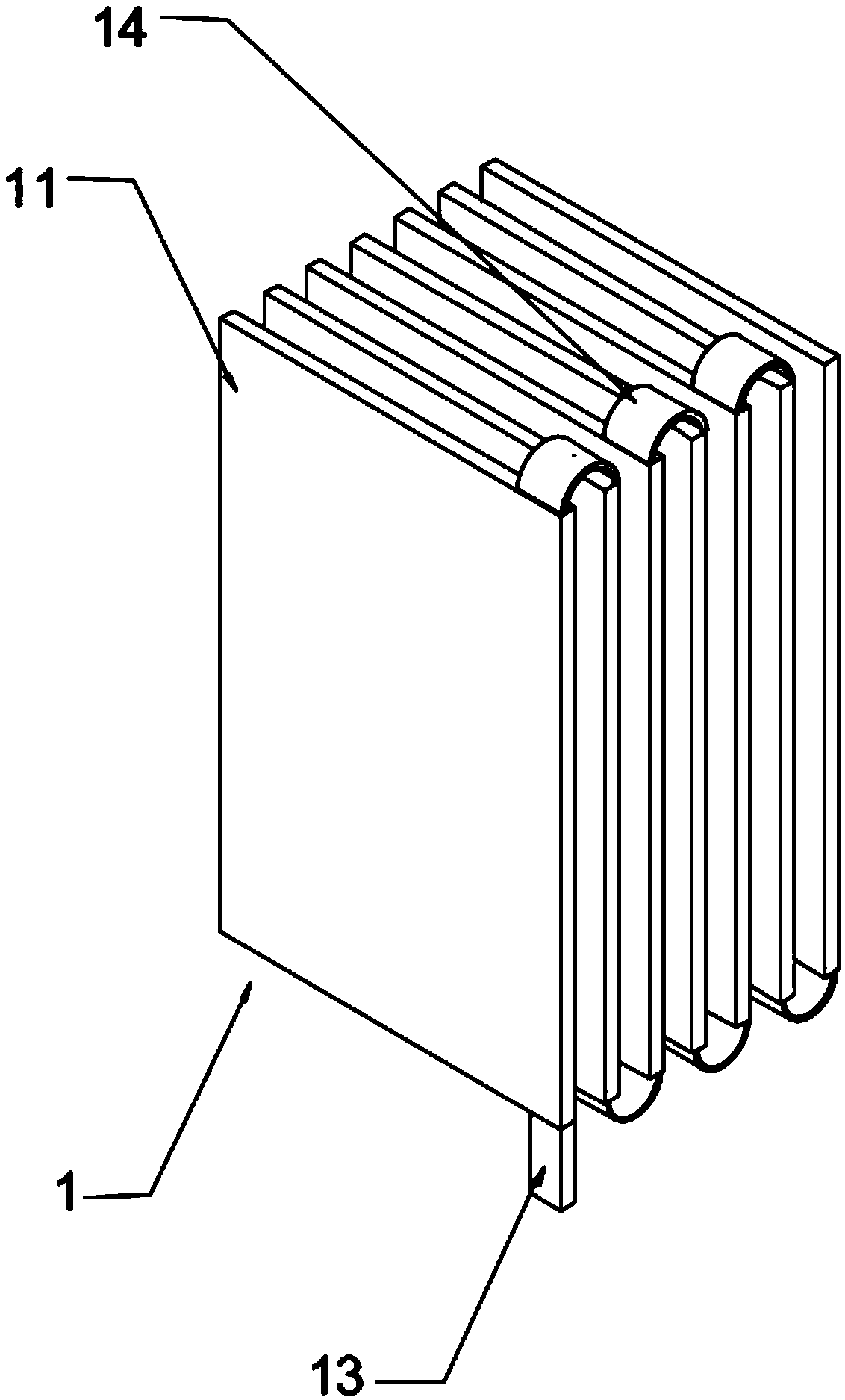

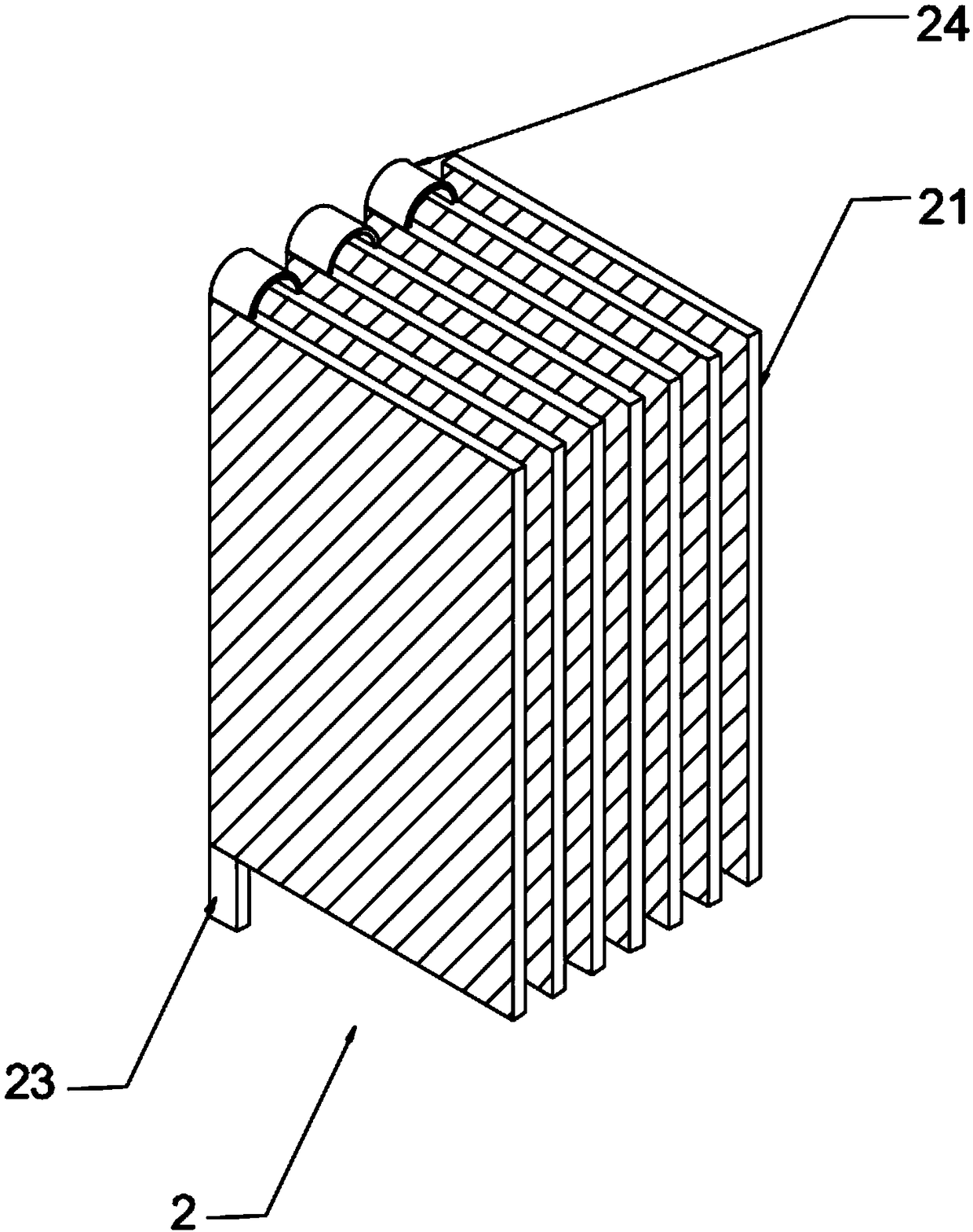

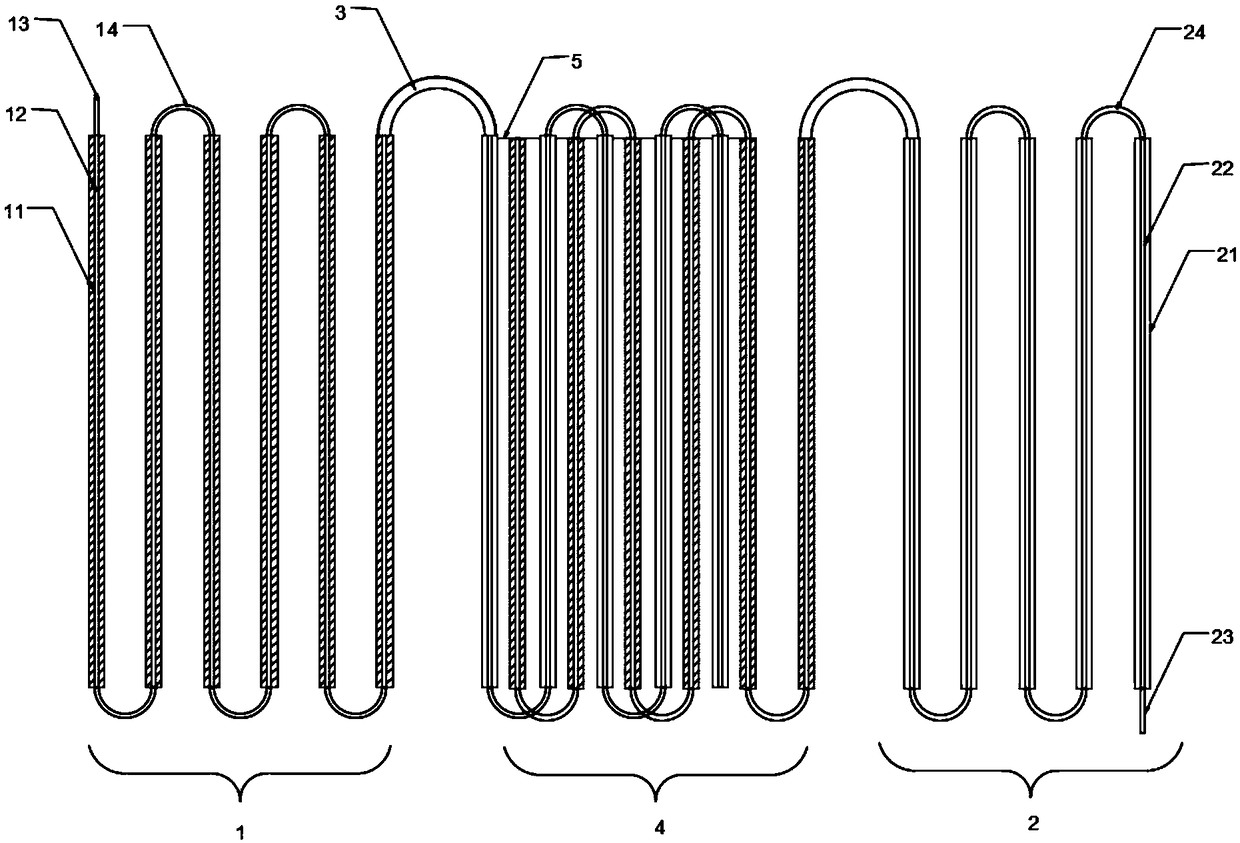

