Electric double layer capacitor package and method for manufacturing the same

A technology of electric double layer capacitors and manufacturing methods, applied in the direction of hybrid/electric double layer capacitor manufacturing, hybrid capacitors, capacitor parts, etc., can solve the problem of touching the bottom of the ceramic container or being too far away from it, which is difficult Control the thickness within a certain range, damage the adhesive injection equipment and other issues, to achieve the effect of preventing short circuit, reducing process and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

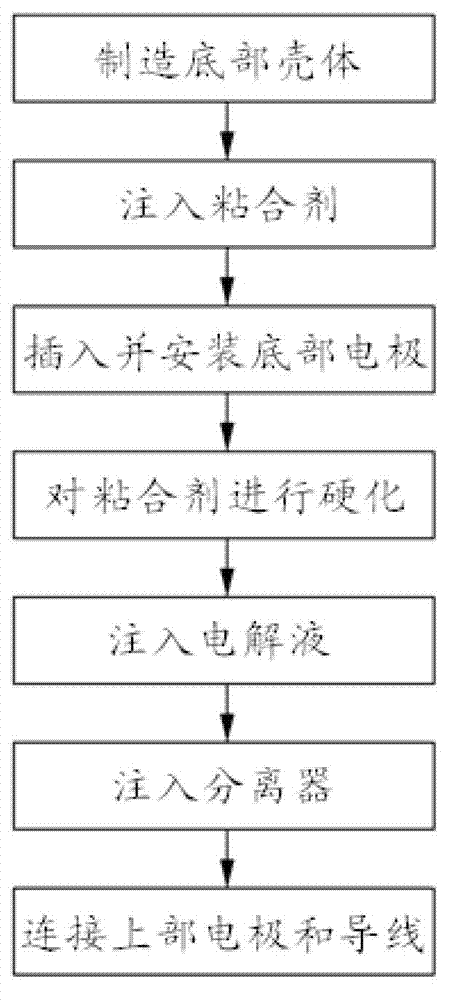

[0035] Figure 4 is a plan view showing the bottom case 200 of the electric double layer capacitor of the present invention, Figure 5 is a cross-sectional view showing an example of the electric double layer capacitor of the present invention.

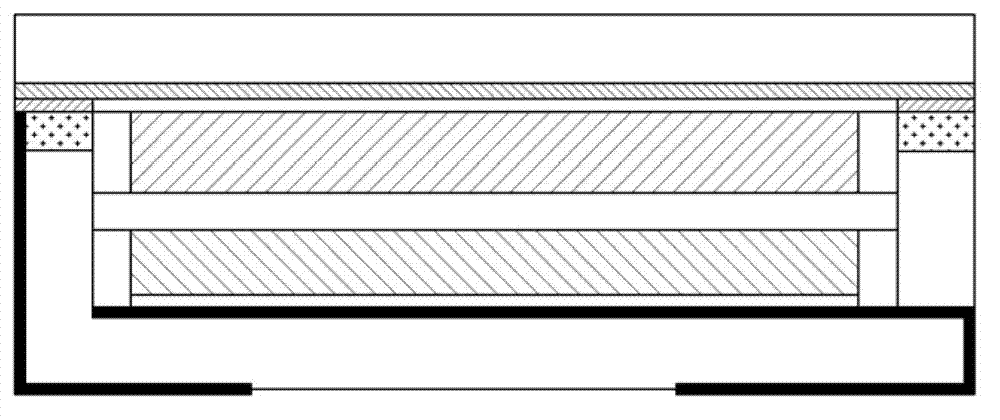

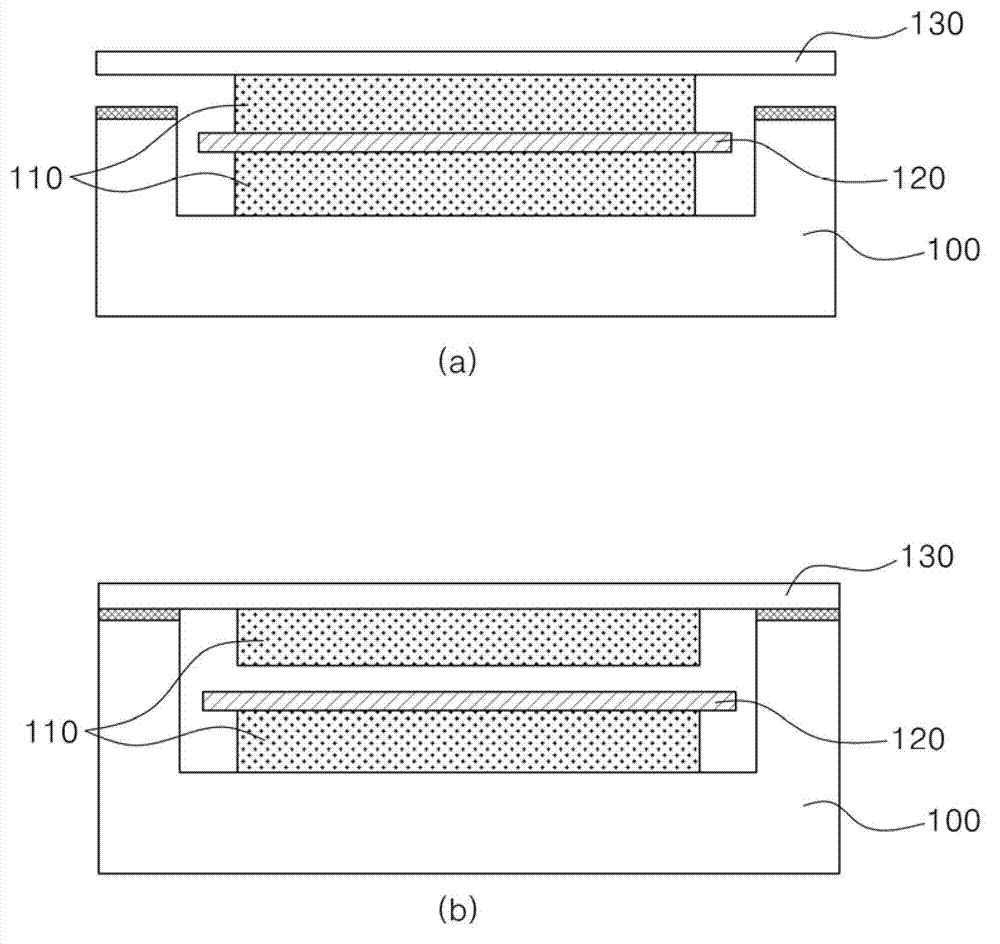

[0036]The electric double layer capacitor in the present invention comprises: a bottom case 200, which is a concave container of ceramic material; an upper electrode 230 and a lower electrode 210, which are arranged in the bottom case 200 in opposite directions; a separator 220 , which is disposed between the upper electrode 230 and the lower electrode 210; the sealing plate 240, which covers the bottom case 200, and the bottom case 200 forms more than one protrusion 250 on its inner bottom surface. exist Figure 4 In the present invention, nine protrusions 250 are formed in a square array, but this is only an embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com