High-strength square chain and manufacturing method thereof

A high-strength, square chain technology, applied in the direction of metal chains, load-hanging components, transportation and packaging, etc., can solve the problems of low tensile performance, high content of alloy elements, fatigue performance chains that cannot meet safety performance standards, etc. , to achieve the effect of low cost, excellent fatigue performance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The high-strength square chain of the present invention and its preparation method will be further described below in conjunction with specific examples, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

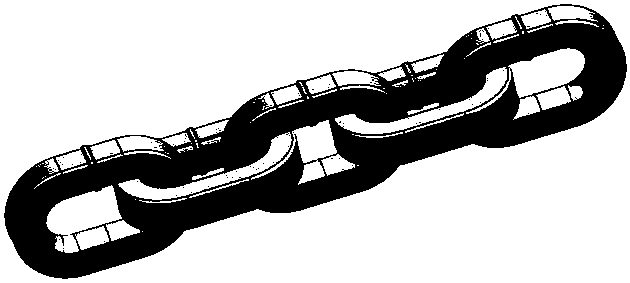

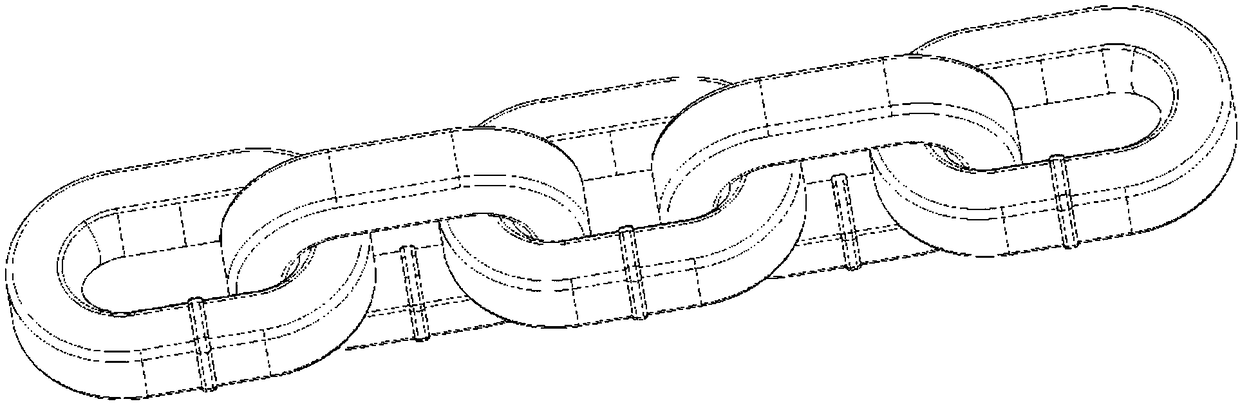

[0022] like Figure 1-3 As shown, the high-strength square chain of the present invention is sequentially braided by chain links with notches, and forms a closed chain link by friction welding; A straight line segment is formed, the gap is located on the straight line segment, and the cross section of the straight line segment is a rectangle. Figure 4 The size of the chain prepared by the present invention is shown, wherein D represents the specification, and a G100 grade chain of 6-32mm can be prepared.

[0023] The high-strength square chain of the present invention can be prepared through a preparation method comprising the following steps: m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com