Valve stem installation system and method of installing the valve stem

a technology of valve stems and mounting brackets, which is applied in the direction of manufacturing tools, transportation and packaging, and other domestic objects, can solve the problems of prior art systems, manual operations are subject to processing errors, and high labor costs, and achieve high degree of accuracy and precision, increase the speed and accuracy of mating, and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

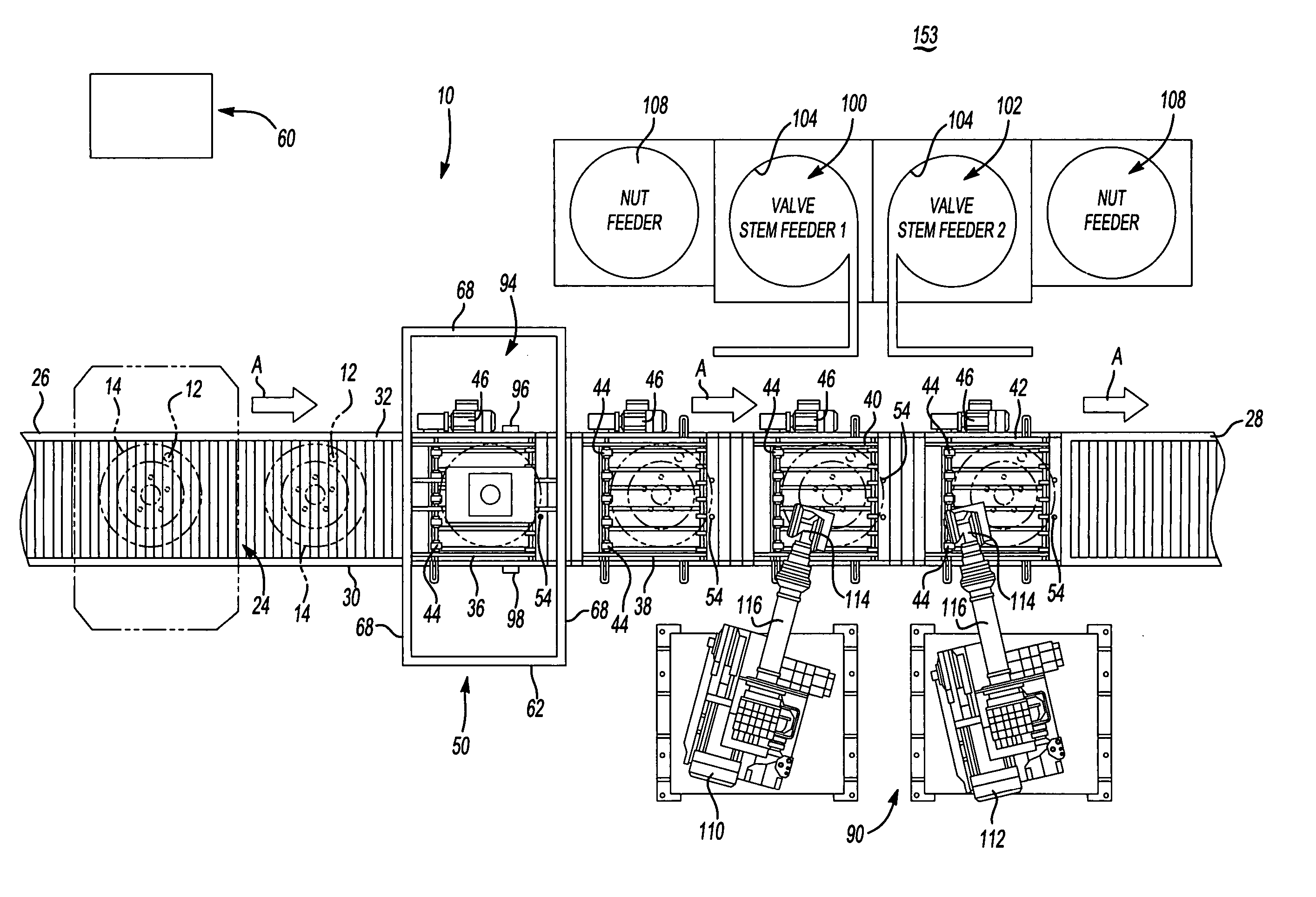