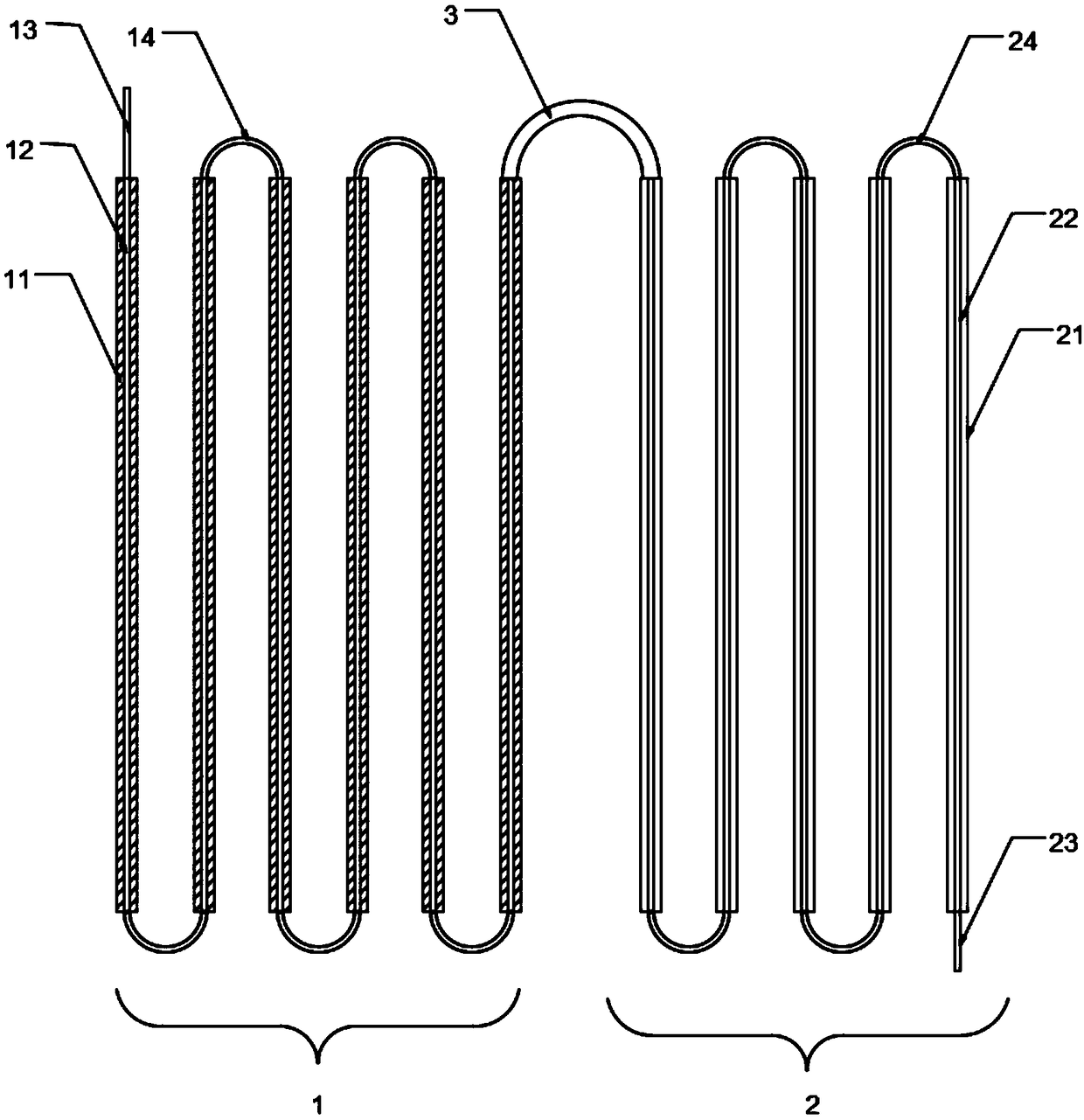

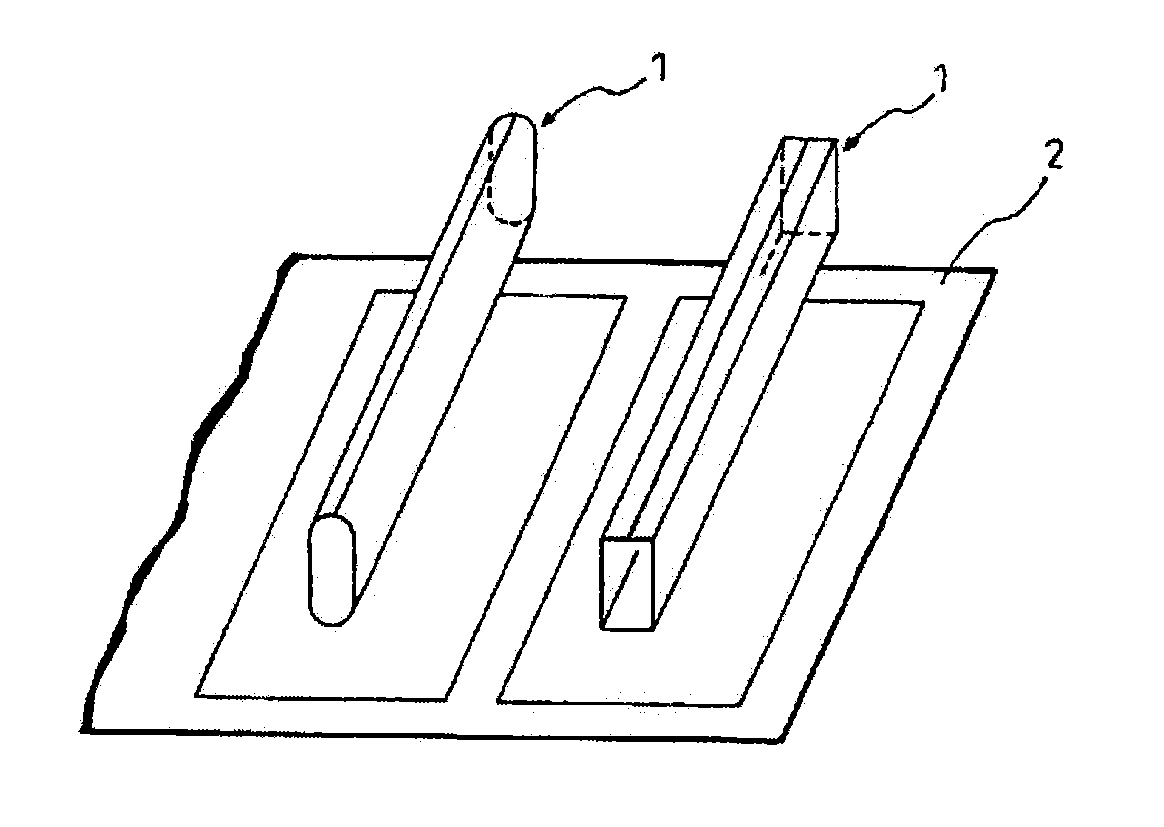

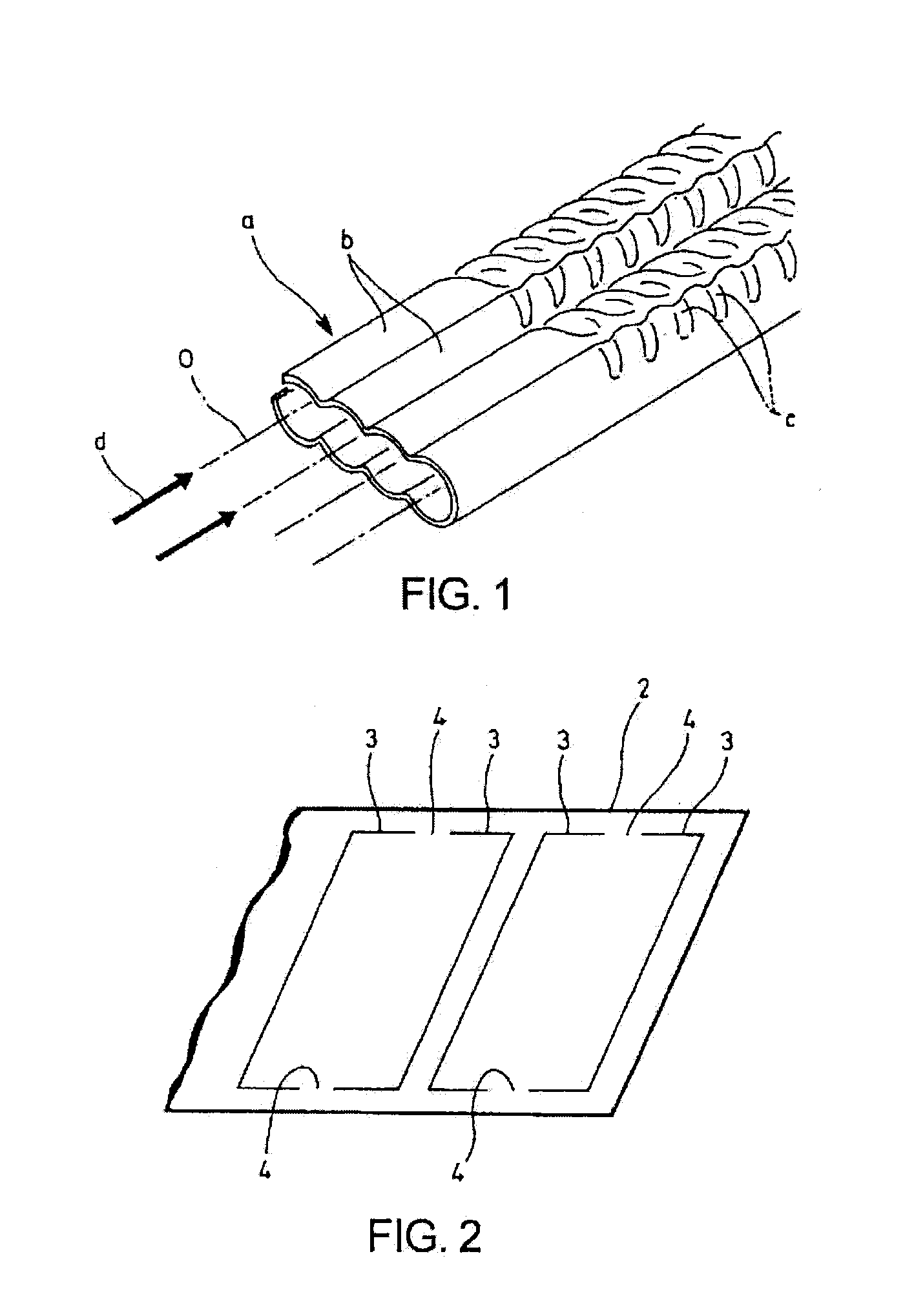

Method for manufacturing flat pipe

InactiveUS20150135795A1Good effectImprove manufacturing process efficiencyMetal working apparatusTubular elementsThin sheetEngineering

