Manufacturing method of mold for nanoimprinting

A technology of nano-imprinting and manufacturing method, which is applied in the directions of nanotechnology, nanotechnology, nanotechnology for information processing, etc., can solve the problem of increasing the probability of damage to the main mold, making it difficult to form the conductive seed layer 14, and reducing the mechanical properties of the mold. Durability and other issues, to improve durability and reliability, reduce production costs, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

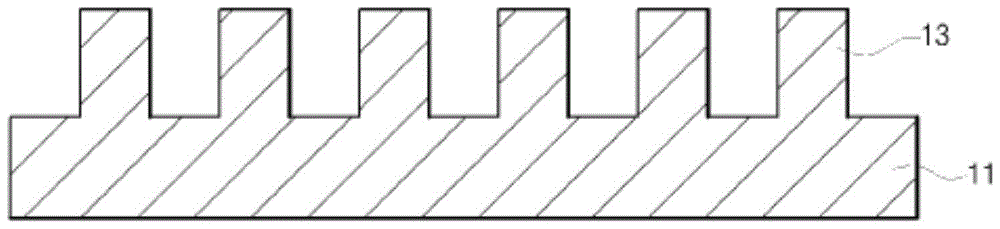

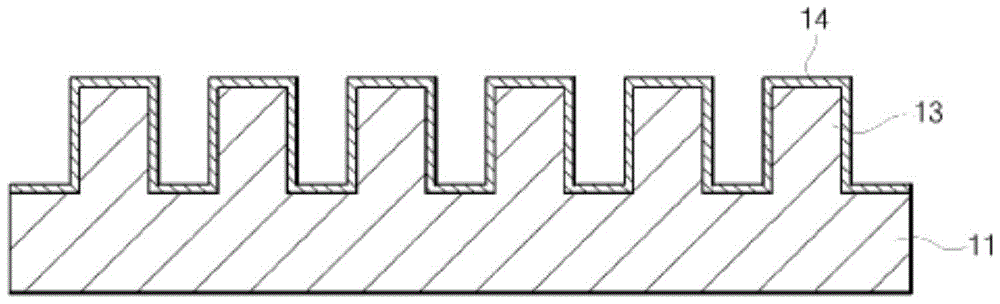

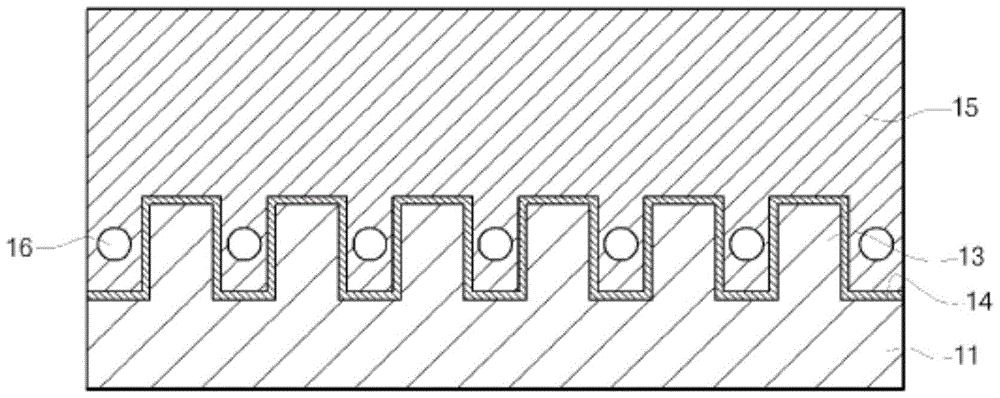

[0030] Exemplary embodiments according to the present invention will be described more fully below with reference to the accompanying drawings so that those of ordinary skill in the art to which the present invention pertains can easily implement the exemplary embodiments of the present invention. The exemplary embodiment described herein and the elements illustrated in the drawings are only one preferred exemplary embodiment of the present invention. It should be understood that there are various equivalents and modifications that may be substituted for these embodiments and elements at the time of filing this application. Also, when referring to detailed descriptions of the operating principles of the preferred exemplary embodiments, when considering that detailed descriptions about well-known functions or elements may unnecessarily obscure the gist of the exemplary embodiments of the present invention, they are omitted. These are detailed. Terms to be described below are t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com