Pixel structure, manufacturing method thereof and display panel

A pixel structure and pixel electrode technology, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of poor adhesion to the sealant and increase in cost, so as to improve the efficiency of the manufacturing process, increase the processing cost, The effect of increased pixel aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

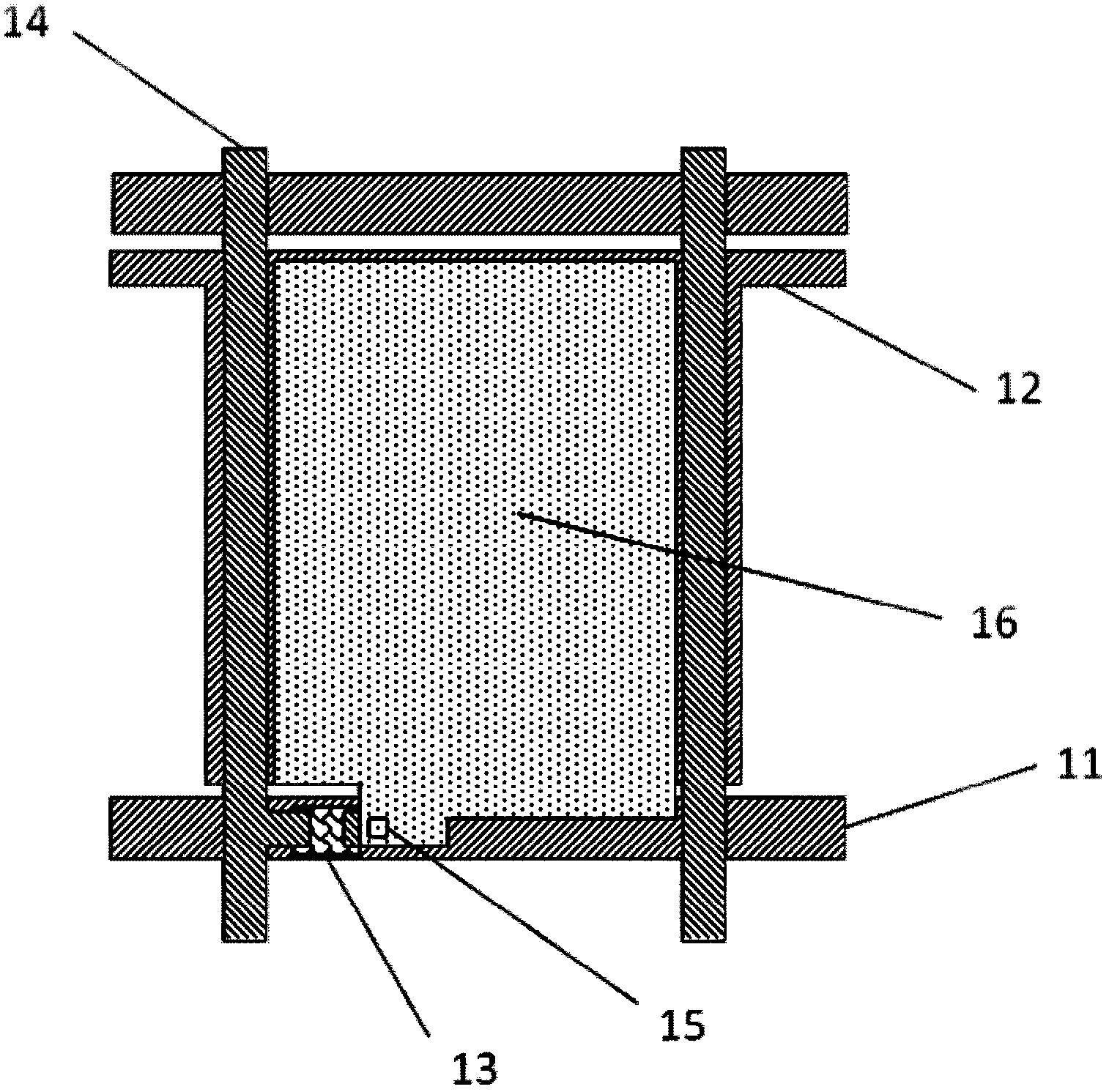

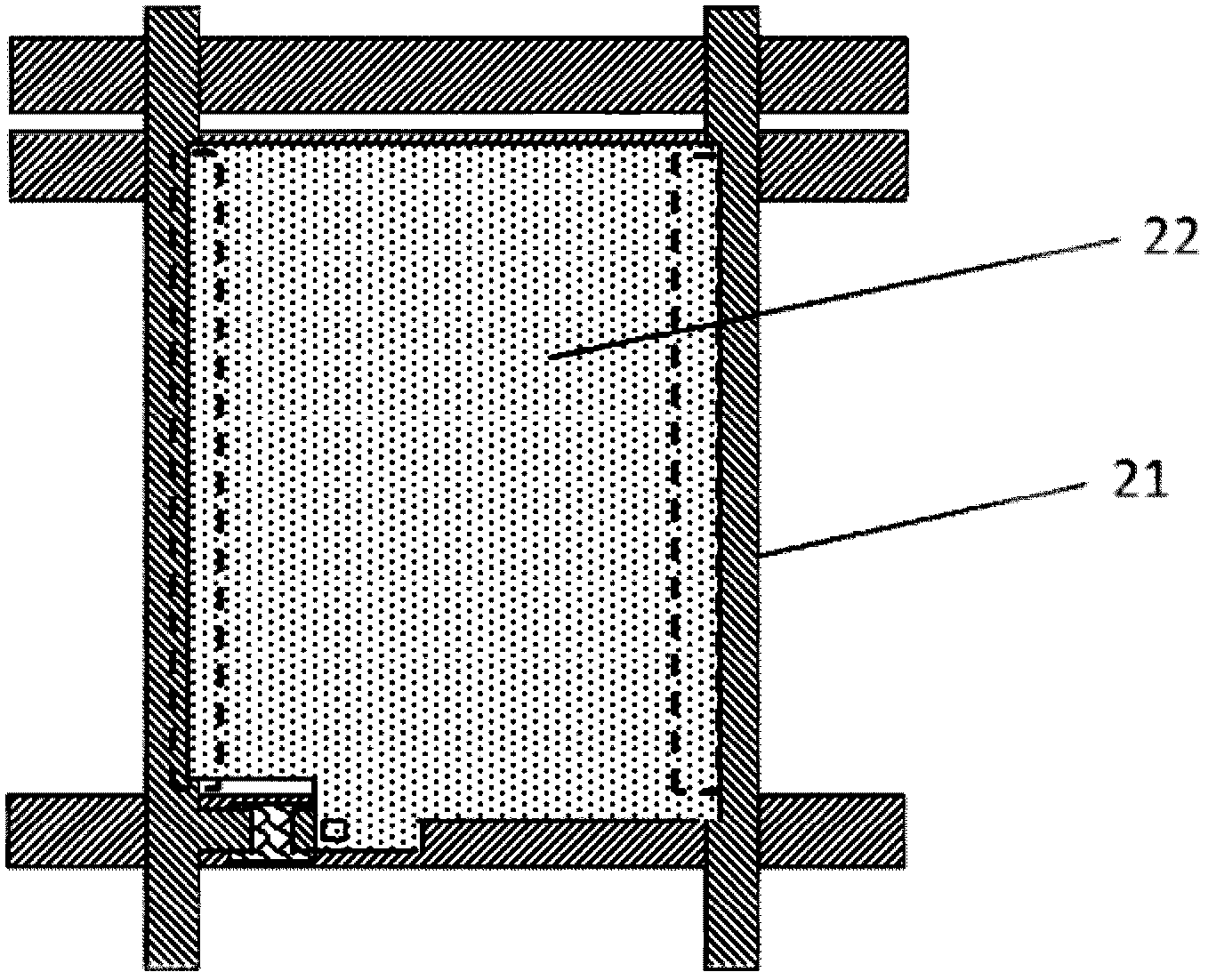

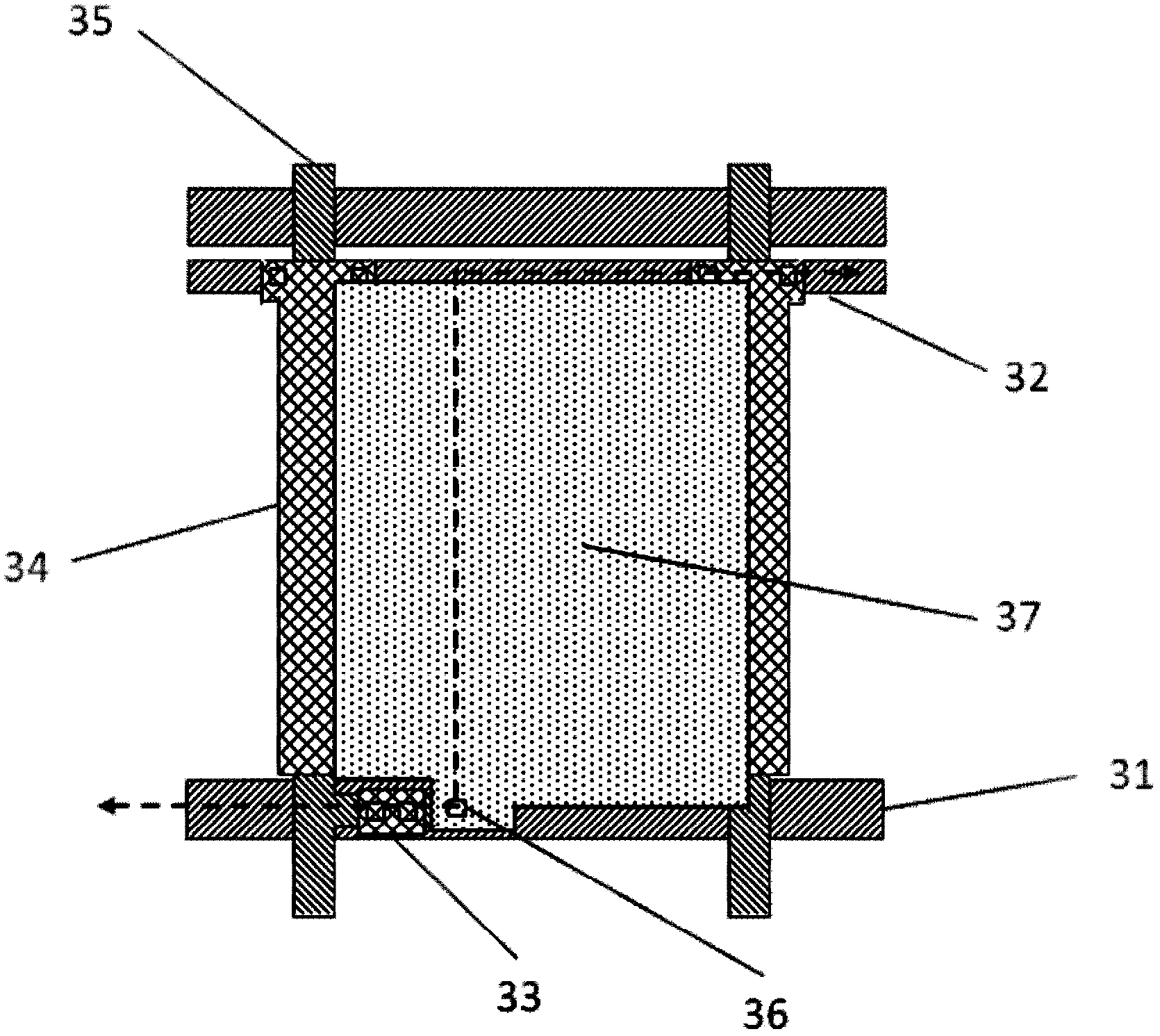

[0044] The present invention provides a pixel structure, its manufacturing method, and a display panel. In order to solve the problem of improving the pixel aperture ratio and saving material cost in the prior art, the present invention uses insulating layers of different materials in the manufacturing process of the display panel, specifically Specifically, by forming an oxide insulating material layer on the insulating layers on both sides of the oxide semiconductor layer, the metal oxide used in the semiconductor device exhibits semiconductor characteristics; by forming a hydrogen-containing ( H) or other insulating material layers containing strong reducing elements, so that the metal oxide above the data lines of the array substrate exhibits conductor characteristics. Wherein, the oxide conductor layer serves as a shielding layer of the data line, which eliminates the influence of the signal of the data line on the pixel electrode, and can increase the aperture ratio of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com