A method for manufacturing a flat pipe 1 with concave-convex shapes on inner and outer surfaces includes making incisions with an expanded shape of the flat pipe 1 in a metal thin plate 2 such that intermediate portions 4 (middle portions) in the expanded shape of the flat pipe 1 widthwise of the expanded shape are left uncut from the thin plate 2, machining the concave-convex shapes in a range of the expanded shape of the flat pipe 1 and raising the expanded shape of the flat pipe 1 from the thin plate 2 as cut-and-raised pieces 8 with the uncut intermediate portions 4 in between, closing tips of the cut-and-raised pieces 8 together to form an overall shape of the flat pipe 2, and separating the uncut intermediate portions 4 from the thin plate 2 to obtain the flat pipe 1.

Owner:HINO MOTORS LTD

Efficient and energy-saving coating for building and preparation method thereof

InactiveCN108977081AHigh tensile strengthFacilitate conductionLignin material coatingsEpoxy resin coatingsBenzoyl peroxideGlycerol

The invention provides efficient and energy-saving coating for a building and a preparation method thereof. The efficient and energy-saving coating is prepared from the following components: nano powder slurry, waste paper, waste plastic, macromolecular emulsion, fly ash, sulfite, benzoyl peroxide, functional filler, glycerol, a thickening agent, a de-foaming agent, a wetting dispersant and de-ionized water. The coating prepared by the invention has good properties including tensile strength, reflection heat energy conduction and heat radiation blocking; raw materials contain a lot of production and domestic waste materials and certain environment problems are effectively solved; and cyclic utilization of resources is realized and the preparation cost of the efficient and energy-saving coating is reduced, so that efficient and energy-saving effects are realized.

Owner:合肥天沃能源科技有限公司

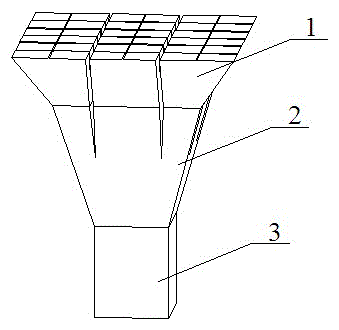

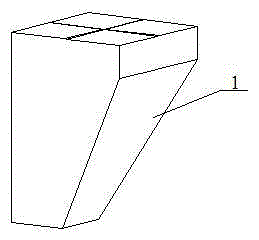

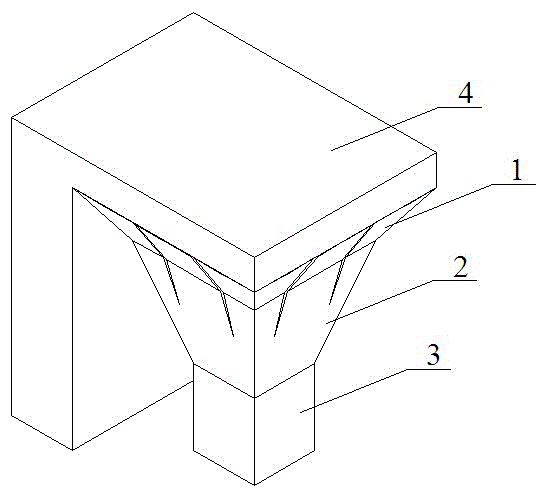

Method and support structure for manufacturing three-dimensional objects and support structure generation method

ActiveCN105117528AImprove manufacturing process efficiencyGuaranteed not to deformSpecial data processing applicationsEngineeringTree shaped

The invention discloses a method and support structure for manufacturing three-dimensional objects and a support structure generation method. The support structure for manufacturing three-dimensional objects takes the shape of a tree; and each product comprises at least one tree-shaped support structure. According to the a method and support structure for manufacturing three-dimensional objects and the support structure generation method, the support structure takes the shape of a tree, so that the materials for generating the support structure are greatly decreased on the premise that the support structure supports manufactured products and guarantees no deformation of the manufactured products , and the material waste is reduced; and the tree-shaped support structure requires a small construction volume, so that the whole manufacturing process efficiency of the three-dimensional objects is greatly improved.

