Method for producing front cover of display apparatus frame by laser beam welding device

A laser welding and display technology, applied in laser welding equipment, auxiliary devices, feeding devices, etc., can solve the problems of poor welding, influence, and deformation of parts at the bend, so as to improve product price competitiveness and product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

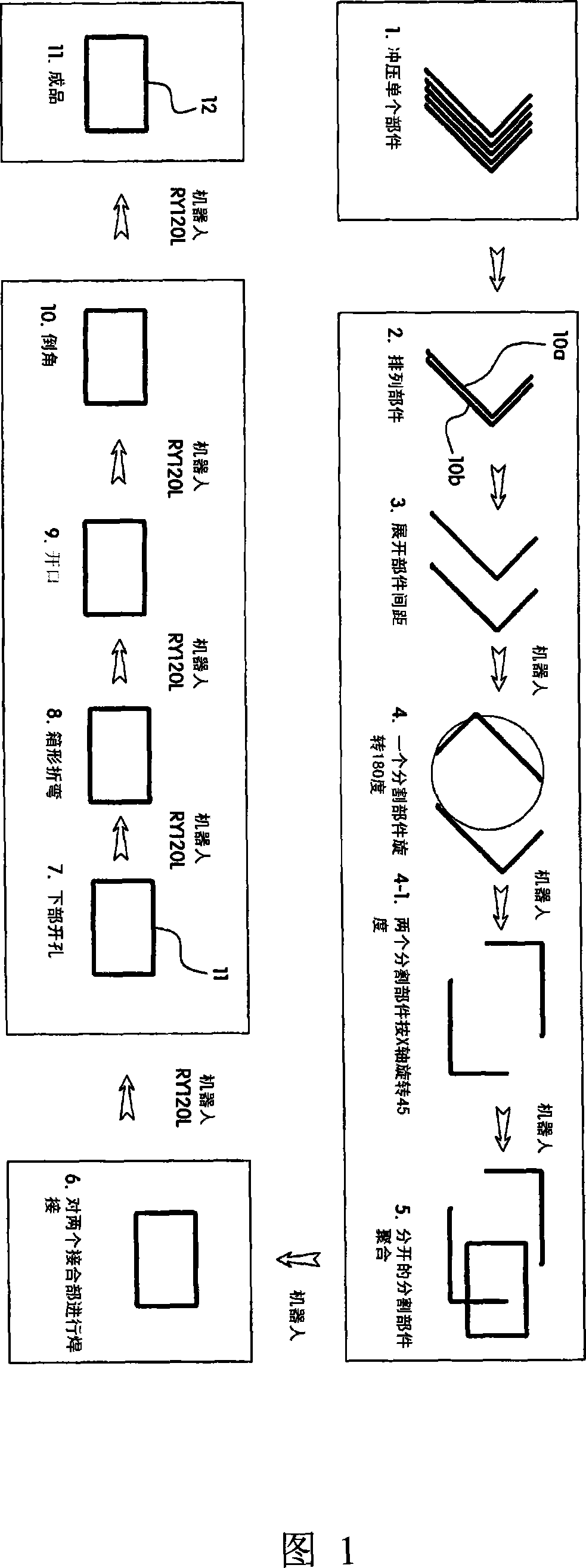

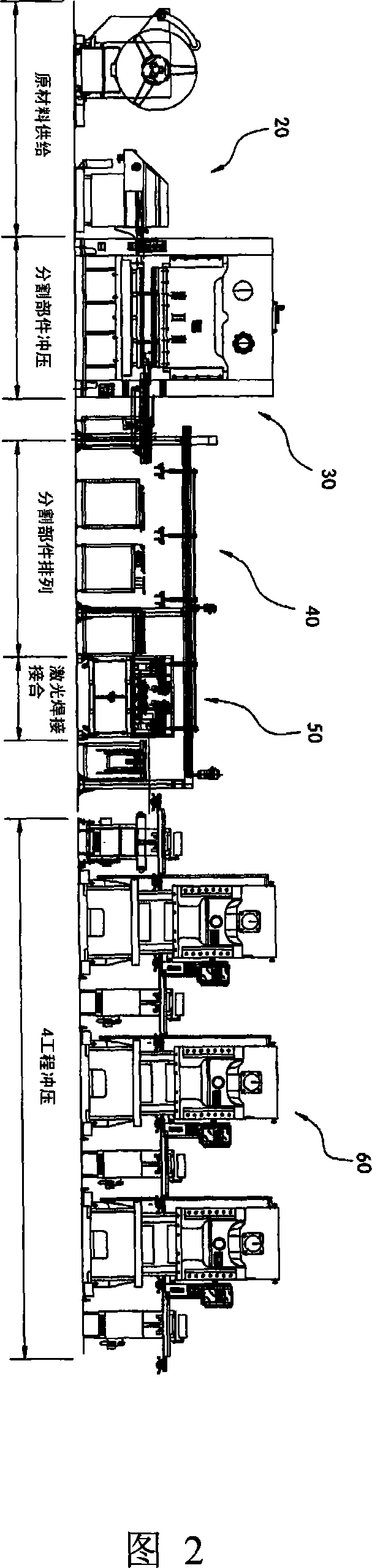

[0031] Embodiment: As shown in Figure 1 and Figure 2, the above-mentioned split type display frame front cover is after the split type parts that are manufactured into 2 split (or 4 split) forms through the stamping process of the split parts, and are combined into a shape similar to that through a certain arrangement process. The box shape of the finished product, and then through the laser bonding process and the subsequent stamping process, a one-piece box-shaped finished product, that is, the front cover of the display frame, goes through the post-processing process, that is, the cleaning step, checking for defects or bending and other bad appearance steps and flattening Step out of the warehouse after final packaging.

[0032] The raw material is continuously supplied in strip form from the supply device (20) including a coil etc. for supplying the raw material, and the thus supplied raw material passes through several stages of stamping steps in the part stamping device (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com