Lead and lead alloy strip continuous casting and rolling production equipment and production process

A technology of continuous casting and rolling, production equipment, applied in the direction of metal rolling, metal rolling, metal rolling racks, etc., can solve the problems of high energy consumption, large lead fume emissions, poor grid quality, etc., to achieve Good physical properties, save production space, and improve corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

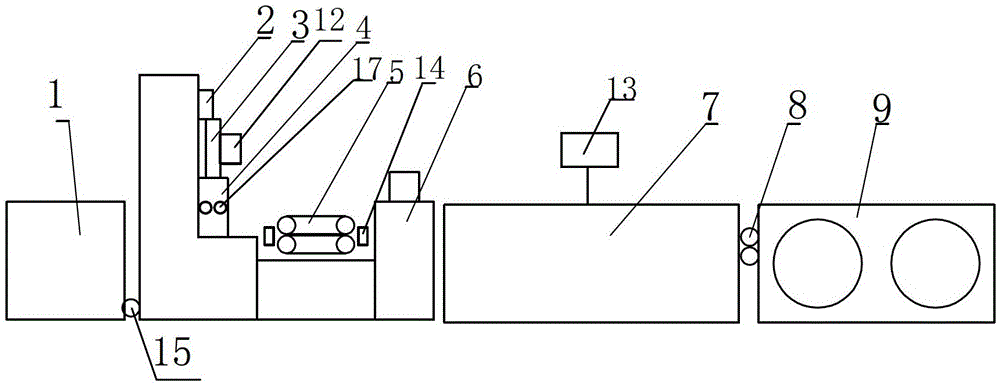

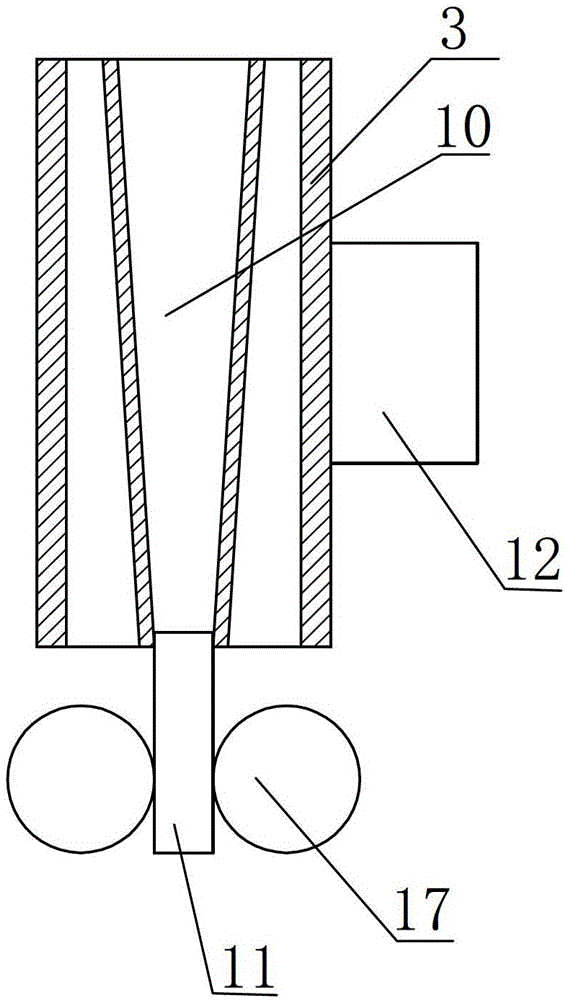

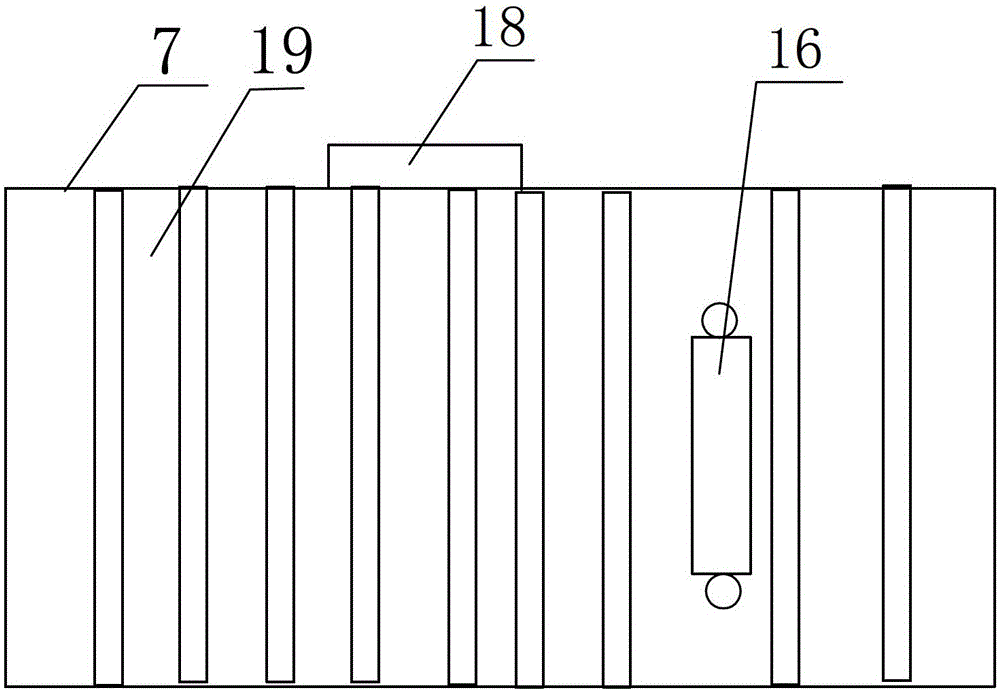

[0032] This embodiment provides a continuous casting and rolling production device for lead and lead alloy strips. figure 1 As shown, it includes a furnace for melting lead or lead alloy 1, a ladle communicating with the furnace 1, a high-temperature pump 15 for pumping lead liquid or lead alloy liquid in the furnace 1 to the ladle 2, and The continuous casting water jacket 3 under the ladle 2, the traction device 4 arranged under the continuous casting water jacket 3, the feeding device 5 connected with the traction device 4, the front hydraulic cutting device 6, and the outlet of the front hydraulic cutting device 6 The continuous rolling unit 7, the trimming device 8 set at the exit of the continuous rolling mill 7, the automatic winding device 9 located at the exit of the trimming device 8, and the PLC control system 13; the feeding device 5 can feed To the front hydraulic cut-off device 6 and the continuous rolling unit 7.

[0033] As attached Figure 4 As shown, the ladle 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com