Owner:HUNAN FARSOON HIGH TECH CO LTD

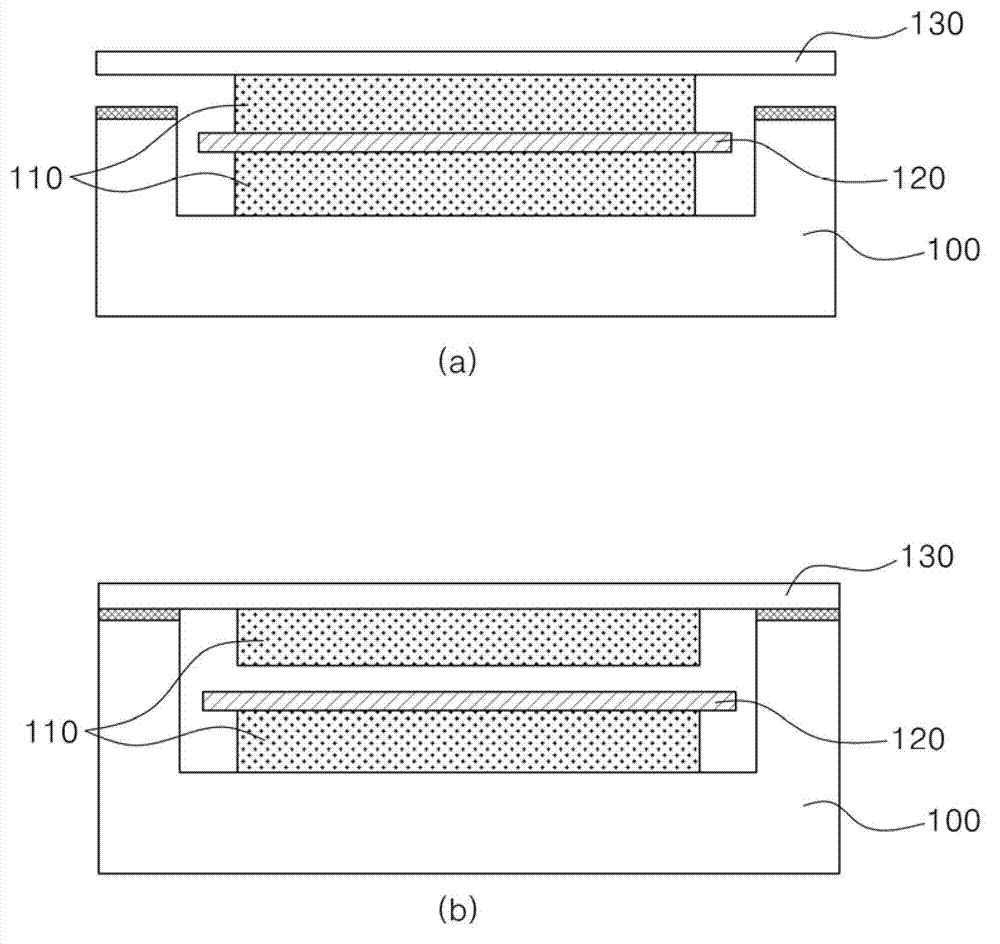

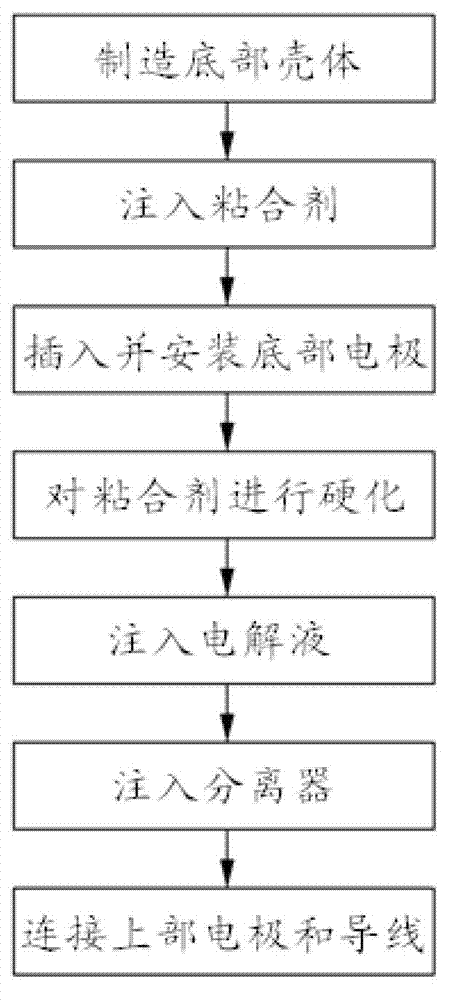

Electric double layer capacitor package and method for manufacturing the same

InactiveCN102856082AAvoid short circuitReduce contact resistanceHybrid capacitor electrodesCapacitor housing/encapsulationEngineeringElectric double-layer capacitor

An electric double layer capacitor and a manufacturing method thereof are provided. Concretely, lamination of a lower part electrode, a separator, and an upper part electrode is performed sequentially in the bottom housing of a ceramic concave container, in the process of covering the bottom container via a sealing plate, more than one protrusion is formed on the inner bottom of the bottom container. According to the electric double layer capacitor package and the method for manufacturing the same, binder pouring technology can be eliminated, and the lower part electrode and the bottom container, and the upper part electrode and a sealing plate are combined in a firmer way, thereby preventing short circuit and effectively reducing interal resistance.

