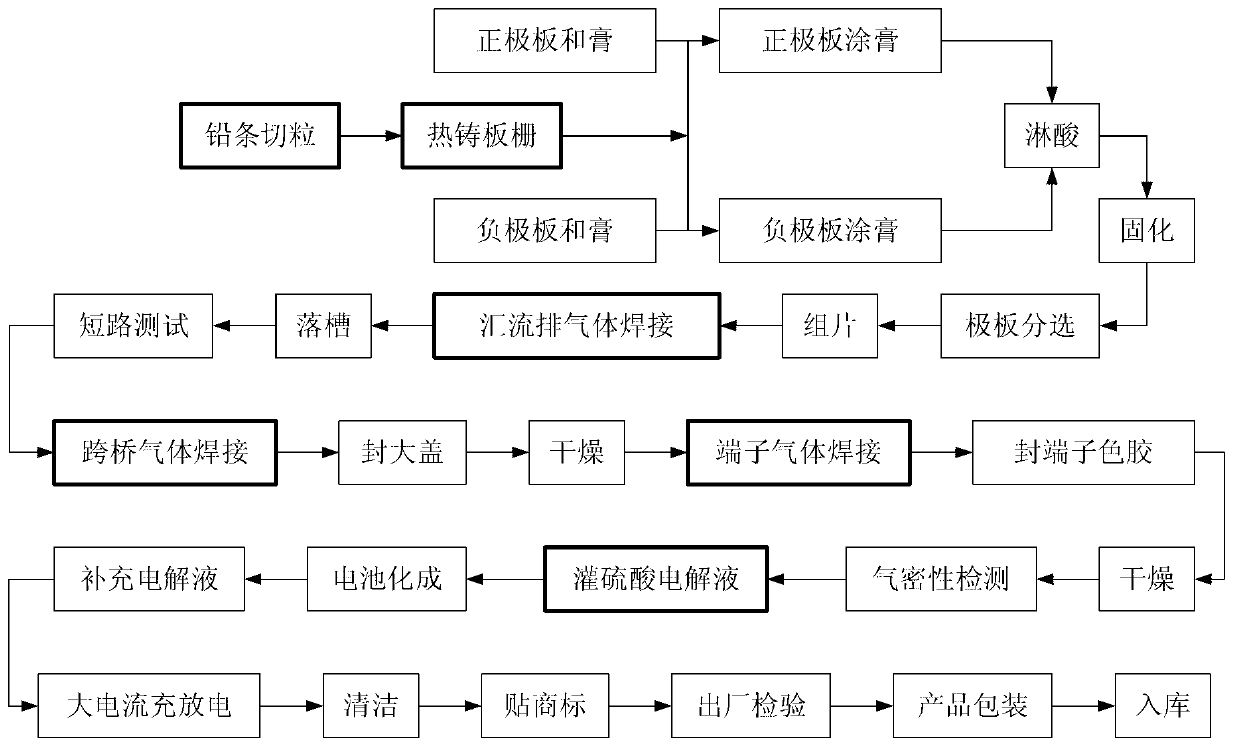

Assembly method of carbon fiber composite storage battery

A composite material and assembly method technology, applied in lead-acid batteries, battery pack parts, lead-acid battery construction, etc., can solve the problems of heavy weight, large pollution, restricting the development of batteries, etc. The amount of lead, the effect of protecting the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

