Method and support structure for manufacturing three-dimensional objects and support structure generation method

A technology for supporting structures and three-dimensional objects, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of reducing workpiece manufacturing efficiency, material waste, and large volume, and achieve reducing material waste, reducing waste, Build small effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to allow those skilled in the art to better understand and realize the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

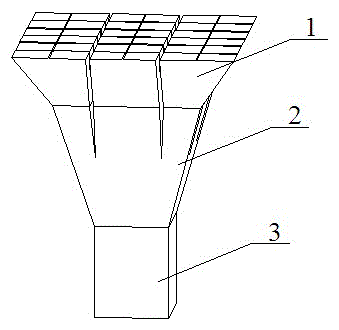

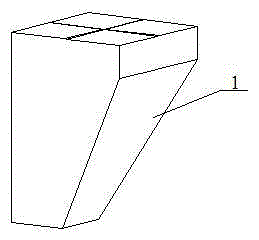

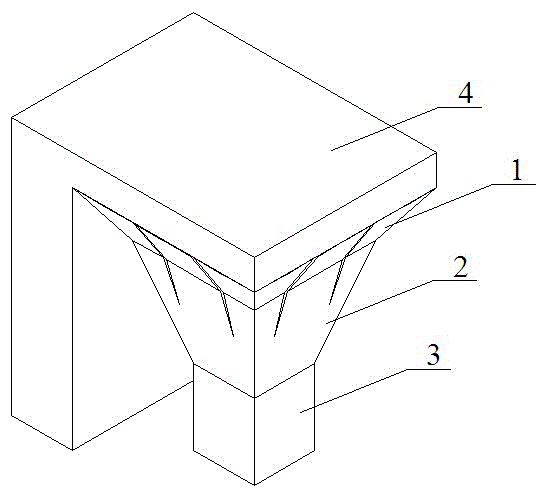

[0052] Such as Figure 1-Figure 4 As shown, the support structure for manufacturing three-dimensional objects, wherein the shape of the support structure is a tree, and includes at least one tree support structure for each workpiece 4, the tree support structure includes leaves 1, branches 2 and trunk 3. Understandably, due to image 3 The part 4 in has only one area that needs to be supported, so only one tree-shaped support structure is drawn, but if there are multiple areas of the part 4 that need to be supported, multiple tree-shaped support structures will be included.

[0053] Depend on figure 1 , image 3 with Figure 4As shown, the number of the leaves 1 is several, and they are evenly arranged on the lower surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com