Owner:ROSWIN

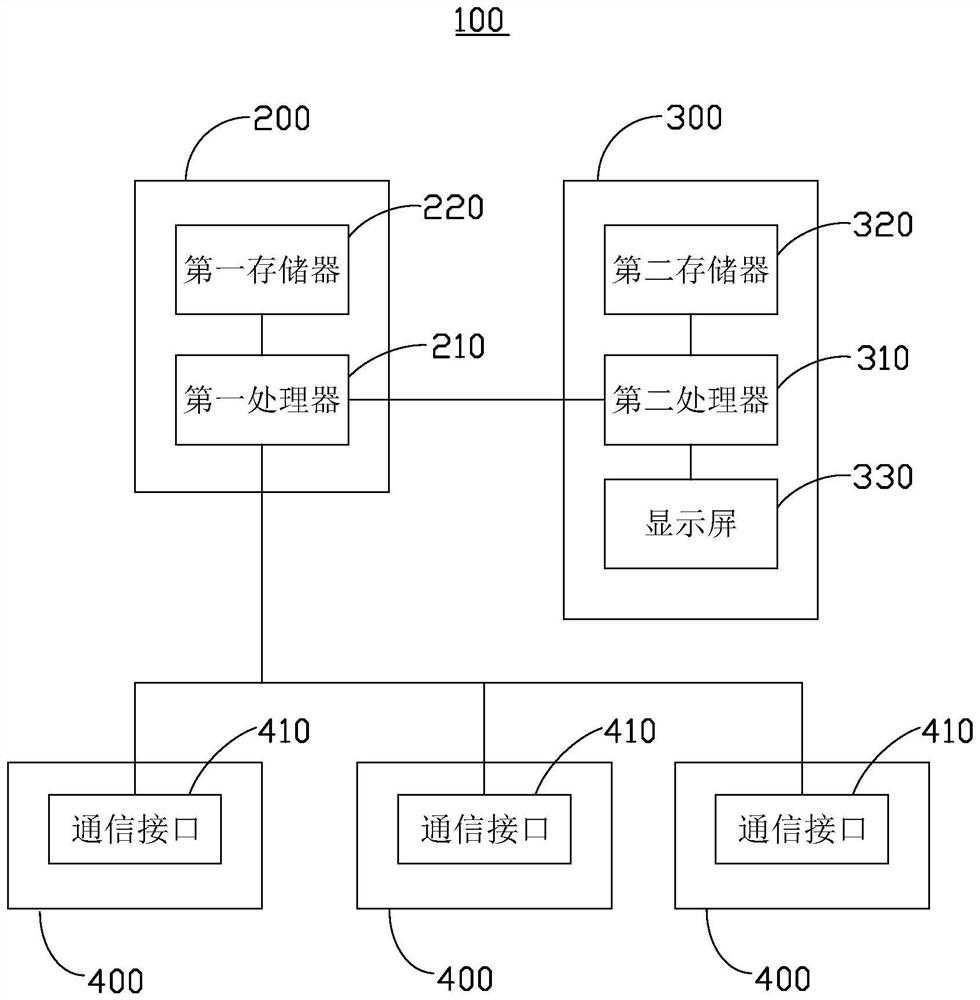

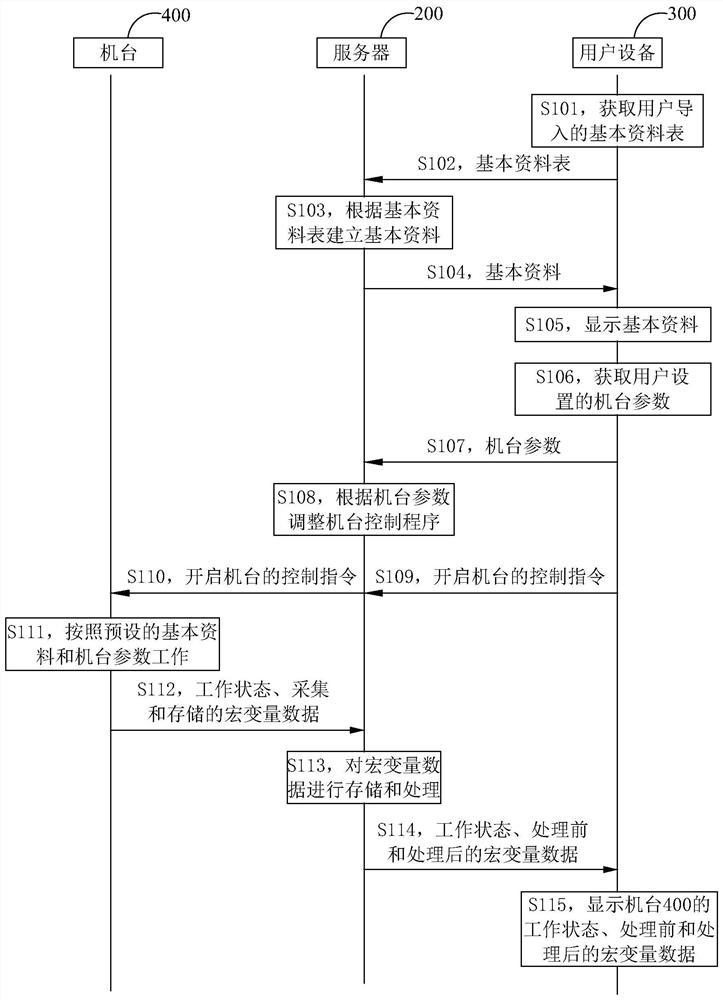

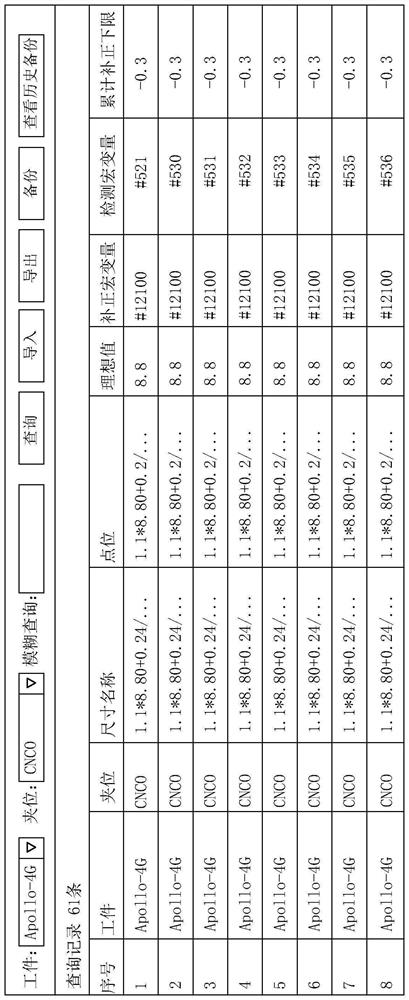

Machine data storage control method and system

PendingCN114217578AReduce labor costsImprove manufacturing process efficiencyTotal factory controlProgramme total factory controlUser deviceMachine control

The invention discloses a machine data storage control method and system, and relates to the technical field of machine control. The machine data storage control method comprises the steps that in response to a first operation of a user on user equipment, a server establishes basic information, and the basic information comprises a machining workpiece, a clamping position, a macro variable address needing to be stored and size details; in response to a second operation of the user on the user equipment, the server sets machine parameters, and the machine parameters comprise the collection frequency of the machine for collecting the macro-variable data and the storage frequency of storing the macro-variable data. And in response to a third operation of the user on the user equipment, the server controls the machine table to be started and controls the machine table to collect and store the macro variable data according to the basic data and the parameters, and the server obtains the macro variable data from the machine table and stores and processes the macro variable data.

Owner:HONGFUJIN PRECISION ELECTRONICS ZHENGZHOU

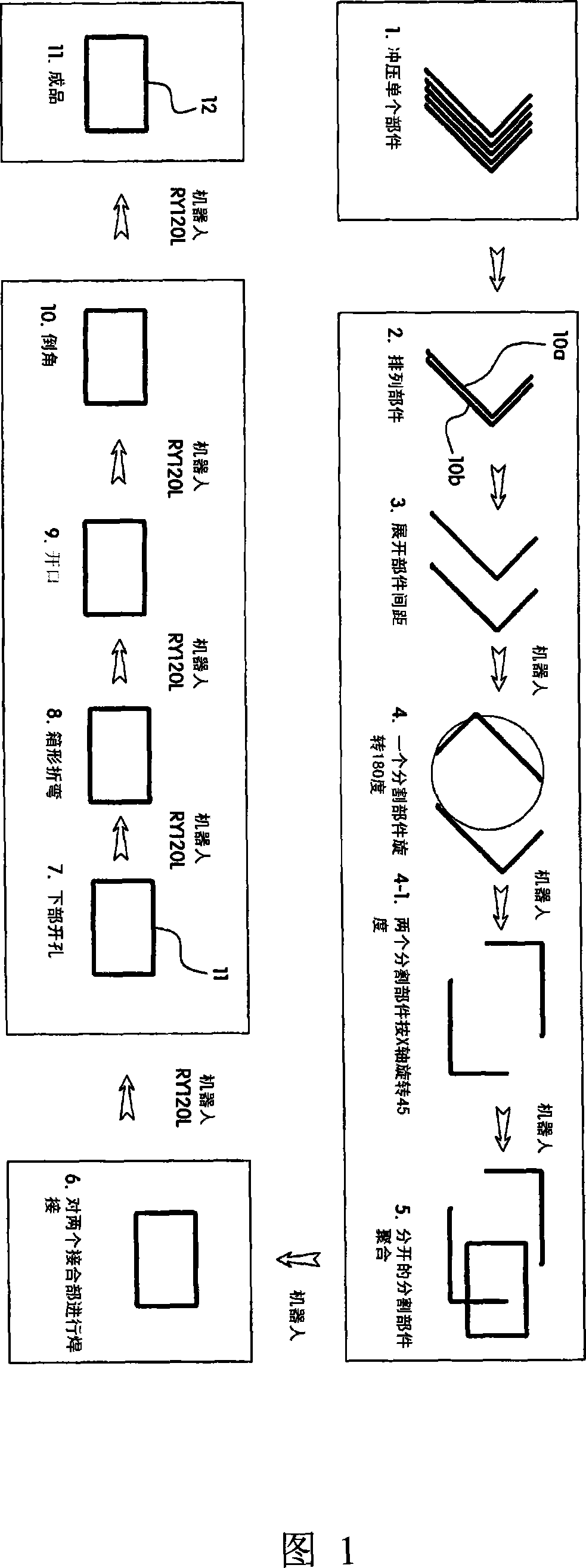

Method for producing front cover of display apparatus frame by laser beam welding device

InactiveCN101138820AIncrease production capacityEasy to operateMetal-working feeding devicesWelding/cutting auxillary devicesLiquid-crystal displayDisplay device

A manufacturing method of the division fence chassis top is provided as the process of being collective to the laser welding and end-product press is the series automated process in the matter supply. A manufacturing method of the division fence top chassis using the laser chamber type performs the followings: a step for pressing the divided parts from the supplied coil material(30); a step for dividing one set a step for arranging to the box type 2 parts(40); a step for welding the connected region of the divided parts which is arranged as laser to box type(50); and a step for completing the final finished product the product which is welded through the following press to the unique of the box type(60).