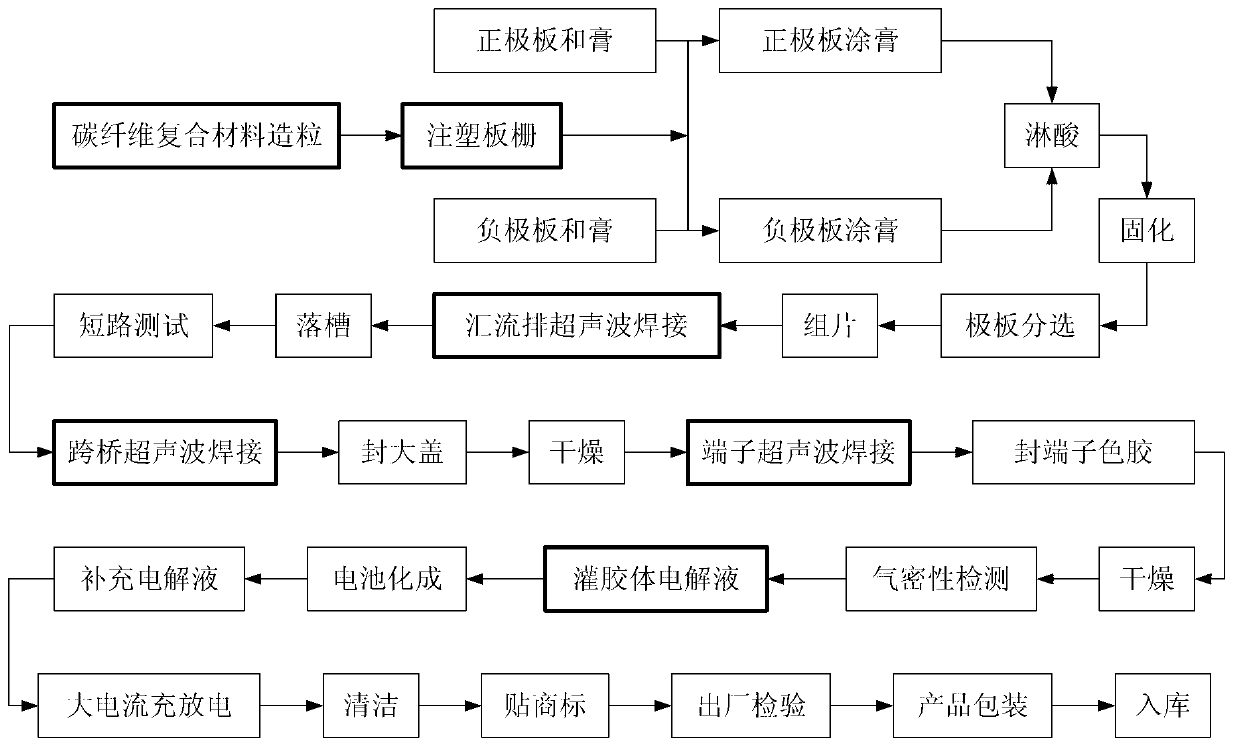

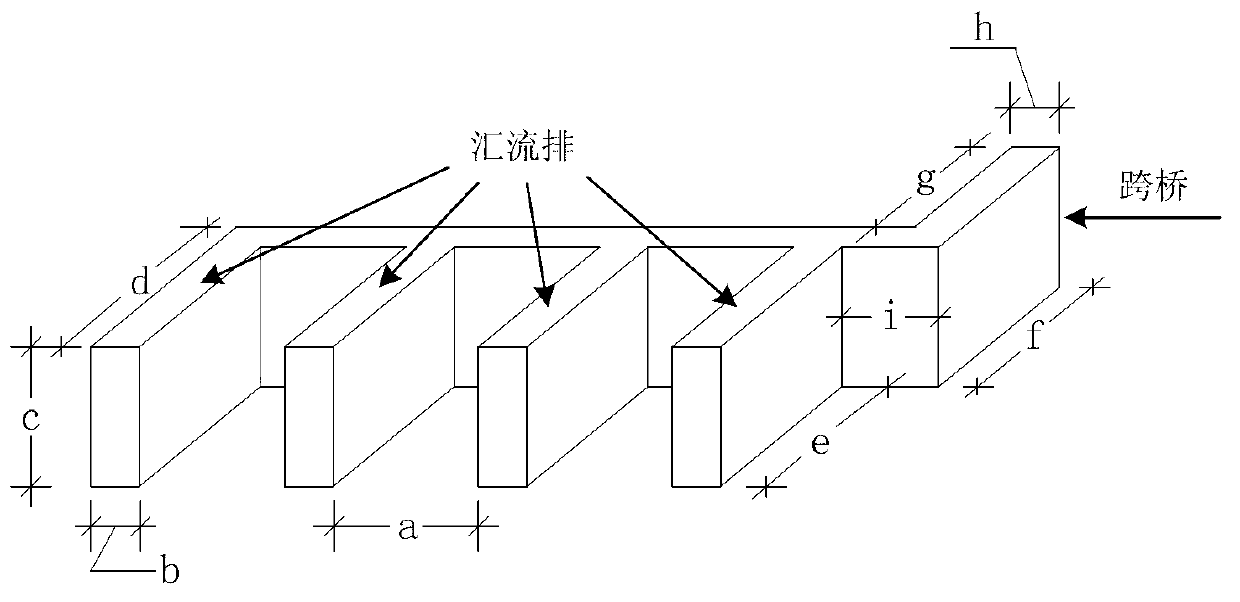

[0040]The embodiment of the present invention provides a method for assembling a carbon fiber composite battery, including the preparation of a connector and the connection of the connector. The connector is made of carbon fiber composite material; the connection of the connector adopts an ultrasonic welding process.

[0041] The carbon fiber composite material is obtained by mixing: 45-55wt%: 15-25wt%: 25-35wt% of plastic PP: active polymer polyaniline: carbon fiber.

[0042] Among them, plastic PP was purchased from: Beijing Nashengtong New Material Technology Co., Ltd.;

[0043] Active polymer polyaniline was purchased from: Beijing Nashengtong New Material Technology Co., Ltd.;

[0044] Carbon fibers were purchased from: Guangzhou Carbon Composites Co., Ltd.

[0045] The present invention will be further described below by using a valve-controlled battery box of the national standard 6-FM17 and assembling a 12V25Ah small sealed battery.

[0046] The assembling method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com