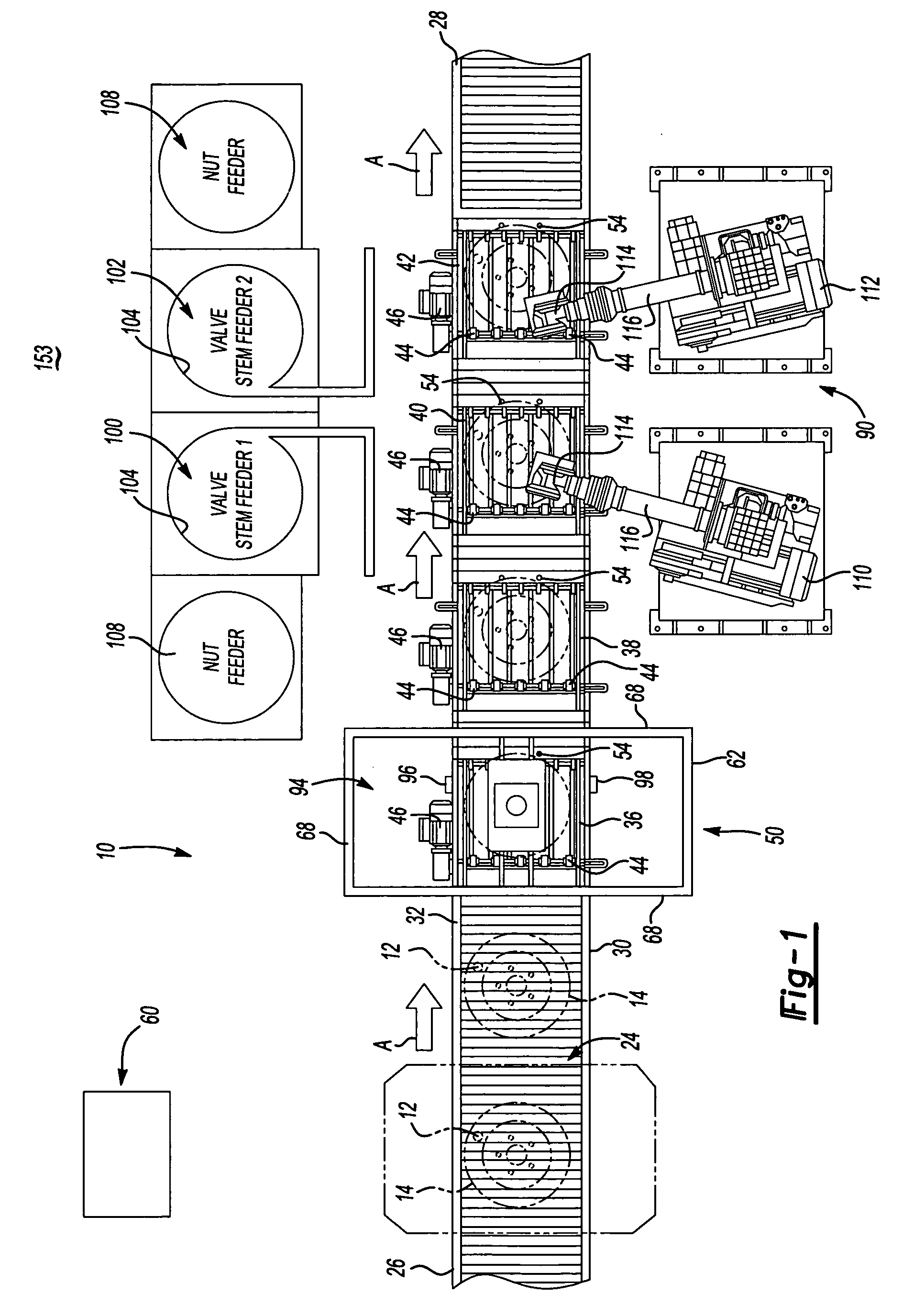

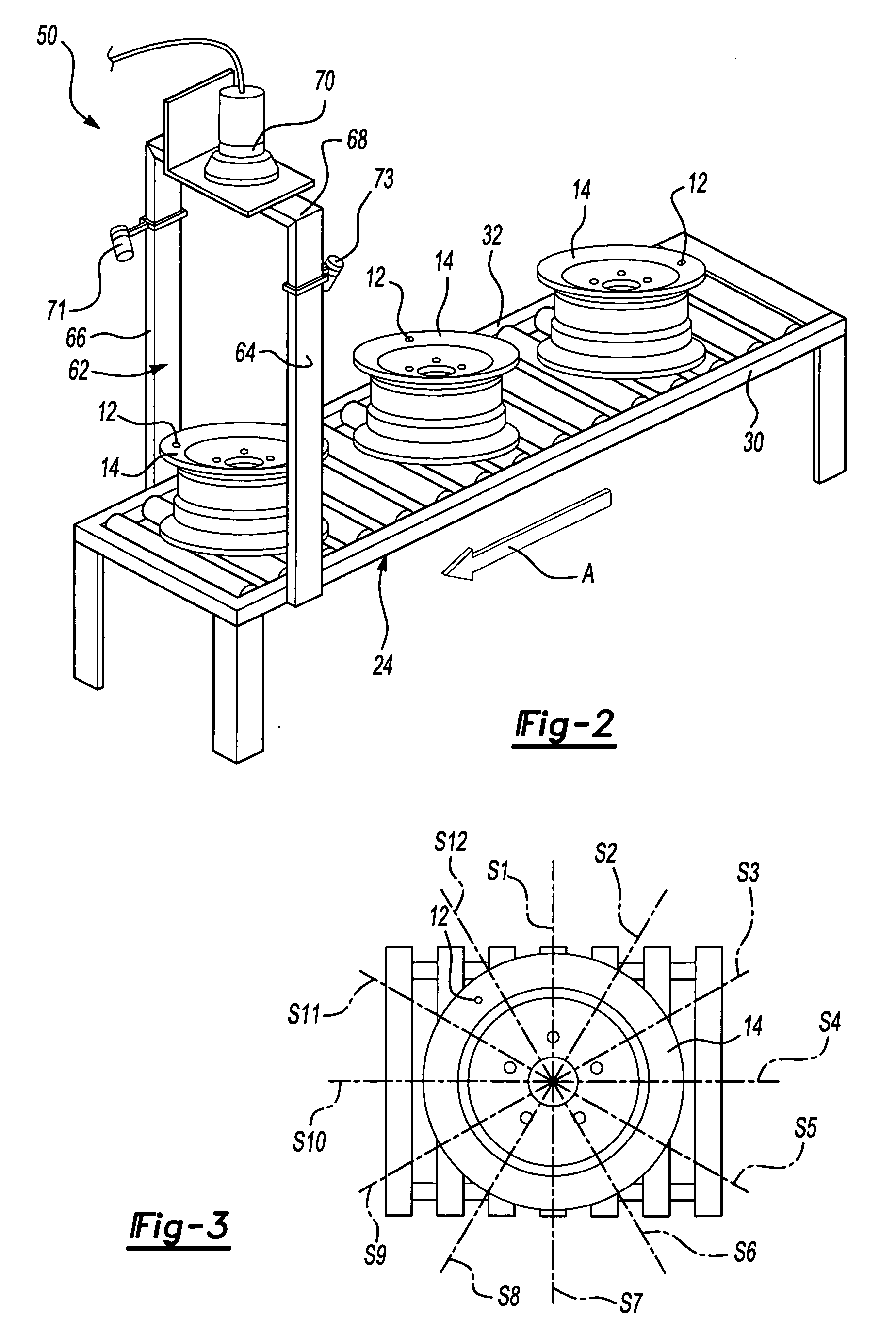

[0023] Referring to FIGS. 1 and 2, a valve stem installation system (the system) is generally shown at 10. The system 10 is adaptable to insert an individual valve stem chosen from among a plurality of differently configured valve stems into an aperture 12 defined in a wheel rim 14. These valve stems include and are not limited to a standard rubber valve stem 16 (the valve stem) and a tire pressure monitoring device type of a valve stem 18 (the TPM), both known to those skilled in the art. Any of the aforementioned valve stems is inserted in the aperture 12 as the wheel rim 14 is moved along an assembly path, generally indicated by an arrow A. The TPM 18, for example, includes a pressure sensor for monitoring the pressure in a tire mounted to the wheel rim 14 and transmits a signal corresponding to the sensed pressure. The TPM 18 is affixed to the wheel rim 14 by a nut (not shown) disposed upon an opposite side of the wheel rim 14 from the pressure sensor. The system 10 is adaptable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com