Owner:认知显示株式会社

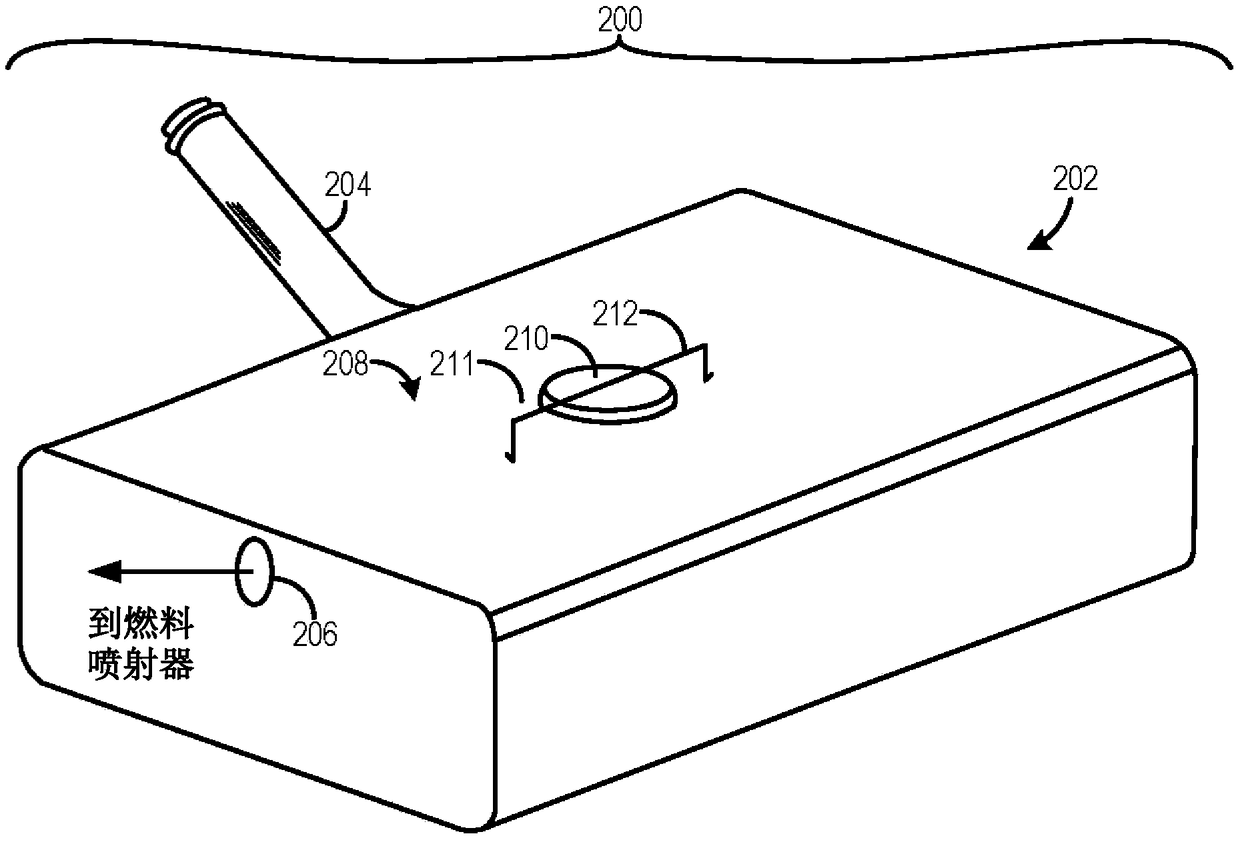

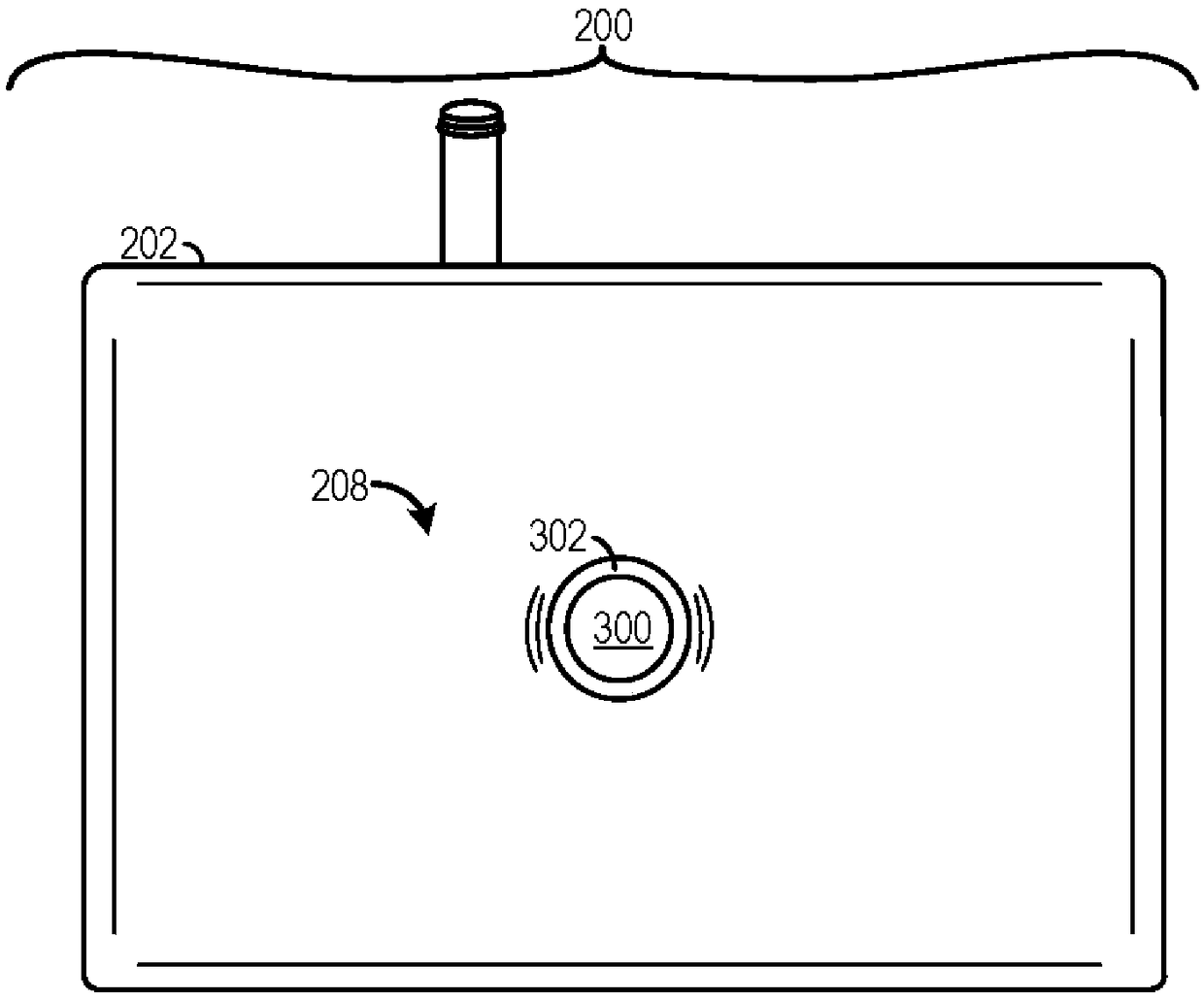

Reinforced fuel tank and method for reinforced fuel tank construction

ActiveCN108705930AImprove manufacturing process efficiencyReduce manufacturing costUnderstructuresDomestic articlesFuel tankEngineering

A method for manufacturing a fuel tank is described herein. The method includes subsequent to molding of a housing of a fuel tank, positioning a strut inside the housing. The method additionally includes snap-fitting a flexible projection of the strut with a corresponding flange section in a first wall of the housing, the flange section surrounding an opening in the first wall of the housing and the flexible projection including a surface overlapping an interior surface of the flange section subsequent to the snap-fitting.

Owner:FORD GLOBAL TECH LLC

Circuit board structure

PendingCN107666771AThe process steps are simpleImprove processing yieldPrinted circuit aspectsElectrical connection printed elementsMaterials sciencePhysics

The present invention provides a circuit board structure. The circuit board structure comprises a base plate, a plurality of metallizable photosensitive developing substrates, an electroless plated seed layer, and a second patterned circuit layer; the substrate includes an upper surface, a lower surface opposite to the upper surface, and a first patterned circuit layer; the metallizable photosensitive developing substrates are respectively disposed on the upper surface and the lower surface; each of the metallizable photosensitive development substrate includes a plurality of blind holes whichexpose at least a portion of the first patterned wiring layer; the materials of the metallizable photosensitive development substrates contain a photosensitive material; the electroless plated seed layer is disposed on the metallizable photosensitive substrates and covers the inner walls of the blind holes; and the second patterned circuit layer is disposed on the first electroless plated seed layer and fills the blind holes so as to be electrically connected with the first patterned circuit layer. According to the circuit board structure, the process steps of the circuit board structure areeffectively simplified, and the process efficiency of the circuit board structure is improved.

Owner:同扬光电(江苏)有限公司

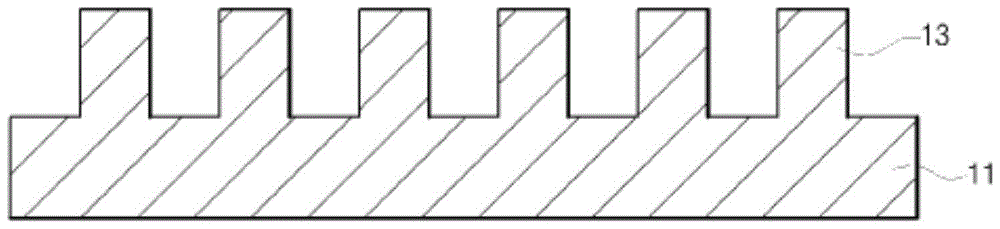

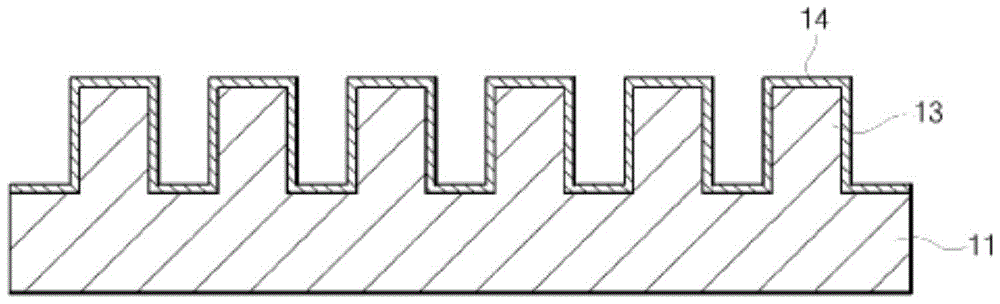

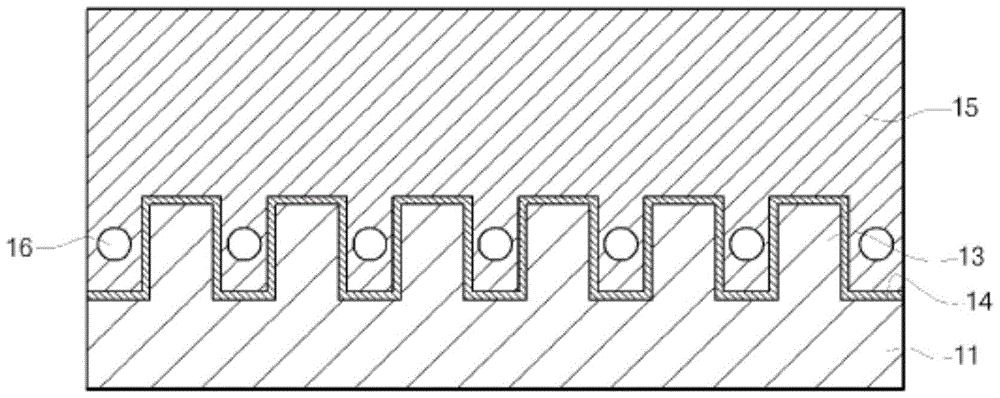

Manufacturing method of mold for nanoimprinting

InactiveCN103842861BIncreased durabilityImprove reliabilityNanoinformaticsPhotomechanical apparatusGrid patternMetallurgy

Provided is a method of manufacturing a mold for nano imprint comprising: forming a plurality of grid patterns on a substrate; forming a metal grid pattern on the grid patterns; forming a plated layer on the metal grid pattern; and separating a mold consisting of the metal grid pattern and the plated layer from the grid pattern, which can reduce a production cost, improve the efficiency of a process, and provide the mold for nano having improved durability and reliability.

Owner:LG INNOTEK CO LTD

Injection molding foaming wood-plastic composite material and preparation process

InactiveCN107177095AImprove manufacturing process efficiencyLow-density polyethyleneMaterials preparation

The invention discloses an injection molding foaming wood-plastic composite material which comprises PP (polypropylene), wood powder, AC (azodicarbonamide), LDPE (low density polyethylene), MAPP (maleic anhydride grafted polypropylene) and super-fine talcum powder. The invention further discloses an injection molding foaming wood-plastic composite material preparation process. The wood powder can be used on a large scale, and the preparation process is high in efficiency.

Owner:陈海银

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com